2.76 / 2.760 Lecture 10: Error modeling Macro Meso Micro

advertisement

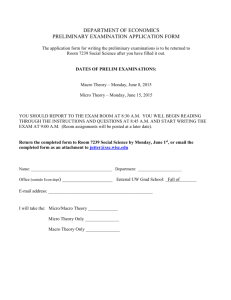

2.76 / 2.760 Lecture 10: Error modeling Macro Meso Micro Nano K K K esystem = Oerror − Ono min al ⎞ ⎛ f12 ⎜⎜ SR Meso ⎟⎟ ⎝ Macro ⎠ ⎞ ⎛ f13 ⎜⎜ SR Micro ⎟⎟ ⎝ Macro ⎠ ⎞ ⎛ f14 ⎜⎜ SR Nano ⎟⎟ I Macro ⎝ Macro ⎠ OMeso ⎞ ⎛ f 21 ⎜⎜ SR Macro ⎟⎟ ⎝ Meso ⎠ ⎞ ⎛ f 22 ⎜⎜ SR Meso ⎟⎟ ⎝ Meso ⎠ ⎞ ⎛ f 23 ⎜⎜ SR Micro ⎟⎟ ⎝ Meso ⎠ ⎞ ⎛ f 24 ⎜⎜ SR Nano ⎟⎟ ⎝ Meso ⎠ ⎛ ⎞ f 31 ⎜⎜ SR Macro ⎟⎟ ⎝ Micro ⎠ ⎞ ⎛ f 32 ⎜⎜ SR Meso ⎟⎟ ⎝ Micro ⎠ ⎞ ⎛ f 33 ⎜⎜ SR Micro ⎟⎟ ⎝ Micro ⎠ ⎞ ⎛ f 34 ⎜⎜ SR Nano ⎟⎟ I Micro ⎝ Micro ⎠ ⎞ ⎛ ⎞ ⎛ f 41 ⎜⎜ SR Macro ⎟⎟ f 42 ⎜⎜ SR Meso ⎟⎟ ⎝ Nano ⎠ ⎝ Nano ⎠ 2.76 Multi-scale System Design & Manufacturing ⎞ ⎛ f 43 ⎜⎜ SR Micro ⎟⎟ ⎝ Nano ⎠ ⎞ ⎛ f 44 ⎜⎜ SR Nano ⎟⎟ ⎝ Nano ⎠ OMicro ONano I Meso ⋅ I Nano itunnel [nA] OMacro ⎞ ⎛ f11 ⎜⎜ SR Macro ⎟⎟ ⎝ Macro ⎠ ← 2.76 STM surface sensing 8 6 4 2 0 0 2 4 6 Gap [Angstroms] 8 Announcements Grades…. I am behind, apologies… Literature critique Posted: First come, First serve WAIT UNTIL AFTER CLASS!!!!! 2.76 Multi-scale System Design & Manufacturing Questions 1. How did the STM reading go? 2. What do you perceive as being the most helpful way we can (outside of lecture) help your group get started on the design? Meetings Recitation Etc… 3. What would you like to hear about from Thursday’s lecture? 2.76 Multi-scale System Design & Manufacturing Where are we at, where to go now… Sept. Design •Perception •Approach Oct. Nov. Dec. 2.76 Multi-scale System Design & Manufacturing Model •Components •Interfaces •System •Examples Project •Model •Design •Integration •Validation •Characterize PSets •3 p. max! •Schedule •Risk •Mitigation Purpose of today Connect qualitative analysis/view with component-level view Error models link components and system behavior Error budgets set limits on system and component errors 2.76 Multi-scale System Design & Manufacturing Types of errors in systems 2.76 Multi-scale System Design & Manufacturing Principle of determinism Systems transform inputs into output Desire a one to one relationship between inputs/outputs Deterministic relationship = one relationship Closed form modeling is then possible! 2.76 Multi-scale System Design & Manufacturing System design principles Inputs System (Deterministic!!!) Outputs People Material properties Environment changes Residual stress Desired output Perceived Error System Measured output Actual output Forces Vibration Equipment 2.76 Multi-scale System Design & Manufacturing Friction Real error The strategy for dealing with errors What is the nature of cause/effect? Deterministic: Is there 1 output for a set of given inputs Sensitivity: d output = ? d error input People Material properties Environment changes Residual stress Desired output Perceived Error System Measured output Actual output Forces Vibration Equipment 2.76 Multi-scale System Design & Manufacturing Friction Real error Principle of accuracy How well you achieve the goal 2.76 Multi-scale System Design & Manufacturing Principle of repeatability How well you can perform same function a multiplicity of times 2.76 Multi-scale System Design & Manufacturing Accuracy