SULFITE DIGESTIONS U WESTERN W11-11 11T PINE January 1940

advertisement

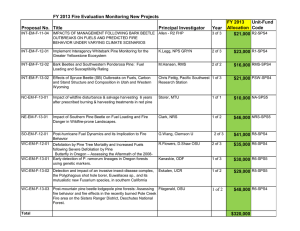

AGRICULTURE ROOM SULFITE DIGESTIONS U WESTERN W11-11 11T PINE - January 1940 UNITED STATES DEPARTMENT OF AGRICULTURE !FOREST SERVICE L....FOREST —PRODUCTS LABORATORY Madison, Wisconsin In Cooperation with the University of Wisconsin SULFITE DIGESTIONS OF WESTERN WHITE PINE By J. N. MCGOVRN, Assistant Technologist and. G. H. CHIDESTER, Senior Engineer Western white pine (Pinus monticola) is an important timber tree growing in northwestern United States, with the heaviest stand located in northern Idaho. A relatively large amount of western white pine logging and mill waste and second-growth material is available and has been suggested as a 'possible pulp raw material. At present this wood finds very little outlet in the 7'.ndustry ar.d there is little published information regarding its suittiiiiLy for pulp. The limited number of experiments reported by re were urdertaken to amplify the available data on the behavior of this woodi” ed by the sulfite process. There is a close resemblance between western and eastern white pines. A certain amount of information is known about the latter (Pinus strobus). According to Wells and. Rue l sulfite pulping of eastern white pine resulted in a dark-colored, harsh pulp containing a large number of shives or uncooked slivers and bleached with difficulty. Eçperimental Part The western white pine material used for these experiments was supplied by the Northern Rocky Mountain Forest and Range Experiment Station. Three bolts 4 feet long were cut from each of two trees, to correspond to the top, middle, and butt portions of the log. These bolts were evaluated according to Forest Products Laborato'ry standard methods.. Pertinent physical and chemical data are given in tables 1 and 2. Only a small amount of material was available U. S. Dept. Agriculture Bull. 1485. rProgress Report, "Physical and. Chemical Properties of Western White Pine (Pinus monticola), Shipment 1526" by J. C. Pew and E. R. Schafer. Mimeograpdreport, Forest Products Laboratory. R1412 for the pulping tests. Since the butt bolts of pine are usually the most difficult to pulp satisfactorily by the sulfite process, owing to their greater heartwood content and the presence of larger amounts of resins, they were chosen for these trials. rive-eighths-inch chips were prepared from two of the butt bolts in the usual manner. The digestions were made in a stainlesa-steel-linei, steamjacketed autoclave with a capacity of 1.5 cubic feet, under conditions previously found favorable for jack pine. The pulped chips *ere broken up with a stirrer and the pulp screened through 0.012-inch slots in a diaphragm screen. The digestion conditions are given in table 3. Each charge of wood, containing abbut 43 percent moisture, weighed. approximately 10 pounds when oven-dry, and the acid charge averaged 90 gallons per 100 pounds of oven-dry wood. The yield, strength, and bleach requiremettsof the pulps are given it table 4t Results and Discussion The Wood The trees came from a stand burned over in about l g 50, were relatively young-65 years as compared to 100 to 150 for a mature tree-and were somewhat lower in density than the average of 27 pounds per cubic foot reported for this species. When compared with average figures (tables 1 and 2) for jack pine (Pinus ban,ksiana) from data recently obtained for butt bolts of four diameter classes ranging from 5 to 11 inches, the older western white pine was fpund to have a somewhat slower growth rate, to be appreciably less dense, and to contain about twice as much heartwood. The higher heartwood content was not reflected in the chemical analysis, since the western white pine, as compared to the jack pine, had higher cellulose and lower lignin contents in addition to smaller amounts of pentosans and extractives. Chemical data for eastern white pine (Pinus strobus), also included in table 2, show that this particular wood sample, in comparison with the western pine, had higher alpha-cellulose and lignin contents and more extractives. • R114. 