INFORMATION .LEAFLET FOREIGN WOODS Forest Products Laboratory, 1,Forest, Service

advertisement

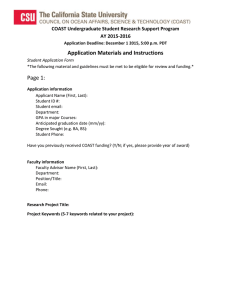

INFORMATION .LEAFLET FOREIGN WOODS Forest Products Laboratory, 1,Forest, Service U. S. Department of Agriculture 1954 OBECHE AYOUS SAMBA AFRICAN WHITEWOOD Schum. Triplochiton sclêroxylon Family: Sterculiaceae or Triplochitonaceae By ELOISE GERRY, Forest Products Technologist and CAROL M. MILLER, Scientific Aid Division of Silvicultural Relations AUG 31 1954 Other Common Names srATE Obeche is known by a considerable number of other names, the most common of which are starred in the following list (22)._2 ...France, Ivory Coast, Germany Ivory Coast, Gold Coast, French Cameroons, Nigeria *African Whitewood.......... United Kingdom France, Ivory Coast, Nigeria *Arere...... ...... ..... France, Ivory Coast, French *Ayous Cameroons *Abachi. ............ African (or) bush maple 1 —Maintained at Madison, Wis. , in cooperation with the University of Wisconsin. ?Underlined numbers in parentheses refer to the list of numbered references at the end of the report. ( Report) No. 1974 Agriculture-Madison Ivory Coast Bamba Ivory Coast Batobus Ivory Coast Cofa (Kofa) Nigeria Egin-fifen Cameroons Ejuong Nigeria Ewowo Ivory Coast Hofa Nigeria Kpa Cameroons Nkom Nigeria, Germany *Obeche (1) Germany Obeechi Ivory Coast Ofa (Ouofa) Nigeria Okpa (o) . Ivory Coast Oua-oua Gold Coast Owawa Gold Coast Owowa Ivory Coast Sam.............. Ivory Coast Sama France, Ivory Coast *Samba ... Ivory Coast Samba-Ayous ......... Ivory Coast Samkamba Ivory Coast Sankamba............. United Kingdom Satinwood (substitute) . Ivory Coast Serama ....Nigeria Soft Satinwood......... .... Ivory Coast Wana................... Ivory Coast, Gold Coast. ....... Wawa... ...... Distribution Obeche is found in most of the countries of West Africa, from French Guinea to Gaboon (43), especially in Nigeria, the Gold Coast, the Ivory Coast, and the Cameroons (6, 22, 28, 39, 44, 50). The Tree Size and Form Obeche trees are among the largest forest trees in West Africa and may attain heights of 150 or more feet and diameters up to 5 or 6 feet above the buttresses that often extend for some 20 feet up the trunk. Under Report No. 1974 --2.- good growth conditions the trees may add 6 feet in height per year. They frequently form clean, cylindrical boles, free from branches for a considerable distance above the buttresses and afford exceptional lengths of clear material (19, 22, 26, 39, 43, 44). The Bark The thin, soft, smooth and light-colored bark in young obeche trees makes them conspicuous. As they grow older the bark becomes scaly and flakes off in patches. The bark has been used locally for roofing (28, 39, 43). The Leaves The shape of obeche leaves suggests those of maple. They are deciduous and may measure 3 or 4 inches across. They are in alternate arrangement (28, 39). Flowers and Fruit The flowers are pinkish or mottled white and red, and fragrant. They appear after or at the time the old leaves are shed. The pods contain three rather hard, woody layers surrounding the seeds which are winged (28, 39). The Wood Color When the trees are freshly felled the wood of obeche is creamy white to pale yellow in color, with little or no difference in color between the heartwood and the sometimes 4- to 6-inch thick sapwood. The wood weathers to a light brownish-yellow color (2, 6, 7, 9, 21, 22, 41, 46). Luster The luster of obeche wood is described as high and satiny (25, 26, 43). Report No. 1974 -3- Odor and Taste When well-seasoned, obeche is free from odor, but it may have a disagreeable odor when the tree is first felled. It lacks distinctive taste (28, 39). Grain, Texture, and Figure The grain of obeche may be straight or generally interlocked (13, 44). The texture is medium to rather coarse, but uniform and rather open. The wood may present a mild to lustrous stripe or ribbon figure when quarter sawed (6, 13, 21, 26). Weight Obeche is a relatively light wood. When green it may weigh about 35 pounds per cubic foot but when seasoned so that it contains about 10 percent moisture it may weigh about 20 to 25 pounds (13, 22, 39, 44, 45, 46). Reported specific gravities range from 0. 