Test Engineering Laboratory

advertisement

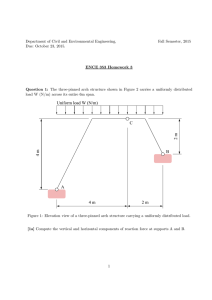

Test Engineering Laboratory Test Report: BLE 11091 Date: July 31, 2012 6” Imperial Galvanized Steel Cable Ladder Horizontal Bend Load and Deflection Test Report from a laboratory experiment conducted to measure cable ladder fitting load and deflection performance Cooper B-Line 509 West Monroe Street Highland, IL 62249 USA Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 Abstract: The International Electrotechnical Commission (IEC) published a document in 2006 named International Standard 61537 - Cable management –Cable tray systems and cable ladder systems. This publication specifies requirements and tests for cable tray systems and cable ladder systems intended for the support and accommodation of cables and possibly other electrical equipment in electrical and/or communication system installations. In Section 10.7.1 of IEC 61537, a test procedure is highlighted for verifying the declared safe working load (SWL) of 90º horizontal cable ladder bend fittings. The procedure is designed to test unsupported fittings. This IEC procedure was used as the basis for test design. Additionally, the National Electrical Manufacturers Association (NEMA) published a document in 2006 named VE 2-2006, Cable Tray Installation Guidelines. This publication is a guide for the proper shipping, handling, storing, installing, and maintaining of cable tray systems. VE 2-2006 discusses the recommended support locations for cable ladder system horizontal bend fittings and attached cable ladder sections. However, the document allows for variations to this guidance if the manufacturer offers an alternative recommendation. Cooper B-Line Engineering felt that the VE 2-2006 recommendations were excessive based on the designs of B-Line cable ladder, fittings and splice plates. We felt that designers could increase the range of supports needed under the cable ladder attached to each fitting opening by up to three meters if a support was maintained for the fitting. This scenario is not addressed in the IEC 61537 test procedure. A test fixture was assembled to support a test sample consisting of a horizontal bend fitting connected to two straight cable ladder sections. A configuration to test both a supported fitting and an unsupported fitting was set up as well. The fitting was subjected to a comprehensive load test battery where deflection was measured and the test sample was inspected for any damage. Based on the results of the test, Cooper B-Line’s 90 degree imperial cable ladder fittings safely support a load of 275 kg/m (185 lbs/ft) in galvanized steel in both an unsupported configuration and a supported configuration as described in this test report. Further, Cooper B-Line cable ladder allows for a wider range of support placement locations under the attached cable ladder as compared to the NEMA VE 2-2006 standard when a support is provided for the 90º bend fitting. Test Engineering Laboratory i Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 Table of Contents Abstract: .......................................................................................................................................... i Table of Contents ......................................................................................................................... ii 1. Introduction, Background and Theory ............................................................................... 1 2. Description of Test Setup .................................................................................................... 2 3. List of Equipment Used ........................................................................................................ 3 4. Procedure ............................................................................................................................... 3 5. Data ......................................................................................................................................... 5 6. Analysis of Data .................................................................................................................... 6 7. Discussion of Results ........................................................................................................... 7 8. Conclusions ........................................................................................................................... 7 9. References ............................................................................................................................. 7 10. Appendix ............................................................................................................................. 