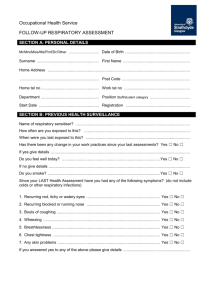

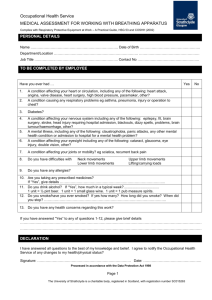

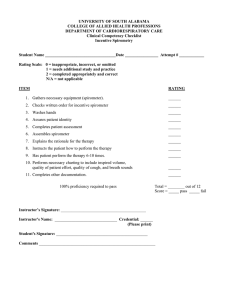

S ACOEM G Spirometry in the Occupational Health Setting—2011 Update UIDANCE

advertisement