IL LING LIQUOR SYSTEMS MR COLD SODA PULPINti December 1956

advertisement

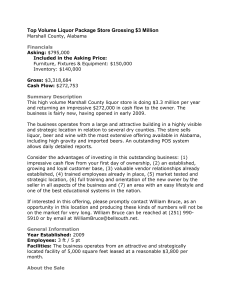

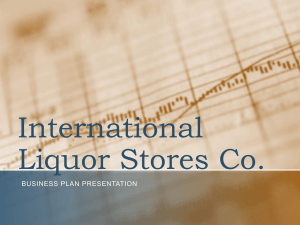

IL Viiej.:0P1 FOREST PRODUCTS LABORATORY LI BRARY LING LIQUOR SYSTEMS MR COLD SODA PULPINti No. 2059 December 1956 .FOREST PRODUCTS LABORATORY MADISON 5, WISCONSIN UNITED STATES DEPARTMENT OF AGRICULTURE FOREST SERVICE In Cooperation with the University of Wisconsin Ni;2.01 FOREST PRODUCTS MORMON, LIBRARY 1 RECYCLING LIQUOR SYSTEMS FOR COLD SODA PULPINGBy P. K. BAIRD, Chemist GIORGIO CERAGIOLI, Research Associate and K. J. BROWN, Chemical Engineer 2 Forest Products Laboratory, Forest Service U. S. Department of Agriculture Summary Comparative data on two countercurrent systems for the reuse and recycling of pulping liquors and wash waters in the cold soda pulping of aspen (Populus tremuloides) were determined. An accelerated batch pulping process was used in both systems that consisted of impregnating pre-evacuated chips with solutions of sodium hydroxide at room temperature for 10 minutes under a hydrostatic pressure of 11 atmospheres. The treated chips were fiberized in a disk mill, and the pulps were washed in a counterflow system. In one system, 13 percent of the volume of the fiberizing liquor from the previous cycle was used, together with each previous drain liquor, in making up the cooking liquor for the next cycle. Because the liquors in this partial-reuse system were recycled until the total solids content of the liquor drained from the treated chips reached 21 percent, the brightness of the washed pulp decreased from 44.4 percent to 40.6 percent, the bursting strength and breaking length of the pulp decreased about 10 and 15 percent, respectively, while the pulp yield increased from 85 percent to 89 percent. Recycling had no effect on the total amount of caustic soda consumed by reaction, which averaged about 9 percent, based on the moisture-free weight of the F 1 or presentation at the TAPPI Alkaline Pulping Conference, New Orleans, La., November 14-16, 1956. Maintained at Madison, Wis., in cooperation with the University of Wisconsin. Rept. No. 2059 -1- Agriculture Madison original wood. The amount of caustic soda in the portion of the fiberizing liquor that was not reused in this system averaged about 6 percent of the weight of the wood. There was no free sodium hydroxide in the washed pulps. These results were obtained after making the equivalent of 60 cooking cycles. In this system, water was used at the rate of 9,100 gallons of water per ton of moisture-free pulp. The other liquor reuse system was completely closed. Reusing the liquors 15 times in this system increased the total solids content of the liquor drained from the treated chips from an original 1.95 percent to a final 12.8 percent. The pulp yield increased from 88 percent to 90 percent, and the brightness of the washed pulp decreased from 46 percent to 40.6 percent. There was no change in either the strength properties of the pulps or in the chemical consumption, which averaged about 9 percent, based on the weight of the wood. Calculations showed that if the liquors in this system were renewed after every 15 cycles, the total chemical requirement would be increased to about 10 percent. The pH of the washed pulp in the closed system increased from 9.4 to 11.5 during the 15 experiments. The water consumption was 5,560 gallons per ton of pulp. The pulps produced in these tests had properties that make them suitable for use in corrugating board. Higher yield cold soda pulps to be used as groundwood substitutes in printing papers are made with lower concentrations of caustic soda– It would be expected in this case that the chemical consumption and the rate of buildup of solubilized organic matter in the liquors would be somewhat less than for the conditions used in this study. Introduction The cold soda process produces high-yield pulp suitable for corrugating medium from many hardwood species. With variations of the treatment, it is possible to obtain pulp that can be substituted for softwood groundwood pulp. Details on the adaptability of the cold soda process to species, the effects of the pulping conditions on pulp properties, and other data pn process variations have been reported by Brown and Carefully controlled caustic soda liquor-penetration McGovern. -Brown, K. J., and McGovern, J. N. Production of High-Yield Pulps from Aspen by Mild Treatment with Sodium Hydroxide. Tappi 33:364-368, August 1950. 4 Brown, K. J., and McGovern, J. N. High-Yield Cold Soda Pulps and Products from Several Woods, Paper Industry, April 1953. Rept. No. 2059 -2- FO nlEST PRODUCTS LABORATOT Lt EIHARY studies were made by Browns by impregnating chips and blocks in a pressure vessel with solutions of varying concentrations. Several levels and durations of pressure for impregnation, use of pre-evacuation, and use of several periods of retention of chemical in the chips before milling were studied. The cooking procedure may be carried out by soaking chips for about 2 hours in cold caustic soda solutions followed by disk milling refining. The treating time can be shortened-by applying hydrostatic pressure. More recent findings have shown the method to be adaptable to a fast, continuous procedure in which caustic-wetted chips are subjected to repeated application and release of pressure in a roller mill. One of the problems in connection with the application of any method has been the recovery of caustic soda from the spent liquor. An excess of caustic soda is desirable in treating the chips, and the drain liquor from the cook or treatment can be fortified and reused. The type of liquor system employed is also important because it controls the use and disposal of,chemicals and liquors used in cooking and washing the pulp. Among the possible applicable liquor systems, the two selected had countercurrent flow of chips and liquors. One reused as much of the second-step fiberizing liquor for subsequent cooking liquor volume makeup as possible, with the balance going to an available alkali recovery plant. This means that the two wash waters and fiberizing liquors move countercurrently stepwise in their entirety up to the cooking stage. The whole system is kept in volume balance by bleeding off the fiberizing liquor not required for volume makeup of the next cooking liquor. Fresh water is added at the second washing stage. This is termed the "partialreuse system." The other, although it has countercurrent movement of chips or pulp and liquors, transfers only enough liquid from step to step to meet volume requirements for the next cook. Enough fresh water is added at the washing or dilution step to replace water lost in the out-flowing pulp in. excess of the amount coming into the system with the chips. This is called the "closed liquor system." The partial-reuse system has definite possibilities where there is a suitable chemical recovery plant already available to process the excess of partially spent fiberizing liquor. The closed system is of special interest in the hope of operating successfully without a recovery plant. 5 -Brown, K. J. Aspects of Cold Soda Pulping in Relation to Penetration. Report No. 9, Committee on. Coordination of Research, June 2, 1953. Rept. No. 2059 -3- It was, therefore, the purpose of these investigations to determine the limitations of these two selected liquor systems for recovery purposes and to gather information on chemical consumptions and losses and other related data. Experimental Methods Theoretical consideration of the operation of caustic liquor systems of the partial-reuse and closed types shows that, at same point, which is different for each system and set of conditions chosen, the pulp would become unsatisfactory in quality. The number of satisfactory repetitive cooks that can actually be made with the same refortified liquors can be determined only by experimentation with each particular liquor system. To establish the process conditions that would most probably meet the Practical commercial limitations of operation, it was considered advantageous to select them from a preliminary study. Then ) with these conditions chosen, the principal studies would consist of a series'of similar cooks for each recycling system. The cooks would vary only in the reaction products present in the reused cooking liquors and in the effects of such changes in composition on chemical concentrations of the recycled drain and fiberizing liquors and wash waters, and on the yield, color, and strength properties and alkalinity of the pulp produced. Preliminary Study on Effects of Process Conditions In some of the earlier experiments on the cold soda process, the chips were treated by steeping. It was decided, however, that better control of the pulping variables would be Obtained in this preliminary study by the use of pressure treatment. Also in. this study, the fiberizing operation. was performed with the digester drain liquor, rather than. with fresh water as had been done earlier when there was no thought of recovering caustic. The use of drain. liquor