29 to 0.50 (6, 26, 36). For wood on the basis of ovendry weight and volume the average is about 0. 30; at 15 percent moisture content about 0. 40 (26, 43). Mechanical Properties Obeche rates as fairly strong, elastic, and resilient considering its weight (1 3), but it splits rather readily and breaks with a short fracture (19, 39). Its hardness (43), compared with black walnut as 100 percent, is 38 (16). It is reported to have about 15 percent less maximum bending strength than Scotch pine and 50 percent less stiffness (22); however, it resists blows and vibrations well (13). Table 1 gives the strength properties of obeche as determined by the Forest Products Research Laboratory of the Department of Scientific and Industrial Research in England and as presented in Bulletin No. 28, page 39, by F. H. Armstrong. The results of another series of hardness tests are given in the following tabulation (16). Report No. 197 4 -4- Obeche (Ayous) from West Africa Moisture content (percent) Specific gravity (ovendry wt. vol. ). Average hardnessi (Average of 100 tests on 10 pieces) pounds ..... . (Compared to black walnut as 100 percent) percent. 6. 0 0. 39 & _ _ . .. . 475 38 1Load required to embed a 0. 444-inch ball to one-half its diameter. Seasoning and Shrinkage Obeche has been found to air season and kiln dry readily and rather rapidly (1-inch boards have been kiln dried in a few days without degrade (46)). The wood has low shrinkage, little tendency to warp or shake, and good dimensional stability. It is, however, important that stock be carefully piled to permit good air circulation in order to control discoloration and decay (13, 39, 43, 45, 46). For kiln drying obeche, the British Forest Products Research Laboratory recommends their Schedule No. 7. The U. S. Forest Products Laboratory schedule that appears most applicable is T8-C4, as given in Report No, 1791. Shrinkage data recorded for obeche dried from the green condition to a moisture content of 10 percent are: radial 1.7 percent, tangential 2. 2 percent, and general average 1. 9 to 2. 5 (U. S. Bureau of Ships - Code 372aL5 (2465) 1952, and (46) ). This compares favorably with shrinkage data for sugar pine. Another record of the percentage of shrinkage occurring from the green to the ovendry condition is: longitudinal 0.15, radial 2. 49, tangential 5.11, volumetric 7. 84 (16) or 9. 5 (43). Durability Obeche is not resistant to decay or insects. It is rich in starch (6), which fosters dark spots, sapstain, pin worm, and beetle damage (13, 42). In large logs, the heart is often decayed and soft (13). The wood has not been found very easy to impregnate with preservatives (22, 43). Discoloration in obeche, due to sap staining fungi, may be prevented or reduced by water storage or immediate manufacture followed by Report No. 1974 -5- storage and seasoning protected as much as possible from rain and by the use of preservative dipping compounds (22). For storage and use, relative humidities below 75 percent are important. Staining due to fungi has been observed at 90 percent relative humidity (42). Incipient decay may be associated with blue stain in discolored logs. Botryodiplodia theobromae Pat. , a fungus known to cause die-back and pod-rot in cocoa, has been found in obeche logs. This fungus reduces toughness, bending strength, stiffness, and specific gravity of the wood, by attacking the cellulose, pentosans, and