DESIGN AND IMPLEMENTATION OF CELLULAR MANUFACTURING IN A JOB SHOP ENVIRONMENT

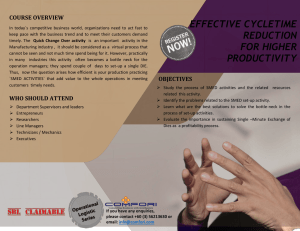

advertisement