in. the attrition mill prolonged the period of chemical reaction, so that less of the total treatment occurred in the digester. In. the preliminary study,• the cold soda pulping was done in. an 0.5cubic-foot-capacity jacketed digester capable of holding 4 pounds of -.This study was made by R. Singh, Collaborator, as a course requirement for the Departnent'of Chemical Engineering, University of Wisconsin, and was done in 1_954 at the Forest Products Laboratory. The complete results are recorded in an unpublished report. Rept. No. 2059 -4- wood chips. The jacket was used as a liquor reservoir for pneumatic pressure impregnation. Aspen (Populus tremuloides) chips of standard 5/8-inch size and at about 13 percent moisture content were prepared. The three temperatures chosen. were about 5°, 25°, and 35° C. to simulate varying mill conditions and give a practical range of experimentation for the temperature variable. The three concentrations of sodium hydroxide in the cooking liquor were 25, 50, and 75 grams per liter. The total liquor volume was 5.0 gallons. The cooks were of 10-minute duration at 11 atmospheres of pneumatic pressure. This treatment was preceded by an evacuation. to about 26 millimeters of mercury for a few minutes. At the end of the cook, the unabsorbed cooking liquor, termed drain. liquor, was blown, from the digester and its jacket. The chips were then. dumped from the digester into a screen box for further liquor drainage and were fiberized in. the 8-inch Laboratory attrition mill. The combined drain liquors were thoroughly mixed, measured for volume, and sampled for analysis. The drain liquor was retained for use in the attrition mill treatment. A standard setting of the attrition mill plates was selected to give the desired degree of processing to the pulp for all cooks. The.drain liquor was recirculated continuously through the mill by a pump from a sump in the tray collecting the milled chips to furnish a medium to carry the chips into and pulp out of the mill, and to dissolve and collect any residual unreacted caustic and solubilized organic matter held within the chips. This liquor was also used instead of water to restrict the volume of liquors containing free useable caustic. The fiberized pulp slurry was then pressed in a hydraulic press to a dryness of about 35 percent. The combined residual fiberizing liquor collected at the tray sump and that expressed from the pulp was measured and sampled. The pulp cake was broken up / diluted with water to a volume of 7 gallons (including the residual fiberizing liquor of about 1.2 gallons in the cake), let set for 10 minutes, and pressed as before. A volume measurement was made on the expressed wash water, and a sample was taken. The washing operation was then, repeated once more. The drain liquor, fiberizing liquor, and two wash-water samples were analyzed for free caustic soda. The residual washed pulp cake was shredded, mixed, weighed, and sampled for a moisture content determination. The yield was calculated from these data. The analyses for free alkali in the raw and cooking liquors, in the drain and fiberizing liquors, and in the wash waters were made by the usual volumetric methods. Rept. No. 2059 -5- Five of the 9 possible combinations of the 2 major variables (3 temperatures and 3 concentrations) were selected for study. These cooks were made in duplicate in some instances. The pulping data are given in table 1. The strength and other test-sheet properties of representative pulps of this study were determined by standard TAPPI methods. The pulp testing data are given, in table 2. temperature.--At a concentration of about 5 1i grams of caustic per liter, there was only a slight increase in chemical consumption, between 26° C. and 34° C. under the conditions of these experiments. Unfortunately, the data for the consumption at 8° C. were not obtained, so a wider range of temperature effects could not be evaluated. The combined consumption of chemical in the digester and in. the mill showed no regular trend, but these data were not exact because of an intermittent plugging of the attrition mill with consequent temperature rises of as much as 30° C. in some instances. The plugging was caused by an inadequate volume of liquid to carry the pulp out of the mill. Effects of The effects of temperature an pulp properties were more evident. Data are given in table 2 for the temperature range from 8° C. to 34° C. At approximately the same total chemical consumption of 13 percent and strength properties of the pulps, at about the same yield of pulp, except tearing resistance, showed increases with temperature increases. The tearing strength remained constant. Effects of chemical concentration.--The chemical concentration was varied from 25 to 76 grams of caustic soda per liter at about 26° C. As shown, in table 2, an. increase in concentration increased the caustic consumed from 7.6 to 16.3 percent, on. the moisture-free wood basis. The pulp yield was reduced from 86 to 78 percent, while the amount of residual caustic in the pulp increased. In. the standardized recycling and washing system described earlier, the amount of residual caustic, although small, increased as the chemical concentration, in. the digester was increased. All strength properties of the pulps were markedly lower for each increase in chemical concentration, and suffered an overall average loss of about 50 percent. Significance of Results It can, be observed from this preliminary study that (1) the volumes of liquors in each step, number of cycles, and concentrations for the particular recycling and washing system chosen should be adjusted to achieve a minimum final residual caustic content in, the pulp and still produce a satisfactory product; (2) from a strictly economical standpoint, it is advantageous to operate at the lowest feasible chemical concentration; (3) the pulp strength values increase (in. the range of Rept. No. 2059 -6- 86 percent) with increase in yield caused by reducing the chemical concentration; (4) the amount of fresh wash water required increases with increasing chemical concentration in the cooking liquors; and (5) the residual alkali can be washed from the pulp quite easily. 78 to Partial Reuse of Fiberizing Liquor with Countercurrent Liquor Flow 0 The flow diagram for a partial-reuse and recycling system for liquors and wash waters designed to operate in a mill with a recovery plant for alkaline spent liquors is shown in figure 1. The amount of liquor from the fiberizing operation that would not be needed for volume makeup of cooking liquor for the next cook would be diverted to a recovery plant. Four pounds of aspen chips (moisture-free basis) and 4.0 gallons of caustic soda solution at 55 grams per liter were used. The moisture content of the chips was 45.5 percent : which added an additional 0.3 gallon, and brought the chemical concentration down to the desired 50 grams per liter. The digester was evacuated to a pressure of 26 millimeters of mercury before the pneumatic impregnation of the chips at 11 atmospheres for 10 minutes, The temperature was held at 25° ± 1° C. At the end of this treatment, the excess cooking liquor was blown from the digester and its jacket, and the chips were dumped from the digester into a screen box for drainage of any surface liquor. The drain liquor, which averaged 3.1 gallons, was sampled and combined with 0.9 gallon of used fiberizing liquor for volume makeup. The caustic content of the combined liquors was raised to the desired 55 grams per liter by the addition of caustic soda flakes. This solution was used as the cooking liquor for the next cook. After the chips drained for a few minutes, they were passed through an 8-inch attrition mill under conditions previously selected to give a freeness of about 700 milliliters, Canadian Standard. The volume of liquor added to carry the chips through the mill was 5.8 gallons, which, together with 1.2 gallons of residual cooking liquor in the chips, made a total of 7.0 gallons in the fiberizing unit, thus making the fiberizing consistence 6.5 percent. The first wash water from the previous cook was used as the fiberizing liquor. It was obtained by pressing the pulp from the attritionmilled chips in a hydraulic press to about 30 percent dryness on a moisture-free basis. This first wash water was the "second wash" water of the previous cook. The pulp from the mill was discharged into a screened drainer and tray, from which the liquor was recirculated to the mill by a centrifugal pump. At the end of the fiberizing operation, Rept. No. 2059 -7- the pulp was pressed to a dryness of about 30 percent. The expressed liquor was combined with the recirculated liquor to yield a volume of about 5.7 gallons of fiberizing liquor, which was analyzed for residual caustic, total solids, and specific gravity. As previously explained, about 0.9 gallon was used as liquid makeup for the next cooking liquor. The balance, or about 4.9 gallons, was withdrawn from the system and would be sent to the recovery plant in commercial operation. The pulp cake from the