SURINICAGF OF WOO D May 194 7 No. R1650 Madison, Wisconsi n

advertisement

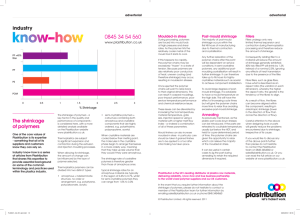

SURINICAGF OF WOO D May 194 7 No. R1650 UNITED STATES DEPARTMENT OF AGRICULTUR E FOREST SERVIC E LFORES`l -PRODUCTS LABORATOR Y Madison, Wisconsi n In Cooperation with the University of Wisconsin SHRINKAGE OF WOO D By EDWARD C . PECK, Technologist - _ -■ ,t - -1 Moisture in Wood . The large quantity of water that most green wood contains may be separate d roughly into two parts, that which is contained as free water in the cel l cavities and intercellular spaces of the wood, and that which is held as adsorbed water in the capillaries of the walls of such wood elements a s fibers and ray dells . It is the adsorbed water, amounting to about 30 per cent moisture content based upon the oven-dry weight of _the wood, that is of primary interest in the consideration of shrinkage, because when-thi s -water is removed the finer wood, elements approach each other and thereb y cause shrinkage . , Effect of StructureOf: VoQd-U -Sr Wood is composed of hollow fibers or cells, most of which--lie nearly parallel to the axis of the tree trunk . The cells of the ,wood rays, however , are perpendicular to the main body of cells . The cell walls that sur r°und the open spaces, or cell cavities, possess a crystalline structure (fig . 1) .. In normal wood, the greater part of the crystallites of the ,cell walls , both in the main body` of cells and in the wood-ray cells, are. oriente d nearly parallel to the axis of the tree trunk . The crystallites of th e primary cell wall, which lies in-the center of a wall between two cells , are oriented, however, so that they fall in planes perpendicular t_o, th e crystallites of the rest of the cell walls . Since thecrystallites ar e joined end to end, when the water between them is removed they approach each other in the lateral directions only . The crystalline structure, o f the cell walls, and the opposing structure of the different crystalline parts of the cell walls, somewhat like crossbanded plywood, make the shrink age of wood, complicated . When water, is removed from between the crystallltea ._of the cell _wall, they approach each other and thereby cause the wall to decrease in thicknes s and in circumference . The cell cavities tend to remain the same size durin g the shrinking of the cell walls, because of the nature of the cell-wal l structure . The volume of the cell walls decreases by an amount equal t o the volume of the adsorbed water removed from them . Since the shrinkag e along the length of the crystallites is zero, and since the majority of th e crystallites are nearly parallel to theaxis of the tree trunk,",the volu metric shrinkage of the cell walls is translated into decreases in the Rept . No . R1650 lateral dimensions of the wood, radial and tangential . Since the crysta l lites of the cell walls Of the wo•od~-r-ay-cells are nearly parallel to the ' axis of the tree trunk, but nearly perpendicular to the axis of the wood-- , ray cells themselves, the wood-ray'cells shrink chiefly along their length ._ If they did not act in this manner, they would seriously restrain radia l shrinkage . Directional Shrinkag e Wood shrinks most in the direction,o .f .the annual growth rings (tangen- tially),_'about one-half as much as this acros s, these rings (radially), .and very . little, as a-rule, along the grain (longitudinally) . The causes o f these differences in shrinkage are the he x:arOgeneous'nature o f . wood-and the complexities of the .cell-wall structures In some abnormal types o f wood, such as compression wood In conifers and,awood of exceptionall y - low specific gravity in hardwoods, the longitudina)•shrihkage is unusually great . This is accounted for by-the fact that the -crystallites of the cell wall s of such types of 'wood 'make a considerable angle to