Polymer Blends

advertisement

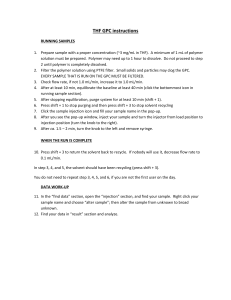

Polymer Blends Good References on Polymer Blends: • O. Olasbisi, L.M. Robeson and M. Shaw, Polymer-Polymer Miscibility, Academic Press (1979). • D.R. Paul, S. Newman, Polymer Blends, Vol I, II, Academic Press (1978). • Upper Critical Solution Temperature (UCST) Behavior Well accounted for by F-H theory with χ = a/T + b • Lower Critical Solution Temperature (LCST) Behavior FH theory cannot predict LCST behavior. Experimentally find that blend systems displaying hydrogen bonding and/or large thermal expansion factor difference between the respective homopolymers often results in LCST formation. Why? Phase Diagram for UCST Polymer Blend Predicted from FH Theory 6 T A χ = ; add a constan t B T 5 Equilibrium Stability x1 = x2 = N binodal ∂2ΔGm =0 2 ∂φ ∂ ΔGm =0 3 ∂φ 4 χN ∂ΔGm =0 ∂φ low Two phases 3 A' B' 2 spinodal Critical point A 1 φ'A 3 critical point 0 hot B φ"A One phase Thigh 0.0 0.2 0.4 A 0.6 φ 0.8 1.0 B B Figure by MIT OCW. A polymer B polymer x1 segments x2 segments v1 ≈ v2 & x1 ≈ x2 χ= A + B T 2 Principal Types of Phase Diagrams T T Single-phase region Two-phase region Tc UCST LCST Tc Two-phase region 0 Single-phase region 1 φ2 0 1 φ2 PS-PI 2700 180 PS-PVME 160 180 T(oC) T(oC) 140 140 120 100 P1 80 2100 100 Wps 0.2 0.4 0.6 60 0.8 PS 0 PS 0.2 0.4 0.6 φ 0.8 1.0 PVME Figure by MIT OCW. Konigsveld, Klentjens, Schoffeleers Pure Appl. Chem. 39, 1 (1974) Nishi, Wang, Kwei Macromolecules, 8 Today - Measuring Polymer MW& Size • c2* • Intrinsic Viscosity – alpha, Mv and more scaling exponents! • Osmometry – chi and Mn Spinodal Decomposition of LCST Blend Bicontinuous Structures LCST By up-quenching into the unstable spinodal regime and then after a short hold, rapidly cooling, one can trap the bicontinuous spinodal structure. Over-annealing results in coarsening and droplet formation (figure d) just like in metal alloys. Image and text removed due to copyright restrictions. Please see Fig. 28 in Platzer, Norbert A. J. Copolymers, polyblends, and composites: a symposium. Advances in Chemistry, no. 142. Washington, DC: American Chemical Society, 1975. Overlap Concentration c2* c2* is the so called overlap concentration; the polymer concentration at which the coils of molecular weight M just begin to touch. Note: at and above c2* the solution is reasonably uniform in composition (i.e. mean field situation, no large regions of pure solvent) Sphere of pervaded volume c2* ~ M / NA 4 2 3/2 π<r > 3 Volume of sphere c2 ≈ c 2 * c2 > c2* Viscosity, η • Basic information on chain dimensions in a particular solvent. v Shearing of a fluid velocity profile y x Boundary Conditions - no slip τ= τ= η If dγ dt N viscous force = Pa = 2 area m dγ dv cm/sec = = = γÝ sec−1 dy cm dt shear stress η= = Pa ⋅ sec rate of shear η ≠ η (γ tot , γ& ) the fluid is a Newtonian fluid Polymers are very nonNewtonian! We are interested in the effect of additives on the viscosity of simple (low molar mass) fluids. (1). suspension of hard spheres -- (Stokes 1850, Einstein 1905) (2). suspension of polymer coils Stokes and Viscosity η0 v • sphere of size Rs falling through a fluid of viscosity η0 with velocity v. Fviscous= f v f is the friction factor of the solution f = 6 ρ η0 Rs Stokes’ Law • How to treat a polymer molecule? 