12 The western white pine was comparatively light-colored; both. the heartwood ana sapwood from the present sample had a brightness of 45 percent white. Sulfite Pulping Experiments The mixture of western white pine chips from the two butt bolts was fairly well reduced by the sulfite process, using the 12-hour schedule. The digestion at 136° (no. 220, table 4) resulted in 4.1 percent screenings and an average bleach requirement of approximately, 18 percent. Since this digestion was continued until the base in the cooking liquor was , nearly ; exhausted as measured by the Sander test, the data represent-substantially the miriithuvin screenings and bleach requirements .obtainable under the condittons used. The application of somewhat milder conditions (schedule 2, table 3) including a digestion temperature of 1300 C., effected no reduction in screenings when the , digestiori was not continued until the base was exhausted (no.221),. When the milder conditions were applied and the digestion carried completely to the end, however, the screenings content was reduced to 2.9 percent and the bleach requirement was slightly lowered. . The lowest bleaching pulp (no. 222) had slightly higher bursting strength values, slightly lower tearing and tensile strengths, and required slightly less beating to develop a given freeness than the higher bleaching pulp(no.220). The chemical analyses of these pulps also showed only small variations (table 5). The lower bleaching pulp in this case had a slightly higher cellulose content but lower alpha-cellulose and higher lignin contents. Table 6 gives a comparison of results recently obtained' from jack pine to those from western white pine. The jack pine pulps were prepared from the butt bolts described in tables 1 and 2. The data on western white pine were taken from table 4. The two sets of conditions, except for ,total. digestion time, were the same for each of the two woods. The western white pine required a slightly longer time to reach the point of base exhaustion than did the jack pine. The difference wasj4.6 haur. At 136° C. and 0.8 hour at 130° C. The screenings. and screened pulp yields were the same for the two woods when the digestion temperature was 136° C. At the lower temperature smaller Amounts of screenings resulted from both woods. The reduction in screening from jack pine corresponded to an increase in 3Growth Rate and Position of Wood in Tree as Faetors Influencing Kraft and. Sulfite Pulps for Jack Pine, Problems B-190 and A474. Proj. 1168-61 U. S. Forest Products Laboratory. R1412 • • the screened pulp yield with no change in the bleach requirements but in the case of western white pine the reduction in screenings was accompanied by a decrease in the bleach requirement wits no change in the screened pulp yield. Because of its higher density the jack pine gave more pulp per cubic foot of wood than the western 'white pine. The unbleached pulp colors and bleach requirements of the western white pine pulps were appreciably higher than those of the jack pine pulps. The strength values of the pulps from the two woods were quite similar in each instandes and were considerably lower than