lignin in a way that is similar to the action of a white-rot fungus (14, 39, 46). Working Characteristics Because it is comparatively soft and uniform, obeche wood is easy to work with either hand or machine tools (6, 13, 22, 26). It contains no gums, oils, or resins to interfere with cutting, staining or painting (39). Sharp, thin-edged tools are desirable, however, and a cutting angle of 35° to 38° has been found helpful for avoiding any "picking-up" or crumbling of the surface of the wood (22). For staining and finishing, little filler is required. Obeche veneers and glues well and takes nails and screws without undue splitting, but fasteners do not hold particularly well under rough usage (5, 6, 22, 39). Uses The use of obeche has steadily increased (22) so that it ranks as an important and increasingly imported species (43). Locally it is used for dugout canoes, but it has wide application in interior joinery, framing, furniture, shop fittings, veneer (as a substitute for yellow-poplar), core stock for plywood (46), vehicle bodies, laundry appliances, boxes, furriers nailing boards, and pattern stock (under test by Philadelphia Naval Shipyard, Bureau of Ships in 1952) because of its low shrinkage (6, 13, 19, 22, 39). It has sometimes been used as a substitute for satinwood and for primavera but is considered inferior. When stained, it has also been substituted for mahogany (26). Supplies Ordinarily supplies of obeche in good widths and lengths and free from knots have been plentiful (22, 46). The wood has been exported in considerable volume from Nigeria, and the Gold Coast, and to a lesser extent from the Ivory Coast and the French Cameroons (13, 22). Report No. 1974 -6-- It may be shipped in the log form, or squared, or as lumber. It ranks as an increasingly important export wood (43). Structure Growth rings. --Growth rings are present but rather indistinct. The boundaries are due chiefly to slight differences in density (21, 24, 39, 43, 46). Pores. --The comparatively few, rather large pores are diffusely scattered, usually open, mostly solitary, but sometimes in radial pairs or groups; tyloses may be present but have not been found to be abundant (19, 21, 24, 39, 46). Rays. --The rays are faintly visible without magnification on cross sections and in tangential surfaces and are distinct but not conspicuous on the radial surface. Ripple marks are present and fairly distinct under a lens (25). Parenchyma. --Parenchyma is abundant round the pores and in fine lines, barely visible under magnification (25). Fibers. --Fibers are short and storied. They are of a special, relatively nonelongated type frequently found in very soft woods (9, 21, 40). Report No. 1974 -7- References 1. Anonymous 1929. Nos bois coloniaux (C8te d' Ivoire et Cameroun). Schum) Samba - Ayous (Triplochiton scleroxylon Publ. by Assn. Colonies-Sciences & Comite Natl. des Bois Coloniaux, Paris, pp. 4, 2 plates. (Trop. Woods 19: 68). (A concise account of this species from both the scientific and commercial aspects. ) 2. 1936. Three Nigerian Timbers (Reprinted from Wood (London) Dec. 1936.) Issued by the Office of the Chief Conservator of Forests, Nigeria. Pp. 8. (Trop. Woods 53:61) 3. 1938. Gold Coast Timbers. Published in connection with the Gold Coast exhibit at the Empire Exhibition at Glasgow, Scotland, 1938. Pp. 27; 7 x 10; 11 colored plates, 1 map. (Trop. Woods 56: 32) 4. 1939. I. Abachi, Triplochiton scleroxylon K. Schum. (Sterculiaceae) Merkblatter fiber Koloniale NutzhOlzer. Inst. f. ausland. und. Kol. Forstw. der Forstlichen Hochschule No. 1, p. 8, Tharandt. (Forestry Absts. 1(3): 168, 1940. Trop. Woods No. 60: 61, 1939) (Leaflets on vernacular and trade names, range, occurrence, form of tree, anatomy, properties, and utilization. ) 5. 