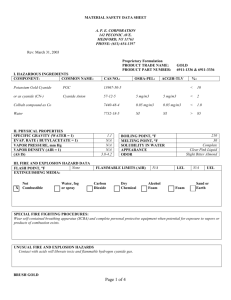

Residual cyanide distribution in a neutralized gold leach heap

advertisement