Document 13609617

advertisement

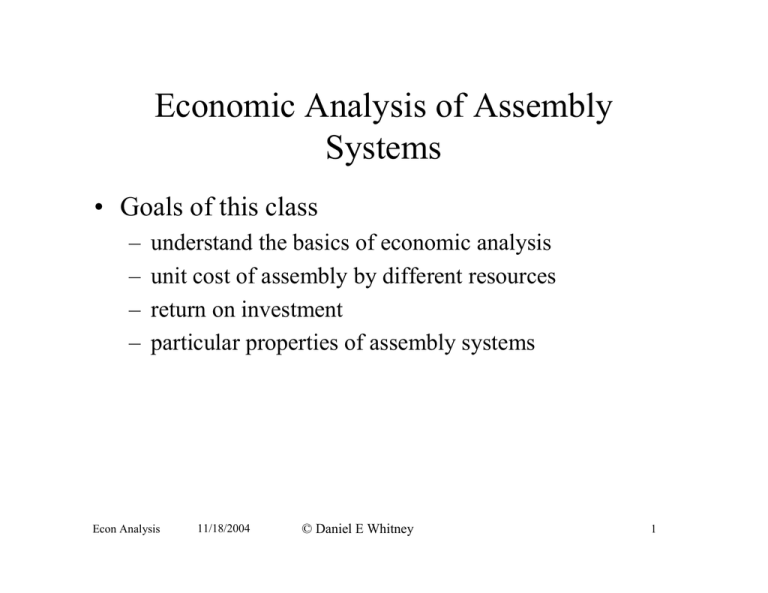

Economic Analysis of Assembly Systems • Goals of this class – – – – understand the basics of economic analysis unit cost of assembly by different resources return on investment particular properties of assembly systems Econ Analysis 11/18/2004 © Daniel E Whitney 1 Cost and Price Considerations Development cost Unit cost Unit mfr cost: materials labor depreciation waste, scrap, rework Production ramp-up Marketing Ongoing support “Supply curve” Prod’n volume/yr Cost Cost Loss Profit Prod’n volume Sales volume 3 2 1 Price Price “Demand curve” Sales volume/yr Econ Analysis 11/18/2004 © Daniel E Whitney 2 “Price Has Nothing to Do with Cost” • • • • Price is about value Value is often perceived and can be influenced Direct value involves functions and ilities Perceived value involves or is influenced by – Marketing – Perceived quality – Number of choices available even if most will not be taken • Value > Price > Cost, otherwise no sales or no profit Econ Analysis 11/18/2004 © Daniel E Whitney 3 Cost Analysis is a Murky Area • Engineers need to know the basics of cost analysis for three reasons – so they can make sound technological choices – so they can judge the suitability of a supplier’s bid – so they can argue effectively with accountants • “Don’t ask us how we do investment justification. We just fill out a form and after a while an answer comes back Yes or No.” • “MAPI means ‘makes a project impossible’” – MAPI = Manufacturing and Allied Processes Institute Econ Analysis 11/18/2004 © Daniel E Whitney 4 Kinds of Cost Categories • Fixed cost = what you pay to set up (usually investment in facilities) • Variable cost = what you pay that depends on how many you make per unit time – – – – Labor, both direct and indirect (maintenance, supervisors) Materials cost: what you buy that you add value to Expendables: energy, lubricants, tool bits, etc Scrap, rework • Institutional cost = all other costs of doing business • In many cases, labor is a fixed cost, due to contracts or the inability to lay people off for short periods when business fluctuates Econ Analysis 11/18/2004 © Daniel E Whitney 5 Cost Distribution in Engine Plants Image removed for copyright reasons. Source: Figure 18-1 in [Whitney 2004] Whitney, D. E. Mechanical Assemblies: Their Design, Manufacture, and Role in Product Development. New York, NY: Oxford University Press, 2004. ISBN: 0195157826. Econ Analysis 11/18/2004 © Daniel E Whitney 6 Sources of Cost in the Supply Chain Image removed for copyright reasons. Source: Figure 18-3 in [Whitney 2004] Whitney, D. E. Mechanical Assemblies: Their Design, Manufacture, and Role in Product Development. New York, NY: Oxford University Press, 2004. ISBN: 0195157826. Source: Daimler Chrysler via Munro and Associates Econ Analysis 11/18/2004 © Daniel E Whitney 7 A Small Problem • Fixed costs are usually expended all at once, usually before production starts • Variable costs are incurred as production runs • How should these two kinds of costs be combined to provide a true picture of the cost per unit? • The usual method is to allocate the fixed costs to the units by choosing a time period during which the investment is “recovered” • unit cost = variable cost + Some_Fct (fixed cost, # of units made in some time period) Econ Analysis 11/18/2004 © Daniel E Whitney 8 Cash Flows Over Time Image removed for copyright reasons. Source: Figure 18-4 in [Whitney 2004] Whitney, D. E. Mechanical Assemblies: Their