8 Test Engineering Laboratory ii Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 1. Introduction, Background and Theory In 2006, The International Electrotechnical Commission (IEC) published a the second edition of a document named International Standard 61537 - Cable management –Cable tray systems and cable ladder systems. This publication specifies requirements and tests for cable tray systems and cable ladder systems intended for the support and accommodation of cables and possibly other electrical equipment in electrical and/or communication system installations. In Section 10.7.1 of IEC 61537, a test procedure is highlighted for verifying the manufacturer’s declared safe working load (SWL) of 90º horizontal cable ladder bend fittings. The procedure is designed to test unsupported fittings that are attached via splice plates to cable ladder straight sections. This IEC procedure was used as the basis for test design. Additionally, the National Electrical Manufacturers Association (NEMA) published a document in 2006 named VE 2-2006, Cable Tray Installation Guidelines. This publication is a guide for communicating the proper shipping, handling, storing, installing, and maintaining of cable ladder systems. Cable ladder system design must comply with NEC Article 392, NEMA VE 1, and NEMA FG 1, and follow safe work practices as described in NFPA 70E. VE 2-2006 helps in ensuring compliance to all these standards. The guidelines in this publication are useful to engineers, contractors, and maintenance personnel. VE 2-2006 discusses the recommended support locations for cable ladder system horizontal bend fittings and attached cable ladder sections. However, the document allows for variations to this guidance if the manufacturer offers an alternative recommendation. Cooper B-Line Engineering felt that the VE 2-2006 recommendations were excessive based on the designs of B-Line cable ladder, fittings and splice plates. We felt that designers could increase the range of supports needed under the cable ladder attached to each fitting opening by up to three meters if maintaining a support for the fitting. This scenario is not addressed in the IEC 61537 test procedure. On page 22 of VE 2-2006, Section 4.4.1 discusses the recommended support locations for fittings. NEMA suggests placing supports under attached ladder sections within 600 mm (24 inches) of each fitting extremity and another support at the mid-point of the arc under the fitting itself. VE 2-2006 allows for variations to this guidance if the manufacturer offers an alternative recommendation. Cooper B-Line Engineering felt that these recommendations were excessive based on the designs of B-Line cable ladder, fittings and splice plates. We felt that we could either eliminate a support specifically for the fitting, or increase the range of supports needed under the attached ladder sections at each fitting extremity from 600 mm up to the attached ladder’s half span (not to exceed 3000 mm) if a fitting support was provided. Two test fixtures were assembled for this test. One, to test Option #1 in SK-3425 Support Recommendations for Steel Cable Ladder Horizontal Bend Fittings, supported a test sample consisting of a 90 degree horizontal bend with a single support underneath and connected to two straight cable ladder sections supported at 3000 mm Test Engineering Laboratory 1 Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 (118 in) from the fitting splices. The second test fixture, to test Option #2 in SK-3425, supported a test sample consisting of a 90 degree horizontal bend with a single unsupported fitting connected to two straight cable ladder sections supported at 600 mm (24 in) from the fitting splices. The fittings were loaded with weights up to 275 kg/m (185 lbs/ft). After each incremental load was applied and the described soak time was reached, the deflection of the fitting was measured. Following the measurement, visual inspection was performed to ensure no damage to the test sample occurred during the load. 2. Description of Test Setup Figure 1 - Test Setup for Option 1 and Option 2 Option #1 - The test set-up consisted of a cable ladder test assembly (90 degree horizontal bend, two straight cable ladder sections, and four splice plates) supported by three support structures placed as shown in Figure 1. Steel bars were evenly loaded onto the bend fitting in a quantity that provided the desired test loads along with a counterbalance weight equaling one half of the test load on the opposite side of each attached straight section. Test Engineering Laboratory 2 Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 Option #2 - The test set-up consisted of a cable ladder test assembly (90 degree horizontal bend, two straight cable ladder sections, and four splice plates) supported by four support structures placed as shown in Figure 1. Steel bars were evenly loaded onto the test sample in a quantity that provided the desired test loads along with a counterbalance weight equaling one half of the test load on the opposite side of each attached straight section. 