pressing operation was broken up in a 15-gallon capacity can. for the "first washing" operation. The liquid added came from the second washing operation of the previous cook. After a thorough mixing with a mechanical stirrer for 3 minutes, the pulp slurry was allowed to set for 5 minutes for further extraction of any caustic from the fibers. The pulp was then dewatered to 30 percent dryness in a hydraulic press. The expressed liquor from this operation was termed "first wash water," and was reserved for use as fiberizing liquor for the next cook. It was also analyzed for amount of caustic soda and total solids. The pulp cake was again broken up in a can. for its second and final wash to remove caustic soda. Fresh water (7.4 gallons) was'added to give a consistency of 4.7 percent. After it was stirred, as in the previous washing, the pulp was pressed to remove wash water for reuse in the next cook as first wash water. The balance of the liquor was used to hold the pulp slurry at about 4 percent consistency for subsequent operations such as bleaching or refining in the attrition mill. In this study, the pulp was then. pressed to about 30 percent dryness for yield determination and subsequent strength tests. Results of Partial Reuse of Fiberizing Liquor In table 3 may be found the values for the caustic content total solids, alkalinity, and specific gravity of the various liquors used in this study. In. addition,, the yield and brightness of the pulps were recorded. The data were used to develop the quantitative relations for the distributional changes of chemicals from cook to cook as shown in tables 4 and 5. In. series I of the study, which consisted of 12 identical cooks, the buildup of solubilized organic matter in the cooking liquor was slow, as indicated in columns D and E of table 4. To accelerate the rate of buildup, eight additional cooks (series II) were made in which all the fiberizing liquor of each was concentrated by evaporation to the proper volume and used for the makeup. Concentrated liquor from another source was also added to cycle 19. Rept. No. 2059 -8- The values for the properties of the pulp from the last cook in. series II were used to establish the tolerable limit of contaminating organic matter for an acceptable product. As shown in table 3, the total solids in. the drain liquor had built up to over,2O percent. The high viscosity of the cooking liquor made from the drain liquor apparently lowered the diffusion rate of the caustic into the chips, with a consequent reduction in. proper penetration. Examination of the chips showed large, raw centers. This so reduced the pulping action that the yield increased to 89 percent (table 5, column P), and the brightness dropped from 44.4 percent to 40.6 percent (G.E.), as shown in. table 3. The chips contain free caustic and the caustic-combined organic matter (table 4, columns I : J, K, and L). No doubt a part of the solids is sodium carbonate, but some of the principal constituents probably are sodium acetate, sodium uronate, pentosans: and other hemicellulosic materials, and possibly a. small amount of lignin and sodium lignate. Under one hypothesis, the caustic penetrating the chips could be taken. as only that present in the part of the cooking liquor that penetrated the chips. This value can. be calculated from the volume difference between the drain. liquor and the cooking liquor. The value (column J, table 4) for the caustic actually penetrating the chips, which was obtained by difference between. the caustic content of the cooking liquor and that of the drainaiquor, was found to be greater than the hypotable 4) based on loss of cooking-liquor thetical value (column volume. Since the point of removal of liquor for reuse was at the discharge from the attrition, mill : a tabulation of the approximate amounts of all materials entering and leaving the mill was made. These values are Shawn in tables 4 and 5, and are summarized in columns M, N, and 0 of table 5. The soluble materials entering the attrition. mill are in. and on the chips and in. the previous first wash water (table 5, column C) used as the milling liquor. The milling or fiberizing liquor is the first wash water of the previous cook plus the cooking liquor in the chips. Thus, the free caustic and residues of solubilized organic matter removed from the two previous pulps in. their second and first wash waters are added at this point. The methods for calculating or determining the amounts of solids present in the various liquors and the amounts reused are indicated by formulas below the column headings in tables 4 and 5. The overall solids balance for the attrition mill is also roughly indicated in columns M, N, and 0 of table 5. Organic matter buildup.--In series I, the amount of solubilized organic matter present in, the drain. and cooking liquors increases gradually with each cycle. The composition of the fiberizing liquors coming from the attrition mill is shown in columns A through F in table 5. The values in. column F, table 5, show a small gradual increase through the Rept. No. 2 059 -9- series that is probably due to an increase in the amount of solubilized organic matter returning in the wash water and that which was carried along on the surface of the chips. There is a more definite, but not a great, increase in the total solids in the fiberizing liquor, as shown in. column B, table 5. The cooking liquors show a gradvial buildup of solubilized organic matter, as indicated in columns C, D, and E of table 4. In all cases, the maximum useable volume for makeup of the next cooking liquor, or 12.85 percent of the fiberizing liquor, was combined with the drain. liquor. Returning with this fiberizing liquor would be 12.85 percent of the solubilized organic matter present in all the fiberizing liquor. The average value for this quantity for the balance of the series other than for cook No. 3116X was 338 grams, which is obtained by reducing the average of column F, table 5, by the average value for column E, table 5. Again, the same quantity is obtained if the average value for the combined sodium ion, value (88 grams), column K, table 5, is added to the average wood loss of 250 grams, as calculated from column. H, table 5. Therefore, 338 grams of solubilized organic matter produced in each cook seems to be a firm average value, and 12.85 percent of it would be returned each time with the makeup liquor. The actual amount for each cook is recorded in column B, table 4. In. visualizing the mechanism of cooking under the conditions of the two hypotheses were evolved. Under hypothesis experiments in series an amount of solubilized organic matter up to as much as that present in 22.5 percent of the cooking liquor that penetrates the chips could pass on to the fiberizing liquor after the chips are milled. The data in. columns C, G, and K are based on. the value of 22.5 percent. there would be no impregnation of solubilized Under hypothesis organic matter into the chips, but some would diffuse or kick back from the reaction into the cooking liquor and be retained in the drain liquor. The first hypothesis was tested by comparing the directly calculated data on amounts of solubilized organic matter with the actual data in. table 4, and by calculations from equations. The derivation of the direct data are shown in the subhead for each column, C, G, and K in this instance. Although the data in column D, table 4, are incomplete, they do not agree, even roughly, with the calculated data for the cooks in column C I as developed under hypothesis I. Thisiis also true for the amounts of solubilized organic matter in the drain liquors, as shown by comparing column G with 'column H, table 4. It may be seen that the actual values for the solubilized organic matter present in the cooking liquor and the drain liquor for any particular cook are considerably greater than those calculated directly under this first hypothesis. Rept. No. 2059 -10- A more precise evaluation of hypothesis I on a mathematical basis was attempted by means of equations that are developed in the Appendix to this report. The basic relationships of proportions and movements of the solubilized organic matter are expressed in the various equations. The accumulative amount of solubilized organic matter present in the cooking liquor for each cycle, Sn, was found from equation (4): Sn , am (1-rn) 1-r These data, ' when calculated under the assumption of a 22.5 percent impregnation of solubilized organic matter from the cooking liquor into the chips : were considerably lower than those in column C, and only a fraction of the actual data in column D. The value for the accumulated solubilized organic matter for the eighth cycle (n = 8) was calculated to be only 173 grams. Also : if recycling were continued indefinitely: the maximum amount of solubilized organic matter that it would be possible to accumulate in the cooking liquor / according to equation (5)2 would be 221 grams. Again : assuming a nominal value for b of 0.01: which represents 1 percent of impregnation, the S 8 value for equation (4), that