and propagation constant of porous materials Hideo Utsuno, a) Toshimitsu

advertisement

Transfer function method for measuring characteristic impedance

and propagation constant of porous materials

HideoUtsuno,

a)Toshimitsu

Tanaka,andTakeshiFujikawa

MechanicalEngineering

Research

Laboratories,

KobeSteel,Ltd., TakatsukadaiI-chomeNishi-ku,Kobe,

673-02,Japan

A.F. Soybert

Department

ofMechanicalEngineering,

University

ofKentucky,Lexington,

Kentucky40506-0046

(Received12December1988;accepted

forpublication

3 April 1989)

A methodfor measuring

thecharacteristic

impedance

andpropagation

constantof porous

materialsis described

in thispaper.Measurements

wereperformedbasedon a surface

impedance

methodthat requireda setof distinctacoustic

impedances

derivedat thematerial

surface.This requirement

is satisfied

by arbitrarilychangingthe air spacedepthbehindthe

material,andthena new formulationis derivedsothat a recentlydevelopedmethodof

determination,calledthe transferfunctionmethod,canbeapplied.An appropriatesetof air

spacedepthsis alsodiscussed.

Glasswoolandporousaluminumwereusedto assess

the

usefulness

of the presentmethod.The normalacousticimpedance

andnormalabsorption

coefficient

of the testmaterialswith arbitrarythicknesses

or with an arbitraryair spacedepth

behindthemwerecalculatedfrom the obtainedcharacteristic

impedanceand propagation

constant

andwerecompared

withthemeasured

valuesthatwereobtained

directlyby usingthe

transferfunctionmethod.The goodagreement

achievedsuggests

that the presentmethodis

reliableandeffective

enoughto measure

thecharacteristic

impedance

andpropagation

constantovera broadbandfrequencyrange.

PACS numbers: 43.55.Ev, 43.20.Mv

INTRODUCTION

assumingthe surfaceof the porousmaterial is not locally

Porousmaterials,suchasglasswoolor foam,are generally usedto attenuatenoise.In addition to thesewell-known

materials,new materialssuchas porousmetal, Kevlar, or

ceramichavebeendeveloped

to satisfytheneedfor a porous

material that can be usedat high temperatures,can be exposedto high-speed

air flow,or whosephysicalcharacteristicswill remainunchanged

whenexposedto a chemicalgas

atmosphere.

The mostfundamental

acousticpropertyof theseporousmaterialsis their soundabsorptioncoefficient.

This

maybemeasured

by usingan acoustic

impedance

tube.Sev-

eralpaperst-3

havereported

usingarelatively

recently

developedtransferfunctionmethodratherthan the conventional

reacting?

In thatcase,theporous

materialcanbecharacterized not by the normalacousticimpedance,but by the characteristicimpedanceand the propagationconstant.Evenif

the surfaceis assumedto belocallyreacting,theseproperties

are usefulbecausethe soundabsorptioncoefficientand the

acousticimpedancecanbe calculatedfrom them.

As mentionedabove,it is importantto obtainboth the

characteristicimpedanceand propagationconstant.Two

approachesare usedto obtain theseproperties.One is to

establishan appropriatedescriptionof the porousmaterial

from the first principle: the propagation of the sound

through it. The characteristics of sound propagation

throughporousmaterialshavebeeninvestigated

by several

•-• butmostnotablyby ZwikkerandKosten.

6

standing

waveratiomethodto measure

thesoundabsorp- researchers,

To utilizethetheoryin Ref. 6, it isnecessary

to obtaincertain

parameters,

such

as

flow

resistance

and

structure

factor,that

signalasa soundsource,sothatthenormalsoundabsorpare

measured

by

means

of

nonacoustical

experimentation.

tion coefficient

and normalacousticimpedance

are meaAnother approachinvolvesmeasuringtheseproperties

suredin a shorttime overa broadband

frequency

range.

directly

usingan acousticalexperiment.The moststraightThough the soundabsorptioncoefficientand acousticimforward

methodwasdeveloped

by Scott.•- His technique

is

pedanceare measuredmoreefficientlyby thisnew method,

based

on

measuring

the

attenuation

and

phase

change

of

an

to obtainthemis not sufficient

in orderto usethe porous

materialeffectively.

