Voltage Regulators

Service Information

S225-50-12

Back Panel Upgrade 10- to 18-Position Terminal

Strip Installation Instructions

Contents

Product Information������������������������������������������������������ 1

Parts Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Tools Required������������������������������������������������������������ 1

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Information

Introduction

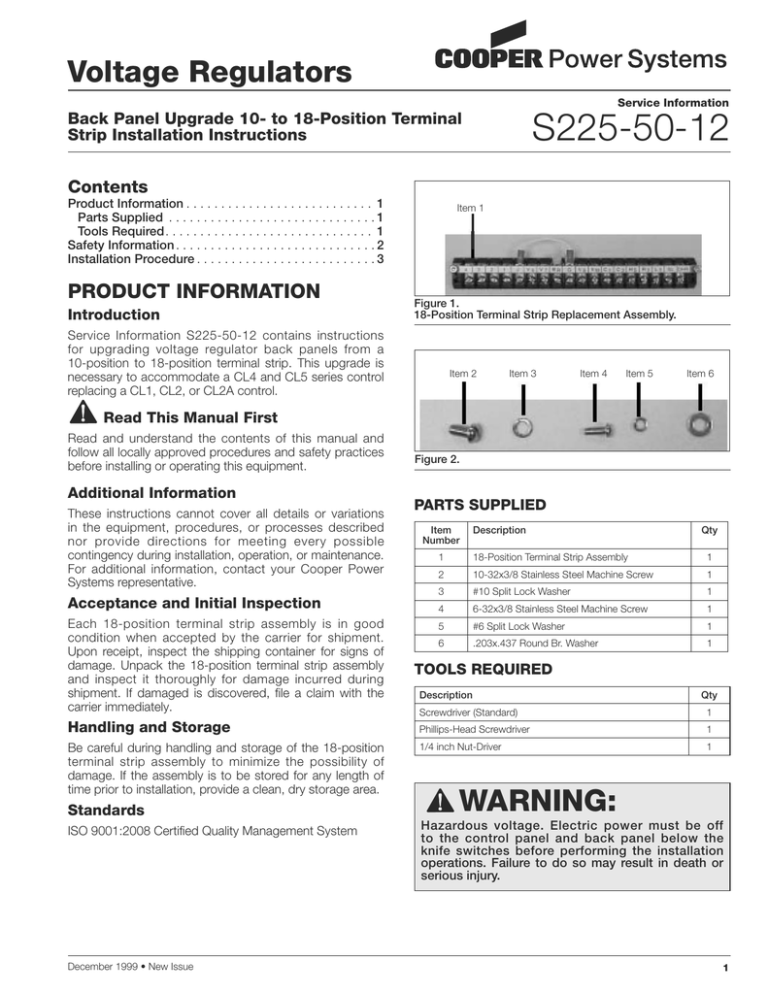

Item 1

Figure 1.

18-Position Terminal Strip Replacement Assembly.

Service Information S225-50-12 contains instructions

for upgrading voltage regulator back panels from a

10-position to 18-position terminal strip. This upgrade is

necessary to accommodate a CL4 and CL5 series control

replacing a CL1, CL2, or CL2A control.

!

