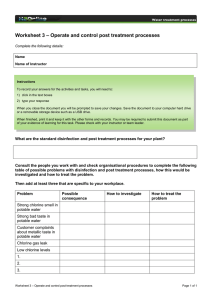

Biocide action of chlorine on Pseudomonas aeruginosa biofilm

advertisement