HOME BREW TEMPERATURE CONTROLLER Neville DeWitt Pierrat

advertisement

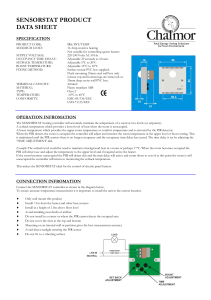

HOME BREW TEMPERATURE CONTROLLER Neville DeWitt Pierrat Connor Fiechtner December 2 nd , 2011 OVERVIEW Project Background System Description Circuit Input and Output Thermocouple Input Heater Output Pushbuttons LCD Control Design System Model & Simulation Controller Development Programming State Machine Interrupts THE PROJECT Implement a control algorithm using a microcontroller Design friendly user interface Must be modular and self contained Promote saccharification of various cereal grain starches Synthesize a disaccharide isomaltose solution for organic conversion to ethanol THE SYSTEM Control is achieved through sensing the temperature and changing the duty cycle of the heater. The slow response of the system allowed a long sampling time of 10s, permitting the use of interrupts without worr ying about timing. Arduino Duemilanove ATMEGA328 16 Mhz clock 10-bit A/D Electric Kettle heater 1500W Thermocouple Solid State Relay Optically coupled LCD display Pump CIRCUIT DIAGRAM THERMOCOUPLE INPUT Thermocouple Data sheet included temperature – resistance table Exponential was fit to data Gives relation between Temperature and resistance Voltage Divider The board will read the voltage and convert to digital Voltage: digitizedvoltage ∗ Resistance: ∗ Temperature: 47.65 ∗ log 517.05 HEATER OUTPUT 1500W Heater on 120VAC Salvaged from thrift-store electric kettle Draws 12.5 Omron G3NA -225B 25A Solid State Relay Allows Arduino to control current to heater Optically Coupled Switched by 5VDC Cheaper than an otherwise identical 15A version TEMPERATURE CONTROL BUTTONS SPST Pushbuttons to Increment or Decrement Temperature Setpoint Require 10kΩ Pull-down resistors Interrupt-based response Software debouncing ignores edges within 100ms of first edge Immediate LCD updates LCD TEMPERATURE DISPLAY Common Toshiba HD44780 chipset Identical to that used in class 16x2 Character Display Parallel Signaling 5V Operation 4- or 8-pin Data Bus SYSTEM IDENTIFICATION Run system at steady state and plot the response of step input (10% duty cycle to 90%) LEAD COMPENSATOR DESIGN A lead compensator controller was designed to achieve and maintain a temperature set point Closed-loop simulation of controller output and temperature response: PROGRAMMING Identification of two discrete states for PWM led to development of time-dependent state machine Heater On State Heater Off State Control algorithm evaluated at the end of every PWM period Current temperature display updates every second Interrupt routines adjust set point and update set point display RECAP Project Background Brewing beer System Description Electronic temperature control Input and Output Sensors and Buttons and a Heater Control Design Mathin’ Programming State Machine with Interrupts QUESTIONS?