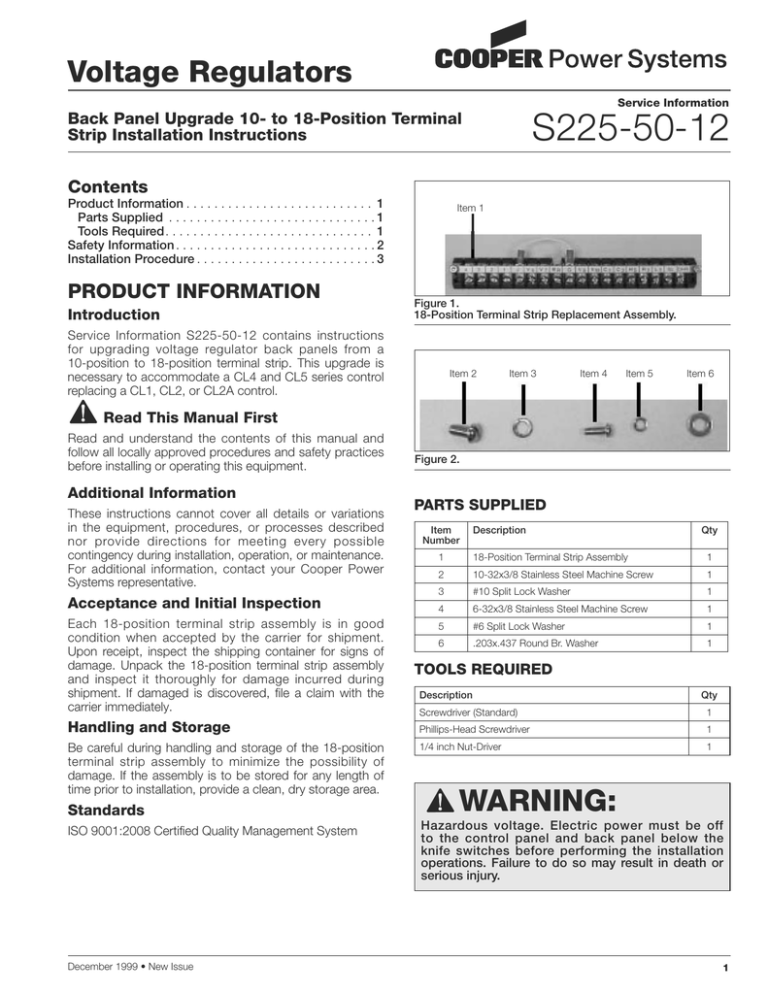

Item 2

Item 3

Item 4

Item 5

Item 6

Read This Manual First

Read and understand the contents of this manual and

follow all locally approved procedures and safety practices

before installing or operating this equipment.

Additional Information

These instructions cannot cover all details or variations

in the equipment, procedures, or processes described

nor provide directions for meeting every possible

contingency during installation, operation, or maintenance.

For additional information, contact your Cooper Power

Systems representative.

Acceptance and Initial Inspection

Each 18-position terminal strip assembly is in good

condition when accepted by the carrier for shipment.

Upon receipt, inspect the shipping container for signs of

damage. Unpack the 18-position terminal strip assembly

and inspect it thoroughly for damage incurred during

shipment. If damaged is discovered, file a claim with the

carrier immediately.

Handling and Storage

Be careful during handling and storage of the 18-position

terminal strip assembly to minimize the possibility of

damage. If the assembly is to be stored for any length of

time prior to installation, provide a clean, dry storage area.

Standards

ISO 9001:2008 Certified Quality Management System

December 1999 • New Issue

Figure 2.

PARTS SUPPLIED

Item

Number

Description

Qty

1

18-Position Terminal Strip Assembly

1

2

10-32x3/8 Stainless Steel Machine Screw

1

3

#10 Split Lock Washer

1

4

6-32x3/8 Stainless Steel Machine Screw

1

5

#6 Split Lock Washer

1

6

.203x.437 Round Br. Washer

1

Tools Required

Description

Qty

Screwdriver (Standard)

1

Phillips-Head Screwdriver

1

1/4 inch Nut-Driver

1

!

WARNING:

Hazardous voltage. Electric power must be off

to the control panel and back panel below the

knife switches before performing the installation

operations. Failure to do so may result in death or

serious injury.

1

Back Panel 10- to 18-Position Terminal Strip Upgrade Installation Instructions

!

SAFETY

FOR LIFE

SAFETY FOR LIFE

!

SAFETY

FOR LIFE

Cooper Power Systems products meet or exceed all applicable industry standards relating to product safety. We actively

promote safe practices in the use and maintenance of our products through our service literature, instructional training

programs, and the continuous efforts of all Cooper Power Systems employees involved in product design, manufacture,

marketing and service.

