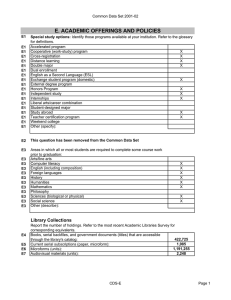

2008 Canadian Utility Telecom Conference

advertisement

2008 Canadian Utility Telecom Conference Power Station Automation Workshop – Part II Robert O’ Reilly Senior Application Engineer Cooper Power Systems – Cybectec Energy Automation Solutions Power Station Automation-II P Presentation i S Summary • Review of what has been presented in Part – I • What are the goals of Automation? • Connectivity issues • Station data – Operational vs NonOperational • Moving the data to the next level • Future A review • Summary of information given in Part – I – IED’s The Goals of Automation • To automate certain actions within the station itself. • Provide and receive information from higher up systems. • Meet M t the th intents i t t off NERC-CIP NERC CIP in i regards d to the access of information within the station. t ti Connectivity • The stations contain many legacy devices: – Serial devices of different speeds and different communication types (i (i.e. e RS RS232, RS-422/RS-485). – Different Diff t protocols. t l • The new equipment q p is q quite often Ethernet based but again with different protocols protocols. Typical substation 832 009 714 Power metering Power metering 832 009 714 Transformer Data & Alarming Transformer Data & Alarming RTU Overcurrent Overcurrent Overcurrent Bus protection Overload Overload Frequency Voltage Overload Fault Indication Differential Reclosure I/O to RTU 832 009 714 Metering Reclosure 832 009 714 Distance Metering Bus coupler Distance Transformer Data & Alarming 51 – Overcurrent Relay 832 009 714 Metering Typical Connections Initial Substation A t Automation ti Project FRAD Port switch and serial port converter From serial devices 832 009 714 832 009 714 Power metering Power metering To serial port switch To serial port switch Transformer Data & Alarming Transformer Data & Alarming RTU/PLC To serial port switch Overcurrent To serial port switch Overcurrent To serial port switch To serial port switch Overcurrent Bus coupler Bus protection Overload Overload Overload Overcurrent Relayy Advanced protection relay with: - Frequency - Voltage - Fault indication Differential Reclosure 832 009 714 M t i Metering To serial port switch Reclosure 832 009 714 Metering Distance Distance To serial port switch Transformer Data & Alarming To serial port switch 832 009 714 Metering To serial port switch IED Integration New IEDs and users… ASSET MANAGEMENT DEREGULATED PARTNERS LOCAL HMI POWER QUALITY …lead to Limitations ASSET MANAGEMENT DEREGULATED PARTNERS LOCAL HMI POWER QUALITY Integrating the Information for many Systems ASSET MANAGEMENT DEREGULATED PARTNERS LOCAL HMI POWER QUALITY Data Concentrator features The key component in any integration project should provide: – Physical interface to the IEDs (RS-232/485, Ethernet) with Pass-thru capabilities (transparent connections) – Data acquisition, acquisition normalization, normalization redistribution capabilities – Support for most of the industry protocols – Automatic retrieval of event/DFRs with file pushing capabilities – Local Security server: Users, credentials and privileges management. Embedded firewall, VPN and logging p capabilities – Time-synchronization of all connected devices – Local, substation-wide