1945. Empire Timbers. Forest Products Research. Pub. by His Majesty's Stationery Office, London, pp. 75-76. 6. 1949. Nos Bois Tropicaux-Ayous, p. 16. Plaquette Documentaire Editee sous les auspices du Comite National des Bois Tropicaux. Paris. 7. Ainslie, J. R. 1938. In the forests of Nigeria. Supplement (in color) to Wood (British) (describes Empire Exhibit, Glasgow). May Nema Press, London. Report No 1974 -8 8. Aubreville, A. 1928. Notes sur le Samba (Triplochiton scleroxylon). Bull. Mensuel de PAgence Economique de l'Afrique Occidentale Fran5aise, Feb. , Vol. 9, No. 86, pp. 5052. Paris. 9. Boulton, E. H. B. and Price,T. J. 1931. Some Further Notes on Triplochiton scleroxylon. Trop. Woods March 1, No. 25, pp. 3-4. Yale Univ. School of Forestry, New Haven, Conn. 10. Chevalier, A. 1909. Le bois de la Cote d' Paris. 11. 1917. La fork et les bois du Gabon. Paris. 12. Chipp, T. F. 1922. The Forest Officers' Handbook of the Gold Coast, Ashanti, and the Northern Territories. London. 13. Cox, H. A. 1949. Wood Specimens, 100 reproductions in color. The Nema Press, Proprietors of "Wood" London. (Same article in "Wood" Vol. 1, No. 12, pp. 553-554 (No. 12) Dec. 1936) 14. Findlay, W. P. K. and Pettifor, C. B. 1939. Effect of blue stain on the strength of obeche (Triplochiton scleroxylon). Empire Forestry Jour. Vol. 18, No. 2, pp. 259-267. 15. Foggie, A. 1947. Some ecological observations on a tropical forest type in the Gold Coast. Jour. Ecology Vol. 34, No. 1, pp. 88106. 5 figs. Feb. (Trop. Woods No. 91, p. 62, New Haven, Conn. ) 16. Harrar, Ellwood S. 1941-42. Some physical Properties of Modern Cabinet Woods. 1. Hardness; II. Screw-holding Power; III. Directional and Volume Shrinkage. Trop. Woods No. 68, p. 4; No. 70, p. 5; No. 71, p. 27, Dec. 1941, June and September 1942. Yale Univ. School of Forestry, New Haven, Conn. Report No. 1974 -9- 17. Hedin, L. 1929. Sur quelque Essence Forestieres Exploitees au Cameroun. Rev. Bot. Appl. & dl Agro Tropicale Vol. 9, No. 89, pp. 39-51, January. Paris. Trop. Woods No, 20, p. 47. 18. Holland, J. H. 1922. The Useful Plants of Nigeria. Bull. Misc. Inf. Kew, add. ser. lx; pp. 104-105. London. 19. Howard, A. L. 1948. Timbers of the World. 3rd. ed. p. 428. Macmillan & Co. , Ltd. , London and New York. 20. Hutchinson, J. and Dalziel, J. M. 1928. Flora of West Tropical Africa. Vol. I, pt. 2, p. 248. London. 21. Jane, Frank W. 1951. The Structure of Timbers of the World -- Triplochiton. Timber News Vol. 59, No. 2149, November. 22. Jay, B. Alwyn. 1950. Timbers of West Africa. (Red Book Series, 3rd. ed. ) Pp. 63-65. Timber Dev. Asso. Ltd., London. 23. Jentsch, F. and Appel, E. 1937. Beschreibung tropischer Holzer aus dem Urwalde Kameruns. Zeitschrift fur Weltforstwirtschaft Vol. 3, pp. 110-120; 235-246; 331-341; 497-506. 72 figs. Neudamm & Berlin. (Trop. Woods No. 50, p. 53) 24. Johnston, D. R. 1951. Obeche (Structure). Wood (Brit.) Vol. 16, No. 9, p. 349, sheet 3, Sept. Nema Press, London. 25. Kribs, D. A. 1950. Commercial Foreign Woods on the American Market. Pp. 139-140 (illus). Forest School, State College, Pa. 26. Lamb, George N. 1948. Foreign Woods: Origin, Use, Properties and Nomenclature: Obeche. Wood Products, Vol. 53, No. 4, p. 24, April. Chicago. Report No. 1974 -10- 27. Martineau 1930. ttude sur le Temperament des Principales Essences de la Cote d'Ivoire. Actes et Comptes Rendus de P Assoc. Colonies-Sciences Vol. 6, No. 56, pp. 30-35, Feb. Paris. (Trop. Woods No. 22, p. 47) 28. Mell, C. D. 1930. The Ayous or the Satinwood of West Africa. Veneers Vol. 24, No. 2, pp. 21-22, Feb. Indianapolis, Ind. 29. Meniaud, Jean 1922. La foret de la COted'Ivoire et son exploitation. P. 29, Paris. 30. et Bretonnet, Frederic 1926. Les Bois Coloniaux d'Afrique dans l' Industrie. Melun. 31. Metcalfe, C. R. and Chalk, L. 1950. Anatomy of the Dicotyledons, Vol. 1, pp. 249-254 (refs.) Clarendon Press, Oxford, England. 