OF F.)

advertisement

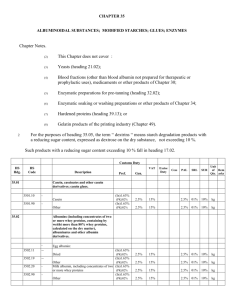

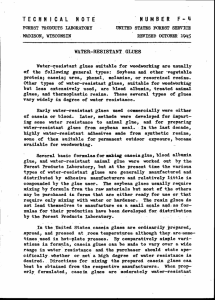

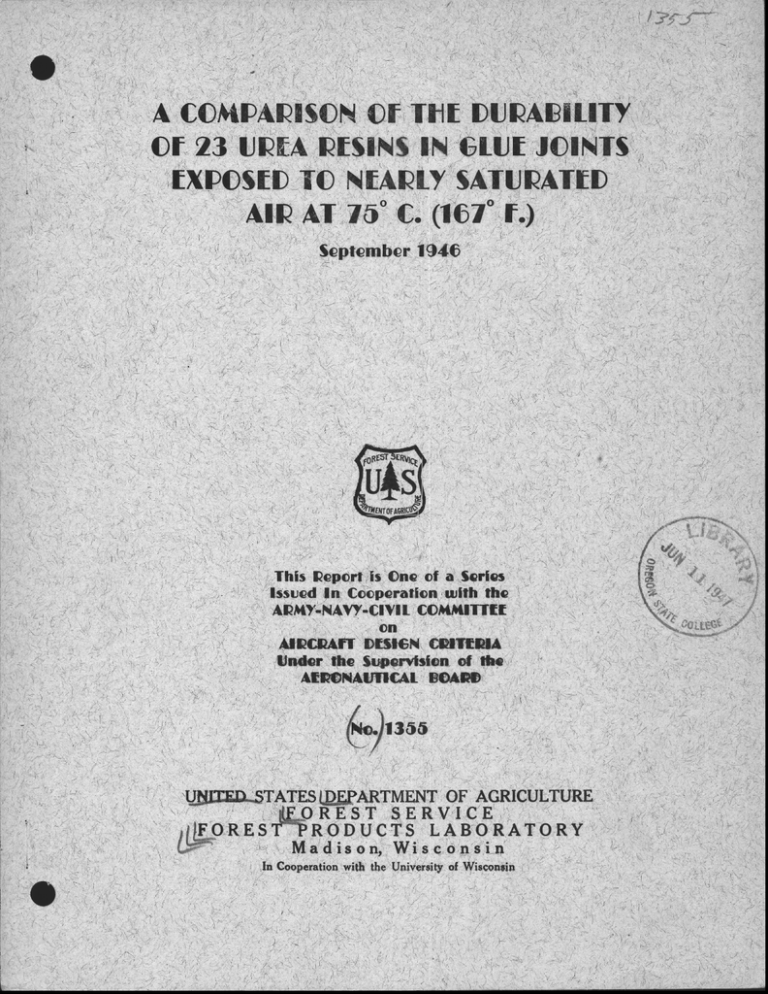

A C IPAIRISCS OF Tilt INUIPAII3ILITY elf 23 UPFA I 431_1X JOINTS EXPOSED N NEARLY SATUVAILID AM 41 75° C. (1€7° F.) - September 1946 This !Report is One- of a Series Issued in Cooperation with the ARM, -N4VY-,C1VII IL COMMITTEE ,on IDESMN (*MOM Under the Supervision of the AtIRONAINICAL BOAIND) )11355 TA FbRES • ARTMENT OF AGRICULTURE ()REST SERVICE RODUCTS LABORATORY Mad is o n, Wise 0 in S in Cooperation with the University of Wisconsin T Or 7F2, D 3?..A3IL,12Y OF 23 A COIT...APIS07''' 7 _ m T 7 :rakaLY SATURN= AIR AT 75 0 0. (167° F. 1 TJPTA .R-!, S 1. -S I': GLUE JO 7 S'3X '032D By A. 013RT-31, Chemist . Summary pl:Rfooe.. s p ecimens Fc.;luee, with 23 urea-forrialdehyde.j.;lues were e in [Jar- jars to nearly saturate_ air at 750 C. (167° F.) for periods 1.17 to 96 :lours and the joint otrerigths were periodically tested. The rate of (leterioration of the jo i nts varied 'for different glues, inica-ing (. eme to be much more durable than otl-ler. For a few 1ues where connarioon I Tar poscible their relative behavior at this high condition of teml2er2t;urc anc:_ relative humidity vas in clone agreement with the order of nerforiaLnco obcorved during proloned exposure of plywood to la:')oratorycoatrolled c:clec and to the weather. From the rermlts obtained, it amears that thio test might be used as a quick means of corroarinz the durability of different urea-resin luec, exoc mt roduction In an earlier re--)or q. wore presented the results of a preliminary study to find maitable accelerating conditionr, for com p -ring the resistance of different urea-formaldehyde resin glues to the deteriorating influence of heat and humidity. From these ex-)oTiments it appeared that exposure of yellow birch pl:ft rood specimens at the fiber saturation point to saturated_ air at 75 0 C. (1370 .7.) was suitable for a. sufficiently rapid and reproducible te . .t. Tho-ntr--)ose of the present retort is to indicate what Doi-formal-Ice in t1-ii test can be er- yocted of t;-71-)ical urea glues, how Tide tile • 1Thi 5 is one of a serics-of-progress re p orts prepared by the Forest Products Laboratory relating to the use of wood in aircraft. Results here reported arc proliminary and may be 3:ivised as additional data become available, 2 -Forest Products Laboratory Report Yo. 1533, 113xperiments to Develop a P.a-oid Durability Test for Urea-rosin Caues" - February 1945. Rep ort Yo. 1355 -1.