3. List of Equipment Used Option 1 Test Set-Up: Each Option #1 test sample consisted of: • One 6G-36-90HB36 galvanized steel 6” high x 36” wide, 36” radius, 90 degree horizontal bend fitting • Two 464G12-36-240 galvanized steel 6” high x 36” wide x 240” long cable ladder straight sections • Four 9G-8006 galvanized steel splice plates with standard 3/8” attachment hardware (carriage bolts and serrated flange nuts) Each test sample was support by a test fixture including: • Four or five 36” high metal workhorses with a 1.75” support surface • Two calibrated dial gauges • Rectangular steel strips each weighing 5 pounds (2.3kg) 4. Procedure Support options #1 and #2 from Figure 1 was performed on galvanized steel test samples. The test procedure for support option #1 was performed as follows: 1. The test sample was assembled to standard work instructions per Cooper B-Line catalog number CT-10. The straight sections were attached to either side of the horizontal bend using a splice plate and hardware, and all hardware was tightened to 27 foot-pounds of torque. 2. A test fixture consisting of three support workhorses was set up per Figure 1 with a single support beneath the center of the horizontal bend fitting, mid-arch, at a 45o angle respective to the straight sections and contacting both rails of the horizontal bend, and a support under each attached cable ladder section 3000 mm from the fitting splice. 3. The test sample was installed on the test fixture and counter balance weights were installed at the ends of the straight ladder sections at the farthest point from the fitting. 4. The test sample was leveled and two dial gauges were placed contacting each rails of a single straight section, midway between the straight section support and the fitting support. This distance is approximately 2080mm from either support.at Test Engineering Laboratory 3 Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 the midpoint of the cable ladder’s inside rail (Point A) and outside rail (Point B), where the gauges were to set to record the zero-load dial position from which deflection distance would be measured. 5. The test sample was loaded evenly with steel strips representing a load of 44.6kg/m (30 lbs/ft). 6. The test sample was subjected to that load for a period of approximately five minutes, and then a measurement was taken at Points A and Point B to measure the deflection. The test sample was also visually inspected for any damage. 7. The test sample was loaded with an incremental 44.6kg/m (30 lbs/ft) for a total load of 89.3 kg/m (60 lbs/ft). 8. The test sample was subjected to that load for a period of minutes, and then a measurement was taken at Point A and Point B to measure the deflection. The test sample was also visually inspected for any damage. 9. Steps 7 and 8 were repeated in increments of 44.6kg/m (30 lbs/ft) per trial for a total of 133.9, 223.2, 267.9, 276.8, and 303.6 kg/m (90,150, 180, 186, and 204 lbs/ft), the stopping point determined by either test sample failure or excessive deflection. 10. The weights were removed and the test sample was visually inspected then disassembled for further inspection. The test procedure for option #2 was performed as follows: 1. The test sample was assembled to standard work instructions per Cooper B-Line catalog number CT-10. The straight sections were attached to either side of the horizontal bend using a splice plate and hardware, and all hardware was tightened to 27 foot-pounds of torque. 2. A test fixture consisting of four support workhorses was set up per Figure 1 with a support under each attached cable ladder section placed 600 mm from the fitting splice and a support at the far end of the attached cable ladder straight sections. 3. The test sample was installed on the test fixture and counter balance weights were installed at the ends of the straight ladder sections at the farthest point from the fitting. 4. The test sample was leveled and two dial gauges were placed at the midpoint of the fitting’s inside rail (Point A) and outside rail (Point B) to set and record the zero-load dial position from which deflection distance would be measured. 5. The test sample was loaded evenly with steel strips representing a load of 200 pounds or 26.3 lbs/ft (39.1 kg/m). 6. The test sample was subjected to that load for a period of approximately five minutes, and then readings were taken at Points A and B to measure the deflection. The test sample was also visually inspected for any damage. 7. The test sample was loaded with an incremental 200 pounds yielding a test sample load of 52.9 lbs/ft (78.7 kg/m). Test Engineering Laboratory 4 Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 8. The test sample was subjected to that load for a period of approximately five minutes, and then a measurement was taken at Points A and B to measure the deflection. The test sample was also visually inspected for any damage. 9. Steps 7 and 8 were repeated in for loads of 79.3, 105.7, 132.1, 158.5, 185.0, 211.4, 237.8, 264.2, 290.7 and 303.9 lbs/ft. (118.0, 157.3, 196.6, 235.9, 275.3, 314.6, 353.9, 393.2, 432.6 and 452.3 kg/m), the stopping point determined by either test sample failure or excessive deflection. 