Further,it is moreimportantto obtain incidentsoundwaveinsidethe porousmaterial.The materithe characteristic

impedance

and propagation

constantof al was thick enoughto preventthe wavefrom reflectingin

theporous

materialbecause

thematerialmightessentially

be the impedancetube.

The surfaceimpedancemeasurement

methodwasstudcharacterized

by theseproperties.

For example,previous

ied

by

¾aniv.

•3

The

characteristic

impedance

andpropagawork4hasshownthattheporous

materialitselfmustbecontion constant were calculated from a set of distinct acoustic

sideredas a medium in which the soundwave transmits,

impchancesderivedby measurements

takenat the surfaceof

the

porous

material.

The

distinct

impedances

wereachieved

Visiting

scholar,

Department

ofMechanical

Engineering,

University

of

Kentucky,Lexington,KY 40506-0046.

by changingthe air spacedepthbehindthe porousmaterial:

tion coefficient.This new method usesa broadband random

637

J. Acoust.$oc. Am. 86 (2), August1989

0001-4966/89/080637-07500.80

@ 1989 AcousticalSocietyof America

637

wnloaded 28 Sep 2010 to 128.163.157.101. Redistribution subject to ASA license or copyright; see http://asadl.org/journals/doc/ASALIB-home/info/terms

( 1) porousmaterialbackedby a rigid wall and (2) porous

material backed by one-quarter wavelengthair spaceterminatedin the rigid wall.

Smithand Parrott'4 achievedthe distinctimpedances

by using two different thicknessesof material backedby a

rigid wall. They called their method the "two-thickness

method" and referredto Yaniv's methodas the "two-cavity

method." They measuredacousticimpedancesby usingthe

conventionalstandingwaveratio method.

Terao15usedthe two-thicknessmethod,where acoustic

impedanceswere measured using the transfer function

½al

method.

The work reported here is an attempt to improve the

two-cavity method, which was initially describedin Ref. 6

and wasstudiedfurtherby Yaniv.'3 Previously,the twocavity methodrequiredthe acousticimpedances

behindthe

material to be zero and infinity. The latter is easilyachieved

by a rigid wall. The former is achievedat eachfrequencyby

changingthe air spacedepthto one-quarterwavelength,terminatedby a rigid wall. This meansthat the air spacedepth

mustbe changedat everyfrequencyof interest.

In this paper,a new formulationis derivedto calculate

the characteristicimpedance and propagation constant

when the porousmaterial is backedby an arbitrary impedance.Consideringthe acousticimpedancebehindthe material asa closed-tubeimpedancethat can beobtainedtheoretically, it becomesunnecessaryto changethe air spacedepth

at every frequencyaccordingto the new formulation.This

meansthat the transferfunctionmethodcanalsobe applied

to the two-cavity method.

As comparedwith the two-thicknessmethod,the improvedtwo-cavitymethodhastheadvantageof reducingthe

numberof timesof mountingtestmaterials,aswell aselimination of the variationassociatedwith test-piecemounting

and the variation

of the material

/

/

l•ic.B

Hic.A

Speaker

Referenceplane --•

Porous

Hovable piston

eaterial

A i r sl•ce

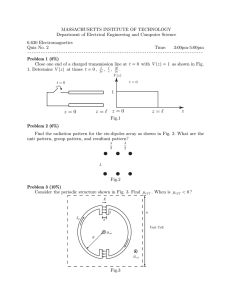

FIG. 1. (a) Experimentalapparatususedto measurethe characteristicimpedanceand propagatiouconstant;(b) block diagram of the impedance

tube and accessoryequipment.

itself between two test

SolvingEqs.(2) and (3) forZc and ?'gives

pieces.

I. FORMULATION

FOR A NEW TWO-CAVITY

METHOD

follows6:

Zo= Z •

Z I cosh(yd) + Zc sinh(yd)

Z msinh(yd) + Zc cosh(yd)

(1)

= exp(2j?'d).