is, the amount of solubilized organic matter accumulatedin the cooking liquor for the ninth cycle, was found to be 333 grams. This is still considerably less than the actual data value of 518 grams given in column. D. These calculated results, then, constitute a second basis for rejection of hypothesis I. It can be concluded : therefore: that the assumed conditions in this hypothesis did not represent the actual cooking mechanism and movement of chemicals. an equation representing the To test the validity of hypothesis quantitative relations set forth in this hypothesis was also developed. The mathematical expressions are given in the Appendix. Under this hypothesis, it is assumed that there is no impregnation of solubilized organic matter into the chips, but that there is diffusion of this matter out of the chips into the cooking liquor. The value for S at each cycle was obtained by using equation (9) : and is shown in column E : table 4. The particular value of 0.046 for d„ which was obtained from equation (12) : was used. It represented 4.6 percent of diffusion. It was used so that the value for S 10 in equation (9) would exactly equal the actual value for solubilized organic matter as given in column D for cook No. 3132X, or cycle 10. The data for this cook were deemed the most accurate at that point in the series. The deviation of the values in column E from column D, where data is available for comparison : is not large, and the table trends are similar. 4, the viscosity of the cooking liquor had inAt the end of series creased to the point where a noticeable amount of coating of the chips Rept. No. 2059 -11- occurred. This condition would carry some of the solubilized organic matter present in the cooking liquor along on the chips to the attrition mill and fiberizing liquor. Only 12.85 percent of this transported matter would be returned to the drain liquor, while the balance would be discarded. Consequently, it could be expected that the conditions of hypothesis I might exist to a small degree simultaneously with those of hypothesis II, and the residual solubilized organic matter in the drain liquor and cooking liquor would not build up quite so rapidly. Also, diffusion out of the chips could stop, which would carry additional organic matter into the fiberizing liquor. These conditions could account for the larger differences between values in columns D and E toward the end of the series. From the close agreement of the values calculated from the mathematical expression of conditions under hypotheses II with the actual data, it is evident that this hypothesis is reasonably representative of the mechanisms involved in this pulping process. In series II (cycles 13 to 18), where all the solubilized organic matter was returned in the concentrated fiberizing liquor, the amount of such matter increased from 641 grams to 930 grams (table, 4, column B). An additional amount Of solubilized organic matter from a previous series was added to the concentrated fiberizing liquor from cycle 18. This produced a large increase in solubilized organic matter in the drain and fiberizing liquors from cycle 19 used in the cooking liquor of cycle 20. At these high concentrations of solubilized organic matter in the cooking liquors, the highly viscous liquor left a heavy coating on the surface of the cooked chips. This coating was carried along to the fiberizing operation, and probably explains some of the loss of solubilized organic matter from the cooking liquor, as indicated by comparison with the drain-liquor analysis (table 4, columns D and H). Also, it is probable that the diffusion of solubilized organic matter from the chips into the cooking liquor had ceased at this point. As a result of these high concentrations of solubilized organic matter, the penetration of the chips became incomplete and the brightness and velity of the pulp from cook No. 3159X was unsatisfactory. About 3,366 grams of solubilized organic matter, as shown in. column D of table 4, in 4.0 gallons of cooking liquor used to cook 4.0 pounds of chips was therefore considered the practical limit. This is 222 grams of solubilized organic matter per liter, or about 19 percent on a liquor weight basis. Tolerable maximum number of cooks.--A study of the amounts and distribution of the solubilized organic matter in the cooking liquors, as shown. in columns D and E, table 4, indicates the progressive rate of buildup to the maximum tolerable limit (cycle 20) for the production of pulp with acceptable properties for corrugating purposes. Rept. No. 2059 -12- The amounts and distribution calculated under hypothesis II were reasonably close to the actual data available for comparison. Under the con, ditions of the experiments, there was a gain of 57 grams of solubilized organic matter per cycle in the cooking liquor. With a limit of 3,366 grams of solubilized organic matter, it would be possible to make about 6o cooks before this value was reached. Then, a part of the drain liquor would need to be discarded and replaced with fresh liquor after each cook. where all the If the liquor system were operated as in series fiberizing liquor from each cook is evaporated to makeup volume and returned to the cooking liquor, the maximum number of cooks would be con, trolled by the total solubilized organic matter produced in each cook, which is 338 grams. This value, then, would produce the limit in. about 10 cooks, after which new cooking liquor would be required. Effects of recycling on pulp properties.--The brightness of the pulps gradually decreased in the series from 44.4 percent to 4o.6 percent (G. E. equivalent) as the dissolved solids going along with the chips' increased. As indicated in table 3 (cook No. 3153), the difference between the total solids and the caustic soda content in the wash water (W-1) was about 0.3 gram per liter, which would represent the solubilized organic matter at that point in the washing of the pulp. A second washing removed all the free caustic, but there was still an alkalinity of about 0.7 gram of sodium carbonate per liter. Apparently, the exposure of the pulp to the air during the second washing converted any residual caustic to carbonate. The effect of recycling, that is, the increase in solubilized organic matter in the liquors, on the strength and other properties of the pulps is shown in table 6. It was felt that the bursting, tensile, and tearing strength values would be most significant when compared at three freeness levels. Also, the brightness, pentosan and lignin contents, and yields are indications of the effects of any buildup of solubilized organic matter, and the degree of its removal from the pulps by washing. From table 6, it may be seen. that there was no marked effect of increase of solubilized organic matter in the cooking liquor on the strength properties of the pulps at three commonly used freenesses. The pulp from the fresh-liquor cook (No. 3116X) was slightly superior to those of the subsequent cooks with liquors containing from small to moderate amounts of solubilized organic matter. In the final cook (No. 3153X), however, where a maximum tolerable amount of organic matter was present in the cooking liquor, the properties were definitely reduced, although not seriously, at the same freenesses. When the pulps were compared at similar sheet densities, only the tearing resistance was lower. This effect could be due to a lower sheet density being obtained from pulps of the same freeness when the fibers contained sane of the pulping residues. There was little change in the Rept. No. 2059 -13- lignin content, but the pentosan value increased 3.3 percent. The pentosan value of 17.6 percent at a yield of 89.2 percent, when calculated on the basis of original wood, becomes 15.7 percent. Thus, 2.9 percent of pentosans were removed by cooking. Consumption and loss of caustic.