From: AAAI-86 Proceedings. Copyright ©1986, AAAI (www.aaai.org). All rights reserved.

A Mobile Robot with Onboard Parallel Processor

and Large Workspace Arm

Rodney

A. Brooks, Jon Connell, and Anita Flynn

MIT

Artificial

Intelligence

545 Technology

Cambridge,

Lab

Square

Mass, 02139

ABSTRACT

a.

The

MIT

number

AI Lab’s

of unique

second

32 processor

sor system,

robot,

design features.

two of them in detail.

cheap

mobile

First,

control

BARNACLE,

no central

locus of control.

Unlike

processors

this one has no expensive

The communication

a distributed

patch

almost

Second,

lightweight,

but has an extremely

MOBOT-2

by the parallel

with

all other

parallel

communications

rout-

is determined

All computing

panel.

The proces-

asynchronously

topology

the robot.

arm is controlled

has an extremely

system.

runs

ing network.

is done

by

onboard

has an onboard

arm.

It is

large working

volume.

The

The MIT

MOBOT-1,

constructed

machine

sensors

rooms

which

an offboard

Lisp machine

emphasis

architecture,

known

system.

which

testbed

and TV

microlink to

is done.

The main research

par-

and strengths

as the suhumption

of the

architecture.

here, is intended

runs the subsumption

of this paper explores

parallel

architecture,

tasks in the world than simply

of MOBOT-2.

decisions

Figure

uninteresting

it more

it works

and there’s

interesting.

extremely

Another

and weight.