- variation in performance may be, ana, as far as posniblo, to co;4pare the 'Performance in this quick toot with the p erformance euring longer exT)osure to milder conditionc. The 23 glues are designated by the letter A to J in thin r-ort. Nineteen of the glues were commercial p roducto mixed and used in accordance with the manufacturer's directions, 'our of the glues, A, C, E, and R were commercial uroa-renin syrups to which typical quantitico of ammonium-alt hardonorn were added. Seventeen wore room-tom p eraturo-f!etting gluor; six wore ho-r,ottinL;. Glues A, B, C, X, R, and T had film nH values below 2.0; all otherf-: had a film -H of 2,8 or higher. Three of the glues, U, 7, and U, wore dosicaated by the manufacturer a fortified, Procedures The ex-erimental technique wan as follow': Throe-1)l, 3/16-inch, plywood wan made of 1/16-inch straight-c;rained, yellow birch heartwood veneer at about 12 percent moisture content , by .gluing with each of the 23 , glues. Approximately 20 grams of wot glue por square foot was Emread on each side of the core p ly. About 15 minutes closed assemVie" 60 minutes was allowed for bly time was allowed for the cola-press all the hot-pross glues except glue U, which waf . given 24 h gurs. A pressure of 150 :pouncls nor square inch was applied for 16 hours at 75 0 F, for ,the cold,..preor:; glues and for 10 to 15 minutes at 260° F. for the hot-press glues. After gluing, 6 dayp . were allowed at 80° F. and 65 percent relative humidity for conditioning to equilibrium moisture content. Prom this p lywood were cut c -tandara test 7, p ocimenc with 1-inch nquare shear area. The s p ecimens wore brought to a moisture content of aoproximately 30 percent by immersing them in distilled water for 2-1/2 hours, then s'Goring overnight in an atmosphere of 97 percent relative humidity to effect uniform mosture distribution. After this, 10 of the specimens, scioctod at random as controls , were tested after soaking 24 hours in water at room tomp eratul-o and the rest wore stackod in bundles of 10, hold ap art by vortical thin plastic stri p s, in a copper-gauze cup inside a quart glass jar ac shown in figure 1. In the bottom of the jar was a layer of water about 1/4-inch deen above which the cur bias supported by a coper-gauze platform. Above the ---)ecimons on the ends of the plastic f7tri p s vas laid a dome of cellophane to shield the s-oceimcm, from dri p ping condensation. To jar wan covered with a lid that was l2orforated, to p ,,,rmit equalization of pressure, with a 1-millimeter hole in which r,:sted a thumb tack. :Mc jar with its content- wac then immersed u--) to it- nee:: in a bath of glycerine at 167° F. -±", 2 0 in an olectrically-heate& oven that averaged 167° F. in tomperaturo with a 9 0 F. variation, The bath was large enough to accommodate six quart jars