--

Zo-ZcZ,+Zc

(5)

wherethesignin Eq. (4) isselected

soasto let therealpart

of Z• bepositive.UsingEqs.(4) and (5), Z½and?'canbe

calculatedfrom the measuredimpedances

Zo and Z• and

the impedances

of a closedtubewith depthL andL ', i.e.,

--jZ.i r cot(kL),

jZ,,

cot(kL'),

(6)

(7)

wherek isthewavenumber

of air andZ,•, isthecharacteris-

The right sideof Eq. (2) is a functionofd and y. While the

thicknessremainsconstant,the same equation is obtained

evenifZo and Zmare changedto other values.Let anotherbe

representedby ('); then Zo and Z, are replacedby Zg and

Z •, respectively.We obtain

Zo+ZcZ,-Z

(zo-z•)

I ln(Zo+ZcZ,--Zc•,

?'= 2jr

z, zd

Z; =

(2)

(z,-z;)

(4)

Zi:

Then, Eq. ( 1) yields

Zo+ZZ,-Z

-Zo-ZZm

+

Z½

=.qL

(ZoZ•(Zi

--Z•)--ZiZ

•(Zo-Z•))1'2,

\

A layer of homogeneous

porousmaterialis considered,

asshownin Fig. 1(b). The acousticimpedanceZ o at a referencesurfacecan be related to the characteristicimpedance

Z o the propagationconstanty, the acousticimpedancebehind the porousmaterialZl, and the materialthicknessd, as

638

(b) !!• A

--

z;-zc

zi,-zcz;+z

J. Acoust.Soc.Am.,Vol.86, No.2, August1989

(3)

tic impedanceof air.

To summarize, Eqs. (4) and (5) are derived without

assuming

Zm to bezeroandZ; to be infinity.Considering

themas theoreticalclosed-tube

impedances

and measuring

the referencesurfaceacousticimpedancetwice usingthe

transferfunction method permit the determinationof the

characteristic

impedanceand propagationconstantovera

broadbandfrequencyrange.

Utsunoet at: Transferfunctionmeasurement

of porousmaterials

638

wnloaded 28 Sep 2010 to 128.163.157.101. Redistribution subject to ASA license or copyright; see http://asadl.org/journals/doc/ASALIB-home/info/terms.

aluminum). The dimensions of the test materials and air

spacedepthsusedare shownin Table I. The glasswool test

material was 50 mm thick, while the porousaluminum test

material

was 20 mm thick. In order to calculate

the charac-

teristic impedanceand propagationconstant,it would be

sufficientto measurethe impedancesbasedon two different

air spacedepths,but in this paper the impedanceswith six

differentair spacedepthsweremeasuredindividuallyto investigatewhetherthecombinationof air spacedepthsaffected the experimentalaccuracywhenthe presentmethodwas

used.

FIG. 2. Porousaluminumabsorbingmaterial.

III. EXPERIMENTAL

II. EXPERIMENTAL

PROCEDURE

Measuringthe acousticimpedanceusingthe random

I--3

excitationtechniqueiswell documentedin severalpapers.

In this paper,we describethe experimentalapparatusutilized to mount the porousmaterial to accomplishan arbitrary air spacedepth.

The experimental

apparatusis shownin Fig. 1(a) and

(b). The impedancetube, havingan internal diameterof

87.5mm anda lengthof 1 m, is terminatedby a loudspeaker

and a movablebrasspiston.The impedancetubecanbe separated at cross section A-A. The test material was cut into

circular slices with flat faces and attached to the tube so that

onereferenceplanewasaccuratelyestablished

at crosssection A-A, and anotherwas"flush"againstthe surfaceof the

movablepiston.After visualinspectionof the mountedtest

material, the tubeswere connected.Then, the piston was

movedbackwardto createthe arbitrary air spacedepth.The

air spacedepthL wasmeasured

by thescaleattachedto the

tube. The distance Lx between the reference surface and mi-

crophoneA wassetat 17 mm, and the distanceDx between

the two microphones

wassetat either70 or 300 mm, according to the frequencyrangeof interest.

A randomsignalwasgeneratedfrom the loudspeaker,

and the transfer function H betweenthe two microphones

was measuredusinga two-channelfast Fourier transform.

The acousticimpedancewasobtainedfrom

Z o =JZair

-- H sin(kLx) q- sin[k(Lx q- Dx) ]

Hcos(kLx) -- cos[k(Lx + Dx) ]

(8)

After measuringZo with air spacedepth L, the pistonwas

movedto anotherdepthL ', andZ• wasmeasuredusingthe

sameprocedure.