32. Meyer, Hans 1933. Buch der Holznamen. (Book of Wood Names) N. & H. Schaefer, Hanover, Germany. 33. Monnin, M. M. et Collardet, J. 1930. Etude Physique et Mecanique de Bois Coloniaux, pp. 34, 89, table A I. Assoc. Colonies-Sciences et Corn. Natl. de Bois Coloniaux, Paris. 34. Muller, J. F. & Son 19278. Jahresbericht fiber Nutheilzer. Hamburg. 35. Normand, D. 1943. La Denomination Officielle des Principaux Bois Coloniaux Fran5aise. Rev. Bot. App. grdl Agr. Tropical 23, pp. 160-164. (Trop. Woods No. 91, p. 57) 36. Organization for European Economic Cooperation (OEEC) 1951. African Tropical Timber, pp. 54, 55, 314, 315, 354, 355. Paris. 37. Perrot, Emile 1921. Le bois de la cite d' Ivoire. I. Paris. Report No. 1974 -11- 38. Prain, D. 1905. Mansonieae, a new tribe of the natural order Sterculiaceae. Jour. Linnean Soc. (Botany) Vol. 37, pp. 250-263. London. 39. Record, Samuel J. 1929. The West African Abachi, Ayous, or Samba (Triplochiton scleroxylon). Trop. Woods No. 18, pp. 43-54, June 1. Yale Univ. School of Forestry, New Haven, Conn. 40. and Mell, C. D. 1924. Timbers of Tropical America. Pp. 285-286. Yale Press, New Haven, Conn. 41. Roddis Plywood Corporation 1950. Characteristics of Modern Woods. 3rd ed. , p. 7. Marshfield, Wis. 42. Savory, J. G. 1953. Surface Moulds in Obeche. Timber Tech. Vol. 61, No. 2164, pp. 81-83. Illus. Feb. London. 43. Schmidt, E. Schum.) (Familie 1951. Abachi (Triplochiton scleroxylon Sterculiaceae. Nr. 28) OberseehOlzer, Beipage der Zeitschrift ftir Weltforstivirtschaft Band 14, Heft 5, Illus. a Color plate and photomicrographs. Fritz Haller Verlag. Berlin-Grunewald. 44. Scott, M. H. 1943. Some West African substitutes for well known timbers. Journ. So. Afr. For. Assoc. (Pretoria), No. 10, pp. 29-39. April. (Trop. Woods No. 77, p. 46) 45. 1949. Weights of Timbers Used in So. Africa etc. Jour. So. Afr. For. Assoc. No. 17, page 91. Feb. Pretoria. 46. 1950. Notes on the More Important African Timbers Imported into the Union with Special Reference to Portuguese East African Species. Jour. So. Afr. For. Assoc. No. 19, pp. 56-57, Jan. Illus. Pretoria. Report No. 1974 -12- 47. Solereder, Hans. 1908. Systematic anatomy of the Dicotyledons. Pp. 843-845. Oxford, England. 48. Stebbing, E. P. 1937. The Forests of West Africa and the Sahara, pp. 149-150. W. & R. Chambers, Ltd. London. 49. Stone, Herbert and Cox, H. A. 1922. A guide to the identification of the more useful timbers of Nigeria. Pp. 19-21. Nigeria. 50. Unwin, A. Harold 1920. West African Forests and Forestry. Pp. 87, 417, 436. T. Fisher Unwin Ltd. London. Report No. 1974 -13- 1 Table 1. --Strength properties of Nigerian obecheGreen Property Moisture content .......... ....... .percent: : W eightper cubic foot ................. lbs • 12 76 •▪ ° Static bending (center loading) Maximum bending strength.. lb. per sq. in. : 5, 100 : Stiffness (modulus of elas- 700 ticity). . . . . ...... . . 1, 000 lb. per sq. in. : : Energy consumed in bending 6.2 o maximum load.. in. -lb. per cu. in. : T : To total fracture (total 14.0 work). . . . . .... . . in. -lb. per cu. in.. Impact Resistance to suddenly applied loads Maximum drop of 50 lb. hammer... in.: : Air dry 23 : : 7, 500 : 850 : . : 6.9 : 10. 9 24 19 Compression Maximum compressive strength Parallel to grain ..... ...lb. per sq. in. : 2, 580 : 3, 940 Hardness -- ball test Resistance to indentation On side grain.... . On end grain.. ....... • .......... lb.. ...... lb.. 420 460 : : 430 690 Shear Maximum shearing strength Parallel to grain ..... .1b. per sq. in. : 670 : 990 Cleavage Resistance to splitting In radial plane ...... lb. per in. width: In tangential plane... lb. per in. width: 200 170 : : 230 210 1 —Reported by F. H. Armstrong in the 1953 Forest Products Research Bulletin No. 28, page 39. Report No. 1974