at one time. The relative humidity of the air in the jar at 167° F. as measured by wet and dry bulb thermometers, was a p proximate17: 98 Percent. P mxiodically snecimons were removed ii groups of 10, roa:1-od for 24 hours in water at room # i.,emp oraturc, and tented 'Jet in shear in a conventional plywood-testing machine with tho loading rate at a p proximately 750 p ounds per minute. Rep ort Yo. 1355 -2- In these experiments, each group of 10 specimens was weighed before and after exposure in the heated jar and also after testing and oven drying to obtain a record of the moisture content of the specimens during the period of exposure. The specimens ranged from 26.0 to 30.0 percent moisture content before exposure and from 26.5 to 30.5 percent after exposure. Results The average results of the shear tests on the plywood specimens bonded with the 23 glues and exposed in the manner described are given in table 1. It may be seen from the data that the resistance of the glues to the influence of the elevated temperature and humidity employed in this experiment varied over a wide range. Of the glues set at room temperature, the more acid glues, A, B, and C, deteriorated the most rapidly, although glue K, having approximately the same acidity, showed better performance. Glues V and. W, fortified with melamine, were the most resistant, and somewhat superior to glue U, fortified with resorcinol, possibly because of greater percentages of fortifier. The three unfortified hot-pressed glues, R, 5, and T, appeared on a par with the better cold-pressed glues. It is known that urea-resin glued joints deteriorate when exposed to elevated temperatures as reached in sunshine ?- and that the higher the relative humidity, the more rapid the deterioration .q t It seems likely that the deterioration at 167° F. and 98 percent relative humidity differs only in rate and not in kind from that which takes place at other temperatures and humidities. Hine of the glues had been previously included in long-term durability studies made at this Laboratory, in which birch plywood specimens were subjected to continuous and cyclic exposure conditions. In table 2, the shear test results of these nine glues after 18 months exposure to three different conditions are compared with. the results after 48 hours' exposure in high relative humidity at 167° F. in the accelerated procedure described in this report. The estimated relative order of performance of the nine glues by the 48-hours accelerated test is not exactly the same as by the other three exposure conditions, but, considering the fact that the tests were made at different tmes and on different samples, the comparison is sufficiently