FOREST PRODUCTS LABORATORY

advertisement

U. S. Department of Agriculture ,Forest Servic e

FOREST PRODUCTS LABORATORY

LL

In cooperation with the University of Wisconsi n

MADISON, WISCONSI N

DETERMINATION OF CELLULOSE AND AMOUN

OF CHLORINE CONSUMED IN ITS ISOLATIO N

A Short Method

By MARK W. BRA Y

Chemist in Forest Products

Published in

INDUSTRIAL & ENGINEERING CHEMISTRY

January 15, 1929

11

DETERIIINAT01OF CELLULO

OAI=O

OF

1OIRIn

1 1

CONSULIN 1141MOLATI

2 -

*AIM IMO

-

1

L

it

.p

r _1

*

OM* *tot,

41-1

. n - re' ?

t il7l. r t =rN T i m

1-1

aemis t

'7 0.1;21 .

1

Methods fo

t e rmi noklitta lie" CTILE'Lose

. the meastagge*tc ' givild0irtiWasoobta ined by

Ilt*

a 6444 ,o,it 461orraOitstL

with the Iiiew to simpl

and

'

i

A preo.WrPe

porating the-best faature, Ofit.I!fie severa l

zfa$lsle.te otistiNa .4svp tglft,

terms. TfWf't accurate

which r,

r.g;:Ogas vi gitt tgrm 6sliftelvdistv

,

obtained by previous

nwtrilsktigt” b-tht

Zipe same yield a,f .llulose regard1,gfiPs

Kit B.

JeWrinated . Ina

ion, this method

:.

moun$

eAlireri

iiktm' ed i the isolatrian

Atar,0010 (Ibpiyk

-Atttg-oft.

wo*4T

a

edure of

+~ye a

g;

,

treat-tents

tion has been modi fied in vellOgus w

ase yi

graded cellulose ,

their i .eie:&, ilt the bR.0% ' is ID'e;-st blow.n.

ee;r -tive koilPat .ion o f

the cellulosic reside fi.eat

osels and has r*02agla the earlier

and lasts effective bee.blaination

.-■

"

-lFresented under the t .iae "'Me Ms.*tIgiution of C.e.k .1-iWe in L-igNartMAM-ose4 '

and the -Aae-ant of Milerll.e. 4oneglS- in Its -J- p3aa' An" before 441I:e Division of Cullulosa OUomttry at thy. 75th, liieeOw 0 the. American Cbm,ical

Society, 4t,. Lol4o.,, No,., April fib. .o 1_9,

k

- AMahood and Cable, J . Ind .

3Cross and Bevalk,

91 (1S) .

Chem‘,

ap. Chem.,, 12 ., SU 0920) 4

6664 OM) ; .ep.em. Vews ,

lee, "Die 23j,ab.zenMlee-- n in iltTlotresm. t

2 , 27- (18TVX .

ihgtwick . Chem . *grsLjxv

Originally the time of chlorination was 1 hour or longer .

Schorger5 shortened the time for the first chlorination to 1/2 hour ,

while Ritter and Fleck showed that the same quantities of lignin an d

substances other than cellulose are removed in a 5- to 3-minute chlorination period and that the cellulose thus isolated had undergone les s

degradation than that obtained as a result of the longer periods of chlor ination, Prior to Ritte r t s work the author. showed that prolonged chlor ination degrades cellulose and therefore yields less alphacellulose, whic h

sometimes becomes gelatinous and difficul to filter and wash . It i s

therefore difficult to obtain corresponding amounts of alpha-cellulose fro m

a sample of wood cellulose prepared by the long chlorination method . However, shortening the chorination period below that prescribed by Schorge r

in order to obtain a maximum yield of alpha-cellulose was not attempted a t

that time,

Many investigators chlorinated their material in beakers, place d

in a specially designed apparatus, while other sg '4 used Gooch crucible s

provided with a calico pad. .1

0 Dore,ll using the crucible method, ha s

designed a special apparatus and filtering medium in which the chlorin e

gas is drawn through the material by suction .

These methods, with a few exceptions ,1 disregard the meas'u e msnt of the amount of chlorine gas required for the isolation of the ^Fa lulose, which is of interest in the interpretation of the data on the cellu lose determination . Recently apparatus has been devised by Roe-13 for the

determination of the chlorine absorbed by unbleached pulps, as a measure o f

their bleachability .

