Implementing Real-Time Statistical Analysis of in a Distributed Generating Environment

advertisement

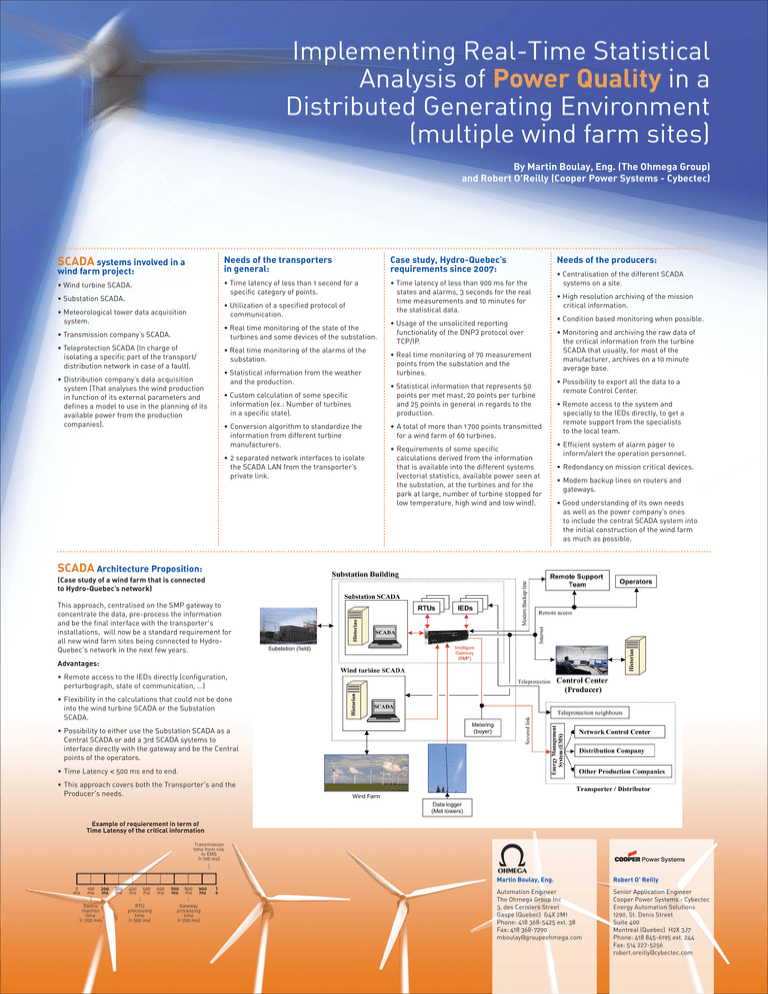

Implementing Real-Time Statistical Analysis of Power Quality in a Distributed Generating Environment (multiple wind farm sites) By Martin Boulay, Eng. (The Ohmega Group) and Robert O’Reilly (Cooper Power Systems - Cybectec) SCADA systems involved in a wind farm project: • Wind turbine SCADA. • Substation SCADA. Needs of the transporters in general: Case study, Hydro-Quebec’s requirements since 2007: • Time latency of less than 1 second for a specific category of points. • Time latency of less than 900 ms for the states and alarms, 3 seconds for the real time measurements and 10 minutes for the statistical data. • Utilization of a specified protocol of communication. • Meteorological tower data acquisition system. • Transmission company’s SCADA. • Real time monitoring of the state of the turbines and some devices of the substation. • Teleprotection SCADA (In charge of isolating a specific part of the transport/ distribution network in case of a fault). • Real time monitoring of the alarms of the substation. • Statistical information from the weather and the production. • Distribution company’s data acquisition system (That analyses the wind production in function of its external parameters and defines a model to use in the planning of its available power from the production companies). • Custom calculation of some specific information (ex.: Number of turbines in a specific state). • Conversion algorithm to standardize the information from different turbine manufacturers. • 2 separated network interfaces to isolate the SCADA LAN from the transporter’s private link. • Usage of the unsolicited reporting functionality of the DNP3 protocol over TCP/IP. • Real time monitoring of 70 measurement points from the substation and the turbines. • Statistical information that represents 50 points per met mast, 20 points per turbine and 25 points in general in regards to the production. • A total of more than 1 700 points transmitted for a wind farm of 60 turbines. • Requirements of some specific calculations derived from the information that is available into the different systems (vectorial statistics, available power seen at the substation, at the turbines and for the park at large, number of turbine stopped for low temperature, high wind and low wind). Needs of the producers: • Centralisation of the different SCADA systems on a site. • High resolution archiving of the mission critical information. • Condition based monitoring when possible. • Monitoring and archiving the raw data of the critical information from the turbine SCADA that usually, for most of the manufacturer, archives on a 10 minute average base. • Possibility to export all the data to a remote Control Center. • Remote access to the system and specially to the IEDs directly, to get a remote support from the specialists to the local team. • Efficient system of alarm pager to inform/alert the operation personnel. • Redondancy on mission critical devices. • Modem backup lines on routers and gateways. • Good understanding of its own needs as well as the power company’s ones to include the central SCADA system into the initial construction of the wind farm as much as possible. SCADA Architecture Proposition: (Case study of a wind farm that is connected to Hydro-Quebec’s network) This approach, centralised on the SMP gateway to concentrate the data, pre-process the information and be the final interface with the transporter's installations, will now be a standard requirement for all new wind farm sites being connected to HydroQuebec's network in the next few years. Advantages: • Remote access to the IEDs directly (configuration, perturbograph, state of communication, …) • Flexibility in the calculations that could not be done into the wind turbine SCADA or the Substation SCADA. • Possibility to either use the Substation SCADA as a Central SCADA or add a 3rd SCADA systems to interface directly with the gateway and be the Central points of the operators. • Time Latency < 500 ms end to end. • This approach covers both the Transporter's and the Producer's needs. Example of requierement in term of Time Latensy of the critical information Transmission time from site to EMS (< 100 ms) 0 ms 100 ms 200 ms Device reaction time (< 200 ms) 300 ms 400 ms 500 ms RTU processing time (< 500 ms) 600 ms 700 ms 800 ms 900 ms Gateway processing time (< 200 ms) 1 s Martin Boulay, Eng. Robert O’ Reilly Automation Engineer The Ohmega Group Inc 3, des Cerisiers Street Gaspe (Quebec) G4X 2M1 Phone: 418 368-5425 ext. 38 Fax: 418 368-7290 mboulay@groupeohmega.com Senior Application Engineer Cooper Power Systems - Cybectec Energy Automation Solutions 1290, St. Denis Street Suite 400 Montreal (Quebec) H2X 3J7 Phone: 418 845-6195 ext. 244 Fax: 514 227-5256 robert.oreilly@cybectec.com

![Energy NSW 2008 The [R]Evolution in Networks](http://s2.studylib.net/store/data/013667500_1-160af8430fc6262e886ce6bb41393edc-300x300.png)