larger motors

The remainder

and trade-offs

in

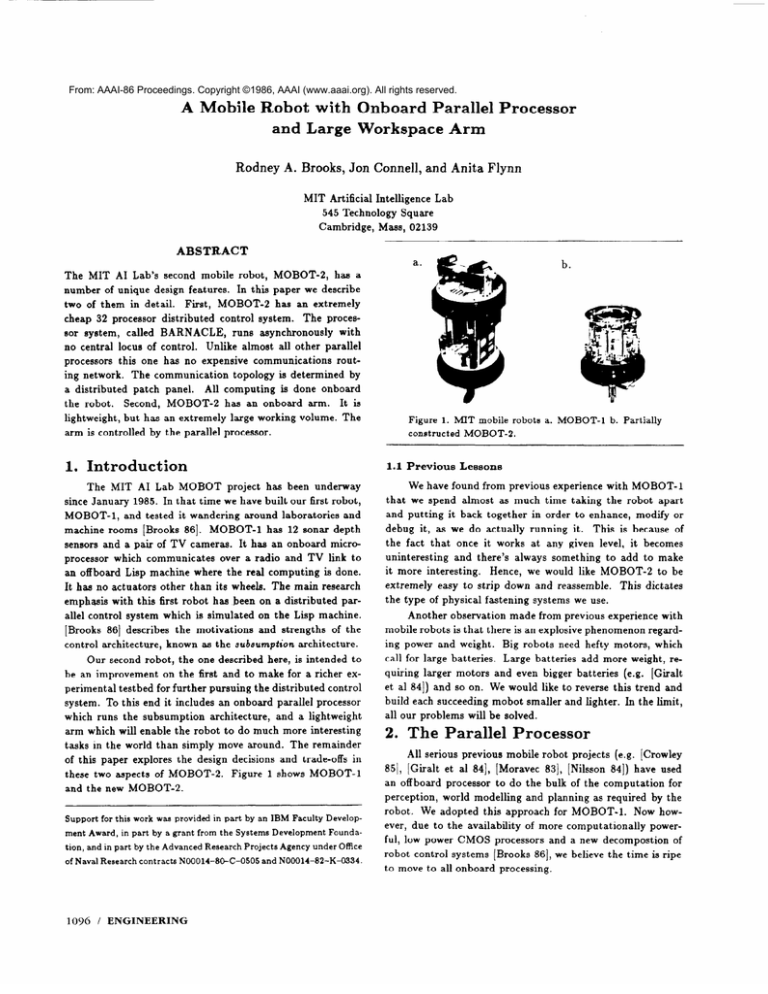

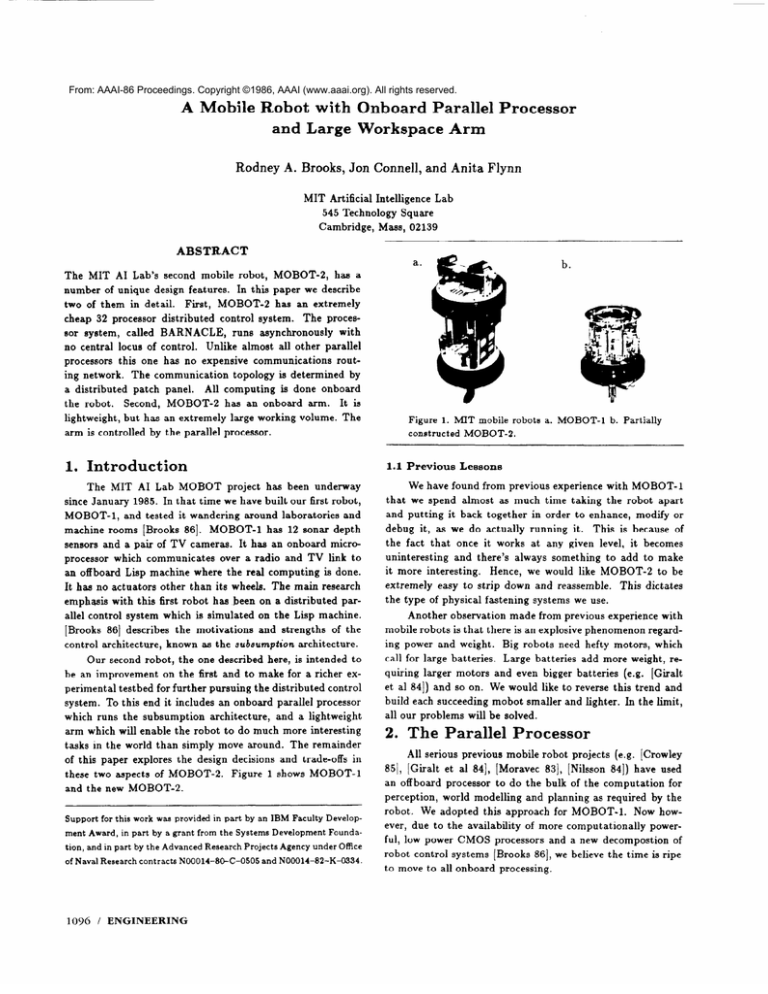

1 shows MOBOT-1

all our problems

Founda-

tion, and in part by the Advanced Research Projects Agency under Office

and NOOOlrl-82-K-0334.

the robot

This

of

it becomes

to add to make

to be

This dictates

we use.

made from previous

Big robots

or

is because

level,

and reassemble.

systems

apart

modify

like MOBOT-2

is that there is an explosive

call for large batteries.

with MOBOT-1

something

we would

fastening

observation

mobile robots

quiring

always

Hence,

the type of physical

it.

at any given

easy to strip down

experience

phenomenon

with

regard-

need hefty motors,

Large batteries

and even bigger

which

add more weight,

batteries

(e.g.

re-

[Giralt

like to reverse this trend and

smaller and lighter.

In the limit,

will be solved.