--The consumption of caustic for each of the cooks is given in columns P and Q of table 4. These values were calculated from the data given in columns M, N, and 0 of table 4. There was little change in the percentage of caustic that reacted with the wood from the first to the last cycle. The values ranged between 7.4 percent and 9.8 percent. It would appear that the increase in yield of pulp, as shown in column P of table 5, was due to reaction residues left or deposited in the pulp rather than to lower reactivity of the caustic on the wood. In addition to the average consumption of 8.4 percent of caustic during cooking for the series where 12.85 percent of the fiberizing liquor was returned for cooking liquor volume makeup, an average loss of 7.3 percent of free caustic would occur by discarding the balance of the fiberizing liquor. Also, after about 6o cooks, 2 percent of the drain liquor would have to be discarded to continue operation, which would be an additional loss of 0.6 percent of free caustic. The total caustic requirement, therefore, would be about 16.3 percent, based on the wood. Significance of Results It is evident from the results obtained by partial reuse of fiberizing liquors that the conditions of experimentation followed in this study, where a relatively large amount of caustic was applied to the chips, would be suitable for economical operations only in conjunction with some kind of a recovery system. The original concept of operation for a small cold soda plant obviously did not include a recovery plant. Further work must be done to determine the feasibility of removing the solUbilized organic matter from the saturated drain liquor. Another purpose would be to recover valuable components of the wood that could be processed to yield furfural or other chemicals. Complete Recycling of All Liquors With Single-Stage Pulp Washing Most of the process conditions for this study were the same as those for the partial-reuse system. The differences become evident when the flow of liquors in the two systems shown in figures 1 and 2 are compared. In the partial-reuse system, shown in figure 1, some of the fiberizing Rept. No. 2059 -14- liquor is used for volume makeup for the next cooking liquor. This is also true for the closed system (fig. 2), but here the similarities cease. The fiberizing liquor in the partial-reuse system was completely replaced for each cycle by using the first wash water of the previous cook. For the closed system, the fiberizing liquor is repeatedly reused, except for a part that • is removed for makeup of the next cooking liquor. The fiberizing liquor is then restored to volume for the next milling by the addition of a part of the wash water from the previous cook. In the partial-reuse system, the first wash water consists entirely of the second wash water from the previous cook, while in the closed system, the first wash water is used repeatedly. The portion that is removed for fiberizing liquor makeup is replaced by fresh water. As in the first system, the second wash of the second system consists of fresh water, but, in addition, it serves as dilution water for transport of the pulp to the next process. The results of the previous study were used as a guide in choosing the following cooking conditions: For 11.0 pounds of aspen chips (moisturefree basis), 4.22 gallons of caustic soda solution were used at a concentration of about 31.6 grams per liter. The moisture content of the chips was 36.6 percent (green basis), which added an additional 0.277 gallon to the system, and brought the chemical concentration down to the desired 30 grams per liter. Because three different batches of chips were used, each with a slightly different moisture content, the volume and concentration of the liquors had to be varied somewhat for concentration standardization. The digester was evacuated, as it was in the partial-reuse system, before the chips were impregnated with the cooking liquor at 11 atmospheres of pressure for 20 minutes. The balance of the cooking, fiberizing, and washing procedures were similar to those of the previous study. The pressed pulp cake was broken up into a 15-gallon-capacity can for a single washing. The wash water used came from the previous cook (1.8 gallons) plus about 1 gallon of fresh water to replace an equal amount of the wash water that had been drawn off for use in the next fiberizing-liquor makeup. After a thorough mixing and dewatering to 30 percent dryness in a hydraulic press, the pulp cake was again broken up into a can for its final dilution, which in effect corresponded to a second wash. Fresh water (about 9.0 gallons) was added to give a consistency of 4.0 percent. The pulp was again stirred and then pressed to remove the dilution water. The expressed water was sampled and tested for alkalinity and pH value. In a commercial operation, this pressing would be omitted, and the pulp slurry would normally be pumped to a bleach plant or paper mill after it was neutralized or treated. In these studies, the pulp cake was pressed to about 30 percent dryness for yield determination and titration Rept. No. 2059 -15- of a sample for residual alkali in the pulp. Calculations were made to show how much sulfuric acid would be required per ton of pulp to neutralize the residual caustic. Results With the Closed Liquor System In. this group of experiments, which consisted of 15 cooks that were identical in all respects except for the increasing amount of organic matter in the cooking and other liquors, the effects of a closed liquor system were rather pronounced. The data on the composition of the liquors are given in table 7. All cooks had practically the same adjusted starting concentration of about 30 grams of caustic soda per liter. There was sane variation in the causticity of the drain liquors and first wash water from cook to cook that was no doubt due to temperature variations within. the attrition mill that affected the rate of reaction. The specific gravity and total solids of the three kinds of liquors showed a gradual increase through the series, indicating the accumulation. of caustic and dissolved organic solids. The closed-system liquors became more nearly saturated with solubilized Organic matter at the twelfth cycle than did the partial-reuse liquors. Further comparison. is not possible because of the accelerated loading of the partial-reuse liquors with solubilized organic matter after the twelfth cycle. Also in the closed-system series, the pulp characteristics had not deteriorated to any great extent at,the fifteenth cycle. The pi-milled chips had not been properly penetrated, however, as evidenced by the raw centers, which indicates the necessity of further reaction in the attrition mill, with increased power requirements. The final pulp brightness of the closed systom reported in table 8 showed a disproportionate drop in relation. to the total solids content of the drain liquors (tables 7 and 3), however, when compared to the final pulps of the previous study (table 6). The amounts of caustic consumed from cook to cook did not change in any regular fashion or to any marked degree. The average value for the series was 8.5 percent. Two percent of caustic was lost in the drain and fiberizing liquors and in the wash water discarded from the final cook that would be included under the closed system of liquor reuse, bringing the total alkali consumption to 10.5 percent. The alkalinity of the pulp gradually increased from a pH value of 9.4 to 11.5 for the final cook. The yield of pulp increased very slightly from 88.1 to 90.5 percent. These and other test data on pulp properties are given in table 8. Rept. No. 2059 -16- If the process conditions used in this closed-liquor system study were followed, about 5,560 gallons of water would be required per ton of pulp product. This is a very favorable factor in same areas. Significance of Results The decision as to the maximum number of cooks that could be made with one batch of liquor under the closed liquor system was based on the poor penetration of cooking liquor into the chips and on the high alkalinity of the pulp from the last cook (cycle 15) of the series, as well as the build-up of organic matter in the drain liquor and the pulp quality. The data in table 7 indicate that 38 pounds of sulfuric acid per ton of pulp would be required for neutralization of the residual free alkali. Also, the properties of this pulp approached the least acceptable standards set in the partial-reuse system study. It would seem, therefore, that only about 15 cooks could be made under the closed liquor system before the liquors would have to be replaced. Under these circumstances, the question of periodic replacement of liquors arises. Such operations are not in accord with usual industrial practices. Continuous instead of periodic withdrawal of drain liquor to hold down the amount of solubilized organic matter, however, would remove a disproportionate amount of free caustic, and could make the operation uneconomical. These facts, then, indicate the need for some kind of a recovery system for the periodically discarded liquors. The pentosans might be removed and marketed, and the free caustic recovered if the plant produces liquors in sufficient quantity, or the alkali in the liquors could be utilized by the pretreatment of raw chips. The residual organic matter might then be removed by ponding, or it could be concentrated and sprayburned for fuel. Obviously, further research is indicated to develop such ideas. Conclusions The conclusions for the two systems for liquor reuse and recirculation were drawn on the basis of the following specific conditions of experimentation: Chemical concentrations of 30 and 50 grams of caustic Rept. Uo. 2059 -17- soda per liter, applied for 20 and 10 minutes, respectively, at about 25° C.; an impregnating pressure of 150 pounds per square inch (gage) after evacuation to about 25 millimeters of mercury for 5 minutes; a liquor-to-wood ratio of about 5 to 1 in the digestion zone; and a degree of digestion to give about a 90 percent final yield of pulp suitable for corrugating board. System applicability.--Both methods of reusing and recirculating the liquors appear to be feasible. One requires the availability of a chemical recovery or disposal unit, while the other possibly does not, but functions as a closed system requiring a complete renewal of the principal liquors periodically. Pulp alkalinity.