AN ECONOMIC EVALUATION OF COPPICE FUELWOOD PRODUCTION FOR CANTERBURY John R Fairweather

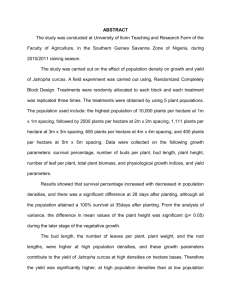

advertisement