Cold & Refrigerated Environments

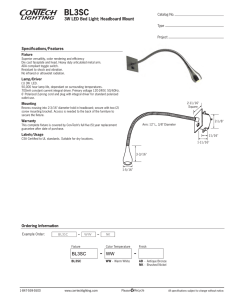

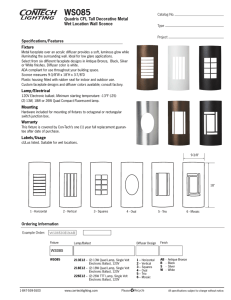

advertisement