Two differenttest materialswere usedfor the experiment:one,a glasswool;and the other,a porousaluminum

absorbingmaterial(Fig. 2, hereafterreferredto asa porous

RESULTS

The measuredcharacteristicimpedanceof the glass

wool is shownin Fig. 3(a). These resultsare normalizedby

the characteristicimpedanceof the air, Z• r. The solid lines

representthe complexcharacteristicimpedance.The experimentalresultswerepresentedovera frequencyrangeof from

300 Hz to 2 kHz, wherethe experimentalerror causedby the

distanceof separationbetweenthe microphonesmight be

negligible.It is possibleto measurethecharacteristicimpedanceoverhigheror lower frequencyrangesby shorteningor

lengtheningthe distancebetweenthe microphones.

The complexpropagation

constant(rad/m) of theglass

wool is shownin Fig. 3 (b) overthe samefrequencyrangeas

the characteristicimpedance.The measureddata shownin

Fig. 3(a) and (b) were obtained usingdistinct setsof air

spacedepths:(L, L ') = (20 mm, 40 mm), (20, 70), (20,

100), (40, 70), (40, 100), and (70, 100). From the graph, it

can be seenthat there is very goodagreementamongthe six

distinct measured values.

On the other hand, Fig. 4 showsthe characteristicimpedanceof glasswoolcalculatedfromsetsof air spacedepths

different than those usedfor the data shown in Fig. 3(a).

The air spacesusedfor the caseshownin Fig. 4 were: (L,

L')

----(20, 150), (20, 170), (40, 150), (40, 170), and (70,

170). In general, the figuresshow the same trend as was

evidentin Fig. 3(a), but significantsystematicdiscrepancies

appearin the 1100-to 1700-Hz frequencyrange.The reason

for this will be discussedlater. The resultssuggestedthat

there is an ideal setof air spacedepthsof which the characteristicimpedanceandpropagationconstantcanbecalculated correctly.

Figure 5(a) and (b) showsthe characteristicimpedanceand propagationconstantof the porousaluminum.Becauseporousaluminumhasattractiveacousticcharacteristics at low frequencies,it was measuredover a range of

frequencies

of from 100 to 450 Hz. This wasaccomplished

by spacingthe microphones300 mm apart.The testmaterial

TABLE I. Propertiesof the materialstested.

Sample

Glass wool

Porous aluminum

639

Density

Diameter

Thickness

Air spacedepth

(kg/m•)

(mm)

d (mm)

L (mm)

30

87.5

50

20, 40, 70, 100, 150, 170

250

87.5

20

20, 40, 70, 100, 150

J. Acoust.Sec. Am., Vol. 86, No. 2, August 1989

Utsunoeta/.: Transfer functionmeasurementof porousmaterials

639

ownloaded 28 Sep 2010 to 128.163.157.101. Redistribution subject to ASA license or copyright; see http://asadl.org/journals/doc/ASALIB-home/info/terms.js

,-

2

Ca)

5a

(b)

40

30

Re[Zc/Zai r]

20

I

I

I

I

I

I

-IO

-38

o

i

i

i

500

1000

1500

Frequency

-s6

2000

o

i

i

i

500

1000

1500

CHz]

Frequency

2000

CHz3

FIG. 3. (a) Thecharacteristic

impedance

ofglass

woolnormalized

byair;(b) thepropagation

constant

ofglass

wool,wherebothproperties

wereobtained

at

d = 50 mm and (L, L ') = (20 mm, 40 ram), (20, 70), (20, 100), (40, 70), (40, 100), and (70, 100).

was20 mm thick,andfivesetsof air spacedepthswereused:

(L, L ') = (20, 40), (20, 70), (20, 100), (40,70), and (40,

100). The characteristic

impedance

wasnormalizedby that

of air. It canbeseenthatthereisgoodagreement

amongthe

measuredvaluesobtainedfrom distinctsetsof air space

depthsovera frequencyrangeof from 150to 400 Hz. While

thereare slightdiscrepancies

below150Hz and above400

describes

two factors:( 1) the selectionof an appropriateset

of air spacedepthsand (2} the verificationof measured

acousticproperties.

A. The selection of an appropriate set of air space

depths

Hz, a consistenttrend is observed.

If Z• approaches

Z; in Eq. (4), thenZ, approaches

+ Z•; i.e.,thecharacteristic

impedance

of theporousmateIV. DISCUSSIONS

rial is equalto the acousticimpedanceof the closedtube.