close to lend support to the possible validity of the test described herein as a practical method of comparing the relative durabili4. ties of different urea-resin adhesives. Three of the glues, D, L, and U, had previously been used as the adhesive in unpainted yellow birch plywood panels, 18 by 18 inches in size, that were exposed to the weather on a test fence. These panels are shown 3 -Forest Products Laboratory Reiort No. 1530. 4 • -Forest Products Laboratory Report No. 1345. Report No. 1355 -3- in figure 2 after 3 years t outdoor exT)osure and delamination -measurements are given in table 3 4 The -)erformanco of the three glues in the ranolf= under as their ,orformanco after exterior. ox2ofmr was in the same 1 or 2 days in the quick test. The exact correlation between the accelerated tsost and various service conditions is not known, but the evidence indicates that it i a quick, useful method of detecting differences in the , durability of urea–resin glues. Rcnort Yo 4 1355 –4– Table 1.--Averagol. rosults of wot-shcar g. tests of ur.„a-formaldeh vde -luea birch r17wood snecimons before and after exposure at fiber 167 0 T. saturation to nc-)arl ,, saturated air at 75 0 0, :Hours in air at 167 0 F. ana Glue symbol :0(control); 16 24 ••• 0 P Ts. • • S 4 : -478-71 : : 415-79 : : 438-88 482-99 414-100 : 488-96 : : 485-96 : 512-98 : • 470-95 : • 424-99 t 504-98 : 452-95 477-97 483-97 424-68 500-85 527-99 I • • ; C o ld.--o r c ssed: luo C percent relative humidity .00.4,•••••••••n•.... e••••n••••••••••••,...... •••••• 96 72 ; 48 •n• •••••• ••• n•• ••••••.••• 7-4 98 Hot-precsed 4 -64-0 239-12 253-15 323-20 262-23 315-28 322-5 327-12 322-28 380-83 332-1A 424-74 392-65 353-40 390-32 417-62 442-Q7 '4 t-148-0 99-1 73-0 172-4 203,21 246-12 : 278.7 : 298-17 : 336-39 : 317-40 307-12 : 397-71 : 308-25 359-36 317-6 407-72 : 39872 4 (4) (4) 22-0 24-0 •• ....... •• • • • • • • • • 6 • : 25-'0 :.. ..... ; . . , • • • • • • • •••6*••• : 94.2 • • • • • • • • : • • : 122-9 : ... . • • • • : • • I ..... • • 1 ••• • • • • • • : 135-2 : . . . : 192-2 : . . , .., •• : • • : 207-3 ; . . . . . . . t . .. ... 0*** 209-5 t........t... -10 : ... ... 'na' .4,0 • • • • • • : 231 • • • • • • • O.' 248-6 : • •*••••• 259-17 : • • • n • •• : 295-19 : • • • • • • • • 1• • •. •. • 319-22 : ... . • • • 9 • • • • , • • 9 • • • • • • • • • • • • : 330-8 362-72 : 360-70 ; 272-68 : : 373-53 : 350-56 : 322-50 : • • • • • -lu,s t- S • 452-80 479-98 : 364-60 : 278-23 : 222-9 462-98 463-98 0 • . .... : 348-21 : 302-9 : 356-7 : 280-15 355-34 : 312-32 • 275-10 : 292-15 518-94 • • ..: 363-17 : 353-12 : 543-27 : 325-24 491-100 : •: 424-100: 424-100: 410-100: 403-100 428-100 : 448-100. 