those of sulfite pulps frompruce.' In view of the similarity of the behavior of western white pine to that of jack pine it is to be expected that more complete reduction with less screenings and somewhat stronger pulps would result from the middle and top portions of the trees than from the butt bolts4 As in the base of jack pine thescreenings from woods-run material would probably amount to 3 or 4 percent with a 12-hour cooking schedule and reasonably complete reduction could probably be obtained with a 16-hour schedule. Summary Three sulfite digestions of chips from western white pine butt logs gave fairly complete reduction of this wood and resulted in screenings amounting to 3 to 4. pounds per 100 pounds of oven-dry wood with a screened pulp yield of 44 pounds per 100 pounds, of oven-dry wood. The pulps were light-colored, medium-hard bleaching and had strength properties characterized by a bursting strength at 550 cc. freeness of 0.80 to 0.90 point per pound per ream. Western white pine was reduced to pulp to about the same degree as jack pine under similar conditions. The pulps were somewhat more difficult to bleach but had similar strength properties. The strength properties of the pine pulps were considerably lower than those of spruce sulfite pulps. _31412 -4- • Table 1 .--EasicalaoppnitEIfstern white and dackpirektItt bolts • :Western vhite : Jack pinea pine– : Shipment 1504 :Shipment 1526 : - : • Diameter.•••••••••••••••••••••••• Inches: 8.0 7.2 Years: 65.0 40.3 Rate of growth....4,.......4ngs per filch: 16.2 12.2 Density ty QLP_t_A9_1) Lb. per cu. ft....: 25.2 26.0 Ag e• • •••••• • •••• •••••••*•••••••••• He a rt W OOd* 1 * *• •• ••0 0.0 .0.0 0 110 0 0 41 •ParC e n t ; 65.5 33.3 Average of butt bolts from two trees. 2 – Average of butt bolts from trees ranging in diameter from 5 to 11 inches. R1412 Table 2.--Chemical anal ses of chips from western white, jack ) and sr whiteines :Western: Jack, : white 11': pines .. pine--; Ship- : : Ship- : went .. : : ment : 1504 : 1526 ; :Percent:Percent : Alpha-cellulose.... ilei.0 46,0****0010041: 141.7: 41.4 : Eastern . white pineShipment 1330 . Percent *44.0 , Cellulose....• • . 04/•••••••01, Lignin.......... 01100011.00....0.09.... : ••.......: 60.4: Pentosans --otal..•••••••••••••••••••••••••••*: I n cellulose... .•• ••••••••••••••••: 25.1 946 : 8.5 : Solubility inHot 1 percent sodium hydroxide.....: 12.8 Hot 3.6: 4.0 : Alcohol-benzene,..,. .............,.: 2.1 : Ether•••••*•••••••00*•• •••• •••••• a•7, 57.4 50.0 26.3 27.5 12.0 10.8 10.6 16.2 3.6 : 5.7 4.1 : 4*6 6.5 3.0 1 --Data on mixture of chips from butt bolts from two trees, --Average of data from chips of butt bolts from trees ranging in diameter from 5 to 11 inches. Sample an average of several bolts selected at random. • Table 3.--Conditions for western white • lne sulfite di estions 4 ..... 0 • Schedule : Schedule 1 2 ........... ....... Penetration Time to 110° C.....s....4„.•,...........libum Time at 110° C$4,0***10. so•oltits.•••••••• ...Houk's: 1 . 5 .0 . : 136 : Vale from 110° C. to maximum temperature...Hours: 4 .5 : Maximum t emperature•••4..44•4 9i f . 0 • .... O•a ••0° G . : 'Time at maximum temperat ure..Hours: Total. digeztion time ••• •••• Maximum prosetie••."•••• • • • • • ••••••••••• 0••• 1.5 240 7•0 4...4 ; .Eours: 12.4 : 16.3 : RI • .*** Lbs, per B. in.: Cooking liquor Total sulfur dioxide..... 0 4,1100.• .......Percent: Combined sulfur dioxide.. 00,0••••••••••• Percent: g O 6.20 6.20 1.35 1.35 R1413 • • 1 El) l'el $U). • 0 O tr. 0) 1-r1 4) .. • • 0 0 0 0 .,.1-4 • H a) i 0 • 4-) 0 a) CJ) a) I d •,-, O -4-) $-4 FI:1 PA i •• •• •• tO •• •• •• •• • • •• O 0 g (1) k 0 W 01 0 0 U). 