2 Limiting Cases: I. Impenetrable Sphere II. Penetrable Coil x2 segments/chain Rg2 ≡ s 2 = r2 6 Polymer Molecule in Shear Flow • Case I: Impenetrable Sphere f = 6 π η0 RH RH ~ <Rg2>1/2 so f ~ x21/2 RH is the hydrodynamic radius coil / sphere / nondraining • Case II: Penetrable Coil Solvent passes through coil so f ~ ξ x2 where ξ is the monomeric friction factor coil / open mesh / free draining The model that is most appropriate depends on the size of the polymer Scaling Behavior of Friction Factor f ~ x2 a a Condition 1 low MW coil or any rod 1/2 θ condition (Gaussian coil: RW) 3/5 good solvent (coil: SARW) • For high MW flexible chain molecules correct model is nondraining, impenetrable units f = 6πη0R H 2 1/ 2 R H = γ Rg γ ≈ 0.85 • To develop expression for viscosity use Einstein equation for viscosity of a solution containing impenetrable spheres of volume fraction φhs: η (φhs ) = η0 (1 + 2.5φhs + L) • choose θ condition and dilute solution ( φ 2 << 1), c 2 << c *2 PS #1 • c2* = overlap concentration, note: φ2 ≠ φhs, indeed φ2 << φhs 2 Important Viscosities η sp = • Specific viscosity η − 1 = 2.5φhs ηo (# sphere) ( vol.of sphere) ⎛ c 2 ⎞ 4 3 2 ⎟⎟ πγ R g φhs = = ⎜⎜ ⎝ M/NAV ⎠ 3 Total Volume • Intrinsic viscosity [η] ≡ lim c 2 →0 [η ] ⎛ 4π 3 ⎜ 3 γ N AV Rg = 2.5⎜ M ⎜ ⎝ 2 3/2 ⎞ ⎟ ⎟ ⎟ ⎠ η sp c2 3/2 2.5φ hs = c2 [η]θ At θ condition and collect constants into prefactor Kθ For other solvent conditions use α solvent quality factor R g → α R gθ Expt’l method for obtaining alpha [η] = α 3 [η]θ 3 with K = α Kθ = Kθ M1/2 in general: [η] = KM a Intrinsic Viscosity - Key Idea • A simple method to quickly assess a sample’s molecular weight is to utilize the dependence of the viscosity of a polymer solution (in a good solvent) on the molecular weight of the polymer. The viscosity depends not only on molecular weight and on solvent quality, but also on polymer concentration, so one has to extrapolate to zero concentration to determine the “intrinsic” effect of the addition of the polymer to the increase in viscosity of the solution. Mv Viscosity-average molecular weight η sp [η]= kMva [η ]≡ lim c2 → 0 c2 1/a = ⎛ ΣNi Mi1+a ⎞ Mv ⎜ ⎟ ⎝ ΣNi Mi ⎠ (See following page for derivation) Viscosity-Average Molecular Weight ηsp = η −1 η0 For a polydisperse solution with ni moles of species i of molecular weight Mi ηsp,soln = ∑ ηsp,i [η]i = KM ai i Number average MW ∑ ni M i Mn = ∑ ni nM conc of ith species in g/vol. of solution c i = i i V [η]soln = η sp,soln lim c2 →0 c2 ∑ ηsp,i [η]soln = lim i c 2 →0 ∑ ci ∑ ηsp,i = lim c 2 →0 i [η]soln = i c 2 →0 ∑ n iM i/V c2 → 0 ∑ n iM i i Note: Mv = Mw For a = 1 But in general 0.5 ≤ a ≤ 0.8 so ∑ n iM i/V i ∑ ni M1+a i i ∑ n iM i/V ⋅ KM ai = lim i i [η]soln = K ∑ n iMi /V i ∑ ci [η]i lim i ≡ KM av 1+a ⎞ 1/a ⎛ ⎜ ∑ n iM i ⎟ ⎟ or M v = ⎜⎜ i nM ⎟ ⎜ ∑ i i ⎟ ⎝ i ⎠ Mn ≤ M v ≤ Mw Mark-Houwink-Sakurada [η] = KM a • K and a depend on solvent quality; more scaling exponents! a < 1/2 poor solvent θ conditions a = 1/2 a > 1/2 good solvent • It