IF 1687 nEVLL Hazard•Gard LED Luminaire Installation & Maintenance Information

advertisement

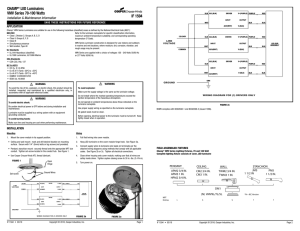

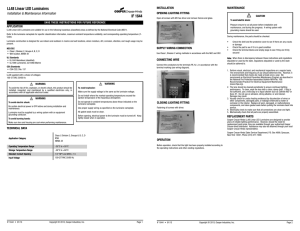

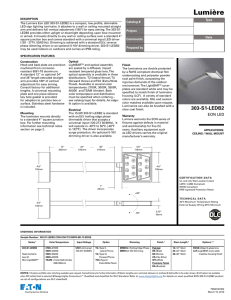

nEVLL Hazard•Gard® LED Luminaire Installation & Maintenance Information IF 1687 SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE APPLICATION nEVLL HAZARD•GARD® LED Luminaires are supplied for use with a choice of voltages: • IECEx UL 14.0053X • DEMKO 14 ATEX 1302151X Refer to the luminaire nameplate for specific classification information, maximum ambient temperature suitability and corresponding operating temperature (T-Code). • 100VAC - 277VAC, 50/60Hz, 108-250VDC • 347VAC - 480VAC, 50/60Hz nEVLL HAZARD•GARD® LED Luminaire is designed for use indoors and outdoors in marine and wet locations, where moisture, dirt, corrosion, vibration, and rough usage may be present. nEVLL: IECEx & ATEX 0359 II 2 G Ex d IIB+ H2 T5 Gb II 2 D Ex tb IIIC T95°C Db IP66 -20 °C < Tamb < +55 °C Ex d IIB+H2 T5 Gb Ex tb IIIC T95°C Db IP66 NEVLL 5L, 7L, 9L Tamb < +65 °C NEVLL 11L, 13L Tamb < +55 °C FIGURE 1 EN 60079-0:2012 IEC60079-0 ED:6 EN 60079-0:2007 IEC60079-1 ED:6 EN 60079-31:2009 IEC60079-31 ED:1 WARNING WARNING To avoid the risk of fire, explosion, or electric shock, this product should be installed, inspected, and maintained by a qualified electrician only, in accordance with all applicable electrical codes. To avoid explosion: Make sure that the supply voltage is the same as the luminaire voltage. Do not install where the marked operating temperatures exceed the ignition temperature of the hazardous atmosphere. WARNING Do not operate in ambient temperatures above those indicated on the luminaire nameplate. To avoid electric shock: All gasket seals must be clean and undamaged. Be certain electrical power is OFF before and during installation and maintenance. Use proper supply wiring as specified on the luminaire nameplate. Luminaire must be supplied by a wiring system with an equipment grounding conductor. Before dismounting, electrical power to the luminaire must be turned off. Keep tightly closed when in operation. DIMENSIONS 354.1 13.9 TERMINAL HOUSING TRUNNION MOUNT UPPER DRIVER HOUSING 445.8 17.5 DRIVER HOUSING BOLT (8) 362.4 14.3 336.8 13.3 339.7 Ø 13.4 LOWER DRIVER HOUSING SET SCREW LED HOUSING 406.3 Ø 16.0 IF 1687 • 04/15 Copyright © 2015, Eaton’s Crouse-Hinds Business Page 1 TRUNNION MOUNT INSTALLATION TRUNNION MOUNTING SHOWN WIRING DIAGRAMS TERMINAL HOUSING 2 YOKE L (BROWN) LED BOARD MOUNT CONNECTOR + (RED) INPUT N (BLUE) DRIVER 1 UNV1/UNV34 PIVOT BOLT (2) (SEE NOTES 3, 4, 5) BLACK OUTPUT - (BLACK) 2 QUICK DISCONNECT RED L (BLK) LED BOARD 2 N (WHT) 2 LOCKING BOLT (2) (SEE NOTES 3, 4, 6) 2 * DIMMING WIRES 2 WAGO 2 - POLE LEVER LOCK PN:222-412 * UNV1 DIMMING WIRES: + (VIOLET) & - (GRAY) UNV34 DIMMING WIRES: + (YELLOW) & - (GRAY) 2 AIMING RANGE L (BROWN) N (BLUE) + (RED) INPUT LED BOARD MOUNT CONNECTOR 1 DRIVER 1 UNV1/UNV34 OUTPUT 5 QUICK DISCONNECT RED BLACK - (BLACK) L (BLK) LED BOARD 2 2 N (WHT) L (BROWN) N (BLUE) LED BOARD MOUNT CONNECTOR 2 + (RED) INPUT RED DRIVER 2 UNV1/UNV34 5 OUTPUT BLACK - (BLACK) 2 5 * DIMMING WIRES LENS DOWN 1. LENS HORIZONTAL Using yoke as a template, mark and drill desired location on mounting surface. 2. Secure yoke to surface using 1/2” bolts or lag screws (not provided). 3. To make final adjustment, loosen the pivot and locking bolts to position at the desired angle*. 4. Rotate fixture to the desired position. 5. Tighten the two (2) 1/2-13 pivot bolts to 45±1.7 lbs.-ft. [61.01±2.3 N-m]. 6. Tighten the two (2) 5/16-18 locking bolts to 11.45±1.2 lbs.-ft. [15.6±1.6 N-m]. 7. Tighten bolts on LED housing to 54±20 lbs.-ft. [61±2.5 N-m] in star fashion. 8. Cover entries are M25 1.5 pitch. 9. Only cable glands and blanking elements with d, tb and IP66 ratings may be used. 10. All unused openings must be provided with certified blanking element with appropriate protection techniques and ratings. 11. If conduits are used, seals must be installed within 50mm. Conduit seals must be rated d, tb and IP66. 2 WAGO 2-POLE LEVER LOCK PN: 222-412 5 WAGO 5-POLE LEVER LOCK PN: 222-415 * UNV1 DIMMING WIRES: +(VIOLET) & - (GRAY) UNV34 DIMMING WIRES: + (YELLOW) & -(GRAY) 100V to 277VAC 50 or 60 Hz or 180V to 250VDC Input 347V to 480VAC 50 or 60Hz Input CONDITIONS OF SAFE USE • • • • • To minimize risk of Electrostatic Discharge adequate grounding must be maintained. Use at least 90°C wire. Contact Crouse-Hinds for replacement fasteners. Only joints that are opened by the user are the driver housing and ceiling mount. Contact Crouse-Hinds by Eaton for information on flameproof joints. All statements, technical information and recommendations contained herein are based on information and tests we believe to be reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Crouse-Hinds “Terms and Conditions of Sale”, and since conditions of use are outside our control, the purchaser should determine the suitability of the product for his intended use and assumes all risk and liability whatsoever in connection therewith. Eaton’s Crouse-Hinds Business 1201 Wolf Street Syracuse, NY 13208 Copyright © 2015 IF 1687 Revision 1 New 04/15