the' axis of the tre e trunk, instead of being nearly-parallel to it, ,In general, the springwood• of the annual ring tends to shrink more "longi t dinally than the summerwood ; and less laterally, for the same reason. Moisture Content-shrinkace Relationshi p Wood starts to .shrink'when it begins to lose the absorbed water . The removal of the frea water, which is held in the cell cavities, does not caus e " shrinking; ' :The-cell walls, as previously statdd, when -complete•ly- full o f water contairi-'about 30 percent moisture . "content based upon the .oven-drys . weight of the wood . This condition is called the fiber-saturation `point . The shrinkage that occurs when the moisture content is reduce d . balow -th e fiber-saturation point Is basically dependent" pon the amount of moisture removed-from the cell walls . In 'drying wood to a 'moisture content of 15 percent,- one-+ho.lf of the total shrinkage takes place ; while in drying i t to a moisture'content-'of-6 percent, four-fifths of the total shrinkage takes place . For practical purposes, swellin g' nay be considered the-re.verse of shrinking . Although basically the moisture content-shrinkage, . curve Is . a straight line 'fro m . the fiber-saturation ._point t-o ' zero moil- ~ tare content it actually is not so, because a piece of wood doe s 'not dry simultaneously from all parts . For purposes of calculating shrinkage, o r swelling, the moisture content-shrinkage relationship may be considered a direct one . The mbtsture cdhtent-=Shrinkage curve in figure 2 i"s typfcal . Shrinkage Variability One of the prominent things about shrinkage is its variability. Shrinkage not only differs along the three directions of grain, tangential, radial , and longitudinal, but among species . It varies widely in material cu t Rept . No, 81650 ' from the same species and even in material cut from a single tree, Woo d of high,specific gravity generally shrinks more than wood of low ape-cia o gravity, which would be expected because wood of high specific gravit y contains a greater volume of water at the same percentage of moistur e content than wood of low specific gravity . 'Another thing that contribute s to-the variability ofshrinkage is the change in volume of the cell cavi ties, either "a decrease, which may be called collapse, or an actual increase . In the first instance, the shrinkage is greater than the amount calculate d on the basis of the volume of the adsorbed moisture with the assumptio n that the cell-cavity volume remains unchanged ; and in the second instance , it is less than the shrinkage calculated on that basis . The changes in the volume of the cell cavities are caused by drying stresse s i or in some instances by liquid tension . Because drying stresses influence the change in volume of the cell cavities, an d , consequently-the over-all shrinkage , the amount of shrinkage is affected by the drying conditions . Generally , the higher the temperature and relative humidity, the greater is th e shrinkage . Water-soluble . extractives -influence shrinkage and tend to re duce the amount . The shrinkage variability within e. single species is illustrated i n figure 3 . The values, total shrinkage in width of plain--sawed longleaf pine heartwood boards, range from 3 .9 to 9 .0 percent, with a mean of 6 . 