2. The Parallel Processor

All serious previous

851, [Giralt

an offboard

perception,

N00014-8GC-0505

once

processor

ment Award, in part by a grant from the Systems Development

/ ENGINEERING

that

running

mobot

Support for this work was provided in part by an IBM Faculty Develop-

1096

it, as we do actually

the fact

experience

time taking

in order to enhance,

We would

and the new MOBOT-2.

of Naval Research contracts

it back together

build each succeeding

and a lightweight

move around.

as much

et al 841) and so on.

to do much more interesting

the design

debug

almost

control

the distributed

an onboard

arm which will enable the robot

and putting

ing power

to

on the first and to make for a richer exfor further pursuing

that we spend

on the Lisp machine.

the one described

To this end it includes

these two aspects

and

has been on a distributed

is simulated

the motivations

Our second robot,

perimental

It has an onboard

where the real computing

which

861 describes

laboratories

has 12 sonar depth

other than its wheels.

system

be an improvement

around

over a radio

with this first robot

allel control

We have found from previous

has been underway

861. MOBOT-1

communicates

It has no actuators

control

it wandering

and a pair of TV cameras.

processor

[Brooks

project

In that time we have built our first robot,

[Brooks

b. Partially

MOBOT-2.

1.1 Previous Lessons

AI Lab MOBOT

and tested

Figure 1. MIT mobile robots a. MOBOT-1

processor.

1. Introduction

since January 1985.

b.

has a

In this paper we describe

MOBOT-2

distributed

called

MOBOT-2,

robot.

mobile

robot

et al 841, [M oravec

processor

world

and planning

this approach

ever, due to the availability

processors

robot

[Brooks

systems

to move to all onboard

[Crowley

as required

for MOBOT-1.

of more computationally

ful, low power CMOS

control

(e.g.

841) have used

to do the bulk of the computation

modelling

We adopted

projects

831, [Nilsson

for

by the

Now howpower-

and a new decompostion

of

861, we believe the time is ripe

processing.

4

,

level 9

level P

reason

b.

about

behavior

plan changes

SeWX9

to the world

identify

obJecta

monitor

changes

build

level 1

of objects

Ez&

maps

Figure

3.

adding

more levels.

Augmenting

level 0

Actuators

an existing control

system

by

explore

wander

avoid object,

Figure 2. Slicing a control system a. Traditional

position b. Subsumption

architecture

2.1 The Subsumption

Architecture

The usual approach

bile robots

to building

is to decompose

of functional

units as illustrated

robot

illustrated

then tie them together

difference

is that

have a contSrol sy&em

petence.

second

which

layer to augment

it.

new decomposition

for mobile

achieves

The

a large number

The

level of CO~Iand build

continues

a

building

more competent

a subsuntptzon

systems,

plausible

control

architecture.

different

with radically

at the hardware

of advantages

Our

limited.

lel processors

or talk to memory.

different

im-

Under

control

as a watchdog

to its attached

functions

The current

and base.

and

It can wait for ceror act

t.imer. The finite state machine .also occasion-

ally passes data

computes

processor

The finite state machine

save partial results in an internal register,

geometry

coprocessor

such as polar coordinate

and monotonic

vector

of modules

Our initial

robustness,

coprocessor

required

boards.

to control

idea was that

precisely

Recently

That

the robot

arm

one physical

play the role of one finite state

pair,

which

addition,

functions.

design calls for 32 processor

should

switch

happen offline.

to reconfigure

is never

between

parni-

talk to each

the subsumption

run of the robot.

is predetermined

machine

coprocessor.

the data flow t,hrough the module.

geometric

part of most

which lets processors

this can essentially

architec-

processors

is

Thus there is no need

message

topology,

as

Instead the communication

by a distributed

patch panel.

to build

per physical

machine-

we are of the opinion

Each processor

and contains

forming

suppression

with

128 bytes

of internal

adding

layers from

collections

of very

Each processor

is 4 inches wide by 3 inches

(described

below).

an architecture

RAM

similar

high

and logic for per-

The 6301 is a CMOS

to the 6800.

and an external

It has

8K piggy-back

The board shown in figure 4 also has provisions

an extra 2K of external

will contain

municating

pairs, which we call modules.

board

a Hitachi 6301 microcontroller

processor

EPROM.

pair

processor.

the program

and the geometric

2.2 Physical Layout

We have chosen

controls

tain inputs,

processor

concerning

expensive

for a fast dynamic

simple processor

of a finite state

geometry

level. It also

is that the architecture

of communications

fixed for a particular

from BARNACLE.

that we may be able to simulate more than one processor

The most

is the switch

ture the topology

pair consists

a peripheral

is the number

architecture

and testability.