Design, Manufacture, and Role in Product Development. New York, NY: Oxford University Press, 2004. ISBN: 0195157826. Econ Analysis 11/18/2004 © Daniel E Whitney 9 Payback Period Method • A payback period P is selected (arbitrarily?) • The fixed cost is allocated equally to each unit made during P: • unit cost = variable cost + fixed cost / (P Q) where Q = quantity made per year P = a number of years Econ Analysis 11/18/2004 © Daniel E Whitney 10 Internal Rate of Return Method • The payback period is replaced by an investment horizon H and an interest rate r • This is equivalent to a mortgage for H years at interest rate r • The annual payment A and the annual cost factor fAC for an initial investment Io are (for zero salvage value): A = I0 Econ Analysis r 1 + rH 1 + rH – 1 11/18/2004 r 1 + rH fAC = A = I0 1 + rH – 1 © Daniel E Whitney 11 Unit Cost Based on IRoR • unit cost = variable cost + fAC *fixed cost /Q where Q = quantity made per year fAC = fraction of fixed cost paid per year, based on: r = IRoR (ranges from 15% to 35%) H = investment horizon (ranges from 2 to 5 years or more) Econ Analysis 11/18/2004 © Daniel E Whitney 12 Annualized Cost Factor vs r Image removed for copyright reasons. Source: Figure 18-5 in [Whitney 2004] Whitney, D. E. Mechanical Assemblies: Their Design, Manufacture, and Role in Product Development. New York, NY: Oxford University Press, 2004. ISBN: 0195157826. Econ Analysis 11/18/2004 © Daniel E Whitney 13 Simplified Unit Cost for Manual Assembly COSTUNIT MANUAL = # People = A$ # People Q TNQ 2000 * 3600 [largest integer] Q = annual production volume T = assembly time per part, sec N = number of parts per unit A$ = annual cost of a person A$ = L H * 2000 L H = labor cos t, $ / hr 2000 = hours per shift year 3600 = sec / hr (assumes no investment required) Econ Analysis 11/18/2004 © Daniel E Whitney 14 Simplified Unit Cost for Fixed Automation f AC N S $ C UNITFIXED = Q where Q = annual production volume, units / year f AC=fraction of machine cost paid for per year S$ = cost of one station in the machine (assumes one station per part) (also assumes no people required) Econ Analysis 11/18/2004 © Daniel E Whitney 15 f ACI L$ + Q Q where I = total investment in machines and tools L$ = annual cost of workers associated with the system I = # MACHINES * $ / MACHINE + # TOOLS * $ / TOOL TNQ 2000 * 3600 [ # MACHINES = ] # TOOLS = N L$ = w L H # MACHINES * 2000 where w = number of workers / station Combining the above yields: C UNIT FLEX = fAC L$ # MACHINES * $ /MACHINE + # TOOLS * $ / TOOL + Q Q f $/ MACH IN E T N f AC $/ TOOL N w T N L H + C UNITFLEX - A C + 3600 Q 2000 * 3600 Econ Analysis 11/18/2004 © Daniel E Whitney Simplified Unit Cost for Flexible Automation C UNITFLEX = 16 Conclusions from Unit Cost Models* • Cost is linearly proportional to number of parts N – one reason for fixation on part count reduction • Cost of flexible automation grows with the “pricetime product”: $/machine * T – shows that cost and time can be traded • Other costs grow as part, station, and tool count grow – floor space – support staff – line downtime (see System Design chapter) *P. M. Lynch, “Economic-Technological Modeling and Design Criteria for Programmable Assembly Machines,” MIT ME Dept PhD Thesis, June 1976 Econ Analysis 11/18/2004 © Daniel E Whitney 17 Unit Cost Example Unit Assembly Cost by Three Methods 2 f AC=0.38 1.8 T=5s 1.6 L H=$15/hr 1.4 S$=50000 $/tool = $10000 Unit Cost 1.2 N = 10 parts/unit 1 w = 0.25 workers/sta 0.8 MANUAL $/UNIT 0.6 FIXED $/UNIT FLEX $/UNIT 0.4 