Thecharacteristic

impedance

andpropagation

constant This incorrectconclusionis causedby eliminationof the

weremeasured

for glasswool,a traditionalporousmaterial, terms(Zo - Z• ) in Eq. (4), and that situationariseswhen

and for porousaluminum,a newlydevelopedmetallicab- theairspaces

L, L' andthefrequency

f satisfythefollowing

equation:

sorbingmaterial. In the aboveexperimentalresults,it is

shownthat bothpropertiescanbe measuredwhenutilizing

f(L -- L ') = no/2,

(9)

an appropriatesetof air spacedepths.The discussion

below

wherec is the speedof soundin the air and n = 1, 2, 3.....

Thefrequencies

of thedistinctive

peaks,•-f4, shownin Fig.

4, arein completeagreement

with thefrequencies

calculated

,.

2

fromEq. (9), sotheappropriate

setof air spacedepthsmust

be selectedsoasto not satisfyEq. (9).

B. The verification of measured acoustic properties

The presentinvestigationwasinitiatedto improvethe

two-cavity method so as to calculatethe characteristicimpedanceand propagationconstant,evenif the acousticimfi:l150

fe:1325

-2

pedancesZ• and Z • are not zero and infinity, respectively.

fa:1565

-1

I

500

I

1000

Frequency

I

f4:1715

I

1500

2000

CHz3

FIG. 4. The characteristicimpedanceof glasswool normalizedby air,

where it was obtainedat d = 50 mm and ( L, L' ) = ( 20 ram, 150 m m ), (20,

170), (40, 150), (40, 170), and (70, 170).

640

J. Acoust.Soc. Am., Vol. 86, No. 2, August1989

The previoustwo-cavity methodhasbeenverifiedin studies

by Yaniv and Smith and Parrott and comparedwith that

obtained using Scott'smethod or the theoretical model due

to Beranek.In this paper,a comparisonis madebetweenthe

calculatedand measurednormal acousticimpedanceand

absorptioncoefficient.Substitutingthe measuredZ, and •'

into Eq. ( 1), the normalacousticimpedancecanbecalculated. A subsequentcalculationis made to determinethe absorptioncoefficient.Both of thesequantitiesare also mea-

suredby usingthe transferfunctionmethoddirectly.

Utsunoeta/.: Transfer functionmeasurementof porousmaterials

640

nloaded 28 Sep 2010 to 128.163.157.101. Redistribution subject to ASA license or copyright; see http://asadl.org/journals/doc/ASALIB-home/info/term

,-

(b)

18

,m

•\

8

•

40

Re[Zc/Zai r ]

f,..

I

I

I

•

I

o

7•zc/za

ir]

•-lfa

I

I

I

I

I

I

I

I

-20

-an

-40

,,%-8

I

I

I

i

Frequency [Hz]

Frequency [Hz]

FIG. 5. (a) Thecharacteristic

impedance

ofporous

aluminum

normalized

byair;(b) thepropagation

constant

ofporous

aluminum,

wherebothproperties

wereobtainedat d = 20 mm and (L, L ') = (20 ram,40 ram), (20, 70), (20, 100), (40, 70), and (40, 100).

I. 0

(a)

.....

(b)

õ

L=100

•:

Re[Zo/Za

i••!••l•l•4amum

i•[Zoa•l

r]--•

---'•'•

L:150

ß

c / L=O

-4

i

0. a

Frequency

i

-5

,

I

[Hz]

t

Frequency

I

[Hz]

FIG. 6. (a) Comparison

between

calculated

(--) andmeasured

(71)normalabsorption

coefficient

for50-ram-thick

glass

woolwithanairspace

depthof

L = 0,40,100,and150ram;(b) comparison

between

calculated

(--) andmeasured

(n) normalacoustic

impedance

for50-mm-thick

glass

woolwitha 100mmair spacedepth,wherethecalculation

wasbasedon theproperties

thatwereobtained

at d = :50mmand(L, L.') = (20 mm,70 mm).

1.0

(a)

5

I

500

I

1000

F-r'equency

I

1500

[Hz]

2080

(b)

•Ir•Zø/Z

Frequency

œHz]

FIG.7. (a) Comparison

between

calculated

(--) andmeasured

(71)normal

absorption

coefficient

for25-,75-,and125-mm-thick

glass

woolbacked

bya

rigidwall;(b) comparison

between

calculated

(--) andmeasured

(71)normal

acoustic

impedance

for25-ram-thick

glass

woolbacked

byarigidwall,where

thecalculation

wasbased

ontheproperties

thatwereobtained

at d = 50mmand(L, L ') = (20 ram,70mm).