One of these advantages

bandwidth

Figure 4. A processor board

scaled comparison,

control

strategies

buildability,

topology

intact

process

system.

layer we already

a certain

system

leads to a radically

robot

plementation

other

control

the lowest

as in figure 3.

We call this architecture

confers

each slice explicit Iy,

t’o form a robot

We leave that running

he-

This is

slices iu figure 2b. As wit,11

layer upon layer to give successively

systems

of the problem.

we implement

after building

slices

requirements

to use task uchievzng

decomposition

decomposition

for mo-

by a series of vertical

by a series of horizontal

a functional

systems

into a series (roughly)

the computational

we have decided

haviors as our primary

control

the problem

in figure 2a. After analyzing

for a mobile

decom-

the geometric

of each module

processor

if needed.

for

The EPROM

to emulate the finite state machine(s)

co-processor(s),

between modules.

state variables

RAM

as well as the code for com-

The RAM will hold the internal

and serve as a scratch

and for the decoding

pad for

of messages.

ROBOTICS

/

1097

Dominant

nnn

Inferior

output

b.

a.

C.

Figure 6. In each of the three cases above the dominant

input suppresses the inferior input.

Figure

5. Physical

arrangement

of processor

boards.

is ignored.

b.

transmitted

inferior

Messages

Inferior

packet

packet

a. Inferior packet

ie blocked.

c.

are sent serially over 2 conductors,

tor is the data line and the other is a control

Each processor

puts.

The input

subminature

board has 3 serial inputs and 3 serial out-

and output

lines of the module

phone jacks on each individual

of one module

are connected

board.

to inputs of another

wires made from a piece of coaxial

end. A single lead contains

terminate

cable with

two conductors,

and the other to carry control signals.

in

Outputs

ln addition

each jack

using patch

plugs at each

one to carry data

All input jacks come in

has a built

in switch

The

5 illustrates

processor

boards

the complete

are mounted

the robot with the chips pointing

on

building

four octagons

gether

with

and stacking

batteries

required

being

nodes

clipped

for running

thC periphery

of

we plan

will be pabched

the robot

toThe

reside in the center

of the octagon.

2.3

Between

All messages

packets.

Making

must

protocol.

None of the physical

deal

are known

processor

Our analysis

quantities

than

be controlled

simpli-

showed

any physical

how many bytes

quantity.

per packet.

with which the robot

8 bits

of accuracy

more precisely

command

for distance.

corridor

orientation

relative

sonar

sensors

more

likely infrared

per ranger

Z, y, and 0.

to the current

position.

mounted

on the robot

depth

can be placed

/ ENGINEERING

sensors

and one

if desired.

length,

robot

was

of the robot

can fit in three bytes:

is plenty for local obstacle

1098

speed

size to

question

by three bytes:

byte can represent

nor

than this.

takes two bytes, one for heading,

A third

description

The remaining

The configuration

in the world can be represented

that

for several

Since 8 bits make a byte, that seemed like a reasonable

A motion

using our lisp machine

Inhibition,

There

a necessary

width,

With

(as in MOBOT-1,

A

and

12

but

on MOBOT-‘L),

two bits

in a single 24 bit packet.

Two bits

detection

of BARNACLE.

inhibit

input

amount

t.he

of time.

to each processors

which

is

can be varied from a tenth

A pulse on

line of the inhibit input starts the timer which in

t,urn prevents

although

architec-

by simply forbidding

for a specified

to a timer whose period

the control

of 24 bits

This is much

part of the subsumption

in BARNACLE

is a special

100 instruc-

Packets

rate we used to run MOBOT-1

simulation

to send any messages

connected

the processor

from sending

any new messages,

it is allowed to finish ones currently

timer can be re-triggered

are 24 bit

for our application

to more

can any of its effecters

represent

faster than the communication

three

All ports are

in progress.