and repeatability Ideal situation, accuracy and repeatability 2.76 Multi-scale System Design & Manufacturing What are most concerned with in the STM? 2.76 Multi-scale System Design & Manufacturing Example OMacro ⎞ ⎛ f11 ⎜⎜ SR Macro ⎟⎟ ⎝ Macro ⎠ ⎞ ⎛ f12 ⎜⎜ SR Meso ⎟⎟ ⎝ Macro ⎠ ⎞ ⎛ f13 ⎜⎜ SR Micro ⎟⎟ ⎝ Macro ⎠ ⎞ ⎛ f14 ⎜⎜ SR Nano ⎟⎟ I Macro ⎝ Macro ⎠ OMeso ⎞ ⎛ f 21 ⎜⎜ SR Macro ⎟⎟ ⎝ Meso ⎠ ⎞ ⎛ f 22 ⎜⎜ SR Meso ⎟⎟ ⎝ Meso ⎠ ⎞ ⎛ f 23 ⎜⎜ SR Micro ⎟⎟ ⎝ Meso ⎠ ⎞ ⎛ f 24 ⎜⎜ SR Nano ⎟⎟ ⎝ Meso ⎠ I Meso OMicro ⎛ ⎞ f 31 ⎜⎜ SR Macro ⎟⎟ ⎝ Micro ⎠ ⎞ ⎛ f 32 ⎜⎜ SR Meso ⎟⎟ ⎝ Micro ⎠ ⎞ ⎛ f 33 ⎜⎜ SR Micro ⎟⎟ ⎝ Micro ⎠ ⋅ ⎞ ⎛ f 34 ⎜⎜ SR Nano ⎟⎟ I Micro ⎝ Micro ⎠ ONano ⎞ ⎛ f 41 ⎜⎜ SR Macro ⎟⎟ ⎝ Nano ⎠ ⎞ ⎛ f 42 ⎜⎜ SR Meso ⎟⎟ ⎝ Nano ⎠ ⎞ ⎛ f 43 ⎜⎜ SR Micro ⎟⎟ ⎝ Nano ⎠ ⎞ ⎛ f 44 ⎜⎜ SR Nano ⎟⎟ ⎝ Nano ⎠ I Nano ← 2.76 Multi-scale System Design & Manufacturing Nature of errors in systems 2.76 Multi-scale System Design & Manufacturing Excercise In-class example 5 people measure Tabulate measurements, one for each end Will call on you in a minute 2.76 Multi-scale System Design & Manufacturing Nature and type of errors Systematic errors Repeatable errors which are inherent to the system These errors are always present Random errors Errors in a given system which are perceived to have a statistical nature to them Error sources Thermal Compliance Manufacturing Etc.. 2.76 Multi-scale System Design & Manufacturing Goal of system design Apply physics to design systems to achieve? Accuracy Repeatability Accuracy & repeatability Error management is key. Types of errors Random: Systematic: Non-repeatable errors, no good way to model Repeatable, can be mapped/calibrated/corrected Accuracy only as good as repeatability Experimentation is not a bad thing, often necessary (e.g. random errors)!!! 2.76 Multi-scale System Design & Manufacturing Random nature of errors Accuracy Repeatability Repeatable Poor combination Error 2.76 Multi-scale System Design & Manufacturing Accuracy & repeatability Accurate and repeatable Accuracy = ? Desired Position Poor combination Error Common sources of errors Common error sources Contacts Vibration Gravity People Material properties Thermal Measurements Friction Environment changes Load Constraint Others….. Wear Stress Residual stress Desired output Perceived Error System Measured output Actual output Forces Vibration Equipment 2.76 Multi-scale System Design & Manufacturing Friction Real error Unexpected error sources If you can’t measure it, you can’t make it Measure the “right thing”… Example: Moral of the story: People are lousy components of measurement systems Measurement gurus… 2.76 Multi-scale System Design & Manufacturing Error budgets 2.76 Multi-scale System Design & Manufacturing Error budgets 101 1. What are they needed? 2. Why are they needed? 3. How do you do predict errors? 