9 percent . The volumetric shrinkage curves in figure 4 illustrate the shrinkage vari ability within pieces cut from the time log . The specimens from which th e data were obtained were cut from a single radial board . The straight lines are the shrinkage curves calculated on the bases of the specifi c gravity of the wood and a fiber-saturation point of 30 percent . Since the hygroscopic water is compressed, its specific gravity is 1 .11 instead o f 1 .00 . Consequently, the volume is reduced so that 30 grams of water occup y only 27 cubic centimeters, The actual shrinkages are represented by th e curves., It is notable that considerable shrinkage occurs before the aver age moisture content has reached 30 percent, because the outer parts of th e pieces have reached a moisture content below 30 percent . The calculate d shrinkage is not attained in some instances, while in others it is exceeded . Despite the variability of shrinkage, the Forest Products Laboratory ha s accumulated, over a long period of time, shrinkage values that may be considered approximate mean values for the various specie-s ., Table 1 give s these shrinkage values in percentages based upon the green dimension . Although the shrinkage values of the table are given in percentages of th e green dimension, they can be converted by simple manipulation to useful units of measurement . Each 3 percent of shrinkage is roughly equivalen t to 1/32 inch per inch of dimension . An examination of the total shrinkage values in the table discloses tha t the following ranges exist : volumetric, redwood 6 .8 to hickory 17 .9 per cent ; tangential, redwood 4 .4 to hickory 11 .4 percent ; and radial, northern white cedar 2 .1 to hickory 7 .3 percent . Hardwoods shrink more than soft woods, on the average, by 13 .5 to 10 .3 percent for total volumetric shrinkage . The hardwood possessing the lowest shrinkage is mahogany, which i s Rept . R1650 -3- not a native wood. Of the . native hardwoods,; butter4ut.: os.qesses thy ; lgwest. . . shrinkage, - Of - the softwoods, tamarack pdsse-s er. the. _highest shrinkage, and i s followed by western larch . The ratteo of total, radial4to tQ al_ .,tangeritial shrinkage-ranges-,fr p m 1- :1,2 in evergreen magnolia to 1 :26 in Eastern whit e pine, . Although in general the woods of high specific gravitypossess-ttie highe r shrinkage, there _ are exceptions . Basswood-,' a-light wood, has a high shrink age, while black locust, a heavy wood, has a moderate shrinkage, . The amount of shrinkage, and the ratio of the directional shrinkage affect the development , ; of seasoning , defects during, drying. In ether instances , they help deterAi.ne the use to which the seasoned lumber . is .put . % - If wood did not • shrink; during . drying, most of the difficulties related t o seasoning would not exist . Shrinkage is , responsible for decrease in dimension, loss of footage, distortion in cross section, warping, surface an d end checking, 'h©neycombing and drying'andcase-hardening stresses . • - :,Shrink-age enters-the,'pieture as soon as . the :-tree is cut into logs . The drying from the,: freshiy„ cut ends is likely, to-cause end checks beca11a the dry •en d , surface is attempting to shrink . If the logs remain in the woods or in_:a dry yard for a considerable period before sawing, especially in hot, dr y weathers -..the- ;end& ohecks may -exten d' for a considerable length into -.the_-iog . ' • . . After, the lumber - i& sawed,._ and= before it is piled. for air,seasoning or kiln drying, exposure.: .to44evere'drying conditions, particularly direct sunshine, . _ will cause end and surface :checking, . : -During:. seasoning, when any part of ;thei_piece reaches a moisture conten t belawr .the fiber-saturation-point, 30' .percent, .it assumes a, tensile-.stress . Under-the influence of this stress, it' shrinks, fails, -becomes . "set ;• o r remains :stressed . Failure of surface layers"under shrinkageestrsss-result s in end checks ; which -may . develop into splits'•or--end: honeycomb,°checks.; and in surface checks, which may-develop into splits ; orhoineyeomb checks .- Failure-of internal parts results in the formation_ef .honeycomb checks, If the dried part does not fail, it assumes a set, which is one of the steps i n the development of a final-case-hardened oondition ; When the piece .of woo d has become thoroughly seasoned, the 'results of shrinkage are evident .