111.11111.1.1.1.011 REIMANCIE OF BONDED WIPE STRAIN GAGES ON WOOD No. 2087

advertisement

111.11111.1.1.1.011

7,0RE.31- :""

"

REIMANCIE OF BONDED WIPE

STRAIN GAGES ON WOOD

1

No. 2087

August 1957

MP'

UNITED STATES DEPARTMENT OF AGRICULTURE

FOREST PRODUCTS LABORATORY

MADISON 5. WISCONSIN

FOREST SERVICE

la Cooperation with the University of Wisconsin

CE.Z.4TER

FOREST RESEARCH CENTER

LIBRARY

(PERFORMANCE OF BONDED WIRE STRAIN GAGES ON WOOD

By

YOUNGQUIST, Engineer

1

Forest Products Laboratory, — Forest Service

U. S. Department of Agriculture

W. G.

Abstract

This report deals with the use of bonded wire strain gages on wood. The results of comparative tests using such gages and two types of mechanical gages

are presented. Methods for mounting bonded wire strain gages on wood and

special precautions_ that must be observed to obtain reliable data are also outlined and discussed.

Introduction

The extremely versatile bonded wire strain gage has been used for a number

of years at the U. S. Forest Products Laboratory for the determination of

strains in wood and wood-base materials and for the determination of stress

distribution patterns in wood structures. However, no report on the performance of these gages when used on wood has been issued. Wood is an anisotropic material with a cellular structure that varies widely in properties

with respect to grain direction, and it is therefore of interest to determine

the probable accuracy to be obtained with these gages when used on wood. It

is the purpose of this report to outline the methods used at the Forest Products

Laboratory for bonding these gages to wood, to indicate certain limitations on

the use of these gages, to present some comparative strain data obtained with

bonded strain gages and other types of strain gages commonly used with wood,

and to report the results of some limited special tests of these gages.

-Maintained at Madison, Wis. , in cooperation with the University of

Wisconsin.

Rept. No. 2087

-1-

This work was not intended to determine the absolute accuracy that can be

obtained when using the bonded wire strain gages on wood, but rather to obtain an indication of the accuracy to be expected when normal testing techniques are used. The commercially available gages have about 4 percent of

the gage wire placed in a direction transverse to , the length of the gage. The

wire so placed responds only to strains in a transverse direction, such as

those caused by Poisson's ratio effect. The gage factor furnished by the

manufacturer corrects for this effect when the Poisson's ratio is 0.285. Only

a limited amount of information, however, is available on Poisson's ratio

for wood. As an example, the ratio for Douglas-fir (specific gravity 0.506,

moisture content 12.9 percent) is 0.292 in the longitudinal-radial direction

and 0.449 in the longitudinal-tangential direction. It is obvious that when

the actual values differ from 0.285 an error is introduced. For many applications these errors can be neglected, but corrections must be made when

more exact values are required. An indication of the magnitude of such

2

errors and a method of correction have been presented by B. M. Radcliffe. —

Correction factors have not been applied to the values presented in this report.

Test Materials and Strain Gages Used

Wood

Douglas-fir, white pine, and sugar maple, were used for these comparative

tests. Each set of compression specimens was obtained from one straightgrained, air-dry plank. The planks were 8 inches wide, 2 inches thick, and

48 inches long. The Douglas-fir tension specimens were obtained from a

section of plank that was end matched to the piece from which the compression

specimens were obtained. A single beam of southern yellow pine was used for

the repeated load tests.

Strain Gages

The bonded-wire strain gages were the commonly used commercial type

gages. The A-1-type gage has a resistance of 120 ± 1 ohm, a nominal gage

length of 13/16 inch, and a gage factor of 2.0. The gage consists essentially

of a grid of fine wires, all lying in one plane, cemented in place on a thin

2

—Radcliffe, B. M. "A Method for Determining the Elastic Constants of Wood

by Means of Electric Resistance Strain Gages. " Forest Products Journal,

Vol. 5, No. 1. Feb. 1955.

Rept. No. 2087

-2-

FO2EST RESEARCH CENTER

111-i2ARY

paper backing, and covered by a piece of felt. Figure 1 shows the A-1-type

gages attached to a compression specimen.

A few A-7-type gages were also used. This is a wrap-around-type gage made

of a continuous length of wire wrapped in a tight helix pattern around a thin,

flat core of paper. This sensitive element is then sandwiched between two

paper covers for protection. The A-7-type gage has a resistance of 120

0.8 ohm, a nominal gage length of 1/4 inch, and a gage factor of 1.9.

A commercial type M strain indicator reading to the nearest 10 microinches

and estimated to half this amount was used to read the strains in these gages

(fig. 2).

The Tuckerman strain gage is of the optical type and is capable of measuring

strains as small as 0.000002 inch. The gage consists of two essential parts;

the autocollimator which contains the calibrated scale and the extensometer

which is attached to the test specimen. A 2-inch gage length extensometer

was used for the compression tests, and a 1-inch gage length extensometer

was used for the tension tests and one of the special tests. Figure 1 shows

two Tuckerman extensometers attached to opposite faces of a compression

specimen. Figure 3 shows a specimen ready for test with extensometers and

autocollimators in place. The extensometers were held in place with wire

spring clips. Simultaneous readings of load and strain for each extensometer

were obtained, the strains were averaged, and a load-strain curve was plotted.

The Lamb's roller extensometer is also of the optical type, and it is frequently

used to measure strains in wood specimens. The extensometer is shown attached to opposite faces of a compression specimen in figure 1. The gage

consists of three essential parts, the light source, the extensometer units

with rotating mirrors mounted on the specimen, and the drum holding the

graph paper for direct plotting of the stress-strain curve, as shown in figure

4. The gage is constructed so that the average strain of the two faces of the

specimen is obtained.

Both the Tuckerman and the Lamb's roller extensometers were calibrated by

means of precision gage blocks before these tests were started, and they were

accurate to within ± 0.2 percent.

Mounting of Bonded Strain Gages

The surfaces of the compression and the flexure specimens to which the gages

were to be mounted were produced with a sharp, hollow-ground saw and were

Rept. No. 2087

-3-

very uniform and smooth. The test sections of the tension specimens were

produced by router knives and were also smooth. Before the gages were

mounted, the surfaces were sanded lightly with a fine grade of sandpaper. A

commercial nitrocellulose type of cement was used. A liberal amount of the

cement was spread over the area to receive the gage, and a straight edge

was used to remove the excess, leaving a thin, smooth coating of glue. After

this glue had dried (usually in 24 hours) a second coating of glue was spread

on the surface, and the gage was carefully placed in position. A 1/4-inchthick soft rubber pad was placed on the gage, and a 1-pound weight was placed

on top of the pad to provide glue pressure. It is sometimes necessary to

apply glue pressure with heavy rubber bands instead of weights. Gages were

allowed to dry for at least 24 hours before use. This general method of mounting gages on wood has been used successfully at the Laboratory for a wide

variety of applications.

Preparation of Test Specimens.

The compression test specimens consisted of rectangular prisms 1 inch by 1

inch in cross section and 4 inches long. Figure 5 shows the cutting method

used to obtain matched specimens from the Douglas-fir test plank. Specimens were obtained which were oriented with the long dimension parallel to

the grain, with the long dimension perpendicular to the grain, and at an angle

of 45 degrees to the grain. The specimens of maple and white pine were obtained in a similar manner, except that specimens oriented at 45 degrees to

the grain were not obtained. Only specimens 1 through 6 were used for these

tests. The eight tension specimens of Douglas-fir were obtained at random

locations in a section of plank, end matched to the one from which the compression specimens had been obtained. Figure 6 shows the dimensions of the

tensile specimens. The test planks had a moisture content of about 12 percent when the specimens were prepared. All specimens were conditioned to

constant weight before test at 75° F. and 64 percent relative humidity. These

conditions bring the average moisture content of wood to about 12,percent.

Methods of Test

Compression Tests

To provide the best possible comparative data, the modulus of elasticity of

each specimen was determined in turn with the Tuckerman gage, Lamb's

Rept. No. 2087

-4-

roller gage, and finally with the bonded-wire gages. It was therefore necessary to stay well within the elastic limit of each specimen to avoid permanent

injury to the test piece. The maximum load applied to each specimen was

selected as less than one-half of the expected proportional limit value for the

species and loading condition. Load increments were chosen to provide about

20 equally spaced increments at which simultaneous values of load and strain

could be determined. All tests were made on the same testing machine. The

testing machine was not located in the conditioned room, therefore it was necessary to keep the specimen in an uncontrolled condition during the test period

of approximately 5 minutes. All three types of gages were attached to the

same two opposite faces. The radial faces of the compression-parallel-to-

grain specimens and end-grain faces of the other specimens were used for test.