0.2 0 0 100000 200000 300000 400000 500000 600000 Annual Volume Econ Analysis 11/18/2004 © Daniel E Whitney 18 Unit Cost Example - 2 Image removed for copyright reasons. Source: Figure 16-5 in [Whitney 2004] Whitney, D. E. Mechanical Assemblies: Their Design, Manufacture, and Role in Product Development. New York, NY: Oxford University Press, 2004. ISBN: 0195157826. Econ Analysis 11/18/2004 © Daniel E Whitney 19 More Detailed Cost Model Image removed for copyright reasons. Source: Figure 18-9 in [Whitney 2004] Whitney, D. E. Mechanical Assemblies: Their Design, Manufacture, and Role in Product Development. New York, NY: Oxford University Press, 2004. ISBN: 0195157826. Econ Analysis 11/18/2004 © Daniel E Whitney 20 Caveats About Examples • If T = 2 s, then Q = 3.6 million, or else the line runs only part of one shift • If # people > # of parts or operations, then extra people are needed for one shift operation • If Q > 7.2 Million / T, then a 2nd or 3rd shift is needed Econ Analysis 11/18/2004 © Daniel E Whitney 21 Discounted Cash Flow Analysis • AKA net present value calculation • More detailed and sophisticated than unit cost comparisons • Seeks to determine if an investment is “good” • Based on comparing return on investment – a base case is compared to an alternate – the alternate requires upfront investment – it creates a saving stream over time, which is discounted to “present value” – do the savings justify the investment? Econ Analysis 11/18/2004 © Daniel E Whitney 22 Discounting Future Cash Flows Money is a two-dimensional quantity ($,t) $ Its value now 1 (1 + DF) i e- ρ t ρ = DF = discount factor Its value if delayed until t t Econ Analysis 11/18/2004 © Daniel E Whitney Time 23 Two Cash Flow Formulas Takeaway: Takeaway:The Theearly earlycash cashflows flowscontribute contributethe themost. most. 10 Sum of future cash flows without discounting 9 8 7 present value of sum of future cash flows 6 5 CF/ ( 1+DF)^ i Σ ( CF/ ( 1+DF) ^ i) 4 e^ -DF t ( 1-e^ -DF t ) / DF 3 2 DF = 0.1 1 present value of future cash flows 0 1 3 Econ Analysis 5 7 11/18/2004 9 11 13 15 © Daniel E Whitney 17 19 21 24 Comparison Analysis • Base case • Alternate case – fixed costs – labor costs – material costs – fixed costs – labor costs – material costs Comparison: What discount rate makes the discounted sum of future savings in labor and material costs greater than or equal to the difference in fixed cost between base and alternate? H Net savingsi / 1 + DF . Investment alt – Investment base = iΣ =1 i Alternatively: set discount rate = cost of borrowing Choose the alternate investment if NPV > 0 Econ Analysis 11/18/2004 © Daniel E Whitney 25 Discounted Cash Flow (DCF) and Economic Value Added (EVA) • EVA is very similar to DCF. The discount rate used in EVA is the weighted average cost of capital (WACC) – Cost of capital includes interest rate on debt plus expected rate of return on stock (not easy to compute) • EVA is usually used to value the whole company but is being used more and more to value individual investments • See http://www.pitt.edu/~roztocki/abc/abc.htm • See Econ DEMO-Stanley Hammer.xls on MIT Server. Econ Analysis 11/18/2004 © Daniel E Whitney 26 Zero or Net Present Value Calculations • Comparing two investments, the savings Sv are considered income • You pay taxes on the income at tax rate Tx, yielding your net income Ni • You can claim depreciation Dp on your investment, decreasing your taxable income and lowering your taxes • The IRS specifies how much you can claim in depreciation