automation server – Embedded alarm and data visualization panel running directly on the local concentrator Substation data • From a few pieces of information to many ten’s of thousand. • Data can come from: – Protection relays – Metering devices – Miscellaneous Intelligent Electronic Devices – Fault recorders – Analysis equipment – Etc… Using the information • • • • • • Control via SCADA system Distribution Automation F d Automation Feeder A t ti Expert system Condition Based Monitoring Special Analytics Systems What we want to achieve What we want to achieve OPERATIONAL DATA TO SCADA REMOTE ACCESS FOR ENGINEERING AND MAINTENANCE NON-OPERATIONAL NON OPERATIONAL DATA TO ENTERPRISE APPLICATIONS Moving data to SCADA OPERATIONAL DATA TO SCADA Retrieve: Currents Voltages Frequency Power Quality Status REMOTE ACCESS FOR ENGINEERING AND MAINTENANCE NON-OPERATIONAL NON OPERATIONAL DATA TO ENTERPRISE APPLICATIONS Providing remote access to devices OPERATIONAL DATA TO SCADA Use native vendor tool to: Retrieve non-operational data Review and change settings REMOTE ACCESS FOR ENGINEERING AND MAINTENANCE NON-OPERATIONAL NON OPERATIONAL DATA TO ENTERPRISE APPLICATIONS Retrieving non-operational non operational data OPERATIONAL DATA TO SCADA Retrieve: Event reports p Disturbance records Oscillography records Equipment monitoring reports REMOTE ACCESS FOR ENGINEERING AND MAINTENANCE NON-OPERATIONAL NON OPERATIONAL DATA TO ENTERPRISE APPLICATIONS HMI 2 Workstation (new) HMI 1 Workstation (new) NOTE: PROTOCOL DMP COLOR 1. INTER-CONN RJ45 2. INTER-CONN F.O (Multi-mode) 3. IEC61850 RJ45 4. IEC61850 F.O (Multi-mode) 5 5. PEER TO PEER LINK RJ45 PEER-TO-PEER 6. PEER-TO-PEER LINK F.O (Multi-mode) Overhead projector Workstation (Additional) TERMINAL LAN SCADA SERVER 1 (Formerly HMI 1-220) INDUSTRIAL ETHERNET/ IEC LAN SCADA SERVER 2 (Formerly HMI 2-220) MES 1- 220 SCADA servers MES 2- 220 MES 2- 33 MES 1- 33 1. 1. 2. 1. Gateways SMP 1C-33 SMP 2A-33 SMP 1A-33 SMP 2C-33 3. MES 1-1- 33 4. 220 KV System Architecture (Refer to sheet 1 for details) 3. MES 3-1- 33 MES 1-2- 33 MES 3-2- 33 4. 6. R.C s/w < 10 R.C s/w < 10 220KV SAS RC RC RC RC RC RC 3. 3. By others 6. 40 IEDs SIPROTEC SIPROTEC 4 4 SIPROTEC SIPROTEC 4 4 SMP 1B-33 SIPROTEC SIPROTEC 4 4 SIPROTEC SIPROTEC 4 4 SIPROTEC SIPROTEC 4 4 SIPROTEC SIPROTEC 4 4 By others 40 IEDs SMP 2B-33 3. MES 2-1- 33 F.O Ring MES 2-2- 33 4. R.C s/w < 5 RC R.C s/w < 5 RC RC RC 3. By others 33KV MRS 1 220KV 0 REV DESCRIPTION 20 IEDs DRN Jerry CHK KEE C Y 13-2-07 APP TONG C B DATE DATE 13-02-07 SIPROTEC SIPROTEC 4 4 SIPROTEC SIPROTEC 4 4 SIPROTEC SIPROTEC 4 4 SIPROTEC SIPROTEC 4 4 Copper links By others 20 IEDs 33KV MRS 2 TITLE: 220KV / 33KV GIS INTEGRATION PROJECT: SYSTEM ARCHITECTURE Major Petroleum Project in Asia JOB NO: - PO NO: - EMS TYPE NO: - DWG NO: TAG NO: - SCALE: NTS SHT NO: 2+ SIZE : A3 HMI 1- 220 HMI 2-220 GPS COLOR DMP Overhead projector MES 1-220 Control Room MES 2-220 To Field Devices 1. Gateways SMP 1A-220 SMP 2A-220 SMP 1C-220 SMP 2C-220 14 x Modbus Meters (RS485) 2. 