turns out α is weakly dependent on coil size (the interior of the coil expands more than the periphery) so longer chains expand more in a good solvent than do shorter chains. α ~ M 1 / 10 which results in a = 8/10 for high MW chains in a good solvent Determination of Intrinsic Viscosity ηspec C2 x x x For a* series of concentrations C2 < C2 η sp x C2 [η] C2 log[η] x x = [η ] + slope ⋅ C 2 For a series of MWs [η ] = K M a x a x log K log M Atactic Polystyrene in (at 25oC) θ condition Slopes: θ solvent a = 1/2 good solvent 8/10 > a > 1/2; MW dependent Solvent K x 102 a Benzene Butanone Chloroform Cyclohexane Dichloromethane THF Toluene 1.23 3.9 0.7 10.8 2.10 1.10 1.05 0.72 0.58 0.76 0.48 0.66 0.725 0.73 Cyclohexane θ = 36oC 0.5 Membrane Osmometry ( M n , A2, χ) • • Osmotic pressure, π, is a colligative property which depends only on the number of solute molecules in the solution. In a capillary membrane osmometer, solvent flow occurs until π increases until the chemical potential μ(π) = μ1o ∂μ1 dP ∂P ∂μ1 ∂ ⎜⎛ ∂G ⎞⎟ ∂ ⎛ ∂G ⎞ = = ∂P ∂P ⎝ ∂n1 ⎠ ∂n1 ⎝ ∂P ⎠ P0 + π μ = μ1 + ∫P p ° 1 0 dG = Vdp − sdT + μdn Solution Pure solvent Semi-permeable membrane Figure by MIT OCW. so T, n fixed ∂G =V ∂P ∂ (V )≡ V1 ∂n1 (partial molar volume of pure solvent) Membrane Osmometry cont’d P0 +π μ = μ1 + ∫P ° 1 V1 dP = μ1 +πV1 0 μ1 − μ1o = − πV1 Recall F-H expression for a dilute solution (φ2 small): ⎡ −φ 2 μ1 − μ1° = RT⎢ ⎣ x2 +( χ −1/ 2) φ22 ⎤ ⎥⎦ Rearranging: ⎡ ⎛ φ2 ⎞ ⎛ 1 ⎛⎜ φ 22 ⎞ ⎤ ⎞ ⎟ + −χ π = RT ⎢ ⎜ ⎠ ⎝ V 1 ⎠ ⎥⎦ ⎣ ⎝ V1 x 2 ⎠ ⎝ 2 Since solution is dilute: V ≅ n1V1 so V1 ≅ V1 n2 x 2 φ2 ≅ recall n1 2 ⎡⎛ n2 ⎞ ⎛ 1 n ⎛ 2⎤ 2⎞ ⎞ π = RT ⎢⎝ ⎠ +⎝ − χ ⎠ ⎝ ⎠ V1x 2 ⎥ V 2 ⎣ V ⎦ The osmotic pressure is a power series ⎛n ⎞ in ⎜⎝ 2 ⎟⎠ i.e., π depends V on the number of molecules of solute per unit volume of the solution. Osmotic Pressure cont’d • For a polydisperse polymer solution, n2 = Σi ni where ni is the number of moles of polymer of molecular weight Mi in the solution. The number average molecular weight of the polymer is simply M = ∑ ni Mi = m n ∑ ni • The concentration in grams/cm3 of the polymer in the solution is just Hence the osmotic pressure can be written ⎡ m n2 Mn c ⎛n c2 = = or ⎝ 2 ⎞⎠ = 2 V V Mn V • ⎞ V1 x 22 ⎤ 1 ⎛1 = RT⎢ +⎜ − χ⎟ 2 c2 ⎥ ⎝ ⎠ c2 Mn ⎦ ⎣ Mn 2 π The “reduced osmotic pressure” when plotted as a function of the solute (i.e. polymer) concentration will give a straight line with: Key Information: π c2 RT Intercept: Mn Slope: Three types of behavior: x x x χ < 1/2 (good solvent) x x ⎛1 ⎞V x χ − ⎜ ⎟ ⎝2 ⎠M 2 1 2 2 n x x x x x x x x x χ = 1/2 (θ condition) χ > 1/2 (poor solvent) c2 n2 Osmometry cont’d • At the θ condition, 2nd term disappears (recall χ = 1/2) and solution is ideal πV ≅ n 2 RT • The slope of the reduced osmotic pressure yields a measure of the polymer segment-solvent F-H interaction parameter, so we have a way to experimentally determine the important χ parameter • For gases, the pressure is often developed in a virial expansion as a function of concentration P = RT ( A1c+ A2c + A3c +...) 2 3 • We can therefore identify the virial coefficients A1 and A2 from 1 A1 = Mn A2 = ⎛1 ⎞ ⎜ − χ⎟ ⎝2 ⎠ ρ 22V1 π c2