--An alkali-free pulp can be obtained with two stages of countercurrent washing under the partial-reuse system, where a maximum of about 13 percent of the fiberizing liquor can be utilized for cookingliquor makeup. In the closed liquor system, the pulp produced has a high residual alkalinity (pH 11.5) due to free caustic soda. Chemical consumption and loss.--The average chemical requirement for cooking under the partial-reuse liquor system is 8.4 percent, on the basis of moisture-free wood. An additional 7.3 percent is lost in the discarded portion of the fiberizing liquor if a recovery plant is not available. Also, after about 6o cooks, 0.6 percent more caustic is lost with the discarded drain liquor (it would be necessary to remove 2 percent of the drain liquor after each cook to maintain a solids balance). The total caustic requirement, therefore, is 16.3 percent. If a consistency higher than 6.4 percent is used in the fiberizing operation, the fiberizing liquor can be reused more times, with a consequent reduction in chemical losses. More solubilized organic matter will be returned to the cooking liquor, however, which in turn will reduce the number of cycles before unsatisfactory pulp would be obtained. For the closed liquor system, the average chemical consumption is 8.5 percent. To this value must be added a 2 percent loss with the periodic discarding of the drain and fiberizing liquors and wash waters after about 15 cycles. A total of 10.5 percent of caustic is therefore required for this type of operation. For groundwood substitute pulp, the pulp need not be neutralized, and some of the caustic could be charged to the bleaching operations, which require a high alkalinity. Reuse cycles.--The number of times that liquors can be reused before a certain maximum concentration of solubilized organic matter accumulates in the cooking liquor can be calculated from the mathematical equations developed for any set of reuse conditions. If all the fiberizing liquor is reused, either after it is concentrated to required makeup volume or as in the closed system, then about 15 cooks, based on final corrugating Rept. No. 2 059 -18- pulp quality, can be made. If about 13 percent of the fiberizing liquor is reused for volume makeup, then as many as 60 cooks can be made with a single batch of liquors before additional discarding of some drain liquor is necessary. Water requirements.--A total of about 9,100 gallons of fresh water per ton of pulp would be required to give an alkali-free pulp with the partial-reuse liquor system. For the closed system with one stage of washing, a total of about 5,560 gallons would be needed. The pulp produced would be highly alkaline, however. These values include the final dilution of the pulp for pumping to the next process. Process feasibility.--Prom the standpoint of caustic losses alone, the closed liquor-reuse system is considered to be economically feasible without a chemical recovery plant, provided a periodic type of liquor disposal and renewal is practiced. This requires the tolerance of some variability in pulp properties during each disposal cycle, and an unusual procedure for operating a pulp-mill liquor system. Only about 15 cycles of reuse are possible, however, before the quantity of solubilized organic matter in the cooking liquors inhibits good pulping. The problem of disposal of the loaded and discarded liquors has not yet been solved. The partial-reuse system is not feasible without a recovery plant, especially because of the high chemical losses, and, to a degree, from the liquor-contamination standpoint. Theoretical calculations based on data from other work indicate that continuous pulping systems would have about the same limitations in the reuse of liquors due to their eventual contamination with solubilized organic matter. Continuous operation holds the greatest promise, provided the continuous disposal of a part of the liquors can be tolerated. Rept. No. 2059 -19- APPENDIX The derivations of the equations expressing mathematically the relations stated in the two hypotheses are given in this Appendix.' These equations were used to evaluate the results and confirm or disprove the mechanisms controlling the cooking (impregnating) of wood chips with caustic soda solutions by the cold soda pulping process. The cold soda process is a two-phase system of liquid and-solid (chips), with the solid being impregnated with a part of the liquid phase. The chips are removed from the impregnating operation and reduced mechanically to fibrous form in another liquid. The liquid is then pressed from the fibrous solids, and a part of it is retained for subsequent use in the next cooking liquor. This part carries with it some of, the soluble extracted reaction product, which is then present in the next cooking liquor. The process is repeated over and over with new chips, reusing the same liquors refortified with dry caustic until the pulp is no longer acceptable due to contamination with the reaction residues. Hypothesis I Under hypothesis I, it is assumed that: (1) any amount of the reaction residues, up to all present in the part of the cooking liquor that penetrates the chips, is impregnated into the chips; (2) a certain negligible amount of the reaction residues diffuses out of the chips into the cooking liquor; and (3) a part of the fiberizing liquor, containing a portion of reaction residues, is reused for volume makeup of the next cooking liquor. Let m represent the total reaction residue from one cook; a the part of the residue in the fiberizing liquor returned for reuse; b the part of the residue in the cooking liquor impregnated into the chips; and 1-b the part of the residue left in the drain liquor. The following values for the, quantities are constant: m = 338 grams; a = 0.1285, or 12.85 percent; and b = 0.275, or 27.5 percent. From the first cook, the amount of residue returned with the fiberizing liquor makeup for the second cook is am grams. For the second cook, the amount of reaction residues impregnated is bam, while that retained in the drain liquor is (1-b)am. The amount returned for the next cook is a(m+bam) grams. For the third cook, the cooking liquor contains (1-b)am + a(m+bam), or am(2-b+ab) grams of residue. The amount impregnated is bam(2-b+ab), while that remaining in the drain liquor is am(1-b) (2-b+ab) grams. The amount returned for the next cook is: a(m+bam 2-b+ab)). Rept. No. 2059 -20- The amount of reaction residues present in the cooking liquor of the fourth cook is then% am(1-b) (2-b+ab) + a[m+bam (2-b+ab)] or, am [1 + (2-b+ab) (1-b+db)] grams. From the fourth cycle, the amount returned is expressed by the quantity: am(1 + [1 + (2-b+ab) (1-b+ab)] (1) (1-b+ab)) If r is equated to (1-b+db) then the above quantity (1) can be expressed (2) as: am(1 + [1 + (l+r) r] r) or, am(1 + r + r 2 + 1-1 ) grams. For the n th Rycle then, the amount of residues returned is: + r) + ----rn-1 ) grams. am(1 + This is a geometric series, the equation for the sum of which is: s n = am (1-rn) 1-r If the process is carried on indefinitely, then the amount of reaction residues returned from each cook approaches the value for S with n at infinity: co am _ 1-r grams (5) To determine the number of cycles, n, required to raise the amount returned to the value for S n , the following equation, derived from equation (4), is applicable: Sn (6) n log [1 - Fru (1-r)] log r For the value of a that will result in a certain value for S when n is infinite, the following equation applies: b a- m+b grams (7) am grams (8) Or, for b, given So: b Rept. No. 2059 1 - a -21- Sop Hypothesis II Under hypothesis II, it is assumed that: (1) none of the reaction residue penetrates the chips during cooking; (2) some of the residue diffuses out of the chips into the cooking liquor around the chips; and (3) a part of the fiberizing liquor, containing a portion of reaction residue, is reused in the next cooking liquor. Let m represent the total reaction residue from each cook; d the part of residue diffusing back into the cooking liquor that becomes drain liquor; the balance, or 1-d, the part present in the fiberized chips (pulp); and a the part of (1:a7m that is returned with some of the fiberizing liquor TO the drain liquor for volume makeup. In the first cook, dm grams are removed by diffusion from the chips into the cooking (drain) liquor, and am(1-d) is returned in the fiberizing liquor to the drain liquor. The cooking liquor of the second cook, therefore, contains dm + am(1-d) grams of residue. Its drain liquor contains dm + [dm + am (1-d)] grams. The cooking liquor of the third cook contains dm + [dm + am (1-d)] plus a returned amount of am (1-d) grams. Its drain liquor contains: dm + dm + [dm + am (1-d)] + am (1-d), or 3dm + 2am (1-d) grams. The cooking liquor for the fourth cook contains: 3m [d + a - ad] grams, while that for the fifth cook contains: 41:11 [d + a - ad] grams. For the n th cook, then, the residue in the cooking liquor is equal to: Sn = m(n-1) (d+a-ad) grams. If the quantity (d4a-ad) is equated to T;-1 i r, then: "inns. Solving equation (9) for n, r, and d gives: Sr, n = MY - + 1 r = Sn m (n-1) Rept. No. 2059 d r-a 1-a -22- 4-, 0 a) ;-4 a) (0 H CO On t-- t— El 4-) (I) pl co •n • •• •• •• •• •• •• •• •• •• •• UN CO • • Cr) ON 0.1 F-1 ro N Cr) k0 • • LC\ CV CV H • N H 0 0 • • LIN • 0 .0 o bk.) , v 92 al o• 0 •• H (a 0 rd rd H El • rs rd I td — a) n-1 01 'd '0 03 • 0 , 5 n--1 di 05 •r-I In H rd Pa o o co 1.11 l0 -P 1 N a) a) -0 O F-I 1.0' rl: a) 0 .0 •01 14 •• • c+-1 (1) U] m". 