Figure 3 shows one of the compression specimens in place in the testing machine with the Tuckerman gages in place. The gages are held in place on the

specimen with spring clips. Great care was taken to space the knife edges,

which were 2 inches apart, equidistant from the center of the length of the

specimen. Load was applied to the specimen at a uniform rate of 0.012 inch

per minute through a spherical head mounted in the head of the testing machine.

The two Tuckerman gages were read individually, an average was obtained,

and the resulting load-strain curve was plotted.

The Lamb's roller extensometer gage is shown in place in the testing machine

in figure 4. This gage permits the direct plotting of a stress-strain curve on

the drum holding the graph paper, as shown. The gage gives an average value

of strain for the two faces of the specimen.

The bonded electric strain gages, glued in position on opposite faces of the

test specimens, were spaced so that the active portion of each gage was distributed evenly about the perpendicular centerlines of the specimen faces.

For the A-1-type gages, only the strain in the central 13/16 inch of each

specimen was measured. The two gages on opposite faces of each specimen

were connected in series and thus served as a single averaging type gage. A

companion specimen, wired in the same manner, was used as a compensating gage. Figure 2 shows a compression specimen with bonded gages attached

ready for test. The indicator was graduated to the nearest 10 microinches,

and readings were estimated to the nearest 5 microinches.

Tension Tests

The dimensions of the specimen used for the tension-parallel-to-grain tests

are shown in figure 6. Load was applied to the notched shoulders through

metal grips at a rate of 0.02 inch per minute. Loads were kept well within

Rept. No. 2087

-5-

the elastic limit of the material. All specimens were first tested by mounting the 1-inch gage length Tuckerman gages centrally on the two opposite

3/8-inch-wide faces and obtaining simultaneous readings of load and strain.

Following the completion of these tests, bonded strain gages were glued to

the same faces, and the test was repeated.

Special Tests

Following the completion of the major series of tests, a number of tests and

observations were made to check the stability and performance of the bonded

gages under varying conditions. The check on the stability of the gages under

supposedly constant conditions was made by using a compression specimen

with bonded gages attached as an active gage and using the gages on a closely

matched companion specimen as a compensating gage. The current to the

indicator was kept on at all times, and intermittent readings of time and indicated strain were taken. To check the behavior of the gages when both gages

were moved to a changed atmospheric condition, the gages and indicator were

placed on a cart and quickly moved to the desired conditioned room. Simultaneous readings of time and strain were taken at arbitrarily selected intervals. The check on the behavior of the gages when only the active gage was

moved to a different atmospheric condition was made as follows: Both of

the compression specimens to which the active and compensating gages were

attached were conditioned to a constant weight in a temperature-humidity controlled room. The compensating gage was then placed in a glass jar with a

tight-fitting metal screw-top cover. Sealed lead wires for the strain gages

were provided through the metal cover. After the compensating gage had

been sealed in the jar, the two gages and the indicating unit were quickly

moved to the desired conditioned room, and the time-strain readings were

taken.

To obtain information on the performance of the bonded gages attached to material with alternating bands of high and low density, such as formed by springwood and summerwood, a composite type of specimen was fabricated. One

white pine compression-perpendicular-to grain specimen and one similar

specimen of hard maple were selected for test. The modulus of elasticity

was first determined for each specimen with a Tuckerman strain gage. Each

specimen was next cut to a length of 2 inches and reassembled into a 1-inchsquare specimen 4 inches long, the top 2 inches being of white pine and the

bottom 2 inches of hard maple. A thin layer of polyvinyl glue was used to

bond the two pieces to each other. The modulus of elasticity of the central

1 inch of the composite specimen was now determined with Tuckerman strain

gages. The bonded strain gages were next glued in place on two opposite faces

of the test specimen. Each gage was accurately centered on the glue line with

Rept. No. 2087

-6-

one-half of the active portion of each gage on the white pine portion of the

specimen and the other half on the maple. The specimen was again tested,

and the apparent modulus of elasticity as indicated by the bonded-wire gages

was determined.

The effect of a large number of load repetitions on the bonded-wire strain

gages mounted on wood was investigated by the following means. A-1-type

gages were bonded to the top and bottom faces at the center of the length of a

southern pine beam 2 by 4 by 43 inches long. The beam was then placed in

a testing machine, supported on a span of 39 inches, and loaded at the third

points. The strain gage on the top of the beam was used as the active gage,

and the bottom strain gage was used as the compensating gage, and a loadstrain curve up to a total load of 1,500 pounds was obtained. Figure 7 shows

the beam in place in the testing machine. Following this initial calibration

of the gages, the beam was placed in a direct-stress fatigue machine, the loading method was duplicated, and repeated loads varying from a minimum of 150

pounds to a maximum of 1,500 pounds were applied at a rate of 550 repetitions

per minute. . The test was continued until 10,011,100 loads had been applied.

The beam was then replaced in the testing machine, and the stress-strain

curve up to a load of 1,500 pounds was again determined. Following this, the

beam was loaded to failure.

Figures 8 and 9 show an actual application of the bonded-wire strain gages in

a series of tests of laminated wood bow-string trusses.

Presentation of Data

The comparative modulus of elasticity values obtained by the Tuckerman gage,

Lamb's roller gage, and the bonded-wire strain gages for the three species of

wood are presented in tables 1, 2, and 3. Individual test values are presented

to permit direct comparisons between the three methods of test. The percentage of variation of each determination from the value obtained with the Tuckerman gage is also . shown. The data presented in tables 1, 2, and 3 are shown

graphically in figures 10 and 11.

The comparative values of the modulus of elasticity of Douglas-fir, tested in

tension parallel to the grain as measured by the Tuckerman gage and bondedwire strain gages, are presented in table 4 and shown graphically in figure 12.

Table 5 presents the results of compression tests of a composite specimen

fabricated from maple and white pine and also gives the stress-strain characteristics of the original pieces of wood from which the specimen was

Rept. No. 2087

-7-

fabricated. The values in table 5 are shown graphically in figure 13. Figure

13 also presents the computed values of the modulus of elasticity for each test

made.

The results of tests to evaluate the effect of repeated loading on the performance of the bonded-wire strain gages are shown in table 6. Table 6 also presents the stress-strain data obtained in testing the beam to failure following

the completion of the comparative studies. The comparative stress-strain

curves obtained before and after the repeated load cycling are shown graphically in figure 14.

The comparison of the stress-strain characteristics of white pine in compression perpendicular to the grain as determined by the Tuckerman gage,

and 1-inch nominal and I/4-inch nominal gage length bonded-wire gages is

presented in table 7. Similar data for white pine in compression parallel to

the grain are presented in table 8. The information presented in tables 7 and

8 is presented graphically in figures 15 and 16.

Table 9 presents time-strain relationships that occur in bonded-wire strain

gages mounted on white pine when subjected to various exposure conditions.

Figure 17 shows a plot of the time-strain occurring in a parallel-to-grain

specimen. Similar data for specimens oriented perpendicular to the grain are

shown in figure 18.

Discussion of Results

Of primary interest in this study is the reliability of the strain data obtained

with bonded-wire gages mounted on wood. The Tuckerman and Lamb's roller

gages are both used to measure strain in wood and were thus chosen for comparative purposes. The Tuckerman values were arbitrarily selected as standards of comparison. In making comparisons in the data presented in tables 1, 2, 3,

and 4, certain important considerations must be kept in mind. The modulus

of elasticity values were obtained by plotting the stress-strain data for each

specimen, drawing a visually selected line of best fit and computing the modulus. The values obtained are thus not exact values, since two independent

operators would probably not arrive at exactly the same value in each instance.

To minimize these variations as much as possible, all of the slope lines were

fitted to the plotted data by one operator.

The bonded-wire gages and the two gages used for comparative purposes do

not measure the strains over identical portions of the specimens. The Tuckerman and Lamb's roller gages measure the strain over the central 2 inches

Rept. No. 20 87

-8-

of a specimen 4 inches long. The A-1-type bonded strain gage, on the other

hand, measures the strain only over the central 13/16 inch of the specimen.

