Exam Revisit (I) • Diagonal term vs. Off-diagonal term • Matrix rearrangement ⎫

advertisement

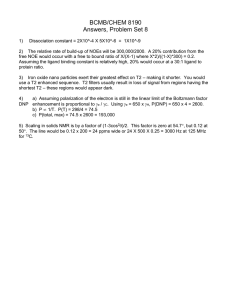

Exam Revisit (I)

•

Diagonal term vs. Off-diagonal term

•

Matrix rearrangement

⎧ FR1 ⎫ ⎡ X

⎪ FR 2⎪ ⎢ X

⎪ ⎢

⎪

⎬=

⎨

⎪ FR3 ⎪ ⎢ O

⎪⎩ FR 4⎪⎭ ⎢⎣ O

O

X

X

X

O

X

X

X

O ⎤ ⎧ DP1 ⎫

O ⎥⎥ ⎪⎪ DP 2⎪⎪

⎬

⎨

O ⎥ ⎪ DP3 ⎪

⎥

X ⎦ ⎪⎩ DP 4⎪⎭

Taesik Lee © 2005

Exam Revisit (II)

•

Allowable tolerance / Probability of Success

⎧ DPa ⎫

⎪ DPb ⎪

⎪

2 0 2 2 0 ⎤⎪

⎧ FR1 ⎫ ⎧2⎫ ⎡ 1

⎪⎪ DPc ⎪⎪

⎪

⎪ ⎪ ⎪ ⎢

⎥

⎨ FR 2⎬ = ⎨1 ⎬ = ⎢0.5 1 0 0 1 0 ⎥ ⎨

⎬

DPd

⎪ FR3 ⎪ ⎪3 ⎪ ⎢ 0.1 0.2 0 0 3 0.5⎥ ⎪

⎪

⎩

⎭ ⎩ ⎭ ⎣

⎦ ⎪ DPe ⎪

⎪

⎪

⎪⎩ DPf ⎪⎭

⎧ FR 2⎫ ⎧2⎫ ⎡0.5 0 0 ⎤ ⎧ DPa ⎫

⎪

⎪ ⎪ ⎪ ⎢

⎪

⎥⎪

⎨ FR1 ⎬ = ⎨1 ⎬ = ⎢ 1 2 0 ⎥ ⎨ DPd ⎬

⎪ FR3 ⎪ ⎪3 ⎪ ⎢ 0.1 0 0.5⎥ ⎪ DPf ⎪

⎭

⎦⎩

⎭ ⎩ ⎭ ⎣

⎩

∆DP 2 + = 2∆FR 2 + = 0.2

∆DP1+ = −0.5∆DP 2 + + 0.5∆FR1+ = −0.05

∆DP3 = −0.2∆DP 2 + 2∆FR3 = 0.16

Taesik Lee © 2005

Exam Revisit (III)

DP1

A

DP1

0.2

0.19

0.16

0.05

0.1

-0.2

0.2

-0.1

DP2

0.1

-0.2

-0.1 -0.05

0.05

0.2

DP2

-0.05

-0.19

-0.2

DP1

DP3

0.2

Joint p.d.f. for (DP1,DP2)

0.16

0.1

0.1

0.1

-0.2

0.2

-0.1

DP2

0.1

-0.2

0.2

-0.1

DP2

-0.1

-0.1

Joint p.d.f. for (DP2,DP3)

A

Taesik Lee © 2005

-0.2

Design of Manufacturing Systems

Taesik Lee © 2005

•

What is a manufacturing system?

Photo removed for copyright reasons.

Photo removed for copyright reasons.

1910… Ford Motor Company

Taesik Lee © 2005

2010… Semiconductor Fab

Design of fixed manufacturing systems

for discrete identical parts

Small Scale Problems

Taesik Lee © 2005

Ι. Simple deterministic scheduling problem

C

D

E

B

F

A

Robot

G

IN OUT

Part

Process module for X

X

Design a manufacturing

system

to eliminate the root cause

of a problem (symptom)

In/Out buffer

Taesik Lee © 2005

Photoresist processing

Vapor

Prime

VP chill

Adhesion promoter

Coating

Photoresist film

Soft Bake

SB chill

Solvent evaporation

Substrate

Developed image

(negative resist)

HB chill

Hard Bake

Developing

Taesik Lee © 2005

Chemical reaction

in exposed area

PEB chill

PEB

(Post Exposure

Bake)

Exposure

Deterministic scheduling problem

Machine diagram removed for

copyright reasons.

D

C

E

B

F

Robot

A

G

IN OUT

Part

X

Process module for X

In/Out buffer

Taesik Lee © 2005

Process

Time (sec)

# of

modules

A

40

2

B

20

1

C

17

1

D

60

2

E

15

1

F

40

2

G

35

2

Level 1

FRs

#.1

#.2

Perform process steps

with desirable quality

Satisfy process flow

and throughput

DPs

Process modules

System configuration

⎡ FR1⎤ ⎡X

⎢FR2⎥ = ⎢

⎣

⎦ ⎣X

X ⎤ ⎡ DP1⎤

⎥⎢

⎥

X ⎦ ⎣DP2⎦

Level 2

FRs

#.1

Manage the recipe

#.2

Support the system

physically

Move wafer when

process is over

#.3

DPs

Recipe handling

module

System layout

Transport system

Taesik Lee © 2005

⎡ FR2.1⎤ ⎡X

⎢FR2.2⎥ = ⎢O

⎢

⎥ ⎢

⎢⎣ FR2.3⎥⎦ ⎢⎣X

O

X

X

O ⎤ ⎡ DP2.1⎤

X ⎥⎥ ⎢⎢DP2.2⎥⎥

X ⎥⎦ ⎢⎣ DP2.3⎥⎦

Level 3 - Sub FRs/DPs of FR2.1

FRs

#.1

#.2

#.3

Keep TAKTprocess below

TAKTsystem

Maintain # of moves by main

robot not to degrade target

throughput

Locate process modules into

200-APS frame

DPs

Number of each process

module

Number of IBTA

Layout (module

arrangement)

