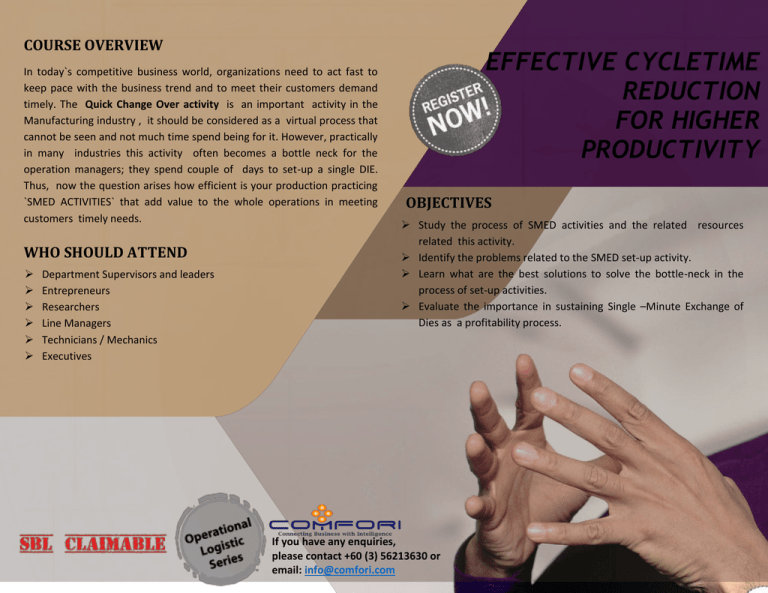

EFFECTIVE CYCLETIME REDUCTION

advertisement

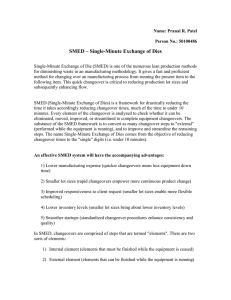

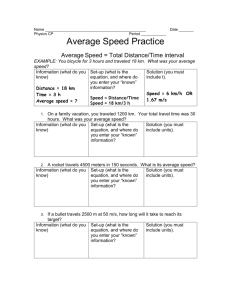

COURSE OVERVIEW In today`s competitive business world, organizations need to act fast to keep pace with the business trend and to meet their customers demand timely. The Quick Change Over activity is an important activity in the Manufacturing industry , it should be considered as a virtual process that cannot be seen and not much time spend being for it. However, practically in many industries this activity often becomes a bottle neck for the operation managers; they spend couple of days to set-up a single DIE. Thus, now the question arises how efficient is your production practicing `SMED ACTIVITIES` that add value to the whole operations in meeting customers timely needs. WHO SHOULD ATTEND Department Supervisors and leaders Entrepreneurs Researchers Line Managers Technicians / Mechanics Executives EFFECTIVE CYCLETIME REDUCTION FOR HIGHER PRODUCTIVITY OBJECTIVES Study the process of SMED activities and the related resources related this activity. Identify the problems related to the SMED set-up activity. Learn what are the best solutions to solve the bottle-neck in the process of set-up activities. Evaluate the importance in sustaining Single –Minute Exchange of Dies as a profitability process. If you have any enquiries, please contact +60 (3) 56213630 or email: info@comfori.com