UNIVERSITY OF KENTUCKY Mining Engineering HANDBOOK FOR UNDERGRADUATE STUDENTS

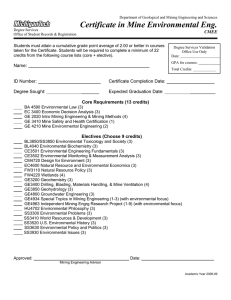

advertisement