The

at any time during the inhibition

the duration.

goes low, the processor

When

in-

at last the timer’s

is free to send whatever

mes-

sages it wishes.

a fixed size significantly

24 bits was the right number

(time for about

can thus he sent in about one tenth of a second.

output

Modules

in the BARNACLE

the packets

fies the communication

reasons.

500 microseconds

terval to extended

Communication

lines to supply

of a second to several minutes by a potentiometer.

t,opologies

into these trays.

I/O

lines on each processor.

t,ions) which is an easy speed to maintain.

module

(conceptually)

Particular

every

one conduc-

line. Both control

to single bits of the processors

We use 12 parallel

ture, is accomplished

system.

Currently

them

frame.

and suppressor

the cables

around

outwards.

above each other on a plexiglass

for the processors

BARNACLE

polled

which

forces the input to a known state if no jack is inserted.

Figure

ports.

input and three output

pairs so that signals which must fan out can be daisy chained

together.

and data wires are connected

parallel

Partially

is fluehed.

and avoidance.

Suppression

special

in BARNACLE

hardware.

Each

is also implemented

processor

board

contains

pressor node which has two inputs and one output.

of a flip-flop

output.

This flip-flop

the dominant

trolled

controls

input,

which

makes

The state

it through

to the

is set by a pulse on the control

line of

and reset after a time-out

by an associated

this works.

input

using

one sup-

The control

potentiometer.

line signals

period

con-

Figure 6 shows how

an impending

message

with a square pulse; the falling edge signals that the message

is about to begin.

There is a lower bound on the length of this

pulse, but no upper bound,

message

indicates

ignored-the

ent message.

be completely

collision

3.

Reassertion

that the message

of this line during

is invalid and should

new falling edge will indicate

Thus

the two inputs

asynchronous

problems

the start of a differ-

to a suppressor

node can

and yet there are no timing

thanks to the protocol

a

be

or

definition.

The Arm

The fact that our robot

is mobile

makes a big difference

in the design of the manipulator.

A mobile

an airplane in that all its resources

only carry n certain

fit in a specified

is linlited.

amount. of weight, all its equil)lllent

power is also scarce.

and weight

is limited

lights and disk drives,

and occasionally

illto

inhabit noisy environthe teleme(ry

communications

What

are in-

(“‘)

y = II sin 8 + 12 sin 4 - f

Requirements

has been said above

ware residing

on a mobile

requirements

is true for any piece of ltnrd-

robot.

There

for manipulators

are, however,

also

on mobile robots.

One

of these is that the arm and its end effector

heavy that it tips the robot

manipulator

throughout

We want our mobile

wafers,

to manipulate

but

7. The manipulator

Figure

the hand

is always

and its kinematics.

must, not be so

they can’t

up rocks for examination.

b.

and range of payloads.

reasonably

ounces

Note that

vertical.

over. This needs to be true of the

its workspace

Arms that can lift a couple

conductor

d

x=f~cos8+f~cos~+d

altogether.

3.1 Special

specific

Fortunately,

to beam information

Yet, because robots

ments full of fluorescent

they ruII, t II(~

they consume.

power, it is possible

and out of a robot.

bandwidth

com~~u~nt?o~(~I

\‘L!sl and C’M( IS,

there are and the faster

space,

unlike electrical

power scarce,

Even with advanced

the more processors

terrupted

(nil

111114

szze, and the power a~nil:~ble f~0111Ijilt t crier:

Not only is electrical

more power,

is ;I lot likfb

rol,ot

are severely lilrlit,cb(l. It

heavy objects.

are fine for shuffling semimove

Making

coffee

the actual

means that it can move faster without

mugs

or pick

arm light also

encountering

control

instabilities.