⎡ FR2.2.1⎤ ⎡X

⎢FR2.2.2⎥ = ⎢O

⎢

⎥ ⎢

⎢⎣ FR2.2.3⎥⎦ ⎢⎣X

O

X

X

O ⎤ ⎡ DP2.2.1⎤

X ⎥⎥ ⎢⎢DP2.2.2⎥⎥

X ⎥⎦ ⎢⎣ DP2.2.3⎥⎦

Level 3 - Sub FRs/DPs of FR2.2

FRs

#.1

#.2

#.3

#.4

#.

#.

Coordinate transport

function

Move wafer from CES

to VP

From VP to VPC

From VPC to CT

M

From HB to HBC

From HBC to CES

DPs)

Command and control

algorithm

CES handler

IBTA

Central handler

M

Central handler

SI handler

Taesik Lee © 2005

* Design matrix depends on

a process plan and selection

of DPs.

•

•

•

•

FR1: move wafer from process 1 to 2

FR2: move wafer from process 2 to 3

:

FR5: move wafer from process 5 to 6

•

•

DP1: robot 1

DP2: robot 2

•

•

•

t=0

t = t1

t = t2

FR = {FR1}

FR = {FR4}

FR = {FR2, FR3, FR5}

DP = {DP1}

DP = {DP2}

DP = {DP1, DP2}

Coupling due to an insufficient number of DPs

Taesik Lee © 2005

D

C

•

Problem definition

B

– Conflict : more than one modules

competing for a robot

– The conflicts make the waiting time of

wafers inconsistent, which degrades onwafer result variation.

Robot

A

SP

T1

P2

P1

SP

T2

T1

P1

SP

SP

P1

SP

T2

T1

In/Out buffer P3

P2

P1

T2

T1

P3

P2

T2

P3

Delay time

T1

P1

P3

P2

Conflict

P1

T3

T2

T1

Process module for X

X

P3

P2

G

IN OUT

Part

P1

E

P2

T2

T1

P2

P1

SP

P3

T2

P3

T1

P2

P1

SP

T3

T2

T1

P1

T3

P3

P2

T1

T2

P2

P3

T2

Example : Process timing diagram with a sending period(6 unit)

Taesik Lee © 2005

T3

P3

Deterministic scheduling problem

i

i −1

i

j =1

j =0

j =1

t i = ∑ Pj + ∑ MvPk j + ∑ MvPl j + n ⋅ SP , n = 0,1,2,...

Dividing both sides by its SP yields

′

i

′

i −1

i

′

t i = ∑ Pj + ∑ MvPk j + ∑ MvPl j + n , n = 0,1,2,...

j =1

′

j =0

j =1

Original pick-up time

Taking only the decimal,

G

τ i = ti ′ − int(ti ′ )

moment of ith transport task

within a period

τD

E

Process

τi indicates the (normalized)

F

τC

D

C

B

A

IN

Conflict

0

0.5

1

1.5

Time (normalized by sending period)

Taesik Lee © 2005

2

Solution

•

Basic concept

– Break the conflicts among number of transport requests from process

modules

– Use predetermined “queue” as a decoupler between process and

transport

– Insert optimum queue at possible process steps

i

i −1

i

i

j =1

j =0

j =1

j =1

t = ∑ Pj + ∑ MvPk j + ∑ MvPl j + n ⋅ SP + ∑ q j , n = 0,1,2,...

*

i

Taesik Lee © 2005

Solution

Condition for no-conflict:

~ ≤ τ * −τ * ≤ − ~

tmax

1 tmax

i

j

Where

*

*

τ i −τ j = τ i −τ j +

i

∑

k =1

for i = 1,2,... , N ; j = 1,2,… , (i − 1)

qk ′ −

~

tmax : longest transport time

j

∑

qk ′ = τ i − τ j +

k =1

N

∑

(aik − a jk ) ⋅ qk'

k =1

Optimize values of qk along with sending period, subject to no-conflict

condition and process constraint (qcritical = 0 sec)

N

min

∑

q 'j

j =1

Taesik Lee © 2005

Solution

Process

Time (sec)

Delay (sec)

A

40

2

B

20

8

C

17

0

D

60

5

E

15

9

A’

40

9

F

35

3

Adjusted pick-up time

A

D

B

IN

0

0.5

1

1.5

2

Transforming a potentially combinatorial

complexity problem to a periodic problem

Solution is obtained for one (and repeating) period

Taesik Lee © 2005

Manufacturing Systems Design

Large Scale Problems

Taesik Lee © 2005

Customer’s view on Toyota products

Models rated

at or below average

GM

Chrysler

28

7

3

19

10

Ford

10

1

Nissan

Honda

Models rated

above average

*The Wall Street Journal

May 4, 2000

Toyota

5

1

8

1

10

• World’s No.2 Automaker

• $12B profit (2003)

• No1. JD Power Initial Quality Prize

• Market capitalization of Toyota ($104B) >

GM ($24B) + Ford ($23B) + DC ($37B) (2003.11.1)

Taesik Lee © 2005

TPS / Lean manufacturing system

Set of 19 slides removed for copyright reasons.

Source: Production System Design presentation by Dr. David Cochran

Taesik Lee © 2005

Conclusion

Cartoon removed for copyright reasons.

Taesik Lee © 2005