- The . piece will be thinner, narrower, and shorter than it was when--green The shrinkage in thickness is of importance in making the proper allowanc e in setting the head saw or gang saw for the green thickness . If the boards . are sawe,ci too thick, a wastage of- weed results, even though all boards . dress to,the =desired dry thicknsav .' _ -If the boards are sawed too thin, ' too large•a percentage of them will fail to .make the required dry thick ness .- Owing to the variability in shrinkage, it is impossible to saw th e boards 'tis a green'-thickness so that they all will make the desired dry a . dressed thickness without excessive waste :; 'The optimum green 'thicknes s should produce a certain relatively_ large--percentage of boards that dress : to the required dry thickness . - The percentage 'of boards that should dress Rept, No,. P1650 - -4- A' to the desired dry t h 'j ckne a ' s shoo]:& be determined on An -e o oa~.i ' baste, . , v; The sawing allowance-for=shrinkage is influenced - by species,- tom= of. lumber, 1 and-by warping . Some species 'shrink more than others ; fore exarsple',one- :mil-l cutting southern yellow pine, . cottonwood, yellow-poplar, and black tupelo • on a gang: saw was experiencing difficulty . with respect totscanty; thicknes s with the cottonwood and black tupelo, but not with the other spehibsa Plain-sawed boards shrink lessthickness than quarter-sawed boards, bu t the outer edges of plain-sawed- boards are often equivalent to quarter-sawe d boards. Warping causes difficulties in attempting to dress to a certain thickness . Shrinkage in width is important, because . it usually causes a reduction in board footage, particularly ducting kiln drying ; The loss i n foetage is affected by the species, type of ]umber, and width of the board s and will be greater in those species having a large tangential shrinkage , in wide boards, and in plain-sawed lumber . Board footage losses, in kil n drying air-seasoned lumber from an average moisture content of 18 percen t down to 5 percent, have been calculated . The figures are based on kiln charges of plain-sawed lumber of normal width .distribution . Wider than average boards will- exceed the footage-loss figure . Quartersawed board s will ordinarily not suffer any appreciable loss in footage, since the total radial shrinkage is less than . 6 .3 .percent for most species . Figure 5 shows the estimated reduction in footage in percent of . air-dried tally, based on .. the total tangential shrinkage value .. Although the wood fibers or coils shrink but slightly in length, a bbard r is seldom cut so that its faces and' edges are parallel to the fibers . Thenature of the dross section•, •therefore, will be changed when the board dries . A square cross section .will no longer be .square, but may be .rectangular o r diamond-shaped. A circular cross section will no longer be-circular (fig .. 6) . Warping, which can'be broken down into cupping, bowing, crooking, and .twist'- ' ing ti . may take pace . Zipping may be brought about by the . nonsimultaneousdrying of the two facers, or- by the greater , shrinkage of the outer face of ' a plain-sawed board.. The other three forms of warping usually result fro m combinatioi'of-shrinkage with such irregularities of grain as spiral , diagonal, or localized irregularities, or with abnormal wood having a greater than normal longitudinal .shrinkage, such as compression wood or very light wood from buttressed tree bases . . Although warping is caused by shrinkage, it is well to bear in mind that much warping is also the_result of poo r -lumber piling. Shrinkage causes the greatest damage when it occurs after the lumber has been put into a'structure or the wood has been fabricated into finishe d articles . Changes in dimension, usually shrinkage but sometimes swelling , -cause defects . Shrinkage in structural members causes settling of buildings and