The test results show that some variation in modulus of elasticity occurs between individual specimens even though they are closely matched. It is logical to assume that variation also occurs along the length of each specimen.

This may be especially significant when obtaining a measure of the modulus

across a number of growth rings, which vary considerably in thickness and

composition.

The modulus of elasticity of each specimen was obtained from the equation

E=—

(1)

E

where

E = modulus of elasticity

Cr = stress

e = strain

The stress was determined for each specimen by dividing the applied load by

the cross-sectional area of the specimen. The strain was obtained from the

Tuckerman and Lamb's roller data by dividing the total movement obtained

by the initial gage length (2 inches). The bonded-wire strain gages give direct

values of strain.

The data presented in tables 1, 2, and 3 show that a close correlation generally

exists between the values obtained by the three test methods. The coefficients

of variation obtained by the three methods are about of the same order of magnitude, but they are somewhat greater for the bonded-wire gages. It is interesting to note that the Tuckerman gage and Lamb's roller gage which measure

strains over the same gage length differ by more than 6 percent in several instances. No apparent reason for the occasional differences of 10 to 14 percent

between Tuckerman and bonded-wire gages was noted. The difference of 21.3

percent between the modulus values obtained with Tuckerman and bonded-wire

gages for the' maple specimen M-0-3 (table 2) requires further explanation.

The maple specimens cut parallel to the grain were obtained from a single

stick and are thus end matched. The two specimens on each end of the stick

were from material that was essentially straight grained. Specimen 3 and,

to a lesser extent, specimen 4 contained considerable curly grain, and this

is reflected in the low modulus values obtained for these specimens by all

three test methods. The deviation from straight grain was most pronounced

near the center of specimen 3, and this probably accounts for the fact that the

short gage length bonded gage gave the lowest modulus value. On this basis,

Rept. No. 2087

-9-

it is not correct to consider the 21.3 percent difference between Tuckerman

gage values and bonded strain gage values as an actual error. To a lesser extent, this same consideration may account for some of the other larger differences noted. However, no apparent deviation from normal grain was observed in the remaining specimens.

Figure 10 shows that for all three species tested in compression parallel to

the grain, the differences between values obtained by Tuckerman and bondedwire gages are generally less than 10 percent, with an approximate normal

distribution above and below the comparative values. Figure 11 shows similar

data for specimens loaded at angles other than parallel to the grain. Again

the modulus values are generally within 10 percent of the comparative Tuckerman values. Most of the values determined by the bonded-wire gages, however,

are high. Such a result could be expected if the bonded-wire gage assembly is

itself stiffer than the material being tested.

The data in table 4 show that the modulus of elasticity of Douglas-fir in tension

parallel to the grain as determined by the bonded-wire gages gives values with

a lower coefficient of variation than the comparable Tuckerman values. The

maximum difference obtained between the two methods of test was 7.6 percent.

An approximate normal distribution above and below the standard of comparison was obtained as shown in figure 12.

The determination of the modulus of elasticity of wood in a direction perpendicular to the grain, that is, across a number of growth rings, is essentially

that of determining what might be called an apparent modulus of a composite

material. An examination of the end grain of such woods as Douglas-fir or

southern yellow pine often reveals a pattern of growth rings that vary considerably, in thickness, in the ratio of dense summerwood to the less dense springwood, and in the gradation between the two. It is known that the dense summerwood is stronger and stiffer than springwood, therefore, it is logical to

assume that a variation in Poisson's ratio also exists in the growth rings. A

strain gage, such as the Tuckerman or Lamb's roller gage measures the total

movement that occurs between knife edges. The bonded-wire gage, on the

other hand, measures the varying strains in the underlying material, and the

results may be affected by the varying lateral strains that occur. Table 5 and

figure 13 present the data obtained in tests of the composite white pine-maple

specimen. Since the maple and white pine differ significantly in modulus of

elasticity perpendicular to the grain, this composite specimen simulates conditions that exist in one growth ring.

Figure 13 indicates that the modulus of elasticity of the maple in the composite specimen was 147,000 pounds per square inch. Similarly, the modulus

of the white pine was 91,800 pounds per square inch. The apparent modulus

Rept. No. 2087

-10-

of elasticity of the composite specimen as determined by both the bondedwire strain gages and the Tuckerman gages was 108,300 pounds per square

inch. It is of interest to examine the relationship which exists between this

apparent modulus and the modulus of elasticity of the individual pieces of

maple and white pine.

The apparent modulus of elasticity may be computed from the previously presented equation (1)

oEa = e

(2)

The Tuckerman gage measures the total deformation that occurs between

knife edges. This deformation is composed of two parts, namely the movement in the maple spanned by one-half of the gage and the movement in the

white pine spanned by the other half of the gage. This can be written

e = em + ep

(3)

where

e = total deformation

e = deformation in maple

e = deformation in pine

also

crh

e-

m

Em

crh

p

(4)

where

hm = height of maple block within gage length

h = height of pine block within gage length

Em = modulus of elasticity of maple

E = modulus of elasticity of pine

Under the conditions used in this test h

= hp= 1/2 inch and e = E (1 inch

m

gage length). Therefore from equation 4,

e=e=

cr

2E m 2E

p

(5)

Then from equation 2,

Rept. No. 2087

-11-

E

2E E

o-

a

0-

= e = u-

2.E

-1- m

a-

2E

p

Em+ E p

(6)

1)

where

E a = apparent modulus of elasticity

Substituting the values for Ern and ED obtained from the Tuckerman test date

in this equation, we obtain E a = 113,b00 pounds per square inch. This compares with the 108,300 pounds per square inch value obtained directly from

the data of the actual test of the composite specimen. This can be considered

as a reasonable agreement, since the separate modulus determinations of the

pine and maple were made on portions of the specimens not identical to those

included in the gage length of the composite specimen.

The bonded-wire gages give values of strain directly. The relationship between the apparent modulus obtained and the modulus of each individual piece,

however, is as previously described and given by equation (6).

The data presented in table 6 and shown graphically in figure 14 indicate that

the bonded-wire gages were not affected by a large number of repeated loads.

The strains shown are the additive compression and tension strains in the top

and bottom faces of the beam. A plot of the load-strain data obtained in the

final test of the beam to failure showed the proportional limit load to be 5,200

pounds. The maximum load was 8,580 pounds. The 1,500 pound maximum

repeated load was thus about 29 percent of the proportional limit load and 17

percent of the maximum load or somewhat lower than the normal design range

for a wood beam.

Figure 15 permits a comparison of the modulus of elasticity of white pine in

compression perpendicular to the grain as determined by Tuckerman gages

and by bonded-wire strain gages of nominal 1-inch and 1/4-inch gage lengths.

Based on the average of the two specimens tested, the 1-inch gage length

bonded gages gave values that were 5.7 percent higher than the Tuckerman

values. The 1/4-inch gage length gages gave values that were 68.6 percent

higher than the comparable Tuckerman values. This confirmed the results

of some previous tests made at the Laboratory in which 1/4-inch gage length

bonded gages were used in an attempt to determine the stress distribution on

the face of a loaded wood beam.

Figure 16 presents similar data except that strains were measured parallel

to the grain. The average modulus of elasticity for the two test specimens

as determined by the 1-inch gage length bonded gages was 2.2 percent lower

Rept. No. 2087

-12-

than the comparable Tuckerman values. The 1/4-inch gage length bondedwire gages gave values 11.7 percent higher than the Tuckerman values. It

is possible that the actual construction used in the manufacture of the 1/4inch gage length gage which employs 3 thicknesses of paper and 2 layers of

wire might result in a component stiff enough to resist through a reinforcing

action the movement of the material to which it is attached. This would be

of most significance in determining the modulus of elasticity perpendicular

to the grain.