Another

nipulators

robots

shortcoming

of most commercially

is that they have too small

inhabit

ferent heights:

a three dimensional

desks, tables,

that t,he manipulator’s

tical freedom.

ma-

Mobile

world that, has mntty dif-

shelves,

workspace

available

a workspace.

floors,

etc.

needs a large mrount

The lateral mobility

Lastly, the precision

mobots

to transfer

t.o do low tolerance

locate

an object

of commercial

things

manipulators

to perform.

from one location

assembly.

Sensors

to a thousand

is over kill

things

and setting

something

where you want it is usually

positioning

does matter,

are often environmental

fine.

down

constraints

atively

straight

very accurate

On the other end,

a]) inch of

absolute

a peg from a hole, there

(like the edges of the hole)

given an appropriate

control

sys-

design of the arm for MOBOT-2

It is a 2 degree of freedom

manipulator

which moves in a vertically

ing through

the central

degrees of freedom

vertical

axis of the robot.

is relplanar

plane passThe two

are used to select a height for t’he gripper

and to give fine grain control

Coarse

oriented

over the hand’s

radial and angular control

is provided

Total

poor

headings

range estimates.

compensate

toward

only 2 degrees

of freedom

The rationale

Each

section

radial position.

by moving

the

behind

vision,

is desirable.

we choose

This

to mount

of the arm consists

that can

is why with

the arm so it

plane.

of a parallel

four-bat

Figure 7 shows how these linkages are arranged.

cause there is no wrist in this design we have decided

the gripper

always point straight

four-bar

mechanisms

gripper

to t’he robot’s

two joints

are capable

cause the motors

it controls.

complicated

serve

down, an attitude

frame.

the motors

power transmission

an unacceptable

a payload

are light, each motor

Mounting

of 2 pounds.

is located

tfihe

Be-

at, the joint

back further would require iL

system

that could

phase lag in the servo control

workspace

The

of the

which actuate

and would likely weigh as much as the motor

The complete

which al-

the attitude

The motors

of lifting

Be-

to have

from flat surfaces.

to reference

this

supply

but relat’ively

a degree of freedom

opera.tes in a radial rather than a tangential

linkage.

we have

posit,ion of t,he

a target object

Having

for these errors

down

in particular

lows the hand to pick up s~nsll objects

et al 831.

forward.

motion.

not.

3.2 Mechanical Design

The mechanical

hand; there is no sideways

of joints

of the angular

to another,

within

a.

area.

To keep the number

fine grain control

is that many long range sensors,

For cases where

like removing

that can aid in the alignment

tem [Lozano-PCrez

ent,ire robot.

our

such as vision call not

of an inch.

for the mmipulntor.

operating

We expect

getting the gripper to within half an inch is sufficient to grasp

most

b. Normal

not provided

we wish our robot

Tip positions

does

base allows it t,o move

the whole arm around.

for the actions

8.

workspace.

of v(br-

of the arm, however,

not need to be very big since the robot’s

Figure

This me3;111s

introduce

of the fingers

itself.

of the arm is shown in figure 8;~.

ROBOTICS

/

1099

b.

9. Close-up

Figure

of a prototype

compliant

gripper.

Figure

10. The hand

finders

(triangles).

returned

However, we are primarily

concerned

with the vel tic al colun~n

shown in figure 8b which is 40 inches high and 18 inches witle.

This

alloys

the arm to work 0x1 both

of tables and to reach anywhere

desk top.

Quantizing

the joint

a1111a quarter

inch accuracy

65530 possible

fingertip

the floor all(l the 101)s

in the front half of a nor~nal

angles to 8 bits eacll gives tllcx

over the entire workspace.

positions

are plotted

All

fingers are 1 inch wide by 3 inches long and contact

control

over the angular

the robot,

lateral

rubber

the jaws of gripper

leeway

2 degrees

furthest

location

is important

of the

of error in the angular

point

Thcb

the object,

with respect,

iWIll

open to a wide 5 inches.

because

in its workspace

it allows

position

t.0

This

us to tolerate

at shorte1

The arm is controlled

the joints.

voltage

by specifying

This is accomplished

to a st,andard

rate. Controlling

a speed for each of

by slowly ramping

proportional

controller

the speed of t,he joints rather than their po-

sition lets us move the hand along a desired trajectory.

ticular,

we can command

up or move it directly

by specifying

sensed, but. the error volt-

ages in the servo amps are also reported.