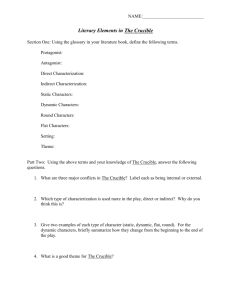

As shown in Figure 1, this apparatus has been modified and a

procedure devised embodying the principles of the several modifications o f

the Cross and Bevan method in which the chlorine required for the isolatio n

of the cellulose in wood and pulp can be :ensured, With this apparatus a

maximum yield of cellulose and a high yield of alpha-cellulose are obtaine d

with an apparent mi irum of degradation ,

5Schorger, J . Ind . Jam. Chem ., 9, 556 (1917) .

'.Ritter and Fleck, Ibid ., 16, 147, 947 (1924) .

.Bray and Andrews, Paper Trade J ., 76, No . g , 47 (1923) .

l'Sieber and Walter, Papier-Fabr., 11, 1179 (1913) ; C . A., g, 1202 (1914) ,

.9-Johnson and Hovey, J . Sac, Chem . Ind„ 37, 1 33 T (191S) ; Paper, 21, No .23 ,

40 (191 g) .

Johnsen, Mahood, Dore, J . Ind . Vng . Chem ., 13, 35g (1921) .

11 Dore, Ibid ., 12, 264 (1920) .

Cross and Bevan, J . Clem, Soc,,55, 199T (l gg9) .

13Roe, Ind, Eng, Chem., 16, 308 {1924) .

R1022

-2-

Water Jacke t

Saturated Ca Cl2 Solutio n

Water Inlet

FL s .1-Apparatus for the Determination of Chlorin e

Absorption in the Isolation of Cellulos e

ZM 8t,22F

.

2

water,- and alkalin e

The method eliminates acid, 1-a>>-ihot

pretreatments of the wood and embodies the alcohol-benzene extraction o f

Renker ; 1.5 chlorination in a crucible by Dore, Sieber, and Walter ; shor t

chlorination periods according to Ritter ; and a measurement of the chlorine

gas according to Roe .

Since considerable heat is developed during the first chlorinatio n

treatment on wood, the crucible is water-jacketed (this may be dispense d

with in the case of pulps) in order to retard hydrolysis of the cellulos e

by the hydrochloric acid formed . Oxidation of the cellulose is reduced t o

a minimum by treating the washed chlorinated residue in the crucib)o wit h

dilute sulfurous acid solution immediately after chlorination . The objections to using a calico or muslin pad in a Gooch crucible have been over come, since the chlorinations are carried out in a chamber consisting o f

a Jena (fritted-glass-bottom) crucible . Chlorination is expedited, as th e

chlorine gas is not drawn through the sample by suction but forced through

under a slight hydrostatic pressure, thereby increasing the speed of reaction . The moisture of the material is evenly distributed through the en tire sample, which gives a more even absorption_ib of the chlorine gas ,

Procedur e

Chlorination .--Approximately 2 grams of air-dry sawdust groun d

to pass a 60-and to be retained on an SO-mesh sieve, or shredded pulp, ar e

weighted in a tared alundum crucible by means of a weighing bottle, an d

dried in the oven for 2-1/2 hours at 105°C .11 The crucible is placed alongside the weighing bottle during drying . After drying, the crucible i s

again placed in the stoppered bottle, cooled in a desiccator over sulfuri c

acid, and then rereighed . The results are therefore based on the actua l

weight of the over-dry wood or pulp .

The crucible and its contents of mood are treated 3 to 4 hours i n

a Soxhlet extractor (the extraction may generally be omitted for pulp) wit h

a 2 ;1 mixture of benzene and alcohol . After removal of the solvent b y

suction the sawdust is thoroughly washed with hot water, again under suction . The moist sawdust is then transferred to a Jena glass crucibl e

(size 35 cc . No . 3, porosity 5-7) provided with a fritted-glass bottom .

1

-Investigators at the Forest Products Laboratory found that it was impos sible to filter off the solutions from the chlorinated residue of bam boo, Phyllostachys perebula, unless the wood had been previously eithe r

treated with hot 1 percent sodium hydroxide solution or boiled water .