loosening of fae.tenings . Settling of buildings causes plaste r cracks,- distortion of, openings, uneven floors, and unsightly openings around . trim . and moldings .. ` Shrinkage. of studs, sheathing, and siding decreases the weather tightness of the wall, loosens fastenings, and reduces. the mechani cal strength and stiffness of the wall . Shrinkage of subfloors and floors . causes :squeaky floors and unsightly floor cracks . Shrinkage of trim and paneling causes open joints, exposure of unpainted streaks, and possibly warping and splitting, Shrinking stairway parts cause squeaky stairs and Rept . No . B1650 Shrinkage ,of ,doci:rg causes. . un s ight .uni5ainted . streaks' And joints Shrinkage in boxing :and . crat i .ng . lumber .causes loosening of :-fasten- . poor fit open infix and . .splitttng , , .w-ith consequent weakening of the. package . Shrinkage o f . parts after their Manufacture into furnitu.re,. .cabinets, and . case goods , reislU.t in waxping, -splitting, cracking, failure 'Qf joints. , and dimuni,-:tion of the strength ." . - . .r .1 . .. . ■ 5" - t . 1: _ I I , :-, . . , . ..„ - Rept . No . R1650 .. Shrinkage Species t =' Air-dried to 15 perc9ent moisture contend (estimated values) : Radial : 3 .6 2.3 3-9 4 .0 2 .0 1 .8 1 .9 2 .6 ' Z M 87996 F 2 .2 1 .4 : 33 .4 .2 = 1 .8 1 .7 s 2 .0 1 .8 2 .5 I Percent - :Percent : 7 6.4 6 .6 5 .8 5 .2 4.1 .7 6 .2 4.3 3 .0 3 .6 s 4 .6 4 .3 1 .8 2 .1 4 .8 4.4 2 .4 s 3 .3 4 .4 1 .5 2 .2 2 j .4 . .0 4 .4 2 .1 3 .3 4 t ! s t: t; 1 .6 2 .1 2 .2 2 .6 2 .7 1 .8 2 .6 3 .4 4.4 33 2 .$ 3 .5 4.6 3 .4 33 .8 .1 1 .14 ) • Oven-dried to 0 percen t moisture content (teat values) ! Tangential Tangential•Volumetric Radial •Tangential Volumetric Radia l :Percent : Percent Alder, red Alaska yellow-cedar Ash : Black Commercial white Oregon Aspen Baldoypress Basswood Beech, American Birch L Birch, paper Butternut Cherry, black Chestnut Cottonwood : Eastern Northern black Douglas-fir Coast region Inland Empire region Rocky Mountain region Elm American Rock Slippery Fir Balsam Commercial whiteHackberry Hemlock : Eastern Western Hickory : Pecs ; True_ Honey locust Incense-cedar California Larch, . Western Locust, black Magnolia: Cucumbertree Evergreen Mahogany ▪ Eiln-dried to 6 percent moisture content? (estimated values) • : 8 .2 .1 5.8 5 .8 7 .e 6 .2 5 .9 5 .33 3 .00 5 .5 5 .0 : 3 .0 a 2 .7 : , 3 .1 . 2 .9 . 1 4 .0 s 3 .3 s . 3.8 : . . . 4 .8 . 6 .0 6 .8 9 .0 5 .4 8 6.6 4 .9 6 .8 6 .2 3 .8 2 .8 . 4 .1 7 .0 6 .9 4.4 4.9 6 .9 . : : 3 .9 2 .2 2 .6 3 .8 2 .4 3 .4 3 .9 5 .8 3 .4 2 .6 3 .4 3 .5 : Percent 10 .1 4.8 : 3 .7 • : 3 .3 : Percent . : . . . : . . 1 4 .2 . 4 .3 : . 2 .8 s 6 .o 6 .5 5. 5 .0 b .8 7 .1 4 .9 5. 7 5. 7 .4 6 .9 6 .2 5.0 7 .6 7 .1 5 .3 5 .7 7 .1 5 .4 6 .3 7 .1 9 .1 5 .3 4 .2 6 .5 5 .5 7 .11 :Percent : Percent 4 .4 2 .8 5 .0 4 .6 4 .1 3 .5 3 .8 .6 556 .1 6 .9 6 .3 3 .3 7.3 6.0 7.8 7 .5 8.1 6.7 6.2 9 .3 11 . 0 8.9 8.6 6.1 : 12 .2 . 10 .2 10 .6 9 .2 12 .6 13 .0 13 .0 18 .2 9 .3 11 .3 9 .9 9 . 14 8 .7 8 .5 11 .7 11 .3 11 .0 8 .6 7 .8 . 11 .0 7 .8 9 .5 : 10 .9 114 .3 8 .6 . 6 .1 10 .6 . 7 .8 10 .9 9 .8 6 .2 3 .4 3 .9 3 .6 .0 4 .1 3 .6 4 .2 . 4 .8 . 4 .9 . 2 .8 2 4. 8 3 .0 4 .3 4 .9 : 3 4 .2 : 33 .3 44 .2 : 4 .4 5 .2 5 .4 3 .5 : . . : : . • . . . . : : : . . : : . : Percen t • • 12 . 6 9.2 15 . 2 12 . 8 ▪ 13 . 2 11 . 5 • 15 . 8 16 . 3 10 . 5 16 . 3 16 . 2 10 . 2 11 5 1. 1 9 .2 8.6 7 .8 7 .6 .2 6 9 .5 8 .1 8.9 6.6 7 .1 6 .9 6.8 7 .9 8 .9 11 4 6 .6 5 .2 8.1 6.9 8 .8 6.6 4 .8 Volumetri c 11 . 6 -s 14 . 1 : 11 . 8 10 . 9 10 . 6 12 . 4 14 . 6 14 . 1 13 . 8 10 . 8 9 8 1 .8 3 9 .7 11 . 9 . 13 . 6 17 . 9 10 . 8 7.6 9 .8 13 . 6 .3 7.7 13 . 2 s Table 1 .