641

d.A½oust.

Soc.Am.,Vol.86,No.2, August

1989

Utsuno

etaL:Transfer

function

measurement

ofporous

materials

641

wnloaded 28 Sep 2010 to 128.163.157.101. Redistribution subject to ASA license or copyright; see http://asadl.org/journals/doc/ASALIB-home/info/terms.

1.9

(b)

(a)

L=100

.8

L=I•O

••

•a•le[Zo/7ai

r]I I

509

FIG. 8. (a) Comparison

between

calculated

(--) andmeasured

(I-1)normalabsorption

coefficient

for 20-mm-thick

porousaluminumwithair spacedepths

ofL = 40, 100,and150ram;(b) comparison

between

calculated

(--) andmeasured

([]) normalacoustic

impedance

for20-ram-thick

porous

aluminum

with a 100-ramair spacedepth,wherethecalculationwasbasedon theproperties

thatwereobtainedat d = 20 mm and (L, L ') = (20 mm, 70 mm).

Figure6(a) showsthe normalsoundabsorptioncoeffi- ficientfor 25-, 75-, and 125-mm-thickglasswooltestmatericientfor 50-mm-thickglasswoolwith an air spacedepthof alsbackedbya rigidwallandthenormalacoustic

impedance

L = 0, 40, 100,and 150ram, respectively.

In thegraph,the for a 25-mm-thickglasswool backedby the rigid wall is

opensquarerepresents

themeasured

valuesderivedby using shown.From thesegraphs,it canbeseenthat the calculated

the transferfunctionmethod, while the solidline represents valuesarein goodagreement

with themeasured

valueswhen

the thickness of the test material is a variable.

the calculatedvaluesderivedfrom measuredvaluesof Zc

and y that wereobtainedat d = 50 mm and (L, L ') = (20

Using the characteristicimpedanceand propagation

constant obtained at d = 20 mm and (L, L ') = (20 ram, 70

mm, 70 mm). The normal acousticimpedanceis shownin

Fig. 6 (b) for 50-ram-thickglasswoolwith anair spacedepth mm) in Fig. 5, the normal absorptioncoefficientand the

of 100min. The measuredacousticimpedanceis represented normal acousticimpedancewere calculatedfor 20-mmby theopensquare,whilethecalculatedacousticimpedance thick porousaluminumwith an air spacedepthof L ----40,

100,and 150 ram. Thesedata and corresponding

measured

is represented

by thesolidline.The realandimaginaryparts

of theacousticimpedances

arenormalizedby thecharacter- data obtainedusingthe transferfunctionmethoddirectly

isticimpedance

of theair. As maybeseen,thecalculatedand

are shownin Fig. 8(a) and (b). The calculatedand meameasureddata showexcellentagreement.

surednormalabsorptioncoefficient

andnormalacousticimIn Fig. 7(a) and (b), thenormalsoundabsorptioncoef- pedance

arealsoshownin Fig. 9(a) and (b) for 10-,30-,and

1.9

(a)

20

•

N

(b)

to

Re[Zo/Zair]

d=•

I

d=•

9.91•

IO9

299

399

Frequency

499

[H=)

599

-29

•99

I

i•[•

399

Frequency

490

œHz3

FIG. 9. (a) Comparison

between

calculated

(--) andmeasured

([3) normalabsorption

coefficient

for 10-,30-,and40-mm-thick

porous

aluminum

test

materials

backed

bya rigidwall;(b) comparison

between

calculated

(--) andmeasured

(VI)normal

acoustic

impedance

for30-mm-thick

porous

aluminum

backed

bya rigidwall,wherethecalculation

wasbased

ontheproperties

thatwereobtained

at d = 20mmand(L, L ') = (20mm,70ram).

642

J. Acoust.

Soc.Am.,VoL86, No.2, August1989

UtsunoetaL:Transferfunction

measurement

of porousmaterials

642

wnloaded 28 Sep 2010 to 128.163.157.101. Redistribution subject to ASA license or copyright; see http://asadl.org/journals/doc/ASALIB-home/info/terms

40-mm-thickporousaluminumtest materialsbackedby a

rigid wall. It canbe seenthat the calculatedvaluesfor the

porousaluminumarein goodagreement

with themeasured

Acoust. $oc. Am. 61, 1362-1370 (1977).

