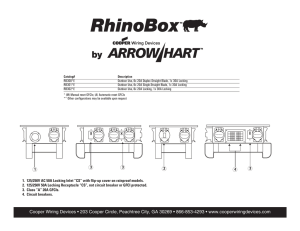

’ Arrow Hart Line Announces New Cooper Wiring Devices

advertisement

203 Cooper Circle Peachtree City, GA 30269 Phone: (770) 631-2100 Fax: (770) 631-2101 www.cooperwiringdevices.com News Release Contact: Lauren Ban (412) 394-6611 lauren.ban@bm.com Cooper Wiring Devices’ Arrow Hart Line Announces New NAFTA Compliant GFCI Offering New line of specification grade, hospital grade and tamper resistant ground fault circuit interrupter receptacles meet provisions of Buy American Act. PEACHTREE CITY, GA, April 30, 2010 – The Arrow Hart brand of Cooper Wiring Devices, a leading electrical wiring device products manufacturer, is pleased to deliver its first line of NAFTA specification grade ground fault circuit interrupter (GFCI) receptacles, designed to meet the provisions of the Buy American Act. This new, durable receptacle line provides unmatched protection combined with incomparable safety features. Unbreakable nylon construction, a large visual indicator light for quick notification of tripped or “end of life” condition and ShockSentry™ technology to deny power and prevent re-setting when the device is no longer able to provide safe, protected power make the NAFTA compliant GFCI an ideal choice for any project. A matching standard size thermoplastic wallplate is also included with the receptacles. In compliance with the latest UL943, Class A GFCI and UL498 Hospital Grade Requirements, the Hospital Grade models were designed to ensure safety and maximum ease of use. Additionally, all of the GFCI receptacles in this offering not only meet, but exceed 10ka Short Circuit Testing and Underwriters Laboratories (UL) 2006 UL943 Safety Standards. "The introduction of these new devices demonstrates Cooper's continued commitment to delivering products that meet the diverse needs and preferences of our customers," said Dave Pawl, President, Cooper Wiring Devices. "As a NAFTA compliant line, our new GFCI receptacles will serve as a practical option for new construction and retrofit projects looking to meet the provisions of the Buy American Act.” -More- Cooper Wiring Devices – Page 2 Arrow Hart commercial products have been developed to the highest standards, engineered with unique features that can help reduce installation time, improve safety and provide years of high performance under constant use. Arrow Hart industrial products are designed to provide exceptional performance in even in the harshest manufacturing environments to reduce downtime, improve safety and increase employee productivity. To learn more about the new NAFTA compliant GFCI line or to download an electronic copy of the new Arrow Hart buyer’s guide, visit www.arrowhart.com. Also learn more at www.cooperwiringdevices.com. About Cooper Wiring Devices Cooper Wiring Devices, a trusted name in electrical products, is committed to providing products that increase productivity, energy efficiency, safety at work and in the home, and provide reliable performance. Our Arrow Hart brand celebrates 120 year of providing performance without compromise and innovative solutions for the toughest electrical problems. Bridging state of the art lighting control with contemporary aesthetics, CORE lighting controls line includes the latest developments in occupancy sensors, dimmers, home automation and designer devices. Cooper Wiring Devices A division of Cooper Industries plc (NYSE: CBE), Cooper Wiring Devices is headquartered in Peachtree City, GA with international manufacturing and distribution facilities. For more information on Cooper Wiring Devices visit www.cooperwiringdevices.com. About Cooper Industries Cooper Industries plc (NYSE: CBE) is a global manufacturer with 2009 revenues of $5.1 billion. Founded in 1833, Cooper's sustained level of success is attributable to a constant focus on innovation, evolving business practices while maintaining the highest ethical standards, and meeting customer needs. The Company has seven operating divisions with leading market share positions and world-class products and brands including: Bussmann electrical and electronic fuses; CrouseHinds and CEAG explosion-proof electrical equipment; Halo and Metalux lighting fixtures; and Kyle and McGraw-Edison power systems products. With this broad range of products, Cooper is uniquely positioned for several long-term growth trends including the global infrastructure build-out, the need to improve the reliability and productivity of the electric grid, the demand for higher energy-efficient products and the need for improved electrical safety. In 2009, sixty-one percent of total sales were to customers in the industrial and utility end-markets and thirty-nine percent of total sales were to customers outside the United States. Cooper has manufacturing facilities in 23 countries as of 2009. For more information, visit the website at www.cooperindustries.com. ### 2