--Shrinkage values of wood based upon its dimension when green species Maple : Bigleaf Black Red Silver Sugar Oak : Rea? white$ Pine : Eastern white Loblolly Lodgepol e Longleaf Ponderosa Red Bhertleat Sugar Western white Redoedar, Eastern Redoedar, Western Redwood Spruce : Eastern% Engletoann silks Sweetgum Sycamore, America n Tamarack Tupelo : Black Water Walnut, black Wnite cedar : Atlantic Northern Port Orford Yellow-poplar (Continued ) shrinkag e Eiln-dried to 6 percent Oven-dried to 0 percent Air-dried to 15 percent moistur e content moisture contentll_ moisture content5. (test values ) (estimated values) (estimated values) Volumetric : Radial : Tangential :Volumetrio :Radial :Tangential : Volumetric : Radial : Tangential : ; ° ----° 1 t^ Peroen t lpercent : Peroent : Percent :Peroent : Percent Percent :Percent : Peroent 11 . 6 : 3•7 1 .8 3 .6 5• 7 9 .3 7 .1 5 .8 3 .0 14 . 0 11 .2 4 .8 9 .3 2 .4 4.6 7 .0 3 .8 7.4 13 . 1 2 .0 4 .1 6 .6 2 6 .6 10 .5 : 4 .0 8 .2 12 . 0 6 .0 2 .4 5 .E 7 .2 1. 36 9 .6 : 30 14 . 9 11 .9 4 .9 9 .5 2 .4 4 .8 3 .9 7 .6 t 7 .4 : : : 9 .0 : 14 . 8 2 .2 4 .5 7 .4 4 s 7.z 11 .E 4 .3 16 . 0 12 .8 5 .4 9 .3 : 2 .7 4 .6 8 .0 : 4 .3 s 7 . 4 2 .3 6 .0 8. 2 : 1 .2 3 .0 : 4 .1 : 1 .8 4 .8 6 .6 12 . 3 : 2 .4 s 3 .7 6 .22 t 3 . 6E 5 .4 : 9 .g : 7 .4 1 11 .3 2. 2 4 S5 : 33 4 9 .5 6 12 . 4 .1 9 .8 5 7 .5 : 2 . 6 : 3 .8 6 .1 5 6 .0 54 .1 .1 : 3 g b .3 i 9. 6 : 2 .0 .0 : 4 .6 1 : 5 .0 33 .2 7 7 t '4 . 6 2 s 11 . 5 2 .3 3 .6 s .E t 8 9 .2 21 .4 .2 : 3 .8 : b .2 i 3 . i b .2 9 .E 29 . 67 12 .; 3 2 .8 i 4 .0 : 2 . t 4 .5 55 7 .4 : 11 . 5 : 2 .0 1 3 .7 3 . s 5 .9 9 .4 : 4.1 5 .9 : 7.8 3 .9 : 2 . t j .8 s 6 .2 t 3 .1 4 .7 : 1 .6 2 .4 t 11 .0 6 .2 2 2 .4 5-( 4 1 8 1 .2 2 .5 3 .8 : 1 .9 2 .6 1- 7 1 .3 2 .2 3 .4 : 2 .1 t 3 .5 5 .4 12 . 6 6 .3 . 3 .4 : 6 .2 10 .1 4. 2 .2 1 3 .8 10 . 4 g $ 6 :6 1 .7 5 .2 2 .4 55 11 . 5 : 3 .8 5 .8 : 2 4 6 .0 : 9 .2 t+•3 7 .5 7 .5 4 :2 7 .9 : 12 .0 : 5 .2 9 .9 5 2 .6 : 5 .0 t 1 24 . 2 1 3 : 4.1 5 .3 11 .4 5 .1 7 .6 2 .6 .8 7 .1 13 . 6 : 3 .0 : 1 1 .8 6 .8 5 .9 : 10 .9 : 3.7 7 .4 3 .7 s : 7 .7 3 .8 1 7 .0 3. 6 .2 11 .1 2 4. 11 1 13 . 9 2 .2 12 . 5 6 .1 10 .0 4 .2 7 .6 2 .1 3 .86 .2 } .4Z 11 . 3 2 .6 3 .6 5 .7 1' .2 5 .7 9 .0 5 .2 7 .1 s : 5 .2 4 .2 6 .77 2 .E E.4 1 .4 2 .6 : 4 .2 1 2 .2 2 .1 4 .7 7.0 1 1.0 2 .4 : 3 .5 1 .7 3 .8 5 .6 10 .1 2 .3 t 5 .0 8 .1 4.6 6 .9 3 .4 3 .7 5 .5 12 .3 : 3 .2 5 .7 9 .8 1 4.0 7 .1 2 .0 3 .6 6 .2 1 - ?These shrinkage values have been taken as one-half the shrinkage to the oven-dry condition as given in the last three columns of this table . 2 -These shrinkage values have been taken as four-fifths of the shrinkage toltse oven-dry condition as given in the last three columns of this table . Average of sweet birch and yellow birch . 'Average of grand fir and white fir . akverage of bltternut hickory, nutmeg hickory, water hickory, and pecan . Average of ehellbark hickory, mookernut hickory, pignut hickory, and shagbark hickory . 7-Average of black oak, laurel oak, pin oak, northern red oak, scarlet oak, southern red oak, swamp red oak, water oa k and willow oak . -Average of bur oak, chestnut oak, post oak, swamp chestnut oak, swamp white oak, and white oak . 2Average of black spruce, red spruce, and white spruce . Z M 67997 F 1 v N e, (NOSNJ/v/c. N3~~ liv~~~~d) ~~r : .. 25 - 20- 5- Ol / 2 3 4 5 6 7 8 SHRINKAGE IN WIDTH - TANGENTIAL (PERCENT OF GREEN DIMENSION ) Z H 67995 F Figure 3,--Frequency distribution of total tangential shrinkag e values of plain sawed boards of longleaf pine heartwood . 9 r r z m 42062 F • rgure 4 .--Volttet;ti•c shrinkage curves of four pieces of sycamore cut from t' he.e4 radial board . Straight lines represent the calcnIate•d :0 1iikiges, based-on 30 percent of water by weight , but 2Z..per,ent by volume ; curved-lines, the actual shrinkages . 6 I J 9 /0 6 7 8 TOTAL TANGENT/AL SHRINKAGE (PERCENT) Z Y 36992 F figure 5 .--Estimated reduction in tally) vs . tangential shrinkage . green) for carload shipments of a moisture content of 5 percent of 18 percent . footage (percent of air-drie d (percent of dimension whe n hardwoods when kiln dried - t o from an air-dried conditio n //