It is a well known fact that wood shrinks as it loses moisture and swells 'as it

absorbs moisture. A piece of wood will give off or take on moisture from the

surrounding atmosphere until the amount of moisture in the wood balances that

in the atmosphere. Thus, wood is almost always changing dimensions, at

least slightly, because of atmospheric changes. The total shrinkage that

occurs in wood in a direction parallel to the grain is small and usually ranges

from 0.1 to 0.3 percent when green wood is dried to 0 percent moisture (ovendry). The amount of shrinkage that occurs in directions across the grain in

drying the three species of wood tested from the green to the ovendry condition is shown in the following tabulation:

Species

Pine (eastern white)

Maple (sugar)

Douglas -fir

Radial

shrinkage

(Across the

Tangential

shrinkage

(Tangent to

growth rings)

growth rings)

Percent

Percent

2.3

4.9

5.0

6.0

9.5

7.8

The rate at which these changes occur depends on many factors, but most important in the present connection is the size of the piece and the amount of end

grain exposed, because a large piece comes to equilibrium at a much slower

rate than a small piece, and end grain is much more permeable to moisture

than side grain. In selecting a piece of wood on which to mount a compensating gage, it is very important that the piece match the actual test piece as

closely as possible. If the compensating gage were placed on a small, thin

wood member and the active gage on a large beam, erroneous readings could

easily occur. This would be of special importance in tests of long duration.

Figures 17 and 18 indicate the possible magnitude of errors caused by changing moisture conditions. Wood will reach an equilibrium moisture content of

about 12 percent at 75° F. and 65 percent relative humidity and a moisture

content of about 6 percent at 75° F. and 30 percent relative humidity. The

Rept. No. 2087

-13-

data in figure 17 indicate that under this rather severe moisture differential

for the two matched blocks, the longitudinal strain was very small during the

first 3 hours and amounted to only about 0.06 percent after 40 hours.

Figure 18 indicates that under similar differential moisture conditions, the

shrinkage across the growth rings amounted to about 0.27 percent after only

2-1/2 hours. Using an average modulus of elasticity of 79,000 pounds per

square inch for these specimens, the movement of 0.0027 which occurred is

equivalent to that resulting from a load of 213 pounds on the specimen. It is

significant that these specimens were loaded only to 160 pounds in determining the modulus of elasticity. Figure 18 also indicates that small but measurable strains occur when both active and compensating specimens remain in

the same controlled condition or are both moved to a changed condition. This

indicates that careful selection of a compensating-gage specimen and care in

exposing both active and compensating gages to the same atmospheric conditions can greatly minimize errors due to differential shrinking and swelling

of the test piece. The effect of temperature is also an important consideration in using bonded-wire strain gages. However, no data on temperature

effects were obtained in this study.

In many instances, it is desirable to use the bonded-wire strain gages to indirectly obtain stresses in a structure or member. If the modulus of elasticity

of the material is known, the strains can readily be converted to stresses.

For metal structures, an adequate modulus of elasticity value can often be

assumed. For wood structures, such a procedure cannot be used. The modulus of elasticity of wood varies between species, and within a species due to

such factors as a variation in density, moisture content, and grain orientation.

The magnitude that variations between species can assume is indicated by the

data in tables 1 and 3 which show the average modulus of elasticity parallel

to the grain of Douglas-fir to be 2,056,000 pounds per square inch and that of

white pine to be 1,219,000 pounds per square inch. The test data in tables 1,

2, 3, and 4 show that some variation in modulus of elasticity occurs in closely

matched material. The most significant differences occurred in the maple

specimens cut parallel to the grain because of grain deviation.

It is recommended that, whenever possible, a separate determination of the

modulus of elasticity of the wood in a test structure be made. The determination can be made on some of the excess material from the test structure or on

material salvaged from the structure after completion of the test. Figure 8

shows a test in progress in which this latter method was used. The test structure is a laminated bow-string truss of 32-foot span being loaded at 12 points

through a cable-pulley system. Bonded-wire strain gages were attached to

the top, bottom, and sides of the top and bottom chords at various points along

the length of the truss. Figure 9 shows the strain gages in greater detail.

Rept. No. 2087

-14-

Following the test of the structure to failure, undamaged sections of the

chords six inches long that contained the strain gages were removed for calibration. These sections were loaded in compression parallel to the grain,

and stress-strain data were obtained for each gage. The individual modulus

of elasticity values thus obtained were used to analyze the results obtained in

the test of the truss.

Conclusions and. Observations

The following conclusions and observations are based on the results of these

tests and on the experience gained at the Forest Products Laboratory in using

the bonded-wire strain gages on wood..

1. The bonding technique described in this report, using nitrocellulose cement

as a bonding agent, is a simple and satisfactory method of attaching gages to

wood maintained in the dry condition. The maximum moisture content in the

wood used in these tests was 12 percent. It can be assumed, however, that

the same bonding techniques would be satisfactory on wood with a moisture

content of 15 to 18 percent. At moisture contents above this level, or where

the gages are exposed to adverse atmospheric conditions, special gages and

moisture-proofing techniques should be used.

2. Tests of Douglas-fir, sugar maple, and white pine compression specimens

parallel to grain indicate that the modulus of elasticity values obtained with

the nominal 1-inch gage length (bonded-wire gages) are in good agreement

with values obtained with Tuckerman and Lamb's roller gages of 2-inch gage

length. The bonded-wire gages give values generally well within 10 percent

of and normally distributed about the Tuckerman values chosen for comparison. A comparison between the Tuckerman gage values and Lamb's roller

gage values shows differences of the same order but of slightly less magnitude. A much closer correlation would probably be obtained if the same gage

length were used for both the Tuckerman and bonded-wire gages.

3. Tests of Douglas-fir, sugar maple, and white pine compression specimens

perpendicular to the grain and Douglas-fir specimens at 45,° to the grain give

modulus of elasticity values obtained with bonded-wire gages and Lamb's roller

gages that are in most instances within 10 percent of the comparable Tuckerman values. In all instances, the modulus of elasticity values obtained with

the bonded gages are higher than the Tuckerman values. The reason for this

is not known. Such a result could be expected, however, if the bonded-wire

gage assembly is itself stiffer than the material being tested.

Rept. No. 2087

-15-

4. The modulus of elasticity values for Douglas-fir in tension parallel to the

grain as determined by Tuckerman gages of 1-inch gage length and nominal

1-inch gage length bonded-wire gages are in good agreement with an approximate normal distribution of differences and a maximum difference of 7.6 percent.

5. Tests of a single composite compression specimen composed of equal

lengths of maple and white pine perpendicular to grain gave identical apparent

modulus of elasticity values with both the Tuckerman and bonded-wire gages.

The values so determined agreed closely with the modulus values computed

from the measured modulus of elasticity values for the individual sections of

maple and white pine.

6. Two bonded-wire gages mounted on a southern yellow pine beam were apparently unaffected by more than 10,000,000 flexural load cycles.

7. Comparative compression tests of white pine, both parallel and perpendicular to the grain, indicate that the bonded-wire strain gages of nominal 1/4inch gage length give modulus of elasticity values significantly higher than

those obtained with Tuckerman gages or bonded gages of nominal 1-inch gage

length. The average differences between the Tuckerman values and the values

obtained with the 1/4-inch gage length bonded gages were 11.7 percent for ,

specimens parallel to the grain and 68.6 percent for specimens perpendicular

to the grain. These results generally confirm those obtained in previous tests

made at the Laboratory.

8. These tests confirm the fact that a deviation from straight grain in a wood

specimen may significantly affect the measured modulus of elasticity of the

piece. A drop in modulus of elasticity of maple from 2,320,000 to 1,070,000

pounds per square inch was obtained in a distance of only 4 inches along the

grain. Care must be taken to mount each bonded-wire gage on wood representative of the piece and in proper orientation with respect to the desired

direction.

9. Highly significant apparent strains can be obtained in strain gages mounted

on wood caused only by differential moisture exposure of the wood samples on

which the measuring and compensating gages are mounted. These apparent

strains are greatest when measured in compression across the grain, but they

cannot be ignored in tests parallel to the grain when the tests are of long duration. The results show that careful selection of a compensating-gage specimen and care in exposing both active and compensating gages to the same atmospheric conditions can greatly minimize errors due to differential shrinking and swelling.

Rept. No. 2087

-16-

10. The use of an assumed modulus of elasticity for wood in converting

measured strains to stresses is not satisfactory and maylead to sizable

errors. It is recommended that whenever. possible a separate determination of the modulus of elasticity of the wood in a test structure should be

made.