2j. y. ChungandD. A. Blaser,"TransferFunctionMethodof Measuring

In-ductAcousticProperties.I. Theory,"J. Acoust.Soc.Am. 68, 907-913

(1980).

3J.Y. ChungandD. A. Blaser,"Transfer

FunctionMethodof Measuring

ones.

From theseresults,it can be concludedthat the sound

absorption

characteristics

of a porousmaterialcanbedetermined accuratelyfrom the measuredcharacteristicimpedanceandthe propagationconstant.It alsoindicatesthat the

soundabsorption

characteristics

of a porousmaterialcanbe

predicted

easilyusingthepresentmethod.

In-duct AcousticProperties.II. Experiment,"J. Acoust.Soc.Am. 68,

913-921 (1980).

4R.A. Scott,"ThePropagation

ofSoundBetween

WallsofPorousMaterial," Proc. Phys.Soc.London58, 358-368 (1946).

•K. U. Ingard,"LocallyandNonlocally

ReactingFlexiblePorousLayers;

A Comparison

of AcousticalProperties,"ASME Trans.J. Eng.Ind. 103,

302-313 (1981).

6C. ZwikkerandC. Kosten,SoundAbsorbing

Materials(Elsevier,New

York, 1949).

7L.L. Beranek,

"Acoustic

Properties

of Homogeneous

PorousMedium

V. SUMMARY

In this paper,an improvedtwo-cavitymethodto measurethe characteristicimpedanceand propagationconstant

of porousmaterialswasappliedexperimentally

to two different porousmaterials.The characteristicimpedanceand

propagationconstantcanbe measuredeasilyovera broad

frequencyrangeby usingthetransferfunctionmethod.The

selectionof an appropriateset of air spacedepthsis discussed,

andit is shownthat the soundabsorptioncoefficient

andacoustic

impedance

of porousmaterialswith arbitrary

thickness

or with an arbitraryair spacedepthmay be predictedaccuratelyusingthe measured

characteristic

impedanceandpropagation

constant.

Thisresultindicates

thatthe

presentmethodis usefulin predictingthe soundabsorbing

capabilityof acousticalmaterialsin practicalapplications.

•A. F. SeybertandD. F. Ross,"Experimental

Determination

of Acoustic

Properties

Usinga Two Microphone

RandomExcitationTechnique,"

J.

643

J. Acoust. Sec. Am., Vol. 86, No. 2, August 1989

IsotropicRigidTilesandFlexibleBlankets,"J.Acoust.Soc.Am. 19,556568 (1947).

•M. A. Biot,"Theoryof Propagation

of ElasticWavesin a Fluid-Saturated

Porous Media," J. Acoust. Soc. Am. 28, 168-t91 (1956).

9M. E. DelanyandE. N. Bazley,"Acoustical

Properties

of FibrousAbsorbentMaterials,"Appl. Acoust.3, 105-116 (1970).

løR.F. Lambert,"The Acoustical

Structureof HighlyPorousOpen-Cell

Foams," J. Acoust. Soc. Am. 72, 879-887 (1982).

IlK. Attenborough,

"Acoustical

Characteristics

of RigidFibrousAbsorbentsand Granular Materials," J. Acoust. Soc.Am. 73, 785-799 (1983).

12R.A. Scott,"TheAbsorption

of Soundin a Homogenous

PorousMedium," Proc.Phys.Soc.London58, 165-183 (1946).

•3S.L. Yaniv,"Impedance

TubeMeasurement

ofthePropagation

Constant

andCharacteristic

Impedance

of PorousMaterials,"J. Acoust.Soc.Am.

54, 1138-1142 (1973).

•4C.D. SmithandT. L. Parrott,"Comparison

ofThreeMethodsfor MeasuringAcousticPropertiesof Bulk Materials,"J. Acoust.Soc.Am. 74,

1577-1582 (1983).

l•M. Terao and H. Sekine,"On Substructure

BoundaryElementTechniquesto AnalyzeAcousticProperties

of Air-Duct Component,"

in Proceedings

of Inter-Noise87 ( INCE, Poughkeepsie,

New York, 1987), pp.

1523-1526.

Utsuno oraL: Transfer function measurement of porous materials

643

wnloaded 28 Sep 2010 to 128.163.157.101. Redistribution subject to ASA license or copyright; see http://asadl.org/journals/doc/ASALIB-home/info/terms