each year – the net income is: Ni = Sv - Tx(Sv - Dp) • “present value analysis” spreadsheet on MIT Server finds the discount rate that gives NPV = 0 •Econ Can be used to find© Daniel NPV for any discount rate 27 11/18/2004 Analysis E Whitney Zero Present Value Analysis ZERO PRESENT WORTH CASH FLOW ANALYSIS 7 YEARS ECONOMIC LIFE 0% SALVAGE VALUE % OF COST AT END OF ECONOMIC LIFE EXPENSE FORECAST YEAR 0 1 2 3 4 5 6 7 8 RATIO 100.00% INCOME FORECAST TAX RATE 34.00% DEPRECIABLE 66.67% SAVINGS DEPRECIATION $100 $181 $198 $150 TOTAL INVESTMENT DEPRECIABLE INVESTMENT INTERNAL RATE OF RETURN TAX RATE CREDIT 14.29% 24.49% 17.49% 12.49% 8.92% 8.92% 8.92% 4.46% 34.00% 34.00% 34.00% 34.00% 34.00% SUM OF UNUSED YRS DEPR= 31.22% USED FOR SALVAGE VALUE OF REMAINING DEPRECIABLE INVESTMENT $400 $267 18.41% GOAL SEEK ON CELL G38 = 0 TAX CREDIT IN YR 0 0N UNDEPRECIATED INVESTMENT RESULT OF PRO FORMA CASH FLOW YEAR INCOME 0 ($400) 1 $100 2 $181 3 $198 4 $150 4 $83 SALVAGE VALUE IN YEAR 4 DEPRECIATION TAXES $38 $65 $47 $33 $0 ($45) $21 $39 $51 $40 $0 CREDITS $0 $0 $0 $0 $0 $0 NET ($355) $79 $142 $147 $110 $83 DISC NET ($355) $67 $101 $88 $56 $42 $355 GROSS INCOME $713 $183 $152 $0 $561 NET INCOME $313 $183 $106 $0 $206 Econ Analysis 11/18/2004 © Daniel E Whitney SUM OF UNDISC INC $79 $221 $368 $478 $561 UNDISC PAYBA FOR EX IN FIG ($0) 28 How to Use this Spreadsheet • • • • • Enter savings, tax rate, depreciation rate Goal seek to get zero NPV Or Put in various discount rates and observe NPV NPV > 0 is desired Econ Analysis 11/18/2004 © Daniel E Whitney 29 Aircraft Development Cost Quandry Aircraft Product Development Cost Recovery PD Investment = $3.5B all taken in year 0 Depreciated over 7 years MACRS $1.2B tax credit in year 0 First plane sold in year 2 2500 2000 1500 IRoR = 7.11% Cost Recovery 1000 Undiscounted Cumulative Income After Taxes and Depreciation 500 0 -500 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Discounted Cumulative Income After Taxes and Depreciation Annual Gross Income Before Taxes and Depreciation -1000 -1500 -2000 -2500 -3000 Year Econ Analysis 11/18/2004 © Daniel E Whitney aircraft pd investment analysis.xls 30 A380 Business Case A380 Cost and Income PD Development cost $10.5B 14000 660 planes sold, price $200M ea 10000 $Millions 8000 6000 4000 First planes sold 12000 Avg profit/plane = $50M IROR = 11.5% Net Income Before Depreciation and Taxes Net Income After Taxes and Depreciation Sum of Undiscounted Net Cash Flows 2000 0 -2000 0 10 20 30 Sum of Discounted Net Cash Flows -4000 -6000 Years Econ Analysis 11/18/2004 © Daniel E Whitney 31 NPV vs Discount Rate for A380 NPV VS DISC RATE FOR A380 5000 4000 NPV, $M 3000 2000 NPV 1000 0 -1000 0 5 10 15 20 25 -2000 DISC RATE, % Econ Analysis 11/18/2004 © Daniel E Whitney 32 Critiques of DCF • Target IROR is arbitrary • The calculations can be gamed • “Cost” is a slippery quantity – People know their expenditures and assume that they know their costs, but these are different even if they add up to the same amount – Overheads are allocated arbitrarily and can distort the calculations – Activity-based costing is intended to overcome this – Robert Kaplan is an EE! Econ Analysis 11/18/2004 © Daniel E Whitney 33 Summary of Economic-Technical Analysis Image removed for copyright reasons. Source: Figure 18-14 in [Whitney 2004] Whitney, D. E. Mechanical Assemblies: Their Design, Manufacture, and Role in Product Development. New York, NY: Oxford University Press, 2004. ISBN: 0195157826. Econ Analysis 11/18/2004 © Daniel E Whitney 34