0 0 00 Ft • O (Y) a) 0 k a) o a) 0 FA w A 1 0 -1-3 t30 9-1 al 40 0 0 !a •r1 o 0 0 q r)-• •• 0 E' 4, a) ri a) A) 0 .121k a) rd a) .• •4.11 • •• •• P-1 •• 0 C.) q-1 • - 43 P 0 (/) •• •• • • •• a) CLI •• •• •••• •• •0 0 co UN Pi •• •• •• •• •• Fri a) P.1 •• •• • •• k4-3 0 Cr) • 0 H 0 d 4, H 0 4-, 0 E-1 a3 a) .• 9 m 0 \ H bo 0 .0 9 rJ ,-1 o 0 A rd •N 0 4-, 4-, 0 a) ;0-1 a) Pi •• •• •• •• •• •• •• a) N ja0 rd 0 0 •N • . • • • (Y.3 (Li), • co o Is% o • • •• ,4 N • • cn •• 8(y-, UN 0 CV • —I •• 1rN CO •• •• ON IA ON Cr) •• •• • 0 P 41 . 14 0 -P H a) 0 0 0 0 0 0 A •• • Oca 0; C) k 0 0 0 0 Fl 0 H 0 0 al 0 01 40 a) •r-i -P H 0 .0 0 09 (1) 100 ND • 0 •01 n-1 0 ti • ON 0 -P 3--P k0 N 1 k 4-/ 4-) r'''s " CH 0 0 N N t— 4.) •• •• •• •• •• •• •• a) I •1 c_) 0 pi 4-3 •• •• •• •• •• •• •• •• •• in 1/40 •• 4-, 30 9-1 4-, n-1 0 03 0 n-1M 0 0 FA rd C) €.4 0 al 4-1 P4 0 > q FA a) P40 I 0) CD 0) CD 0 •• 0 \ u •• •• •• -.1Crl ••• M 0.11 4-, C 1:1 ° t4 c\ 0 0 H cn r-4 cY1 as 0 • •• 0M 00 • n-1 0 0 a) -1-) -1-) -11-1 1-113 cal) 4-, ttO 0 F-1 oan 0 0 0 0 04 a) F-1 0 ••-1 4-3 • .0 0 Pr C— o .0 0 Pta a) W cr) i 0 CD -H 0 0 a) 14 k rd $4 fa, I al 4-i 0 0 -P 0 H 0 0 N N .H0 U1 0 E.:(1-1 . a) a) 1 a) bD •• • -1-) 0 00 00 X0 Al 0 I at 0 a) 34 Pr I-1 40 0 r21 0 0 H 0 0) Cd (1) 4) 0 t1) " 0 0 0 34 H H 0 0 -ri 'd 0 4-1 rd 0 rd .0 q-i • nC) Cr) H H H 0 -1 • In 00 4-, 0) 0 •• 0 I-1 a) H H 0 rd bD F.-I 0 •,-1 ..0 N 0 0 Pc • •• rd 0 —I co o • HH. 0 -, 0 0 0 ta0 S ao a) -4,Hi 0 0 0 E t) 011)(4- a) +3 4-3 0 H 0 cc/ Cfl 0 rd •• •• •• •• a) bD 0 8 • •• •• •• a) CD .0 1 r. 0 n O — r=4 0 o •• •• •• •• •• •• •• 1 N a a) a) F-I r-1 Pq •• •• •• •• •• • •• •• •• bO ,z1 -1-1 , t"' ‘,5 ON1 \,C,r) CV N- ,..0 n1:2, • • • • • • T .O pp •• .. N --t q) 1- e0 N-H H N Mtry - —1- N- t-- CIJ •• •• .• •• •• •• 0 0 0 0 0 0 . \ L(\ 0 0 LP\ 0— VH c0 H t a a coa Ha a a 0 0 0 0 0 0 Q 0 0 If\ Le\ Li \ H ci-i . a) a) tit al 0 a) • • •• N --I- 0 • •• •• •• "P Cr) N- \-0 n0 0 cci H 9 g 1)0 • • • 0 0 -0 Ml- \O ‘.0 P4 • 0 ....1• Lc\ • E-4 4-2 N 00J1 --1-Is—aH a a a N cn • . •• CO•CO• 0 P.1 P4 1 0 F4 M. r LI-N 0 N- • • N M M.-I- •• •• •• •• LC\ \ V\ • • t—• • cr)an0a LC\ 0 (X.) • • •• cm 8. -,L9 •• • • •• •• •• •• •• GO •• 0. ru Pi 40 41 0 4-) 43 0 a) 0 H UI P4 P4 a) • • Fa 4 N - PI 0 4 ..52/ •• Pq• •• •• •• •I1 •• ••• •• Tai M • • •• •• If\ \O O MCV H M 10 MM MACrl M • • • • • • • • • • • • •• •• •• • • ,,:, 2 2 111 4 c13 r'd I 8 ;(1?,. g g F-1 4-1 C.) 43 ......., co 114 0 N ill.• •• •• •• •Y •• • rcl H I 0 rc1 , V A 4-] VI 0 CO E-1 0 0 0 0 •• •• H co •• •• .• CO r— (Y.) " 0 • ' • • ',..0 0 CV-1 r.-- r-I r-I ac • • .• •• •• H ON t__ CO •• •• r..) ell •• PI \.0 •• •• 0 C..) $-4 SO 0 - • . co +3 al NI q 0O 00 0 Lr. L• n Ill TN LPN UN ON MN M 01 00 00 00 LPN L.r, Lc'. ir, LIN 1.1-1 on n.1 CY1 CU i'l CU • • • • 0 i-4 0- IV A rd Pir--1 rJ 1) 0 Cr) • •• •• •• •• •• •• •• ra, 0'1\0 LC\ M • • CO rl 01 CO •• •• •• • 0 0 fr) rt r-i • rri I-I •••• • • •• •• r• •• •• • • • DI CO CO a) 0 CH d II a) .0 CO LC\ •• •• •• •• •• 0 4-) 4-) 03 F-1 0 4-4 d O $-1 0 Cr` bn • •• •-• •• O O H Fr SEI Lc. N L(\ (\I (rN \-0 Lr% 0 0 0 O 0 0 CJ •• •• U •• •• •• • •• •• •• • Fa •• •• •• •• m 0 0, 1 H 1 cn cn 43 ..8 C 4-, r)1 ▪ bU a) 0 rd. 0 CV 0 (—I cn ..-.1. H H cn H (T 0 on CV (T 0 cn HI 00\4) • • 0 0 00 a) O ri -1- a) Fu •• • 4-, H Ol • • • • • • • • • • • . . tiNuNtr\tr\ \-0 1/4.0C.-A0 tr\t-Lc\s0 c0c0000D c0c0cOW C0c0c0C0 a) O Fi a) •••• LcNu-0.00D MEOMoD • AJ Cd a) 4-, U) a) 0 ▪4-; ▪O a) to -Hp N u-N rA CV O • rA 0001r\ 0000 00LrNii", Lr\cip un cOMM 00Mm 0000 0000 0000 ,4 4 ,4 4 -4 ,4 ,4 „ H , 4 ;40' a) .H H •• •NC tr. rA N LlN ir\ LIN tr\ 0 0000 • •••• HHHH C1.urN1 P ,-4 0 d 140. Cl H • • • • • NmN0 •••• MMMM cOoD0D00 •• 0 .CO. \D \ID CO ON -1- 0 m H Ct.10 . . so •• 4, 00 •• C) CV CV CV CU CV m t•--c0 CU en C) C) O • • • rA rA rA 0 CI\ 0 HHHH 5 w 00 P 4-1 ,,,,, 4' 4-1 P •. '0 H a) I.4 al C)• CD• 0• 0• rA rA rA rA , C)(0 -1HHHH HHHH 0 a) 03 •.-1 •• $-1 .0 0 4, = 5 i ro 0 rg 5 Cd1-4 8 • .0 r.0 to 0 0 0 N w A, td 5 ,, 1 14 PT, 01 N H N H M M H p u\OLENO .4-u . -Nmm . . . 0 uOOLIN -N noun ..1-m .... .. ri H .. -P0 0 0 N 0 0 al ▪ ct .... 4, w0 0 N H 0 a) O +.1 4-) .. 04 la.. •.. 0 • • 0 m 6 m 1 1 crl 6 u-N.,A-0LrN mmulrA . . . . rANNN PI H M a) • u"\m00 ic\LE\N.... F.4 fr4 0 .. .. • '.--1 ,•. cr. .. .. .. .. C-N00 nOir\ t•-m .... • ,,Ln Oir\u inai r-c0 tro.0 11 Of-EntEONNC---• • . • 1----0000t.. .. .. .. M .. . c0-4-mc0 MHL.r. • • • • 1-1 , CV Cr) (v") (,) ..t.d-mul mOco-I • • . . CY-1--1- .f u\ u"Nis.0u-\pot/NO mMHN •••• •••• ..1-Lro,0 n0 s.0,0 n0 ONHO t-Omr--. . • • mckj,-)..,1rArAH mt----1-0 NON-v. NmmN n0\0\.0 n0 LE\E---mvN • • (Dplf• •O moD.1-N •••• u-\\o0,-.1 rArA(.1N ,A 0 CO 0 $.4 HO d d. 0 p Cd 0 H 0 0 H4 WH -Pcf-i 0 -1-' (I) .0 TS 0 d N o Cd o 4, .0 4,4-A 0 0 4 4 Wrd 1H 00 H a2 Cd 0H O .0 0 rd cd 04, 4-) 0 01 4, ,c1 a) rd rd 0 a) d 5 .4 a) 4-' -.-I 0 -1-, ?-• ,-1 -P 0 . .-1 H Hd ;-n d 40 P t100 _I H d • a.) CO a) .41 0 SA0 oco O se of 1:11 • I H d 00 06 H• 00 0 • • ir\000 to .0 !4 • 00 O O • OwN00 000DHE- •••• mi.r ._1-__I-I- --- 0000 Is\m0N . . . . •• u-suN00 moDm,.0 • . • 0u-sLnu-, .1-__1- ---- u-Nou-NO -3--1-0H 0` 00\ 0 IiN.--1- tr. ‘ 1.1- \ tr. to---4. .. .. 0 6 .. .. . . .. .. Lr\lr \00LrN0D «n to .4-..1- f --0000 NHONH . . . . oomo tr. trN...1• L.r\ .. .. .. 00 .0 mm.-111-. • • . . .1-Er.LE\ .1-..1- f ir\ou-NEEN tnirNOTN NMmu-N • • • • u-..1-11 -/---1ic\000 5 mmmm .0 0 co4-) _.1. _1- 5 a)0 Li-N(7\0N 11-\\,00,10\ ..1- O\ O\ 1.1" \ Lf\ C,1 C,1 (Y) rAHHH 0-) CO 0'1 en ea -,1 0 4-1 ,-I cpi 0 H a) 0 P. a) to 0, 6,9 H. tr.\ c00 . . .4- _1- -1- -H -4-,4a)-, d ••0 S-, 0 a) .0 -P t• _A- ON \.0 CO .. uN nONM NNNN mmMol HHHH HHHH mmulm mmmm mmmm 04 01-1-NISNO .0 13.0 F4 0 4-, -P •cl al 4-103 41ZI N l4 H 0) Fri a) •H 0 0 . 0 a) H CL en.--1- If\ CO CT\ 0 H CV HHH HHHH H R H • 0,-Acr 0.-A ..0/W rcipp H •.-A HN 0,4 to $.1 H 0 d 0 0 0 Pi r. FI 0 td 0 A 4-) 0 -P a) j c0 .0 4, 0 a) 0 P rd 0 0 0 a) d Cd M M Er) a . m 0 (4N 1 H Ea •n-1 a) .. • . • Er\ nONm \D nDmDLr\ . • • NNNN • t-- ..• .. .41 ;_ico • . nOalcv 0.d-__ • • • • NNNN • A • (0 ... a) N O • 1 E.. 0 A- Fa F• a) • V---LINNV• • • • r=1 1.1 u) ti H • TN CS\ a) -P 0 0000 '0U-. . . tn. am! H ED p., FT O CD 0 5 0 = a) d a) Fa Si N a) al c ,c1 0O 5 0 •.-1 H. cD to to cD C) cOGO 0 • \CD 000H 0 M W m a) 0 0 N rr o 0 . 0107 N - ,3 0\m C(.3 •-0 1. 00 a) • r - H (A0t-r-.1 Cja-3 ,150.3 r1; 1[147n 0; .. • • • • °"O 09 HHHH 0 0 4044 gi cv N tr. HHHH MMONO MW-d HHHH u-s0,,NW trsul\D-d HHHH NOOL, 3.0 t---1-31, HHHH Li-. t- Liss CO 0. LA 4 Ht.-\%.0 n0 0-,1: 0.0 n0 HHHH HHHH ,tic;0 ,Cro• H HHH 0000 • • 00 H o ,,,,, 0 :, 'g/.5 ::: rg +1 .,;, ;' ; .8 1 , 6,H H N o -9 H 4-, g IDA N 0 HN..5 0- n0 HHHH •• •• •• r• i t) , ., 1 ,:c7 40 HI HI HHHH u ,,, 0 4.5 o .71 0-4 0 P., ..4 0 ,,_. 71 0 g -.. 4., ..-i U t3 or, 0OHM HH Ctil HHMM mmNN S N, 0 N..4--1-,N HHHH H HOMH OimMm 01 lf‘ H HI .41 r-1 ' :m112,21!!: 05 „, co ..9 q g ti, , cAN i SP-Va o Ht 7,1 .-Ø1 F....,t - H. 4.3. ',1 t.-. 49 u ' 0 F... 0 ... 40 O. O tal...] r4 s k.. .i, .-91 t,‘ `a .,,,,,...„! e . 0 N7, 0 0-4 yrj r .. 0 ' • 1 4440 ol 1-1 Y c-3 i +3 W 14 ;4 O OZI M v o c4i fr, 5fl0 2, › .: ''' 1 4 9 .=1 N . 7 ii , g ) il ! 1 .,3 1 ..'''8 4,PH u . - 4 c-,1:,.. 8 H h. .-.1 A . .41 Cl -P . 9 I-1 0)u [-0,3-0 H01000 COC001.--1 `AR T12 NMLrsu-N CL;;P-N 0-VD MMNM NNmm mmmN • -43 s-4 ▪ ro cornNCO 0 gt a 041 H 0H 05 0 HNm 0 CHC u, HHMCN MMNN 0 0 0 L.0s-N -1-01 0 400) CO OLAWN HN01_1- •• • • • • • • •• • • • • • • •• • • . • . • ni 0 H H H HH mmmol 0 oo 01-1c0NH m m NN m ‘.0 o ,r) H CO 00 00 rn .-01 151 g.'3 " 1*--- 0 01 HI 01 H ,tpr., • • • • • SO 4 -' g d t C.11.4113H, K I ,, •• 4, 0„.., r 1",0 H .11 ..-TA,_,.: 1 • 4.vr:Lc 0 0 t-- . w w 0 CO CO NHHH HHHH HHHHH • •• CrRl M 2 • tei .,..71-1 . . .... ,..., u -,.% m o -, 0 a, '0 O cy .,,.... 0-0107 nOW W.-t u-NONNirn C-00 MON 0 t4 .44-, .5 "4 '0 1.1 '61 iN HI 0 '" O tr. 01rs14-sixNu-s 0 onMN 01 H 3.01 H 01 CO 1.1"1CINUNC.C\ H H N MOMQ 4R-91"-(4 0 01 10 C-0H H ,․) (.1 0 °D mcv on 0 .0 V6)..5‘, rn M‘g trH W4 ,-1 HI ON • g .0J 7, 0‘,0M0 1nONMM HNHM H101-4-MNNN 000000 3.0 Olt/lir\ 1010%lfs M rn U 00-1-0 NCO- 1.rsHCHH NNM-1- H O O S Sn O , 8,3 ,:;'-'. 'ti4 :24 1 ° El • WHLAL.0, N 4 CO Lf\-1-05," 0 °, MW Nm M Hr.q .21 NN • rl U O O 0.coon cn H C-M,OW mL0043 NNNN 0 N00 cts 0/ 00 00 • ,r0 0 CO 40 0) 01 01 '11 MOM) \SD,IN,D 000W t3-- C.- 00 U-N A -I 0,0) ,0,0 O • 0 0 0 U NI . 00 H .4* m Cn.c0 a-.5 LIN 1:20 rnimmmm WaNM-dNMNM MMODM •• • • • • • • LnW0--ON NNNN HHHH MmMM MODCOM 03 .. g :5 ,,_, I., r, O H mc0 its as 0 0 oN 0000 ‘o. I--c0 CO, HN A4. .54' MHWLrN MMuNN HN-d-M NmOlm WWMM Hrci, 0d3 :0:: e8o, 4_, 0 !I: ,L, 124 ,.