15 Renker, "Bestimmungs Methoden der Cellulose," p . 88, Berlin (1910) ;

Schwalbe, "Chemie der Cellulose," p . 620 .

- Peterson and Bray, Ind . Eng . Chem ., 20, 1210 (1928) .

Il Should the sample contain volatile oils it is necessary to determine th e

moisture by the xylene method and work thereafter on the air-dry material s

Hawley and Wise, "Chemistry of Wood," p . 130 (1926) ; Schwalbe,Z . ;ngew .

Chem ., 21,400(190S) .

R1022

-3-

_i'• ti

-

Th% suction is app lied. t .t bottom of the crucible until the

excess raois ire is removed, then At the top for a few minutes, to remove

the water from the i'FitGe'd=giass Plate awl allow free passage of the

chlorine ga,iMMORO

s through the

a iag the subsequent chlorination treat The crucible is placed in the eh-1orirxa4ion apparatus as show n

in Figure 1 . 4 measure quantity of clelorire gas is passed from the bure t

up through the material in the. crucible and over into the ?iet ,.el gas pipe t

'aptaly as possible . During the first chlorination a a-gPw sample o f

gloterbs approximately 230 cc, of chlorine gas at room temperature an d

under atmospheric pressure . This necessitates refilling the buret thre e

times, which may be done cluickl;y= since it is cor eted to a chlorine tangy

by means of a three-way stopcock. After the first chlorination treatment ,

which requires from 3 to 4 .

, t 4Q gas reee'i g, in the system i s

brawn back into the gftt

anti TIM 4u14ume irr0a5l ed . The cr'ObI'bUe i s

ta{ 7 •

then removed from the apparatus and tl '

try Welshed with co$d

water using the filtrate for subsequent titrations of the hydroghloric rld.

The sample is 'then s .ccessively washed by suction with 50 cc, each of a

3 percent suds roes acid solution, 6eid water and a freshly prV ied

2 percent sodium sulfibst

4>w

: ; sam le is transferred, to a 250-cc . beaker and treat O , cr?

100 cc, of 2 pr-eent sodium sulfite solut.ieal. The material may be= pile d

with sodiu:,i sulfite soli d.oii fn the crue l • as $Bested by Seib -an d

'.

Dore .2-2 The last traces of t h e sample ad i qPh7ig to thh- ptrrae le

the crucible are removed by successively drvin ; 10-cc . poetons of the

;~iw4lfite solution up through the bottom of the cruci! $:e by means o f

,, The 1,ea]eer centaining °t .e material is c6vered vvi: 4 a watch glas s

and placed. in a bo-ill.ng water bath for 30 minutes .

'i ham; :sample is again tra,red too. the g -~s crucible and washed

with about 220 cc . of distilled water, The • oai atb thus far is neve r

sufficient to remove-fall the lignin ; hence. the chlorination

subsequent

treatments as avtlined above are repeated until the fibers are a uniform

white or she only a very fail tin of p4nk upon addition of the sodium

sulfite solution . The Second and following treatments with chlorine shoul d

not require more than 1 or 2 mina e 6 each...

4fter all the ligrxisn has been removed:, the fibers axle tknroughly

washed into the original al-GOANAi crucible (tile fritted Jena glass crucibl e

may be used instead of the alidum eruciole -throughout the whole procedure )

(porosity 9,0 with approximately - . 500 cc, of hot distilled water and stirred

iona .y vkti;t a poin

~ . rod, then w het w h D cc . of 35 perrucible and

agle.e.=.00

egillalie

1,

-1/2 hours oiq

weight at 105°C . in

atTNona , * ,

:

iccator over sul

acid, and weighed .

X0, OM:WAWA

i

4tne consumed in

lm of all the vol

used i tall seft-al chlorination -t-reatments, corrected irAividualar t o

41.4 7t:;4 , gin„ pressure ') emording ti-G the follovatkw 4prmala :

r ll t (P - a) 760 (1+0,00367 0

1. ;

volume i cub* {centimeters under standard corAitions ; a =

ante re

vaporr pressure n

.tinits''air of chlorine gas aver calciua alCride

of chlorina solution sat-aate,el

Qlorine .as at scree tel*vagits.meey

tio4l: Vt. .= volume of chi

tigimperature,, t ;

, &as, 4t

sure in mm, iawcy .

