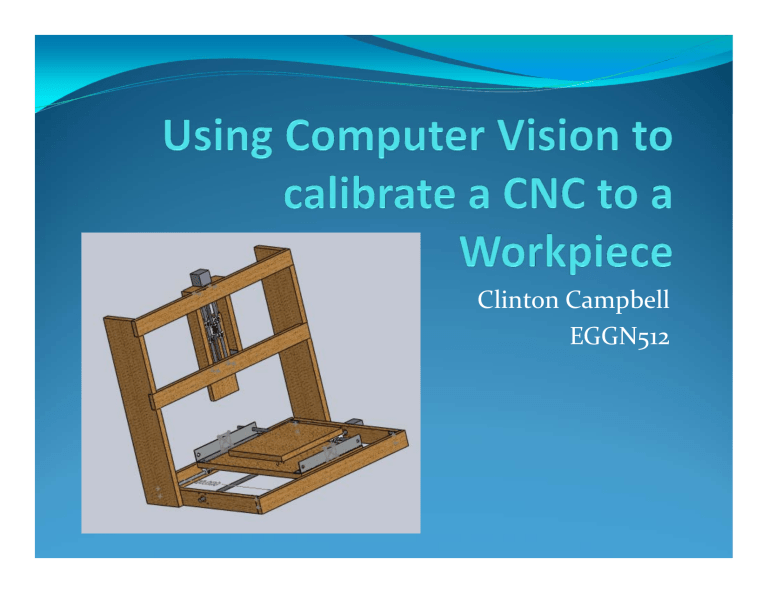

Clinton Campbell EGGN512

Clinton Campbell

EGGN512

Goal: Match drill points to image in

CNC coordinates

Find drill centers

Assume CAM file has no noise

We want white blobs under a certain size

Find the centroids of the blobs

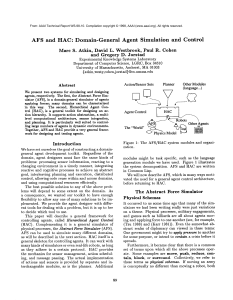

The Platform

1 inch circles with centers spaced at 8 inches

Allows to find object relative to origin

Allows to calculate distance per pixel

The Camera setup

The camera is mounted on the Z axis (it moves with the tool)

3 pictures were taken

1 at the origin at full height

1 at center at full height

1 at center at bottom

Calibration images

First and second image calibrate the conversion factors

Third image finds the origin and calculates the transformation

Matching the Images

Interpretation tree

Match lines by size against other lines, and compare the angle and distance between centers

Match chains of 3

Use a Hough voting pattern for each set of matches

7

2

4

6

8

9

3

5

1

11

10 29

22

7 17

14

8

32

16

18

5

13

38

20

1

34

7

4

22

30

3637

14 2

12

28

6 16

4

19 2

5

17

3

7

9

18

1

11

Found Lines

7

2

1

4

6

3

5

7

4

1 6

2

3

5

Correspondence =

17 11

9 4

13 28

7 6

13 28

7 6

19 13

Angle = 7.13

degrees

True = 6.8

degrees

Translation = (250,267)

True = (238, 267)

Using blobs for more accuracy

Rotate Cam file and close the image and reduce noise

Look for blobs of a certain size, while ignoring the platform markers

1

1

Use the Blob information

The blob centroids and bounding box corner coordinates add information to the translation

Overlaying the images confirms correct matching

Pruning Our Tree

We check that the lines fall within a range of the most common angle

Check that the blob bounding box dimensions match

Check that the translations of lines falls within a range of blob translation

H

Match the Drill Points

cos sin

0

sin cos

0

Tx

Ty

1

Rotate and translate the drill points

Visually Confirm match and send to CNC

Demonstration

Motors Moving

Things That Need Work

Compensating for backlash on lead screws on

CNC

Optimizing traversal of points

Further optimizing of thresholds and line selecting parameters

Using a copper circuit board