We strongly urge that you always follow all locally approved safety procedures and safety instructions when working around

high-voltage lines and equipment and support our “Safety For Life” mission.

SAFETY Information

The instructions in this manual are not intended as a

sub­s titute for proper training or adequate experience

in the safe operation of the equipment described.

Only competent technicians, who are familiar with this

equipment should install, operate and service it.

A competent technician has these qualifications:

nIs thoroughly familiar with these instructions.

nIs trained in industry-accepted high- and low-voltage

safe operating practices and procedures.

nIs trained and authorized to energize, de-energize, clear,

and ground power distribution equipment.

nIs trained in the care and use of protective equipment

such as flash clothing, safety glasses, face shield, hard

hat, rubber gloves, hotstick, etc.

Following is important safety information. For safe

installation and operation of this equipment, be sure to

read and understand all cautions and warnings.

Safety Instructions

Following are general caution and warning statements that

apply to this equipment. Additional statements, related to

specific tasks and procedures, are located throughout the

manual.

!

DANGER:

!

WARNING:

Hazardous voltage. Contact with high voltage will

cause death or severe personal injury. Follow all

locally approved safety procedures when working

around high- and low-voltage lines and equipment.

Before installing, operating, maintaining, or testing

this equipment, carefully read and understand

the contents of this manual. Improper operation,

handling or maintenance can result in death, severe

personal injury, and equipment damage.

Hazard Statement Definitions

This manual may contain four types of hazard

statements:

!

DANGER:

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

!

WARNING:

Indicates a hazardous situation which, if not

avoided, could result In death or serious injury.

!

CAUTION:

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

Caution: Indicates a hazardous situation which,

if not avoided, could result in equipment damage

only.

2

!

WARNING:

This equipment is not intended to protect human

life. Follow all locally approved procedures and

safety practices when installing or operating this

equipment. Failure to comply may result in death,

severe personal injury and equipment damage.

!

WARNING:

Power distribution and transmission equipment

must be properly selected for the intended

application. It must be installed and serviced

by competent personnel who have been trained

and understand proper safety procedures. These

instructions are written for such personnel and

are not a substitute for adequate training and

experience in safety procedures. Failure to properly

select, install or maintain power distribution and

transmission equipment can result in death, severe

personal injury, and equipment damage.

!

S225-50-12

SAFETY

FOR LIFE

installation procedures

SAFETY

Removing 10-Position Terminal Strip

1. If the regulator and or control is energized perform the

following steps before installing the upgrade.

2. Open the V1 and V6 (if present) knife-blade switches

on the back panel. Close the C knife-blade switch

to short the CT. See Figure 1. In some of the earlier

regulators, the C shorting switch must to be pulled

open in order to short the CT.

3. Locate the orange HS lead. Remove the HS lead

terminal from the lower row of screws on TB1.

4. Performing the steps above will isolate the TB2

circuits.

Orange HS Lead

TB1

C Switch

Wiring

Harness

TB2 10Position

Terminal

Strip

Figure 3.

Label Bar Mounting Screw

Label Bar Mounting Screw

Label Bar

Control Faning Strip

Figure 4.

Adhesive Protector

Figure 5.

2. Use a standard screwdriver and remove the two

screws and spacers to remove the terminal board label

bar. See Figure 4.

3. Use a standard screwdriver and remove the control

fanning strip from the bottom row of screws on TB2.

See Figure 4. Remove the control panel from the

control box hinges.

4. Remove the control wiring harness terminals from the

top of TB2. See Figures 3 and 4.

5. Use a standard screwdriver to remove the TB2 terminal

board mounting screws, there could be as many as

four screws. See Figure 4.

Installation of 18-Position Terminal Strip

V Switch

TB2 Mounting

Screw

1. TB2 is the 10-position terminal strip located at the

bottom of the back panel. See Figure 3.

TB2 Mounting

Screw

1. Once the 10-position terminal board is removed

from the back panel, remove the adhesive protector

from the back side of the 18-position terminal strip

assembly. See Figure 5.

