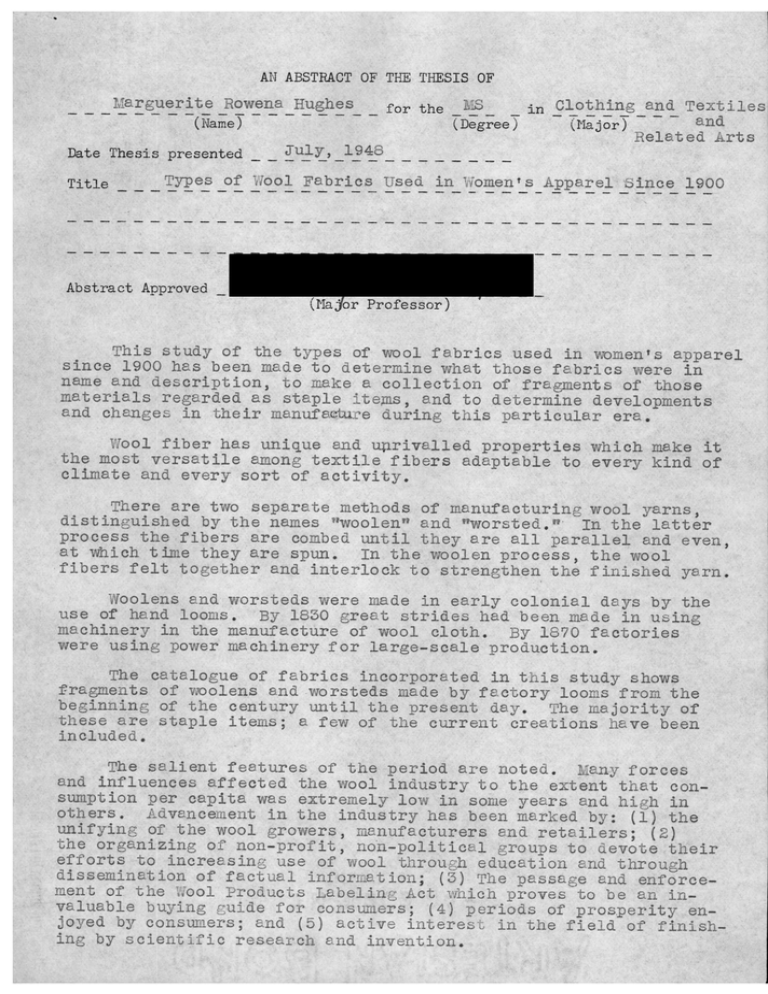

ar&uerite Rowena Hughes Clothing Textiles Related

advertisement