4. How does this apply to project? Macro Meso Micro Nano 2.76 Multi-scale System Design & Manufacturing System modeling fundamentals OMuSS = G (SR ) ⋅ I MuSS OMacro OMeso OMicro ONano ⎛ ⎞ f11 ⎜⎜ SR Macro ⎟⎟ ⎝ Macro ⎠ ⎛ ⎞ f 21 ⎜⎜ SR Macro ⎟⎟ ⎝ Meso ⎠ = ⎞ ⎛ f 31 ⎜⎜ SR Macro ⎟⎟ ⎝ Micro ⎠ ⎛ ⎞ ⎜ f 41 ⎜ SR Macro ⎟⎟ ⎝ Nano ⎠ ⎛ ⎞ f12 ⎜⎜ SR Meso ⎟⎟ ⎝ Macro ⎠ ⎛ ⎞ f 22 ⎜⎜ SR Meso ⎟⎟ ⎝ Meso ⎠ ⎛ ⎞ f 32 ⎜⎜ SR Meso ⎟⎟ ⎝ Micro ⎠ ⎛ ⎞ ⎜ f 42 ⎜ SR Meso ⎟⎟ ⎝ Nano ⎠ 2.76 Multi-scale System Design & Manufacturing ⎛ ⎞ f13 ⎜⎜ SR Micro ⎟⎟ ⎝ Macro ⎠ ⎛ ⎞ f 23 ⎜⎜ SR Micro ⎟⎟ ⎝ Meso ⎠ ⎛ ⎞ f 33 ⎜⎜ SR Micro ⎟⎟ ⎝ Micro ⎠ ⎛ ⎞ ⎜ f 43 ⎜ SR Micro ⎟⎟ ⎝ Nano ⎠ ⎛ ⎞ f14 ⎜⎜ SR Nano ⎟⎟ ⎝ Macro ⎠ ⎛ ⎞ I Macro f 24 ⎜⎜ SR Nano ⎟⎟ ⎝ Meso ⎠ ⋅ I Meso ⎛ ⎞ I Micro f 34 ⎜⎜ SR Nano ⎟⎟ ⎝ Micro ⎠ I Nano ⎛ ⎞ ⎜ f 44 ⎜ SR Nano ⎟⎟ ⎝ Nano ⎠ Input-output mapping OMuSS = G (SR ) ⋅ I MuSS Oideal = G (SR )ideal ⋅ I ideal Oerror = G (SR )random + systematic ⋅ I random + systematic eMuSS = Oerror − Oideal 2.76 Multi-scale System Design & Manufacturing How do we do this? Example Identify Coordinate systems (CSs) Look for symmetric centers and center of stiffness locations Connect the CSs to form stick figures (SFs) Assign length/orientation variables to SFs Formulate component error equations between CSs Formulate system error equation Requires Homogeneous Transformation Matrices (HTM) Obtain error vectors (ideally in parametric form) 2.76 Multi-scale System Design & Manufacturing Homogeneous Transformation Matrices What does this buy us? Example: Translation A Berror BNominal XA XB YA YB = H Nominal ⋅ ZA 1 1 Nominal eError = & ZB XA XB YA YB = H Error ⋅ ZA 1 1 Error XA XA XB XB YA YA YB YB − ZA 1 Error 2.76 Multi-scale System Design & Manufacturing = H Error ⋅ ZA 1 Nominal ZB 1 − H Nominal ⋅ ZB ZB 1 Homogeneous Transformation Matrices Rotations: 1 A H B (θ x ) = 0 y 0 0 0 cos(θ x ) − sin (θ x ) 0 0 sin (θ x ) 0 0 cos(θ x ) 0 0 1 A H B (θ y ) = x z cos(θ y ) 0 sin (θ y ) 0 0 1 0 0 0 0 0 1 − sin (θ y ) 0 cos(θ y ) 0 For small θ, cos(θ)~0 & sin(θ)~θ A H B (θ z ) = cos(θ z ) − sin (θ z ) 0 0 sin (θ z ) cos(θ z ) 0 0 0 0 1 0 0 0 0 1 Order of multiplication is important for large θ 2.76 Multi-scale System Design & Manufacturing Example: Mach. vs. concept model Big issues first Contacts Vibration Gravity Thermal Measurements Friction Load Constraint Others….. Diagram removed for copyright reasons. Detailed schematic of machine tool, which forms the basis for the conceptual model (right). Figure by MIT OCW. 2.76 Multi-scale System Design & Manufacturing Wear Stress Example: Mach. vs. concept model Stick figure model CS A is at stationary part of bottom part Diagram removed for copyright reasons. Detailed schematic of machine tool, which forms the basis for the conceptual model (right). Figure by MIT OCW. 2.76 Multi-scale System Design & Manufacturing General form w/o rotations Multiple transformations XA YA ZA = HB ⋅ A XB XB YB YB ZB ZB 1 1 1 y XC = HC ⋅ B x z YC ZC 1 XC XA A YA ZA 1 B C 2.76 Multi-scale System Design & Manufacturing = H B ⋅ HC A B YC ZC 1 Example cont. Analytic modeling of linear errors XA YA ZA Figure by MIT OCW. 2.76 Multi-scale System Design & Manufacturing 1 XE = H B ⋅ HC ⋅ H D ⋅ H E A B C D YE ZE 1 Statistical treatment of error models Once you have a good parametric error model you can: Put into a spreadsheet/Matlab/MathCAD Run “what if” scenarios Run sensitivity analyses Run optimization Run statistical analyses (e.g. Monte Carlo analysis) 2.76 Multi-scale System Design & Manufacturing