Heavy Duty Expansion Splice Plate Installation Guide

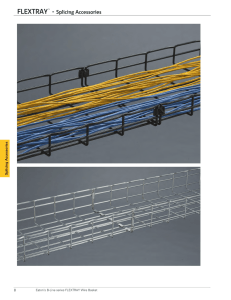

advertisement

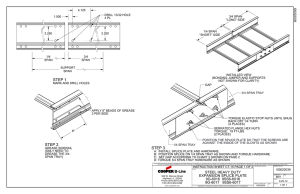

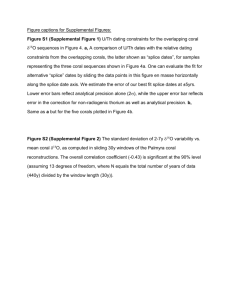

Instruction Sheet Heavy Duty Expansion Splice Plates 9A-6016 & 9A-6017 1/4 Span Patent Pending Serrated flange nuts: Locate bolts as shown (against inner side of slot) torque to 50 ft./lbs. 3/4 Span 7” Gap Torque elastic stop nuts until snug, then back off 1/4 turn. Mark Step 1. Mark line on outside and bottom of siderail. Step 5. a. Torque serrated flange hex nuts. b. Set gap according to Chart 2 shown on page 2. c. Torque elastic stop nuts until snug, then back off 1/4 turn. d. For expansion joint spacings see Chart 3 on page 2. Grease Splice Plate Tray Step 2. Prepare expansion splice plate and tray. Grease first 12” of marked siderail. Step 6. Install appropriately sized Cooper B-Line bonding jumpers. (2 required) (3) 17/32” holes Drill on marked lines an Sp ide ”S ng 3 /4 Step 3. “Lo Install splice plate and drill holes. pan e S 1 /4 ” Sid rt Serrated flange hex nuts (3 places) Elastic stop nuts and flat washers (6 places) o “Sh Be sure bolts are located as shown (against inner side of slot) Cable tray with heavy duty expansion splice plates installed. (Bonding jumpers ommitted for clarity) Step 4. Install hardware as shown. www.cooperbline.com Cooper B-Line • 509 West Monroe Street • Highland, Illinois 62249 Phone: (800) 851-7415 • Fax: (618) 654-1917 CTIS-8 x - - x - - x Typical Cable Tray Installation x Chart 1 - - x - - x Denotes hold-down clamp (anchor) at support - Denotes expansion guide clamp at support x Heavy Duty Expansion Splice Plates Located at 1/4 Span Gap Settings Maximum Temperature Chart 2 C° Minimum Temperature F° F° 50 50 Accurate gap settings at the time of installation are necessary for the proper operation of the expansion splice plates. The following procedure should assist the installer in determining the correct gap: (see Chart 2) 110 110 40 Metal Temperature At Time Of Installation 40 Plot the highest expected 1 metal temperature on the maximum temperature line. Plot the lowest expected metal 2 temperature on the minimum temperature line. Draw a line between the 3 maximum and minimum points. Plot the metal temperature at 4 the time of installation to determine the gap setting. C° 130 130 1 90 90 70 70 30 30 20 20 3 50 50 30 30 0 0 -10 10 10 -10 -20 -10 -10 -20 -30 -30 10 10 4 -30 2 -30 -40 -40 0 (0.0) 1/8 1/4 3/8 1/2 5/8 3/4 7/8 (3.2) (6.3) (9.5) (12.7) (15.9) (19.0) (22.2) GAP SETTING Inches (mm) 1 (25.4) Expansion Joint Spacings - Chart 3 Maximum Spacing Between Expansion Joints For 1" Movement Temperature Differential Aluminum ˚F ˚C Feet m 25 13.9 260 79.2 50 27.8 130 39.6 75 41.7 87 26.5 100 55.6 65 19.8 125 69.4 52 15.8 150 83.3 43 13.1 175 97.2 37 11.3 Material List (2) Heavy Duty Expansion Splice Plates (18) x 11/4” Ribbed Neck Carriage Bolts SS6 (6) 1/2”-13 Serrated Flange Hex Nuts SS6 (12) 1/2”-13 Elastic Stop Nuts SS4 (12) 1/2” Flat Washers SS6 Grease 1/2”-13 Note: every pair of expansion splice plates requires four bonding jumpers for grounding continuity. Cooper B-Line 509 West Monroe Street • Highland, Illinois 62249 Phone: (800) 851-7415 • Fax: (618) 654-1917 • www.cooperbline.com CTIS-8