Tse.cowtIft4

i

and the ]Hem--Y_ l

for t'he gae

NeArre--Calci-um chloride

gas vipe-t':

► elation satu.rated at room temygli. w.% . fcc-NtAsi Degipect both t o

calcium . eilaloride and chlorine gas is preparet(it AO Altered for u.*,t„

t

'Table It *13aishes data for lcffi.ilsisg the eigiculatief

to the above forlit

.

i--Constants fob Chlor '

7605 1 + 0,0036* .

q., 5

- 25 „0

26 4o

27,0

28 . 0

29

5k$

17 . 3

e

18,0

19,E

-20„ t

22 .0

~s d

32 w*

s-wned Espy-i5t". obtained by sub -,

Wcentage'o''.r chlorine em

ig''@LIW Values in the fol le,winii'V formula :

Per,telitit

cons

X 0 06

. 411b, Gf chlarimfg itree lia6

675 gram,

.

:I.

.::. s-

1

■

1

rd te4flilaturefMra.1

•

%WI percentate of chlorine litrvg*lg hydreelaMsic &W in the

process Jim

;t4ty titration of tie water used in washing the sampl e

imme di aotrW aft et

several chlorination treatments .

-5-

d

! Y

rift

dibiab ,,

sawdust leaf

d t4

-melt ~Iydt~art~•

~

remained. 4b

me

plap$d 'i. clo

These

s

sample *c

Mika Ih1w

until it passed a 60-mesh sieve and the

#

mesh sieve was designated as sample 3968

and remaining on a AMMO* w

s ca

and designate d

was then r

retained o n

~•assing t

nple r

, 20

In Schorger's method the periods of chlorination were

15, and 10 minutes, respectively ; in both Rit',.er's and the author's me

ods the sawdust was subjected to four 3-minute chlorination periods ,

data recorded under sample Va g

- represent white spruce wood, which wa s

analyzed several years previous by the method of Schorger . It is adde d

for comparative purposes only .

Application of Schorger's method gave higher yields of cellulos e

from 80-100 mesh sawdust than were obtained from 4o-60 mesh material . The

cellulose obtained from the finer ground material, however, was degraded t o

a greater extent than that obtained from the coarser ground sawdust . This

is evidenced by the low yields of alpha-cellulose and also by the physica l

characteristics of the alpha-cellulose--namely, its gelatinous condition .

These results compare well with those of sample Va, which had been treate d

in the same manner .

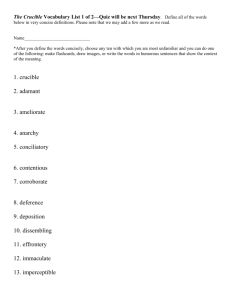

ive400.yticalData on Cellulose of Alcohol Benzene

Wood,ObtainedbyThreeMethod s

ovenweigllt af arlgimal wood)

t--

o

'7inenes tl

Detn .

M0 .

Ye,

39

11-

teria l

*eh

14 S. Dept .:ME

60105

164:;!l s

40-6 o

396 1'06 404 0

39 6A

. 103

396* 104 .

4;5

'0.57

go-=,10o

%-,;,za: 0*6a.

10*100

6S 37saa .aJ7

..

k•

sitter's Method

396

I07

F=Aa

61,2 4§*Q

396

10S 407060

ttt.O

396A

105

39A 106

396

=-400 .

oomt- o9

103

62 . 7

4*e.6o 6.34 k4a

I09

ho-6o

%6 '464p

Ilo 44-6o

6340

4

111

6

44*7

0

60

. 0

ff r

.0

4 4,1

6 .t 4403

12

KMnO4

41eac h

Final KMnO4

bleach

- KMnO4

leach

Fi

ntteaC

..

A

ter•

.0 .

leac4

lap 4p*&4-'-b leach

Mi,

ti@*S

Table

vxtracted

Analytical. Dataon411ulose of Alcohol-Benzene

Obtained by hreaMethods (continued )

Sijrace Wood

k1l)

Xi'-p',raim

1_ os~e 1.cse,

%

396

115

40 .66

65 .0

396

116

Ita,60

6

Average

396B 101

60-.SO

62.6

63 .1

45 . 3

44 .7

396B

60-SO

62 .7

44 . 4

102

396B

. 9

3707

0 ''44 o t

e e

37.1

..

s e

36,2

35 .2

21,7

Ob9it .