Rept. No. 2087

-17-

1. -45

OF

1•

.-4

4

V.

a

'0

•0

NTh

•-1

0a)

7.-

I

+1+4.1

0

0

al

U

O

+3

0

•••

O

0

CI

0

H

4.3

0

4-1

14

07

I-4

a)

0:1

a)

ao

4-1

CC)

0

kit

coo

• •

coo

• .

0

a" \

ctl

0

0

ON

NO

P41

.1

0'

•

•

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 K\0 0 CO \0-f

-1'

\ In

H OH 0 0\ 0\0

•••

01 CU CV CV H H CV

-I.

6

n_.••

q

•-•1

0

1-•

0 0

0]

+-1 -163

V

0A 1

eo-o

0 H .4 in

,.0 K\-I'

2 fl-1

4-•7

an al

•o

1-1

0

0O

0a)

03

a)

o

O 0

'0 0

I-, 0

H

'"0 +3

4-, 7

IC\

..d.

a)

Ta

0

,21•••

0 co

8

Ctl 1-r

0,11

9-1

)-1

0 7

CD oi

C:11

CO 110

(1)

,9 •

0 0

az

In

2087

F.

'

+ + +

V

H

73:1

,

0

4-,

I

.

•

0

In

H

D

IC1

co

ai

•

H CO re\

P01/4.0

• • • • • •

PCN trn trNs.o re\

++++++

t.•

q-.

0

0

CO

9

a)

P-1

•ri

0

r'0

3

0000

0000000

0 0 0 0 0 0 0

0 0 0

CO

H

n-•

0)

0-1

0)

'0

fi

Ea

co

01 In I"- 1C\ 0 C-CV \ID CV H CU H

'0

0-1

10

H

HHHHH

••

,9

'1

ON 0

U) a)

a7,

0 4-,

4-/

03 0

H 4-5

••

CV

(4)

0

0

14

VD

0

0000000

o 0

0oo0o

N tr\ n.o 0 co••• _7N 0 \ 0\ 0 t•-\ LIN

0

0 H 0\\ 0\\ 0

CU CV r-1 v-1 01 NN

•• •• •• •• •• •• ••

+4

41-1

411

44

9,

CV 01 CV

4. 0

0

w

L.P,

-I

H r-1 co co or.co

H 01 0 ON O\0

td

no

ao

-I-,

o

+ . + -1- -I- 1

cd

Cati

CO

021 V

0 1-4

a,

0

••

0

Ca

0

0

4-,

co

0

O!

O

Sa

q

0

R.,

4.

11-, 14)

H

'.

C.3 q

q

••

d

f•-n

0

97

0

Rept. No.

q

4.

a

A.

O ac

1

1.:3,

O

0

r••

)

9-•

9:1 ••

1, 0

•H

Fi

8

0

.•

C14

5

O

.r0

f.•

PA

1-n

tks

••

0

H

g

of

CV --1' H 0 0 In

tC

VC \ 0 0 H

01 CU 01 01 CV 01 CV

;CNN°CY\ `-.0

:41

o

•• • • •• • . •• •• •• ••

0000000

0 0 0 0 0 0 0

H0 t•-•

CV al PC) H 0 \O

H

• • • . • • • • .. • • • •

0

n-e

0

0

CV

14-,

1I1

co]

•• •• •• •• ••

CV

I41

q

•r1

CO 0

'0

• • • •

-1 k

0 4.,

0)

1,0 t..-

co

tr.

CD

C

ON

..-2i In 1C\ 0.1 en H

++++++

•• •• ••

O

•• 0

• • •0•

1-,a1 0

-1-)

H

0 0

17

05

tr..1.7

If \ n 0 0 cc\ H

• • • • • •

0 r-1 11 \ ts• NW)

H

+ -I- + + + +

O OD •CNCO

.• .• , • , • • • 1 • • •

0

0

•••

H

CO

4-1

N

co

la•

•• •• • •

N 0 N'n CO 0\ CO •0

op on on o LC)

ON

H 0 ON 0 0

n • •

-P

a/

CD

4,

4,

q"

0

•• •• •• •• •• •• ••

0

CV

0

ft

01

N

•• •• .. • •

0000000

0 0 0 0 0 0 0

0 H••• 11-\••• 1.-- CO••

CO \ CO CO H CO

-#

-I'

r-1 H

tC1 .-1

r1 H H

CV

•

ON

PC\

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 0 0 0 0 0 0

a

[0

•• •• •• •• .• •• ••

0 0 9 0 0 0

0 0 0 0 0 0

„§n In...01..,r-1,e-1...-.1n. 0..

H 0‘.4 t--. .4 t---*

H as a. ON 0 H 0

CV H H H CV NN

•

0

•• •• •• •• •• •• ••

0 00000

0000000

‘,0 CO••• \00010-1'

•••

PrN 7- 0 ON 7-03 ON

N

IC\ 141 In PC")

HHHHHHH

tl/ NN H NN

CV

H CV H te r•-n \ 0 c0

CV CV CU re) CU

CV

-7• -7• -7• -7• -7• -3-• -3-•

O

H 01 K\-*

--7 In \O •

I

I

I

I

I

I la

o o o o o o .4

1 1 1 1 1 1

Cc.• t.• lk• N. ra. Cr.

-18-

nal

O

0 ‘.0 CO -7

CO \ CO

N"\ r.0'\CV N 1,1

N-‘co CO oNo o

0101HHHO1 CV

• • • • * • •

(1.)

,1

•• •• •• •• •• •• ••

-I' In \O

H CM K\-?

•

In to" on In In to..

14-44- 4. 4- .4

1 1 1 1 1 1

•• •• •• •• •• •• •• ••

H (1 A K\.*

--I- Ill VD

8

_1_7 .3- .3-

Oc• N. r..4 rm• ra• C.•

-3-

I

0

I I

0 o

I

I

I

•

o o o too.

.:4

O\ ON as ON ON 0\a

1 1 1 1 1 1

C.+ a• 4.1 fr.. r‘l Cr•

O

OHHH

H4. 1 N1 1 + +

1,Th

4-2

PeN

t-IM

++++++

4.0

• • • •

00

00

00

00

Oa

ae

Oa

•

44N

04.

rl

In 0

d0

k•••

O

WI

4.;

0000000

0000000

0000000

• • • s • • •

H000.

,00

-1'0/t"...,1000

tc\PCN01,-NNM

NNHHNNH

0000000

0000000

0Ns.clOnw\vD

• ... • • .. n •

r410\CONC-HOD

HHHHHHH

ft

••

••n

ft

••

..

4i

+30

0d

0

•

••

x0

CD

4-3

O

0

000cOn0D

CM

1 CV+H H1 1 te\1

0\

4.0

.1,1A

re.r.9nnnH

NHn

+11++1

/-10

sd

0

O

0

.14

aai

+.

0

0.1

HH

ga

O

CO

CC

0\

04,

17.4

0

0t

O

I

d

+i

+3

X„ 4

„ 11 ,

440 4.

..

Ct.

1341

OH

4, 0

0

0 +4

00

0

0

H

O

0

aq

0.

trN

1

Ad0

°

,C\

'8 A

0

irn

14

a

PAM§ CJ

NiC\HHCOC-0

-1

0M,C\C-HHON

•••

NNHHNNH

•••

0000000

0000000

-#4,A.0\01C\H

1.---peNHCOON4

PCNV"\-*--1.-1-1C1-7

HHHHHHH

••

1

4.0

00

Fi

1140

5.

O

O

0

0

H

•

0000000

0000000

0000000

, , ,

.C C .4.WC"--(Y,

e.

H4-0n

H.r.Nt---HNm

, ,

CV 01 H H CV N H

0000000

0000000

OWNW\4c0 n0\0

C.--401H11-4

in 1('\4 -4 4 -4"

HHHHHHH

\rn-n N•An.-40

(0(.00\T0\O\0N

nnnnnnn

•••••••

0

-50C.;000

kb\O

• • n0\0,.0

• • • n0k0

• •

HaireN.*nkia•

1,11110.

000000.4

1'1111

rialtcv4d-Wa

111111*

0000001.

0\111111

ON0\0\M0h..d

4

o

O

crs

0

Ql

4-44.

+1H

14

2

CQa,

gl

co. 4en/N

04.

5

qj

0

0

0

0 0a)

Rept. No. 2087

ilk

•00

ar

CV

0

A

E,

W.I.

•••

•••0

ri

1.0

•••n•••

02

0

M4

p p ^Q

440

0

O

••• ...