°i' z, ''-'.9.8_w:ga 4 10 1 :11: 4 4 ! 0. ! i .0 gt O 0 0 •-t ; r.; el A :ii ii .67 i g t4 P o 01k. 4-7 ON ;.'J0 n 4.,) y 01 31 0 R'Cco 14 03 .r1%.gq-1'-wl 2 9 H CD 44 "., . imp AI.0 -PE 0 1 0 e N ,_. 0 r-1 g 01 H - u +1 +1 ,i'. ' .- 1 0 23 # p0.4 g g . 14 1 H ,9 N i 4-'7Y, :(.1 4 7' y 8 .01 4-3 1.31,4 -0 n° 0 Cl 7 ! 1 i ;.p i d y . R ' - ' 4:4 4g H "dcl 44 ,,, -I.,0 00, hi H 11 " OD r0 N'S 0 0' , ;6 .,_. 4 r '' >,..0 H ..0 9 : i 48 `";:', .° h' A a, , :::, -P 5 p N €11,_, ,9a ,,,a 118 a 00 .0 , . 8 • 1 ra, ... 0 438 0.1 .10 CA .-. 3 7 . N ,_, 0r... lO 2 Cry +0 1' ,q ; . , ,:,itu ‘.001.-100 .• - • - • - • O O gw 1 -1-7 0 +1 •• ..11 I-I 0 u .1 H H N CO HHH ...P.a' 0 '4, H A al."'4.:1 go ,-. ' ' 4:.4414-' 90 4 0 o o. a, '0 ..,, 0 .4.,, ';' rj .0 fa. Id 1 1 -. 01 3. O ,,,, " " g i ,F., c;) 8, g>.a.,g al -4 ▪ c0 0 , 4 NO ..-1 O rL'' 8 oDc0 c0 CO HHHH 0 CO 00 cc ODOD CO CO 4 0 CO too CO ON 0 92":11°T10 4, 0 "CI 1.3 N) +A ..,.. Is -.'1'1 5,j VI .r1 to 0 4-7 2 ' 0, Z-; :0 1 "0 0 !. ... e l_ i ,... !., N : ,,t, 4.. .0 t v5 8 ..-1 +3 4.4. 70 1 n l-ot , HP u.., . 11 :- • 1 CO N-1 ''.. , 0 4 W 00000:3 ca i, g - H .0 ,O +0C.. 90 9 11 44 H . .:1•1 1 r i 0 ,' •• • • • • • • HN01.-1M010101 HHHH cncnmcn 'd ,moa, mmmm 3.0‘.0 I-0 ON 1.133, HHH 01 01 01 H ,. i.91,- rd * - N 1 ° Pd. .3. N N IN. 14 :i 1..., ........o c, . 8 .1 a.. i43 q 'El 11 ri 0 ....4 , > 9 .F31 41 0 4, g Lq, 1 t 0 .n / 0 C•I 4 AN E .1 g 0 -IT - A u f j A HI 011 xi N - o .-I .. ON0 (1 . CT oro.o HHHN HHHH 00-1- 1 4 pH 0. n•n 000,0,0• WM-1. 0 COHNO • • • • • • • • tr,[-Ln n0 WWWW 0)0)100) WWWW Ina rA3 NMNO rALA4ea3 0)0)0)0) Cr,0 100)0)10 11-111 Ti$9, n 111q21 d@,2"18 1111 NNNN Wg'grt; 0o F11-r81' .•n•n i•I ••n•• 0 4. d 0 c + tr%•' 1-3 m .0 0 410P.4r, E O H 41J Al N,OMM WH&W, HR01(91 1,1AAA NNNN c,Fc\;. c,rc,r c,r,7 cra3N J-F8 4. , 0 0, MIN MM s,\Ja. •-41-0P:1 •.4Ho p. 01 1-Wcn: Lo';V:;d MrOMM 5.4-PN-AgN, HNNw HMCOM ,t2OJH c-8AH 74,mp-'u VRIP 8 toe N(-NN Walclot 44 041 CV,OHM 400,MM LO,0,17,0 kOt..-MM YARcgR r go'S g VIP" 2RWAS T–Br& 0 04040)0) •• • • • • • • • • • . • • • • • • • • • • • • Cr) ON40 LA 00-0 1,1M r+Mj40 ON CU CO tOrc0.0-1HHHH HHHH HHHH ,o MCF, H 403 NW ,001,0W VDOMO HLOON HHH HHHH NOO NW, !n CO ba HL.r7,0 9inMm WHM.17 , • • - • • • • • :EWA c:21Tng -P>C90 Vpgrj WLOt.-,0 MOHM cOMOH • • • , • • HT-1,0 4 01 LIN 1I') In 0 gl a m A 4, cH",2r1H ! "48 rcMm° HNHH •• • • • . • • • • • • • • • • • • • • • • • • lt,u-,NLO LOC-HU, ...1..qors4 HLO,0,0 H H H HHr-1 r-1 H.-11-4H k lm gtv ,.4g8 51T471 H CO q 4-5 .4oUgl-AN :NeOrJr-' rle- P y • - • • • , - • • • ,-1M07w\ MOOvN ,o,coop mmirs_/•• • • • • • • O 4 11;11g 0 -0 o WVI MC-COM VDMWM MMMO, mMNLO NNNN ,OM,Orr,HHCOW,LO NOIM NOINN NNW HHHH o.L.r.00u, tnoi .4 rn 4ONits0 LI\ 0-1-.1. 4 .4- o'n g ,;11 -044. N a q ht49g MI N40 1,1 co '11 'J 2 Id uzl -tHoLw. • • .• • • .• ! .„0„, ;TWO 914 O a,m0 n.14T ,c101,10,H wpon .4m „. LOC... WLO OWt-CVD404040 HHHH HHHH rO-r.Qyr VV 4., 0 A wv, " 41" 410 2 -E 2. 1.'== L.Ist,tRrrni °,9 c") N r9 N -A g 0 •• • • • • • • -6A,218 LX;038 •••••,• \O0,00 0'ODC-01 WCOMO 000-1 00kr, 1014NN C-0000MMrOC, MOOH HHH Nu-qm H 11-1-1 IHH ,000 rj.0, OJM-1. N t,olmm HHHH HHHH MMMM McOMM McOMM •• • • • • • • • • . • • • ,MON mmmm mmmm c,.$111 M3 u14q t-coONO 0 r I t 1r -g -1 4 44 r0g1 017J.-51aJ q 0V/ 0 0 0 P PI • 0 'el fin,' pg. 94 H 14 141 4' g `.=1 A " 11 1 g H N M3 u440 N0) n-z f9 vtE , 00 N-I 0 P a) P-4•• •• •• 6 H •• 1-4 •• •• 1 a0) N •• .• •• mON • • ol V 0 4.) 0 a •• •• 0 '.0• On H •• •• •• • H •• •• •• NON ' C.--• :ON ON H H •• •• •• 40 •• •• -P cd 03 0 r-i. 0H fli •• •• •I •• •• •• .-1 • H H •• •• •• •• so •• ' Lr`. '.0 H H ,.. ...* •• o• 00 •• •• •• 4o •• •• ...... 0 m -P ca gl -I-) 0 0 0 0 0 4,1-1 -P W cd 0 .. Po 4H c-- V CIA F-1 Pc1 0 •• •• •• •• •• •• to CH0 0 •• •• •• VD• N 4 ...1. 4 . •• 6* •• .• •• •• •• • • • a) MI P P4 • CU N- !..r\ coo 1--; . 0 04.0 4-I . ON •• •• •• •• •• •• 0 Lrn 0 C:NCO co • • • •• •• •• in, 0 u-N 0 M N u;0 O, 00 L--- ON 0\ N- CO co 1.-••• • • • • • • IS •• 110 •• •• •• •• •• •• A 0 +3 H W000 000 000 000 000 ou.No 88 g c Fc8,@ c 00Q 1-1 P LC\ In 0 LIN ....1- CIO A CO 0 1 F-i •• •• •• •• .. •• •• •• S-4 cd -P rd (1) • -P • ,c) P-4 ••1--1 •• •• (I) P -H cn.4 • •. •• •• •• •• •• •• •• •• •• \0 MON al • • • • N VZ) • • • •• •• •• •• •• •• •• •• •• c; • • o • 1E1 •• •• I-A 0 • • • d c 0 t--• • • • • •• •• •• •• •• •• Cel--1" •• I 44,----'M -p PI rd o o F-1 w ,cl •• •• •• • •• •• •• 11N‘o • • 000 cr\siNcrN 000 4.4"NirNuN LAI.ross, 000 11\11-\uN 000 LiNisNir\ 000 --I- MN ....1 . coN -4- mal -1- MN .--1- (YIN •• •• •• 0 . irn CO •• •• • • V) . 4r\ 00 •• ••• 0 . n0 00 •• •• •• 0. 00 •• •• •• N• c0 ON ;1 •• • 00 0 O• a) H 0• 0 • •• •• •• 9 e• .S4 • ON al ON c0 %JD ‘.0 • • P4 • CO H es es es Ce")--* LA OD n0 HN (11-1" LA a) S-1 V 180 0 a] LIN • a) S4 0 0 a) Pc • rd 0 01 0 5 0 4.4\ 0 '8 0 O a) •• •• •• •• • • •• •• •• 0 es es es •. • •. 5. •. •. os 5. ... ...1-N 4.r% -.1- Lc% u,--* u, LA .4- u,u,...1•• •• •• •• 4• •• •• •• •• •• •• •• S-4 FA 0 pa) MI c04.4N i.1 p4 -N oD 0 Lcs. i) co •• •• P••:1 •• -P rl ca Al 0 U1 •• •• rd •• •• 0 0 .----. P4 m cd rd Cn -H ;(4-4 0 a) rd cc 0 0 rc 0 0 a) cd cd ;-1 0 +3 0 •• •• •• Pi a Nt 0 4-1 1 c0• ;-1 cd 4-4 ca E-1 a) S-1 •• •• •• •• • S-4 4, IA -4' (1) 0 Wog -P 4,Pi- I 03 0 V H 4-1 -1. el-I 0 4-3 -P 0 L.rN 0 o -P -pco a) 0 Fl 0 a) N F7 U •H ca O •l-I g airl • • • H S-4 •• •• •• 00 4-1 Hy Nv coq ,c) H 0 O C./ • • . • LIN N- • CO CO CO CO •• 0 CA -; •• •• OS H •• •• in N CA CA (3 ,-4 •• • 00 00 c; O\ • . • • n.o• Ni •• •• •• •• •• •• •• ro I\ 0 k.0 c0 c0 CU 01 0 • co 0 • Cu 0 • co 0 • N 0• N 0• co 0• oo co •• •• •• •• •• •• •• •• •• •4 t-- t-- oD H 0 01 O\ 0 I" (3 .-1 C3 H •• •• • •• • 01 •• to. k.0 •• . grs') \ci? • a; • •• •• • F., 0 •• t•- 0.1 • 0 S-1 5 •• •• •• •• •• • • ota gil • • 8 p • :74N • 04 • •• •• Q rr) N 0 0 0 VD •• •• co 01 r-1 4 al al ol al A A A A co •• •• ON •• OD D • • aD c0 .-1 co 1/4.0 0") 1IN U) •• •• •• •• cc? sig8 • • • • • • m0 • •• •• •• •• •• • •• 2 7.1 • • ., u•' •• •• 03 • \ 0 •• •• \ 07,, N ,(0 . 1 • • trN e• 4 4 •• %.0 Ln 4-, 4-, O • • fi •• •• •• •• to ....1-CU 01 H • • •• es .4 1-4 •• •• •• •• •• •• H • • •• •• tiN •• •• c0 0 .4 0 if • • • •• •• •• • • •• OD • •• 0 \ 0 \ 0 1-1 • • 01 •• •• •• •• ..to OD ON 0 0 0 0 H O O co H 0 0 0 0 0 0 0 0 0 0 •• • • • on CC) CV C\ I o o o o o o .4 4 4 .4 4 4 4 4 4 .4 .4 .4 .4 .4 4-) •• •• •• •• •• • • •• N H . L.1^.54\ `e.1 c(-9 ,,t7, (54) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 O 4-1 .4 4 .4 .4 .4 4 4 4 4 4 .4 .4 rl •• •• 00 • ea, •• O 14 0 Id 0 1-1 •• •• 011/ N LA ‘.1) •• •• t- CU .4- Ln an co co o o o o o O •• •• •• irs t•-• 0 cr. •.D •• •• •• •• OS CU kr) 0 0 t'0 t-- t- co o o o o o o o o o 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 Or• • 54 ta 4) 5 5 • •• •• (1./ P. ▪ ,c1 CD g •• 01 A •• • • g H •• •• •• •• •• •s •• •• •• GO SO • •• ao ao H • al ol N oD 0 H 4 0 0 •• •• t- N .• . •• •• •• H O 0 1-1 P.4 H H O QS 0 F-1 01 •• 1 18 r4• • 8 •• •• I $4 I a) 2 ' 13.1 O a,I • O H • •• 00 •• • 'A •• •• • .5,1 o o -A- •••• •• •• OS • 14 CU 8 •• • O co "o OCI ed •• tn 5 • It' •• P.1 4-, O 41 f-I • co •• •4 4.3 a) • •• •• H u. N• a, •• •• O H N c0 t-• CO 0 CM 01 co N -7 N u\t-- C.- co t- t-- t-- oz. •• N •• •• •• •• •• •• • •• ‘.0 • •. •• •• •• M .3 0.1 d m •• •• oD 0 01 cO 01 I" • • • • •• •• • • N N N 01 01 01 CU CU •• •• 1.0 •• •• CO VD C- 0 co N h d en dan M •• •• •• •• o h A A A •• co cr. o N a M no co • •• •• 01 co oD • 01 • N N •• ▪ •• •• cn co N ref •• •• u-, 4 co co co •• •• •• N N co M •• •• 0. 9 ON ce, at 0.1 01 01 CU cr) ( .1 co co co •• •• •• ,c..7 •• •• 1;,..? to r. Eo •4-) 041 RI a) O • H 4-3 •• •• 0 0 O F-I W ra,`:_ co a) 1 - F-F1 pa •ri 4) •• -P a) •• 0P4 co It 0• • •• •• •• .. CO • nC) _1- 3 •• •• •• • • • • • • •• •• • • •• •• •• +3 0 a) H FA CO . C.) a) •n-i ›-1 c0 a) P-1 •• •• •• I •• •• •• 0 0 trN P-, d H F:i W\ 0 O a) r .54 0 • \O ....1- N . ON c0 H H . 0 c0 ON Lr\ • 0 ON •• •• •• •• •• •• •• •• •• LrNQO irNts-0 QC-0 400CC--- UJOIC-CCOCOS- • • • • • • • • • C---NliN C--C-klp • • • LnEr\lf\ Wt-klp • • • •• •• •• •• •• •• •• • • •• • • •• •• • PAr-i-11 .r.14. rd a) 03 0 1-1 lYl •• •• •• •• • rg •• ••"•• a)+) •• •• •• ttO ▪ 4-) 4-I/4 -P 0 04 I) r-1 .. 0 0 N Hil M co 4-4 cH •• •• •• •• •• •• •• •• •• • • . • • • •• •• •• •• •• •• Lrn •• •• •• 0 • • •• •• •• •• •• •• co irN a rn.r..4: LET,, • • • • • • • • •• •• •• •• •• •• •• •• •• • 0H •• •• •• •• •• •• •• -P -P 0 N\OON 01J-NON r-1 \0 \X3•‘4)• 'Oll"\WD • • •\•L)• • • VD‘,0‘.0 • • • • M 8 4-1 50 •• •• •• •• •• 0 -P 0 •• •• •• -P CI •• •• P4 PI MO 0 •• •• •• 000 000 000 0Q0 000 OirNuN liN00 000 IINUL11 1111A0 VD -1'M WW00 ‘.0., Malt-n c0 ‘43M0 _1-Lr\LC\ -1-L1W\ -1-1.11W\ -4-1(.04:3 A fa •• 0 H 0 • a) 71N Ea o) cd •• P4 k .. n $,i:; •Cr-QI M P0 0 •• •• doe •• •• •• .. .. .. .. .. .. 1-1 tr1 M VD \D • • • .. .. 60 co Edrd •H .1 a, ' 5 $-1 rxi ........ cc 00 041 00 SO rOI ,b4 • 00 0 0 .. 00 •• .0 • •• •• •• 000 000 000 000 000 LINIsNirN LrNisNisN LrNtrNirN LrNuNvN uNLI-NUN –1-MN .4-cON .–tcoN •• •• •• •• •• •• •• •• •• •• •• •• c0 • •• 00 410 •• •• •• a) Ea La 8 •• •• •• •• •• •• a) H • O 0 •• •• •• ON •• •• •• •• •• ••