418-100: 414-400: 425400 430-98 . . • • 4 1 -11ach value is the avera6e of 10 specimens. 6-'20,tca wet a-ftor soaking in water at room tempornture for 24 hours. ...Plywóod specimens at about .30 porcent moisturo content worse hoated over water in a glast jar immersed in a bath maintained. at 167° F. m, Liao,.:1.-2f7t value is the average joint strength in pounds per square inch; thesacond is the average noreontage of wood failure. andlTwere fortified with resorcinol or melamine. =-Glucs U, glues in this table aro believed to be unfortifica. B.e--)ort :To. 1355 All other 4 zAL 0 I I 0 0 1 1 0 w I a) .• 0 1.--14 c-4 *, ;-.1 1 i a) g CD1 ‘ -H r.f) ,-C-1 0 a) +' Lr k I .) 0 0 1 P., +3 0 o tn rd I ',I A 1 0 b0 - H I 0 i• •. 1 70 E., „...:1- ..,-, ci) I 1 0 4-) 4-, -4.) 1 ._._-. rd 0 •.....- g c41,---4 C'd . cc, CD I 0 K1 4-) -8-4 • c rn 0 1 cr), ►4 I cd 1r-1 •H -) 0 CH 0 0 LI; 0 +) r-4 0 1 .4 d •• •• •• r1 ,.. ,41 C.) .r--; ,-C) rd 0 cr) C.-I 0 ';-4 0 0, -H 0 0 0 CI) fa 0 Ci) ca rJ ;4- CD 0 0 o CM ,d Ord P 0 •• rn 0` 0 -1-4 -1-) .,••=1 rd S 0 ‘ C.) U) r,--, tn . 0 ;?•4 PI - ...---.... N N ,C4 '''''''' rd o r-f •• f21 1 4.3 0 -H 0 k •r-Z1 r---1 U) I la 4-, I 4-, I) a) 0 0 Fr--; ;.4 ,C1 0 0 Ct3 • • • • • • • 0 •• •• •• 6• •• •• •I. . 4 . • 4* rd :1 • • .. 0 0 Cd •r4 0 g-4 d 4-4 r'..74: 4-, 4-) El rci Ci • . • • ► •• .0 r-4 •• •• •• •• 0 0 •H 0 P- 1 :...: c) r-i 0 ;--4 :C/ 03 0 0 ;4 0 0 cd 1-1f ',--- 0 r-Cir - +.) LID 0 4-D• 5-1 (1) ,d g ;.-1 0 -H 2d rt: ,rr.4 4-) $,0, .4 0 0 0 CD 'NO ,-. ;-1 0 r-t a) L_C-1 -,--1 d 0--i w d r d N Z ,-. .-i g 0 Ci a) . tY) C\J h-i- fl-1 N.-N---0000LCDO !MIMI N N in is-N r.•1 r-i 0 --- 0 r-1 01 1-•--.- N-1 01 k...C.) r-4 0 ,Ci-l'eN C1.1 N r-1 r-i r--4r-4 w ci) Ai 4-, rd P 0 • • • • i• •6 •• •• •• •• r-4 (I) P4 FA CD 0 ,-4 0 w d U) r'i PA ,---• -. ,-. 1. 0 4-I rn, T-4 ,-44 r4 4-D4-D d •4 ...... b0 U) r••1 0 k0 Ci -0 •1 0 • H dr) g a) k ;--1 0k 0 0 0 rd '.4D et-I r0 4-) 0 0 -P f21 ,C) •H CD 0 r---t FA p4 -C>0 0 •H a) 8 +,;.1 r-d 1) Ck) k i40 4-) a) 0 -H0 w •H a) o il-3 o R, H rd 0 rd Ci •r"") 0 0 ;.-4 (0) 0 L.C1 (1)(1) .H tH 4--) ..D w 0.i i i 1--1 r 1 C12 k 0 rd I'. \---- L.C1.0 N- tC al •• •• •• •• •• 0 ,4 -H C6 W ;-I 4-, r-f ci-) 4 c)-4 w a) c+-1 4M r--1 0 0 .-0 r--4 I ° I 1 1 as •• •• ;-1 •1-4 rd 0 rd Cl) RI C=4. 00 -H 0 ,4 0 0 0 Cu - ,1 OFH 0 3 14 40 r-1 •• ••I •• •• •• •• •• 0 Xl,0 1 E-I i •84 •• •• . 4 ere •• v) co 4-I .• 66 6.6 tO .C. In Ell--- CV C31 al 01...0 T-4 r--4 r-1 .CD 0 11111(111 • UI 0I4 '1/4,0 1,0 QJ CO al-Z- -Z- N aTh Fr-i r--4 -H ._._ rx r----_-• 130..4- aN 0 CT\ -4-) +) in Ln re-NZ re1 . N-1 N f•e-1 r-i 0 ;., .-4 u) Iti t0 I 8 4-, +) UI --- ill• ....--n LC1 1•...4 r"'1kn ,-.1 .... 