10. The weights were removed and the test sample was visually inspected then disassembled for further inspection. 5. Data 6” Galvanized Steel – Option #1 Load (lbs/ft) Average Deflection (in) Deflection 1(in) Deflection 2 (in) 0 0.000 3.832 3.627 30 0.285 3.524 3.365 60 0.374 3.459 3.252 90 0.561 3.389 2.948 120 0.706 3.322 2.726 150 0.873 3.280 2.434 180 1.150 3.201 1.959 186 1.233 3.116 1.878 204 1.641 2.960 1.217 Test Engineering Laboratory 5 Notes Failure due to excessive deflection Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 6” Galvanized Steel – Option #2 Load (lbs/ft) Average Deflection (in) Deflection 1(in) Deflection 2 (in) Total Load (lb.) 0.00 0.059 3.929 3.300 0 26.42 0.117 3.924 3.187 200 52.85 0.181 3.905 3.091 400 79.27 0.194 3.889 2.978 600 105.69 0.334 3.964 2.877 800 132.12 0.414 3.805 2.757 1000 158.54 0.484 3.753 2.649 1200 184.96 0.547 3.752 2.510 1400 211.39 0.626 3.741 2.394 1600 237.81 0.747 3.736 2.242 1800 264.24 0.864 3.657 2.078 2000 290.66 0.933 3.569 1.932 2200 303.87 0.974 3.525 1.838 2300 Notes Failure due to excessive deflection 6. Analysis of Data Galvanized Steel – Option #1 This test was to verify that the recommended fitting support locations shown on SK-3425 supported our stated SWL in compliance with IEC standards. Target load for this test was 275 kg/m (185 lbs/ft) which was derived from the experimentally determined failure load of the 464G12-36-240 straight section, which was tested to the IEC standards, and was found to have a deflection failure load of 275 kg/m (210 lbs/ft). Cooper B-Line expected that the deflection at the stated loads would not exceed 42.0 mm (1.654 in) per the IEC standard definition of failure at 1% deflection of the mid line length of the fitting, which was 4201 mm (90.8 in). The target load was reached prior to deflection failure, so our support recommendation was demonstrated to meet IEC standards. A visual inspection of the test assembly during the test as well as the test assembly components following the test showed no damage from the test Test Engineering Laboratory 6 Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 Galvanized Steel – Option #2 This test was to verify that the recommended fitting support locations shown on SK-3425 supported our stated SWL in compliance with IEC standards. Target load for this test was 275 kg/m (185 lbs/ft) which was derived from the experimentally determined failure load of the 464G12-36-240 straight section, which was tested to the IEC standards, and was found to have a deflection failure load of 275 kg/m (210 lbs/ft). Cooper B-Line expected that the deflection at the stated loads would not exceed 42.0 mm (1.654 in) per the IEC standard definition of failure at 1% deflection of the mid line length of the fitting, which was 4201 mm (90.8 in). The target load was reached prior to deflection failure, so our support recommendation was demonstrated to meet IEC standards. A visual inspection of the test assembly during the test as well as the test assembly components following the test showed no damage from the test 7. Discussion of Results The test fixture and test sample was set up to as closely replicate an actual installation as could be replicated in a test laboratory. The only deviation from a “realworld” replication was using steel strips in place of actual power cabling as the system load. However, this was a highly accurate procedure for replicating cable ladder system load stresses. The test galvanized steel samples behaved as expected. The target load ratings were set from published load ratings of Cooper B-Line straight cable ladder sections. There were no observations of unexpected behavior in the test samples during the execution of the testing. 8. Conclusions Cooper B-Line’s horizontal bend fitting support recommendations made in SK-3425 meet our declared safe working load requirements as verified by the IEC 61537:2006 test procedure. Further, either Cooper B-Line’s Option #1 or Option #2 support recommendations made in SK-3425 can be used in favor of the support recommendations made in NEMA VE 2-2006. 9. References Cooper B-Line, Inc. CT-10 Cable Tray Systems. Highland, IL: Cooper B-Line, Inc., 2010. Cooper B-Line, Inc. SK-3425 Recommended Support Locations for Steel Ladder Horizontal Bend Fittings: Cooper B-Line, Inc., 2012. International Electrotechnical Commission. IEC 61537:2006 - Cable management – Cable tray systems and cable ladder system. Geneva, Switzerland: International Electrotechnical Commission, 2006. Test Engineering Laboratory 7 Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 National Electrical Manufacturers Association. NEMA Standards Publication VE 2-2006 Cable Tray Installation Guidelines. Rosslyn, VA: National Electrical Manufacturers Association, 2006. 10. Appendix Figure 2 - Photograph of Option #1 Test Sample and Test Fixture Test Engineering Laboratory 8 Steel Cable Ladder Horizontal Bend Fitting Load Test Report # BLE 11090 Date: July 2012 Figure 3 - SK3425-A Recommended Support Locations Drawing Test Engineering Laboratory 9