ONCN

••

CV

••

•••

.1%,

/.4

,

XEXXXX

-19-

••n

...

.•

n

...

,

••

ZXXXXX

.%

O

r-f15

-4)

nchoo.00

100N.1.\-*10

O

+11.1.4.1

+ + + + +•-n

13-1

• •

• •

• •

• •

• •

••

• •

a

-4•

Ic\

n

CO

F

•• • • • • • • • • • • • •

0

0

8

ta.

• •

• .

••-••

0

n-n•

• •

134

]

r-1 '-1

••

••

V Ii

d

4-1 14

3

• •

• •

•

• •

. •

• •

• •

• •

• •

• •

• •

••

000000

000000 0

8000000

000000

0000000

no.nnn

H 0 N

NN

mooDer.

(Docut--.0

n

apfcapcor

•• •• •• •• ••

0

*1-1

0

HN

C1/4.0

tr•\ co•

•

•

•

•

;4

4

E

o

+.7+1'4

0

4-,

ONCOONChNic\

HHNN

1 1 1 4- 1 +

0

P,

Vro q

...-

67 r1

cr5

1''`.'

s,

PO,

12,,

;',=1

0

.0

A

w

P,

Q,

..

▪ -1-,

CO.

04 4

.

•

',a

•

a.,

1

4-

,

••

o

M

'

0

0

`4.4

$-1

o

o

0

!Ei

w. ...1-cr.mmt-n-1

HNONNNN

.., •S ••• ., •• ••n •

HHHHHHH

•• •• •• •• •• •• • •

0

m

a

Lr1

•-•-•

tg

LIN

• • • • • • • • - • • . •

0000000

n0000nt-

4-1

0

0

,cf

N.M.-dM\ON-0

•••

COC-C-C-C-COC--

0

0

.7...

ON

0

• • • • • • • • • • • • • •

0

O

tO

d

t eN

10

O

+91

O

F-1

k

El

O

C71,

g4i

,>

V7w

Cal)

8

1-1

..

c0

.0

8 8 8 2

° 0

9 8 8

000vv00

••• .. N ••• •• ••• ••

t..... C.Ci t... .../. 0 ••••1. 0

d

b4

11+

•,,,

0

V

0

V

0

0

a

•••4

{tea

%.0

41

0

▪ 441

pl

rnis

'8

6

w

'2

E

..

•0,

,T

if \

93

••

.0

0

1

'''

re%

0000000

0000000

0000000

•••

0C0C-C-01M

WOJDNM.CN H1

HNONN..10

ft ft •

HHHHHHH

rnnnrepiN

0

idON...

-I-

• • • • • • • • • • • • • • ..

tr2

0000000

onnoonva

0-4.CONN0101

anocipainnm

p aurootatl

O

r4NC-HOMN

\O‘M"D‘17\011-VM

tcNt.licpc\K)ieNicS

a

0

O

• •

4?`'

Rept. No. 2087

• •

• .

• •

• •

• .

••

1C01j010T1 0.

0

0

NN0.1N0404

-20-

;• •• •• •• •• •• •• ••

LCVO

H N re. ill

I

000000t.

CisONMONONCT.d

124174PICLIPIN

0

0

0

o n nID nc0

a)

••

0

-

0 Cd

-1

4--1 F-1

• --i

1.4

1:1

r

9-1

.•

C.)

•

.....

a)

C.)

S-1

a)

114

•• •• .

••

•-•,.

N-

0

.1-1

-1 0

I

,g

0

H 0

0

0 4-1

0

•• ••

'0 10

0

cd -1-1

0

$-1

b

O

0

ro

M

cO -P

A o

ai

g

0 • ri

1-1 EH

+3 I>

O

C13

0

•• •• •• •• •

4-1 P•

ri r0

O (0

-ri

•

rl

0

0 -1.)

•H

..--.

0 co

et:, a,

0H

• •• •• ••

4-1 rd

O

(1)

in 0

..--...

••

••

••

••

••

••

••

••

••

••

••

••

0

o

i\

...

o

Pl

\0

r-1

••

••

••

••

••

a•

••

••

••

••

••

••

••

••

000000000

000000000

0 0 0n 0w 0 0••• 0••• 0

•••

n w

N

lf1 H

N

te'n

O

Cl.1

rn 4 t— 0

t-00 t—

0\N re% rcn 0 $\010 N N

w

•••

••n

•••

•••

HNNNNNNNN

•• •• •• •• •• •• •• •• •• •• •• ••

0

•F•

8

a)

•• •• •• •• 1611 •• •• •• •• ••

g

O

O

..---..

rz-N

...._,,

1- t

0

--Y1

o

0

••

E-i

• •

•

t1.0

••

•

-d

•

i

1

Rept. No. 2087

••

0

75

Ctl •r-4

-1-1

ozi

{n r--I

• H H CO

F-1 n3 a.)

c[3 F-1 laOr

cd

E-I

••

•

..--1

•

co

••

0 ,-1

0

43

••

Fi

a)

P-1

a)

b0

Eti

bC1

0I

1)--1 0

0 -p

a)

••

0

-*

.0 .10

-P -I-)

H

••

PI

g •,9

rci n3

0 ;.-1

Fl 1:LO

0 0

-1-

••

f-

Ea

•

P-1

•• •• .

••

c0

+4

irN

.....

H 0

a)

••

••

•

to o

0 -1

d

. 0

;-1

a)

4-)

o

Opi

o

n0

..,....•

rid

-P

••

ON

• • •

• • • •

reN

—O \O

+ + + +

1 + 1

a)

N

H -P

0)

0

r-1

0

'0

0

CD

••

•

•• •• e• •6

•lo

••

•

P-1

.

• •

••

••

••

••

1.0

••

••

••

••

••

000000000

0 0 0 0 0

0 0 0

0 0 0 0 0 0.5 0 0 N

.5 .5 .5 w .5

c0 0c0 CN‘..0

in ON 0

C-0 -4- K\ rcl N CO 0.1

H re\ H 0 -A- 0 N H

•••

f-10.1a1CUNC\INC\10.1 • •

0

a)

0

H

••

HC 141-1- \ \SD C— 00

I

-21-

•

I

I

I

I

1

II

I P

E-1 H H H E-I E-I H 44

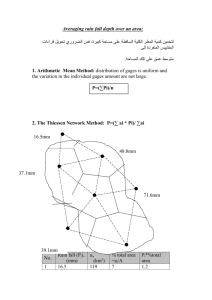

Table 5.--Comparison of the stress-strain relationships of a

composite maple-white pine compression specimen

as determined by Tuckerman and bonded-wire strain

gages

Maple specimen :

White pine

specimen

: Composite maple-white pine

specimen

Load: Strain

: Load : Strain

Strain

: Load :

:(Tuckerman :

:(Tuckerman :

:gage value):

:gage value):

:(Tuckerman :Bonded-wire

:gage value):gage value

Pounds: In./in. :Pounds:

0 :

:

0

20 : 0.000000 : 10

4o :

.000135

20

6o :

.000270 : 30

8o :

.000415 : 4o

100 :

.000555 : 5o

120 :

.000685: 6o

In./in. :Pounds:

: 0.000000 :

0

:

.000000 : 10

:

.000110 : 20

:

.000220 : 30

:

.000325 : 4o

: .000445 : 50

: .00054o : 6o

In./in. :

In./in.