4") 0 • a) al .r.-4 in 'CI .1.-4 0 r-4 l)3 0 F-t 1 i 3 •• t.) II I W CH f:t4 •• 446 •• 4, tr,' N En (1) +2W • E-1 rn rxi t •• •• •• (1) Pf O •• CD CD f-4 P4 04 a)4 0 qØ -H g g • tIO a) u) PI a) a) (II C-1 O (1) 4-) CD 4$ 1x4 i • E(1) +). a) r0 +) rcj F-1 a) +) cd g 414 •• • . tr1 0 0 pa •,-.4 ro i--I •• •• Q.) C\I •• 1/4.0 trl . • • • • •• 1.C1 .../' to . •• 0 tO •• 0 0 Ci PeN L.C1 tn •• .• .• . — ------,, o ,r) 0 0 •a ,21 •• •• 0 0 to 0 0 g a) to 0 •• ...' 1.-- • • ID 0 0 4) 0 to P4 tO •• r---. 4, •• •• •• •• •• •• – • • +) 0 tO Lf1 C.) N a) CD •• •• •• •• •• •• •n • 1 O (0 a) 40 +.) 0 a) 0 C)-r4 a) P4 $.4 g rd r-4 •• I $4 C)) pi •• U") •• •• • • $.4 •• •• .• •• • • -H i 1 .-.1 1 0 a) s a) .-ct 4., g a) (..) 14a) IC) M• . 4.• r*--- I a) ,4 $4,--.44 Cti - 0 O 04 CD r--1 a) •• 14'1 l.0 LC1 '',... LC1 • • • • rta 0 r-4 0 •9 tO . • •• 4, •• f•• r) •• k . 0 ,21 a) $,-, 1 r-, i 41 0 0 reN trn 00 Ln •• A a) I:4 •• tO (0 CD P-t 0 LC1 c.) – . N- 1-.4 r--1 •• •• r-1 • ...- -1* . .../' • CV •• •• f• r--- . to • 1/4.0 k ...' •• .. •• •• •• •• •• •• •• •• •• •• 0 r-4 CV CV CV c'j CV CV 40 • ,4 -H 4) PI 0 ,--4 tok a) .• .• •• •• .. 1 co g 0)0 • ...--... u) -H a) P-4 •. .• •• .• •• .. / C/) • •• •• •• •• •• •• •• 0 (U) U) •• 0 tr1 g • 0) (00 CH I-4 -t--)4 k) CU ..../' U). 14) .r-4 td) +2 0 1/40 r-4 ***-n ta 4.0 a) 4-) OS* 0 0 0 c.) $4 a) •• ors •• tO •• •• .. LC1 6 0 t() r--1 40 (1) re4 LC1 • 0 • •• •• a 9,-4 g O) 0 W 0 U) 1-4 0 "•...... 0 +) k 0f I 1 CO a) .H 4-) $4 ...." 0 c) C.) M 4-3 • • • . 0 0 . 0 in a) •• tO LC1 0 LC1 CD U) 1••••• r 0 0 Ca 0 CD 0 $ a) r2 • Ike •• •• •• . 01 ...1, 1 al 0 • Table 5.—Chemical aAMgIMIL..91L2TILL271121.1±21.1129_ Digestion no. 220 : 221 222 Alpha-cellulose...........Percent : 77.8:........._ : 77.0 Cellulose.................Percent : ......__ :: 92.4 Lignia....................Percent : ........._ 1.5a 2.8 Total pentosans...........Percent Solubility in Alcohol-benzene.........Percent Ether.••••••••••••••••••Percent 9103 ft00.61.4.004,0 : n•••••••n •••• n•• 3.7 2.0 5.1 14.o : 2.0 1.8 R1412 • P4 7 t 4s i N d I 0.) a) 4.) 1 f li 0 rti 1 •• •• •• •• •. •• .• r.4 0 1 1 4-, I (I) ,-0 N I O r-4 N -I 1 i 4., cd r o tO 0 :0 .• CD 1 4.0 a) 4 seil 4,D +3 1 •• d• •• •• 0* •• •• •• •• •• •• •• •• •• •• we (--4 •..0 . •• •• •• •• 0 .. • • •• •6 150 LC1 . •• •• 0 LC\ ..../* tot) 0 r'el t0 N n1:) . •• •• 0 0 hN. rOs C\J ra •r4 g $4 a) "`••••• r".4 . Pi0 4-) •,-4. tto a) 4) g ii) a) d a) F•4 4-, iIi r.e.‘ cD m/-4 •• •• .* •• •• •• As• •• 0 tO • 0 -4-, P.4 •• •• *IP •• 4.1 •0 .4-, •• •• •• •• •• •• • rem to tO e• •• •• I r.0 .7-...t P: Waif 0 cd t PI •P C..) 0 0 • r.-4 g Pi r-i Pi cD a) cs4 0fli P:1 •• •• 1 •• •• •• •• •41 •• •• 40 A •• • • •• •• •• tO tt PO -• 4., 1 0 LC1 0 •• • • • • • • • • • • . • ....... •• •• •• ii4 •• •• .• •• •• •• 0 4., ▪ r-i EAD .r4 CI) 0 r0 44 ^^ a •-4 Ll1 * 0 pi r4 Cti 0 I O i4 .1-4 0 CO,•4 4.1 $,4 CD +3 E-i w N 1"4"1 ..‘1 0 0 •• iö os •• os .* I r 4 4 1-.4 • •• •• .• a) 4 • r••4 • P1 P-4 0 , • • ItO • a • . 44 •• sa) a) g 0/ 0.) . rt . . 4 g $.0 0 g e-4 A (1) O 4. •4 •• • •• •• •• •. •• • •• 0 0 • N. •• •• •• •• •• •• .41 00 r-4 1 a) 4.3 P-4 a) 0 CII •• •• o OE/ •• 46 e-4 •• •• ..4-LC\ • • r-I 0 r-.1 r-4 0 '4) •• ,„ •• -..." 0 0 r-4 C1.1 •• •• •• •• •• •• •• •• •• •• •• •• 041 •• •. • • •• • • cm •• •• •• t4-1 •• • CU E4 ••• •• •• •• •• •• • a) •• •• •• •• • •4 • • •• • • . • • • •• .• • • .• • • • • • • •• .• •• • • •• •• •• •• •.•• re\ Pr\ •• • • •• r-4 •• •• •• ••n •• O (1) rh-s -,-, a) a) •,-I g 4-, ,. r...: .,1 to E-4 LC1 Cr\ •• 114 06 I • •• •• O P.4 0 r.4 Olt •• •• •• •• 0 a) k 43 a) a) •r4 0 0 +) ,.0 .ri A • r4 p., 0 Piw a) 0 a) •0 •• a) ri M :r4 0 p.1 0