2. Locate, center and place the 18-position terminal strip

assembly on to the back panel with the white wire

and metal jumper at the top. See Figure 6. The new

terminal strip assembly should be placed in the same

location as the old 10-position terminal strip. The DHR

label should be located on the right hand side of the

back panel with the terminal strip assembly installed.

3. Using a 1/4 inch nut-driver remove the nut and

lockwasher on the label bar on the DHR end of the

terminal board. Loosen the nut on the opposite end of

the label bar. Remove the label bar from the terminal

board stud on the DHR end. See Figure 7.

4. Wire the back panel wiring harness to the new TB2

terminal strip. The table below shows the wiring color

code and label location for each lead.

Color Code

Terminal Label

White

G

Black

VS

White/Black

VM

Red

C1

Green

C3

Orange

HS

Blue

R3

White/Green

L3

White/Red

NL

White/Orange

DHR

5. Replace the label bar back onto the terminal board

stud. Replace the lockwasher and nut and tighten the

1/4 inch nuts on both ends of the terminal board using

a nut-driver.

6. Place the new control on the control box hinges.

3

Back Panel 10- to 18-Position Terminal Strip Upgrade Installation Instructions

7. Using either a standard or phillips-head screwdriver,

loosen all 18 terminal board screws on the bottom

row of the terminal board.

White Lead

Metal Jumper

DHR

8. Place the control fanning strip on the bottom row of

screws. The white/orange wire on the fanning strip

should be located on the DHR terminal. See Figure 8.

9. Tighten all 18 screws on the fanning strip.

10. Connect the green ground lead on the control panel

to the back panel. From the items supplied, select the

appropriate hardware to be used for connecting the

ground lead. See Figure 9.

Figure 6.

11. Reconnect the orange HS lead back on to the terminal

labeled HS on TB1. See Figure 5.

Terminal Board Stud

12. To energize the front panel, the V knife-blade switches

must be closed and the C knife-blade switch placed in

the open operating position.

Information Notes

1. The white jumper lead must be connected from J to

G on TB2.

2. A metal jumper must be connected between terminals

BR and G. This jumper must be in place for automatic

operation. Another method to inhibit automatic

operation is by setting FC 69 to Blocked.

DHR

Figure 7.

3. In a CL-1 series control the VM, motor supply,

supplied by RCT2, means that your VM lead on TB2

will be coming from the terminal board at RCT2.

Control Grounding Lead and Terminal

4. If you are replacing a CL-1 series control and the

regulator is set up for reverse power flow and you

want to use the present setup, which would include

an internal differential PT and a third RCT. You must

connect a lead from the terminal board on RCT 3 to

TB2-V7 and remove the auxiliary reverse power flow

panel.

Control Fanning Strip

5. If you are replacing a CL-2 or CL-2A front panel and

the regulator is set up for reverse power flow, and you

want to use the present setup, that would include an

internal differential PT and a second ratio correction

transformer (RCT2). You must connect a lead from the

terminal board on RCT2 to TB2-V7 and remove the

auxiliary reverse power flow panel.

6. When replacing a CL-1, CL-2, CL-2A or CL-4 series

control panels with a CL-5C, CL-5C you do not need

to use the internal differential PT or RCTs for reverse

power flow. Refer to the CL-5C or CL-5 series control

manual, S225-10-10 for instruction on setting up for

reverse power flow operations.

White/Orange Wire

Figure 8.

Control Ground

Lead Connection to

Back Panel

Figure 9.

!

SAFETY

FOR LIFE

© 2010 Cooper Industries. All Rights Reserved.

Cooper Power Systems is a valuable trademark of Cooper Industries in the

U.S. and other countries. You are not permitted to use the Cooper Trademarks

without the prior written permission of Cooper Industries.

S2255012 Rev. 0

4

2300 Badger Drive

Waukesha, WI 53188 USA

www.cooperpower.com