:

: 0.000000 : 0.000000

.000095

.000100 :

:

.000195

.000195 :

:

.000290

.000280 :

:

.000380

:

.000360 :

140 :

.000815: 7o :

:

.000650 : 7o :

.000455 :

.00054o :

.00047o

.000560

160

180

'200

220

240

260

280

.000945: 80

.001085

90

.001210 : 100

.001345 : 110

.001485 : 120

.001615 : 130

.001755 : 140

.000745: 80

.000845 : 90

.000965 : 100

.001065 : 110

.001180 : 120

.001280 : 130

.001380 : 140

.000630 :

.000720 :

.000655

.000735

.000825

.000915

.001005

.001100

:

:

:

:

:

:

:

:

:

:

:

:

:

: 150 :

: 160 :

Rept. No. 2087

:

:

:

:

:

:

.001495 : 150 :

.001605 : 160 :

-22-

.000815 :

.000900 :

.001000 :

.001080 :

.001185 :

.001265 :

.001370 :

.001190

.001290

.001380

0

cr3 0 In

.0 a)

4-;-13

40

4-)co

0

g

000000000 0 000 0

co ON te\

0 0 K1 \0

CV

ON -1. o

0 irN CO tfl CO K.\ O1 -4 01 -1

\-.0

re\

000HHal N tcn

000 0

000000000 0

0• 0• 0• 0• 0• 0• 0 0• 0• 0• 0• 0• 0• 0•

0'n

gao

O

a)

U)

0

•• •• •• ••

co

$.4

••

••

•• •• •• •• •• ••

••

•• ••

0000

CO H 0

H

N- CO ON

0000

0• 0• 0• 0•

•• •• •• •• ••

•• •• •• •• •• ••

N- r-4 O1\0 ON lf\ N.0 0 0 0

0 tc1 lf-N ON al 14\‘.0 O\ al \SD 0 K1\S;)

CO H K\\0 trn t- 0 Lf\ o

O ren 1nc0 0 N t- 01 H

.0HH HHHNNNN tcn Km 141 tev-1- 11\ l(\\0

0000

• • • • • • • • • • • • • • • • • • • • • • •

O

•

•

-

• •• •• -•

U)

ni

+5 03

O Hq

E-f

a• •• •• •

00000000000000000000000

C- nTJ

9 00000000000000000000.4C0

ION\000 LC\

n00.4- CON\0000C\1\00-4-C

N--1-cON

N-0•0 CO

LC\ LC\ N.0 %.0

HHNNN 141 te\ --1-

O

•• •• •• •• •• •• •• •• •• •• ••

•• •• •• ••

.9 00

O -I-)

-p

05 0 03

• .0 a)

(0 rd

H

03 bp

+3 P4

O 0

4-)▪

c0

P-r

sk

(1--1

0

•

pi

H

4-1

•

{:21

I-I

O in ir, t--- tnco o N- K1 o In o t\o 0

o .4- ..0 On K1\ n0 0 CV NO 0 ON N- 0 --i • t"---

%.01-1N-CO

0 H al t.(1 LC\ \O CO ON 0 N NH-1-r--1

HH

00000000HH

000000000000000

0 •0 .0 •0 •0 •0 • 0 • 0 • 0 • 0 • 0• 0• 0• 0• 0•

O

•• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• ••

(1)

4.-i

(11

-

•

O

O

F-1

0 In 0 I.C\ 0 \O CU CO K\ CO lfN O If\ CO rcN

0000H 0

H O1 CV K1 K1-1 . ..-1- innO n0 N• • • 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0•

O

•• •• •• •• •• •• •• •• •• •• •• ••• •• •• ••

ti

••

••

••

01

.4

O• •• •• ••• ••

0) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Tt

000000000000000

r-C\ lf\

(1.1 K\--1- LC\ \O C--00 C:NHHHHHH

0

9

q

•• •• •. .

.9 0

0

P-I

•• •• •• •• ••

p

cd 0 c0

ttC) tr\

O '0 03

Hg

Pi

4-)

O0

-1-) •. . •• •• ••

•

U)

3

O

a)

Is

•• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• •• ••

o o L1\

0 0 LC\ LC\ tn LC\ o o 01oN\0

0 CV IC\

o n.0 01N U O\ ∎0

co

141

In

NON

0

H tr\

00000000H r--1 H H 1-4

HH

000000000000000

0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0•

O

•• Oa •• •• •• •• •• •• •• •• •• •• •• •• •• s• s• ••

••

•In •• ••

O

P-1 •-4

O -p

4-3 0

0 a)

N H4-1

a)

,0 I0 \O H \D N N- tC1 01-4- 0 NO (1.1 CO r41N-ON

CO 0 0 r--1 H N 0.1 14 -\ fr\

• 0• 0• 0• 0• 0•

-O 0• 0• 0• 0• 0• 0• 0• 0•0• 0

.• •

cd cd

+) 0

H

•• •• •• •• •• •• •• •• •• •• • n• •• •• •• •• •• •• •• •• •• •• •• •• ••• •• •• •• ••

0

P-I

Rept. No. 2087

00000000000

0 0 0 0

00000

0 0L.C\

0

0 0 0 000

H N0K1-1H

LCN n0 C--00 ON 1--IHHHHH

-23-

a)

to

A Cd

a)

bj)

g

0

to

a)

H

-d

C

EG)

PA

g

H

an

••

i>a

0)

ri g -H

CD

$-1 0

40

0

(I)

to .0 0

-P rt)

cD

rcs 4-) b

0

(1)

rd

- u,

In

••

a)

.N

'al .9

a)

°

as

-1-3

Ca

o o o o• o o• o• o• o• o• o• o• o• o• o• o•

•

• • •

0

I-I

0a)

11-1

421

I CD

H rd

••

••

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -0

t— c0 CO 0 0 al Kr

0 r--1 0 H 01-' irN NCO

Ink.°

ON 0

0

N 0tr\0 0 LC\

0H

00

0 \CD

0 0 0 r-4 H H H H

0000000000000000

0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0•

0

..-1

\

U

0Pi

riD

0

0

I-41

•

(1)

••

0

•••

bD

o3

a)

try

••

a)

att

O

0a)

(1)

f-A!

•

••

•

0

•r-i

•

••

••

••

• •

••

• I

••

••

••

••

••

••

.4

••

••

••

o if\ IC\

Lrn n o tr.\ o H

0 0 In tr\ in 0 0 0C---00

0 K1 IC'. 0

0 141 LC\ 0‘n L`-CO

0 H N K\--I''-0

0 0 0 0 0 0 0 0 0 1-1r--I r-1 8-1 H H v -I

0000000000000000

0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0•

0

.9

a)

co rcsO -P

Ci)

• •

• •

••

••

••

••

•11

••

••

1

.1

••

••

10

• •

••

••

noono n In 0

0 I.(1 0 0 0 Lf00\no

0 H Kl

tr\

0 Cr\ 0 01

n n,c)

CO 0-N o r-1tcn r-4

--I' LCV,..0

0

t .\ 0

HH

0 000J

00

0 0 0 0 H H

0000000000000000

0000000000000000

(1)

a)

V

1-4

Rept. No. 2087

---

0

•H

0 0

H

I.C\ ‘..0 CO 0 H CV

I.C\-I\(:)‘...0

ts-0 H 01 1•C\ --I \C) C-- CU 0\ 0 H C\ I-IH

s--1 r-1

000000000HHH

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

01

cid

H

td

o 00 o o o o o o o o 0 0 0 0 0

H

F-1

••

••

o

0 N II\ L--- C3\ 0 n

Pi

CO

to

bow

a:1

40 a)

••

••

0)

H cd

VI

(D -P

A•

•

0

,OCd

A

t lkj

0

•n9

••

Pi

al

bD

1-1

0 A

0)

1=^-4 -P

-I-)

U rd

••

•

I

0 (0 -4- al ON '-0K\

CCco Co

H

0000000000000000

0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0•

0

• • •• •• •• •• •• •• •• •• •• •• 4.4 .• •• •• •• •.

trn

O o o o O o o o o o o o o o o

_.9

P-1

LC\ 0 0 0 t.C\ Onnoon

tn CV 0

0.1

0 0 H H N K1

O

rd0

H0

g

cll

0 0 LC\ 111 If\

g

•H

I a)

td

bad

•

eci

aD

al N-1

a)

0

a)

p4

a) 4-,

to to

ao

0 0 0 0 0 0 0 If\ 0.0 0 0 LC\ 0 LC\

LC\

0.1

0.1 0

trn K

\D ren 0

0

n \.o c-oo co ON 0 0

o o H

14-N

00000000000000HH

0000000000000000

0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0• 0•

0

C

U)

UZI

P-n

0000000000000000

t(1.--1- LC\ \CI

0 H

H 0.1 K\ trvso C-00 ONHHHHHHH

-24-

••

cv

AW

-1-DW

F:1

H0

;-1

a)

a)

ro

•

ro

mro

00

;-too

Pi

Om

owo

toto

o

.toto

0

Pi

••

'

ate)

rc:/

HO

,10

gfj

a)

to

AW

tO

0*H

0 al

H F-1

E-1

5.„

CH

,0A

o

›,00

ri

I

r1

) ▪ Hcd

co

crircig

H H

a00

W 0

rd

cl-1 g

H

co 0 0

O

F-I

H tap t;r3

0

0

-0 0 bO

,4 cl

-pb0

.49

0

P

Cn

••

a)

••

P4

CO

a)

Pi

CA

••

••

••

--i

•

CO

a)

CO

•• •• •• •• •• •• ••

rci

0

Rept. No. 2087

••

••

•

••

••

••

••

••

••

••

••

••

••

••

••

••

••

••

••

410

••

••

••

•rn

••

••

•• •• ••

oon000nnoonnnnonno

oorcn HoNN-Ho\r--naiHoNt--n.--1-

•

000000000000000000

000000000000000000

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

O

000HHcurc1-*nn

noc---como.oHN

000000000000000HHH

H

000HNK-4-n nCOHNK1

00000000000000HHHH

000000000000000000

000000000000000000

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

0

P

H

9

0

p_,

•.