3 a. rd U) rn r- E.:1 0 4-, (n 1-C1 U) 0 Ei r-1 •• •• •• •♦ •• I• w -0 0 . r0 1,--).4 0 ' s- 4-' 0 4-) g U) N •• 0 r-1 -H 0 • Ln10 Na. ND cTh •4 w 0) il 0 A • ;-4 • 0 i • 0 0 0 0 0 • d ri•I N f•e1..-1- H rd g cd -P Q U) •ri +.) (4-1 --, j ?-4 --4-. r-1 PC U) 0 a) rd H Pi - H (1-1 U) o 11111111 1-i'-i 0 o r.,-4 -H CV l..0 ,-- 0 1"r1.0 C1.1 rel • . -- ...0 Z50 N-- CD • f•-.. • CD r`el ► -..' tel N N N r-.4 N r-1 . td • w r-1 r-1 Q ci-i P ,-- 0 0 r., • 6• •• •• •• l'.... 0 0 C3-1 N _C) 0 0 C) 0 N 0 . PA -H -H r-4 ., . 1 U) 4-D -H rd q r-4 • • • • •• -H .-e . N • . i ♦ 4 • 0 .-1 -P 0r--i ;,-4 0 r1) •H C6 ',i C11 r0 -4-) -ri 0 4 -4-) tr.I cc.,/,C ;-1 ,4 M r-1 •►-1 +) 0 0 +' to k CI (1) 1 in 0 \..D. • . U) 0 4, w . Cf) 1 r-4 r- 0 ID % • H 0 -- 1-1 • • • • 4, A •• -4-' w ,--4 0 r, 0 - -4.- 0 I- ,. --1 f."-I +) 0 a) -H Pi rd -H IX) 0 '1 r-i 0 cd iri T-1 N N ,...." L 1`.. .0 b0 I ..i ,'r*3 w 4-D 0 Ci rd 0 o ai C,1 r-• 0 al r-4 r-1 1'i-1 r-1 r-1 Li-1 1-1 0,1 0 1 I I I 1' 111 I ..." NM N :-.T. ,--4 C)1 In al _LICU Lc-, r-4 ‘....o l'eN 00 0 \ C\I --- P•1Pc1 N N N N T-1 1 !---i ...?-.:N 1 0 0 r-4 •H . 4-, Ct ..... d . in -P M1 0 r-1 -.... .4_, rd rd a) • .. •• t-e- rrn rV ,-.4 I 0 1 $-.4 6 0 H ,ai , H w rd N.-...=4" C0 al 44 •• 4• .4 .. .• . Pi a) I 4-1 4-) .t.. •4 Q Ci ..- I :.-1 CDC) r-i 00 .cn 0 ;-4 -0 .rn 0 1 •• •• •• 6,• w 0 r4 ci-4 Z'd Cn 7-1 0 rd cf-i a) n›P U) E--I 1 1---- r-4 ',...0 0 •r1 r-4 Pi 4-) 0 0 130 -4-) r-i N t-,%4 „D ;A ;•-4 o cH •• •• *. •• at • el 1-1 /"Z 1-1 - '1 c---5 A 0 1--4 0 -0 -4-,() 0 4-) CD 0 rd ,4 0 -4-) ..-• ta CV a) E-4 r- -4-D t,-- UI cdcc; 0 k laf C) za o •--1 U) I 4 r-'-1 IlD 0 . ,-4 4-4 r---1 .0 0 f-1 ,4 EA c' ail .4-, 0 +' 40 g -H Lib r-i ,:d -H k C6 (1) 'I-I 0 C'd rd 0 0 0 r Ci) +--) CJ 4' -H ;-.4 0) a) '-i--i cl) 0 r-i 'i a) d r-4 • 0 1---, C-i 0 ;-.).-i o 03 0 0 -H 0 4-' (1) F-1 p 4 -H rx-i r."1 _._-- in r--4 4-, rd 0 C6 g -1-) > (1) rr. o .4 In (f) "--4 U) Isi i' Table 3.-4-Avorec delamination in urea-for.maldeh;vAe jElluod joints In ycllow birch p lywood p anels omlottod to the weather far 3 vcarTa7-Glue uzod in-panels ..,....-.............- , D L u 1 Delamination : Construction : around crlgos : ...,---,..0.-----:.--- ; . : Porcent f : .2, -.00 : throe-ply, 3/1$4nch; 90 : fiVC-,.LD1-.' . : q8-inch L' ci, ie 1 1 throo-ly 3/16-inch 1, ' 33 .. 5/8-inch fivt-Diy, 25 : throe-p : 0 ir ly , 3/16-inch 4 - : five.--ply, 5/8-inch Un-)aintod panols cxpor,ca in vortical .position, facing south, on tost fonco at liadinon, Ilisconsia. -"Aach valuo LI the avcrao for d_uplicatc-pancas, O • Figure 2.--Yellow birch plywood panels after exposure, unpainted, for 3 years on a test fence. Each panel is labeled with the code letter representing the glue used. Z M 68257 F