'u.

06

6o-g

o

44 . 2

396E

lob

6o- g

o

396B

I07

60-SO

62,7

396B

lo

6o-g

o

62 .7

60-SO

62 .5

39

Ptif#

g

'302,r 109

as

_

Total ITT

10

44 .7

ArqRv kw,

4z311i;

.Q!ow.surr)t io n

2o10I.Lorine.

63 .0

63,1+, o

ss

..

Pit

e s

37 ..0

35. 7

21,„3

54.S

20,6

21 .5

21 .0

I •

35.5

Lost

o .6o

35.S

21.9

o .45 d

36,7

21 .5

o .6o

56. g

22.7

Remarks

Glass

crucible

(too xoist )

crucibl e

Glass

throughout

Alun gum crucib l e

for weighiLg

AARndum critoplo

Aluladmm crucibl e

for. w40ing

A311num efMable

for 1'1,04kl. ftg

4.1undatlwOAel .ag

few weigNi*g

AlumIms cer-wible

for weighing

A.1-gindum crucible

14)r _weighin g

Aa-andcam crucible

for weighin g

Alund-mn crucible

In using the short chlorination method of Ritter, highe r

values for celluilse were also obtained with the 80-100 mesh materia l

than with the 40-60 mesh sawdust„ However, by the short chlorinatio n

methods the cellulose from the finer ground material was not degrade d

as in Schorger's method ; as shown by the uniformly high values fo r

alpha-cellulose . These experiments confirm the work of Ritter--namely ,

that the short chlorination period gives higher yields of alpha-cellulose

--indicating less degradation of the cellulose than is caused by the

longer periods of chlorination .

Chlorination by the crucible method described in this pape r

gave approximately the same values for cellulose regardless of the siz e

of particle used in the experiments--namely, Q-60, 6o- g0, and 80-10 0

mesh sawdust . In addition, practically the same percentage of chloion e

was consumed in isolating the cellulose, although the samples of wood wer e

ground to 3 degrees of fineness .

The alpha-cellulose content is slightly higher in the cellulose :

obtained from the coarser material . This indicates that, the cellulos e

from the finer ground sawdust is hydrolyzed to 4 slightly greater exten t

than that from the coarser saWdust .

e me

~~los

,00NO

iiiangan

d, a1

the 444016

method was omi4tte d

appear to affec t

lulose .

wa s identical re $gw4lks# Of *hithe r

periods of Schorger o r

f ration

the new crucible method were used . Thi s

asutt'jasoe vor ::; .Ot / er,_ ,in waich comparison was made of the ligni n

writ

cell.

.ned 'im

atus by the long an d

's

i oerkwittviat

`'•

remaining i n

'dsr

w

,

t '

the ate].

- $a 4~1 dfie.0mR03 0

ely r e

sodium sulfit e

even Ialrfte

iprol

ination ,

t is furthe r

Ha

IILvelpitk as a - cellu W de ermination o f

~ .i

iv

01 Table

show t4t the Jena glass c:n

-i washing, drying, and weighing of the

the alundum crucible . It was noticed tha t

tle weight durin g

'W_

#theref

Aft 9

them before and afte r

use and t

rgection wh

s occur ;

:-This sometimes tame s

place also -vi] t alundum crucibles .

IOU* eof

wf~

It s reco

fo r the

19 Haug, ' 4 ITber die Natur der Cellulose aus Getreidestroh, N Berlin,

R1022

1916 .

The short method for the determination of cellulose offer s

following advantages over former methods :

■- 1--It combines cellulose isolation and chlorine consumption an d

through uniform chemical action results in higher yields of cellulose .

'

2--The total chlorine consumed together with that forming hydrochlori c

Is acid may be measured at the various stages of the process .

3--Chlorination is carried out under a slight hydrostatic pressure, whic h

increases the speed of the reaction and also insures more uniform an d

more complete chlorination than is secured, when the sawdust or prip i s

chlorinated under suction or in beakers .

" l--There is less degradation of the cellulose as shown by the alj dacellulose content .

'1 ,

5--The work is expedited because the lignin is removed with as great

efficiency

in the short chlorination period as in the long chlorinatio n

Rt.

period .

6--The yields of cellulose and the chlorine consumed are practicall y

the same regardless of the sire of the particl chlorinated .