0000nonnonnoononno

00_1.K1Hocor--HoNcot---

0

•.

••

•• •• •• •• •• •• •• •• •• •• •• •• • •

•

03

0

••

000000000000000000

00 n0-.1.w\HON00C—nrc\NHONMC—n

000H0JrcN

N-1-.4'n nOC-0DONOOHNK1

000000000000HHHHHH

000000000000000000

000000000000000000

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

0

•

••

0

4-•

•• •• •• •• •• • • •• •• •• •• •• •• •• •• •• •• 11 • •• ••

cgd

0

••

000000000000000000

000000000000000000

•• • • • • • • •

• • • •

• • • •

O

•

•

0

••

000000000000000000

oo\D-4-KNNHmo.k.o.4Hmtl....1N

ocp oHurnnot--op mallo Nt/1

00000000000000H

•• •

HO

0

,c)

••

000000000000000000

000000000000000000

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

0

1

0

0

••

oon000000goonnoong

•

M

••

••

oorrNHONN-nrrNH000t--nti-No00

000HHNIcN-1-nn

not--cococr\oHl

000000000000000HH

0

01

bD

0

M;AF-I

r-licctH

sal

C

E-4

••

.

CO

a)

COH

(1)

••

•• • • ••

+•3 •ri

HP

v-p

,C)

•lo

0

cd CD

ttO

4-

000HHNK1-4-1-no0ONMOH

0000000000000000HH

000000000000000000

000000000000000000

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

0

H

a)

••

un

4-30H

U

H0

a)

CO

too

0

oon000000000000nno

oorrNoconrcn ocontnot--HmnrcN

•

.

••

.•

••

••

••

•• ••

• •

•• •• ••• •

000000000000000000

n0000000000000000

H

rc -4- IMO CO ONO H N t4-\ Lf-N no

HHHHHHH

-25-

••

,,

.,„

Ni1:-.

.

c, •,,

-1

7 ,SI, „

•3:1

-I. 7,lj 7,

,2 0

0

0

p to

od -.4 0 0 . t0 .ci

t-- › W N

Mi 0

.1. --I

42042.-4

rciA

drAdTl.I.)

4J-0

A., cd.c1 L.,Odt--.1

. .,owtr.w.

g

CD 11100 C) CD CD C, H

n V\

HInH0 CD CD C) C) rn CD U'n CD C)

r-1 rA CM 0.1 rA

CD CD CD rA H H rA H

CD 0 0 0 0 0 0 C) CD 0 0 0 0 0 0 0 0 0 ren -..1CD CD CD CD C) CD CD C) 0 CD CD CD CD CD CD CD CD CD 0 C) CD

CS CD CD CD 0 CD CD C) CD CD CD CD CD CD C3 C) CD CD C) CD CD

CD C) CD CD 0 CD CD CD CD CD CD 60) CD CD CD CD CD CD CD CS CD

•••••••••••••••••••

a

hP rcl ,-I

rx. ,..0 0 0

0 •

-4-1

-p

rn

g-21i ,9t:

4

▪ ' 2.„2gov,

(D111111111111-111111'11

1 OH011C00111n1A1C\nW\11-\11-10000

rir-IN/C0r-1-1-01c\HIC\

X

40=',!,?,122

g4uYIEBR.V.,

U1 "1'

8 __, -P g a

ml

H H r-I i4-NCO t-- N

N

\0

•• •• •• •• •• •• •• •• •• •

0

•• •

4-,

F n-d

EC P

•-p+1a

m •

O

•,--ipor=r.a

HD p

f=4

rd

▪

6-4

.17,

O

0

d eel 41

y4,

d

. 01 FA lj

,t04,0

.

B..2 W -ct

0 lf-n tr\ to it"\ 0 0 0 0 0

trN 0 0 0 0

0 0 O 0 0 0 0 H 0 TN 0 NN 0 CO

00000000HHOOH H 0

000000000000000

00000000000Q000

0 0 0 0 0 0 0 0 0 0 0 0 000

• • • • • • • • • • • • • • •

0 1 1 1 1

++ +

+ 1 1

.9

0 N.

a

•• •

0 4

9'

ill

H

OHNK14000000000u-n

6-1 Cg K\ \D prN 0 if \ O tn,--4

0 0 •m 4)

0

•

\C)

O

•• .• •• •• •• •• •• •• •• •• .• .

0

II

H

1

4

CUCUu NteN

CU

11)

0

r 1'?

▪ci214M • 'd ?tq 5F-r

AldN rag/fl§

• 1)- LID

p)

a) A-, t4 LC".

M

• 00000000tr“Dootn0000u-\01(\000000008

ri ri ri 01 CM CU CM re\ tc\ KN.-7 .4 in in If\ IrV.0 C-00 CDN-* if\ \C:o

CD

C) C) CS CD C) CD CD CD CD CD CD C3 C) CD CD CD CD CD C3 C) CD ri ri r-1 ri r4 CV

CD CD C) CD CD CD C3 C> CD CD CD CD CD CD CD CD CD CD CD CD CD CD CD C> CD CD CD CD CD

•

CD

C>

CD

C>

C)• CD• CD• CD

C)• CD• CD• CD

C>• C3• CD• CD• C)• CD• CD• CD• CD

C)• C)•CD• C>•

i_ C)• C3• CD• CD

•

•

•

•

•

•

•

•

011 11111 111 111111111111 1111 1 1

"9

en

g

H

olivo.-1..4-opow..ocr.Nina---Hrom-Nr-mw.ow\inaloDn

c)

0 c)

CO

IUi

g

8

€13

al

d0tjA-4.02d0M

a) .0 0:1 0.1

4•3

04-2

P3

c17

NCO ON

r4

,er 0 '2 4.,

to 0

-P 5.4

• •,-4 0 H

0 a)

1'3S: 1

tele 3.1

rA H

0.1 KN.* li"\\D d-1 CV PC\

H

ri

•

r-i

P4

II

.. • • .• .6

• • • • •• •• • • •• •• •• •• •

•• •• ••• •• •• •• • •

•• •• •• •• •• •• ••I

0 0 N 0 0 LIN 0 N 0 0 0 in1[0 \-#

00

LC\ 0 In

Li-VD \D ON

0

0 K\

0 00H0inH

Qr-I0 0 - 0 0 0 0 0 0 0 0

0000000000000000000

000000000000000000

0 0 0 0 0 0 0 0 0 0 0• 0• 0• 0• 0• 0• 0• 0• 0•

• • • • • • • • • •

+ + + + + •11111111111

0

0

of

0

••

▪

4

42

* .4

4

df

a0000nu-Noon000000nnn

O-*

0

0

ro

ri 01 N'N

CO tf \

t--c0 0

cvaial

tr

HCU\

Hi

Rept. No. 2087

-26-

1:11

0

4 1.

U

co „a

E

O

to 4,

G

•

• +4

I-I

.4a

•

Fi •

to 0

4/

•

U

:70

al

1.1 no

g

E

o

to co

4

t'

u

00 0

g

E

ai

co `u

m

a) xi .74

AI 4-, to

co 4

td)

• v-I

Cd

k

bt)

I

O

r-1

ed

g

0

g

0

k

•

7111 4 I

CO 0

0. 0

r.

L.) o)

0

cd

a

td erg

on 4.;

U

m

to

(I)

•

/11 ‘34

a"

O

0 0

a.)

U

o

4-)

k

4 m

cu 0 al

•

.1:eD

fa. ""1

g

0

▪

0

0

O

Len

0

raf