Session #2 INCOSE Model of SE RCI Model of SE Dan Frey

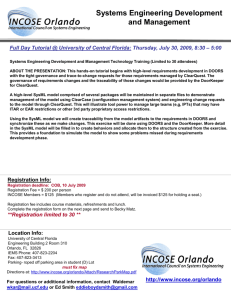

advertisement

ESD.33 -- Systems Engineering Session #2 INCOSE Model of SE RCI Model of SE Dan Frey Don Clausing Plan For the Session • • • • Follow-up from session #1 INCOSE SE handbook RCI model of SE Review assignment #2 Engineering Systems & Systems Engineering ESD mission: To establish Engineering Systems as a field of study focusing on complex engineered systems and products viewed in a broad human, social and industrial context. Use the new knowledge gained to improve engineering education and practice. History of technology Engineering Systems Technology policy Systems Engineering Discussion Point • Did the design of the CFM56 jet engine entail a systems engineering function? • Did the design of Whittle’s jet engine entail a systems engineering function? Scott Thomson Hamilton Sundstrand, Section Lead - Electric Systems • I wanted to comment on the CFM56 vs Whittle engine. • The CFM56 engine is …an example of the system engineering aspects of organizations and their architecture/structure and how they relate to the partitioning of the engine itself. The engine being built by CFMI, which is a consortium of GE, SNECMA and Hispano-Suiza. No single player builds the entire engine … Whittle had his fairly small shop with a collection of machinists and his lab - all probably within his domain and span of control. • One of the other greatly complicating factors of the CFM56 vs. Whittle engine are all of the secondary power extractions that are powered from today's engines, which have an enormous impact on the engine's performance • SyE makes this possible today; whereas Whittle was focused on a revolutionary powerplant for propulsion. Evolution of Gas Turbine Engine Performance 1.05 1.00 Ghost 0.95 0.90 Cruise thrust specific fuel consumption lb fuel/hr lb thrust ( 0.85 JT3D CJ805 0.80 JT8D-17 JT8D-9 0.75 JT8D-15 JT8D-209 JT8D-17A JT8D-219 TAY JT9D-3 JT9D-3A JT9D-7 JT8D-217A JT9D-59A JT9D-7A CFM56-3 CF6-50E/C RB211-524C2 RB211-535C CFM56-2C1 CF6-6D RB211-524D4 UP CF6-50E2/C2 RB211-524D4 JT9D-7R4H1 CFM56-5B JT9D-7R4D (B) CFM56-5A1 V2500 CF6-80A/A1 4460 RB211-535E4 RB211-524D4D 2037 CFM56-5C2 CF6-80C2 4056 4083 4156 4380 4168 0.70 0.65 0.60 0.55 0.50 P&W deHavilland RR GE 2005 2000 1995 1990 1985 1980 1975 1970 1965 1960 1955 0.40 1950 0.45 1945 ( JT3C Certification date Adapted from Koff, B. L. "Spanning the World Through Jet Propulsion.” AIAA Littlewood Lecture. 1991. Performance Drives Complexity P Brayton Cycle 2 3 Consequently, complex secondary flows required 1 4 V Need higher and higher turbine inlet temperatures for efficiency ⎛ p1 ⎞ T1 η = 1 − = 1 − ⎜⎜ ⎟⎟ T2 ⎝ p2 ⎠ γ /( γ −1) Cognitive Parameters g= n i n r f lea 0 ,00 5 t u o ab r /y s k n u ch rate o connections within a brain » 10 6 connections between two brains working memory = 7 ± 2 chunks expert knowledge » 50, 000 chunks Adapted from Simon, Herbert, 1969, Sciences of the Artificial, MIT Press. Secondary flow systems and controls cause a risk of rework FAN system (7 components) LPC system (7 components) Modular Systems HPC system (7 components) B/D system (5 components) HPT system (5 components) LPT system (6 components) Mech. components (7 components) Integrative Systems Externals and Controls (10 components) Design Interface Matrix Adapted from Sosa, Manuel E., S. D. Eppinger, and C. M. Rowles, 2000, “Designing Modular and Integrative Systems”, Proceedings of the DETC, ASME. Plan For the Session • • • • Follow-up from session #1 INCOSE SE handbook RCI model of SE Review assignment #2 Questions to Probe Chapter 2 According to INCOSE: • When did SE emerge as a separate branch of engineering? • What are some of the key functions of SE? • Who should carry out the SE function? • What fraction of the program budget should be spent on SE? • Do SE methods apply to “smaller” systems? INCOSE International