Errors in the joint

being supplied

pling this with the configurat,ion

the weight of the payload

suring the control

sufficiently

necessary

This

the hand is grasping

large grasping force is sensed.

is determined

slowly

The amount of force

by the weight of the payload

directly

until a

as described

above,

which

or esli-

/ ENGINEERING

kinesthesic

range-finders.

sensors,

These

The pro-

switch,

but rather

to local

moving

obst,acles,

formulabes

motors

on the onboard

processes

sensor

MOBOT-2

also has an onboard

care

and

fashion.

arm. Ilnlike other robols

arms this one has a large workspace

objects

The

arm, reacts

information,

high level plans all in a distributed

with onboard

topology.

in the entire system.

enabling

it

quite far above the base of the robot,.

has been

taken

achieve this reach without

to ensure

tipping

that

the robot

can

itself over.

REFERENCES

[Brooks

861 “A Robust

Robot”,

Rodney

RA-2,

Automation,

[Crowley

March

[Giralt

search

IEEE

Giralt,

Integrated

Raja Ch+tila,

for Robots”,

and Russell

Research,

[Morave<:

Mobile

Robot”,

and Automafzon,,

Navigation

Multisensory

831

“The

P. Moravec,

Motion

Robots”,

Robotics

Re-

1984, 191-214.

Synthesis

of Fine-

Tom&s Lozano-PCrez,

H. Taylor,

Volume

and

Mobile

and Marc Vaisset,

et al 831 “Automatic

Strategies

Robotics

and

1985, 31-41.

[Lozano-Pdrez

Hans

oj Robotics

1, Brady and Paul eds, MIT Press,

Mason,

oj Robotics

for an Intelligent

System for Autonomous

Motion

T.

System for a Mobile

Journal

1986

Journal

al 841 “An

et

IEEE

No l., April

851 “Navigation

James L. Crowley,

RA-1,

Layered Control

A. Brooks,

International

Mathew

Journal

oj

3, Issue 1, 1983

Stanford

Proceedings

Cart

and the CM17 Rover”,

of the IEEE,

71, July

1983,

872-884.

the finger separation.

from basic

a cluster of 8 infrared

1100

controls

Georges

For the fingers, mea-

allows us to close the fingers

by measuring

Aside

processor

angles iudicat e

of the arm we can determine

being carried.

processor.

of its communicat~ion

locus of control

parallel

Control

By cou-

parallel

configuration

There is ILOcentral

spring, this can

by t#he mobors.

error tells how tightly

can either be measured

mated

If the servo has a

such as a generalized

be very useful information.

the amount, of torque

joint speeds that

of the arm.

Not only are the joint positions

known transfer function,

111par-

the arm to raise the gripper straight

forward

vary with the configuration

an object.

has an onboard

the cont,lol

at a particular

For the table shown in figure

map looks figure lob.

relies on physical

Special

Control

the fingers as can be seen in figure

a coarse (3 bit) depth measurement

cessor is unique in that it has no dynamic

to manipulate

and

b. Ileights

Conclusion

of the arm at the

and larger errors

extensions.

3.3 Sensors

lOa, the IR depth

MOBOT-2

Since there is no fine grain

pads.

grid surrounding

of the surface in its field of view.

4.

by :I ring of II? range

by the IR ring.

10a. Each sensor provides

in ligtlre 8a.

The hand is a simple linear slide parallel jaw gripper.

via two compliant

hexagonal

is surrounded

a. The arm over a table.

the hand also has

are arranged

in a

[Nilsson 841 ‘Shakey

Center

Technical

the Robot”,

Note 8!?3, April

Nils J. Nileson,

1984.

SRI Al