2. MES 1-1-220 MES 3-2-220 MES 3-1-220 MES 1-2-220 3. F.O Ring To 33KV MRS1 SIPROTEC 4 Relay 1 SIPROTEC 4 Relay 2 SIPROTEC 4 Relay 3 SIPROTEC 4 Relay 4 SIPROTEC 4 Relay 1 Relay 48 SMP 1B-220 SIPROTEC 4 Relay 2 SIPROTEC 4 Relay 3 SIPROTEC 4 SIPROTEC 4 Relay 4 Relay 48 SIPROTEC 4 SMP 2B-220 NOTE: 2 2. PROTOCOL MES 2-1-220 MES 2-2-220 220KV SAS System Relay 1 SIPROTEC 4 SIPROTEC 4 0 REV DESCRIPTION DRN Jerry CHK KEE C Y 14-2-07 APP TONG C B DATE DATE 14FEB2007 Relay 2 SIPROTEC 4 Relay 3 SIPROTEC 4 SIPROTEC 4 Relay 4 SIPROTEC 4 1. INTER-CONN 2. IEC61850 RJ45 3. IEC61850 F.O (Multi-Mode) 4. PEER-TO-PEER RJ45 5. PEER-TO-PEER F.O (Multi-Mode) Relay 48 TITLE: 220KV SYSTEM ARCHITECTURE PROJECT: Major Petroleum Project in Asia JOB NO: - PO NO: - EMS TYPE NO: - DWG NO: TAG NO: - SCALE: NTS SHT NO: 1+ SIZE : A3 Substation Equipment q p Monitoring Equipment monitoring • Asset Monitoring – Collect and act on information from the subsystems internal to the breakers, transformers and switchgear that make up the systems - measured in minutes and hours – Identify abnormal trends and patterns that develop over time with automated notifications – typically hours and days – Notify users ahead of time 24 Equipment monitoring • Why Monitor? – Monitoring the key vital signs on high value transformer and breakers enables the appropriate i response to known k equipment i conditions. – Monitoring M it i • Lowers the risk of failures • Increases reliability • May prolong the life of expensive, high value assets. Equipment monitoring • Using g Expert p System y & Rule Editor – Transform complex raw data into useful information – Automatically monitor information for abnormalities – Diagnose probable causes – Recommend appropriate pp p actions – Predict/prevent major breakdowns Typical Substation – NERC C Compliant li Substation Automation Project NERC compliant Router Intelligent Gateway GPS Clock 832 009 714 832 009 714 Power metering Power metering To serial port -1 To serial port -2 Transformer Data & Alarming Transformer Data & Alarming RTU/PLC To serial port -3 3 To serial port -4 4 Overcurrent To serial port -5 5 Overcurrent Overcurrent To serial port -6 6 Bus coupler Bus protection Overload Overload Overload Overcurrent Relay Advanced protection relay with: - Frequency - Voltage - Fault indication Differential Reclosure Reclosure To serial port -7 832 009 714 Connection to gateway serial port To serial port -X Metering 832 009 714 Metering Distance To serial port -9 Distance Transformer Data & Alarming To serial port -10 To serial port -8 832 009 714 Metering Bandwidth - The dilemma • We have been adding bandwidth bandwidth, but we still need more, what is the solution? • Some of the latest projects having tens of thousands of data points are using statistical computations to reduce bandwidth requirements. The Future • A growing trend more computations and data analysis at the Substation to reduce total amount of data being sent over the network. • One protocol to be used within the Substation and at higher levels. • Synchrophasor S h h d data t and d itits use. Driving the SmartGrid Investment Representative Intelligent Grid Road Map Phase 3 Phase 2 Phase 1 Smart Meter 2 way communications Demand Response Automated restoration Predictive maintenance Fault location Volt/VAR management Outage detection Distributed g generation Consumer portal Communications, C i ti sensors and d software ft applications li ti enabling better data and better grid performance Questions?