Council on Systems Engineering Systems Engineering Process Overview Technical Management Planning Process Plans, Directives & Status Assessment Process Control Process Acquisition & Supply Supply Process Ch 4 Questions Outcomes & Feedback Acquisition Process Requirements System Design Requirements Definition Process Solution Definition Process Acquisition Request System Products Designs Product Realization Implementation Process Transition to use Process Products Systems Analysis Process Technical Evaluation Systems Requirements Verification Validation Process Process • Who participates in each process? • What emerges from each process? End Products Validation Process Systems Engineering Process According to INCOSE, the basic Systems Engineering process tasks are: 1) Define the System Objectives 2) Establish the Functionality 3) Establish the Performance Requirements 4) Evolve Design and Operation Concepts 5) Select a Baseline 6) Verify that the Baseline Meets Requirements 7) Validate that the Baseline Satisfies the User 8) Iterate the Process through Lower Levels INCOSE International Council on Systems Engineering Customer Desired System Assigned Requirements Design Feedback Specified Requirements System Other Stakeholder Requirements Design Feedback Assigned Requirements Other Stakeholder Requirements Layer 2 Solution Blocks Specified Requirements Design Feedback Layer 3 Solution Blocks Assigned Requirements Other Stakeholder Requirements Specified Requirements Design Feedback Assigned Requirements Other Stakeholder Requirements System Design Hierarchy Layer 4 Solution Blocks Specified Requirements Discussion Point Under what conditions should “commercial” enterprises be plotted in the upper left quadrant? Influence of External Rigidities, Especially Governments 1 0 INCOSE LEGACY COMMERCIAL 0 Number of Strong Global Competitors N Asking Better Questions Questions • What is the best way to store and access our inventories? • How can we accurately predict our field reliability? • Another example? Better Questions • ? • ? Plan For the Session • • • • Follow-up from session #1 INCOSE SE handbook RCI model of SE Review assignment #2 Plan For the Session • • • • Follow-up from session #1 INCOSE SE handbook RCI model of SE Review assignment #2 Assignment #2 Frameworks • • Due: Thursday 6/17 at 8:30AM Self select teams of 2-4 (preferably at the same company or in the same industry) 1. Select a company and write about the tools/processes related to RCI at the company 2. Do a value stream map of any value creating process of your choice 3. Develop an example of a set-based approach System Engineering Implemented in FPDS Customer Musts / Wants > Generic VDS & SDS Customer Experience & Feedback Vehicle Level Inputs Vehicle Level Requirements System / Subsystem Level System & Subsystem Design Specifications - SDS > Manufacturing Knowledge & Reusability Requirements Cascade > Technology Production Feasibility Feedback Requirements Cascade > Product Knowledge Vehicle Verification DVM / DVP Vehicle Attributes Vehicle System Specification - VDS > Reusability Constraints & Data DVM / DVP System Verification Feasibility Feedback Part / Component Fabrication / Verification > Warranty Data > Models Part / Component Design Component Design Specification - CDS Highly lterative KO Disposal Feasibility Feedback Requirements Cascades > Competitive Benchmark Data Purchase, Operate & Maintain Customer Requirements Purchase / owner / operator Regulatory (FMVSS, EPA, ...) Corporate (WCR, ABS, Manuf, ...) Corporate Knowledge Customer Satisfaction Customer Focus SI SC Mostly serial PA PR Adapted from Ford Motor Company. J1 Next Steps • Do the reading assignments for session #3 – Womak_Lean Thinking Introduction.pdf – Stanke_Murman_Lifecycle Value in Aerospace.pdf – Ward_The Second Toyota Paradox.pdf • If you want, begin Assignment #2 • Come to session #3 – 8:30AM Tuesday 15 June