Article 500-516 of the National Electrical Code with product

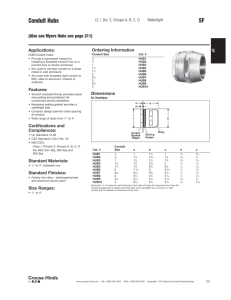

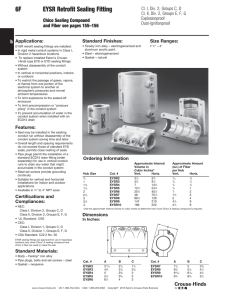

advertisement