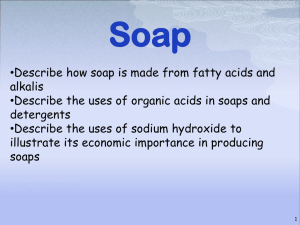

Production of diesel fuel from safflower oil by a soap-pyrolysis... by Scott Eric Kufeld

advertisement

Production of diesel fuel from safflower oil by a soap-pyrolysis process

by Scott Eric Kufeld

A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in

Chemical Engineering

Montana State University

© Copyright by Scott Eric Kufeld (1988)

Abstract:

The purpose of this research was to study the soap-pyrolysis process for making fuel suitable for use in

a diesel engine. The process involved converting safflower oil into a soap and then pyrolyzing the soap

to obtain the diesel range fuel. Commercial high-speed and medium-speed lubrication oils were

investigated with five weight percent soap-pyrolysis fuel contamination relative to polymerization

properties.

The first set of experiments studied pyrolysis process variables. It was observed that: fuel from soap

aged three months had a greater initial kinematic viscosity than fuel from soap aged two days and both

these fuels had about the same kinematic viscosity after 48 hours in the polymerization apparatus;

glycerol in the soap decreased yield; fuels from soap with a 50% excess amount of Ca(OH)2 showed

less thickening after the polymerization tests than fuels from soap with a stoichiometric amount of

Ca(OH)2; calcium soap is superior to magnesium soap since the yield of fuel is greater; the #2 range

distillate has less of an initial kinematic viscosity than the total distillate and both distillates have the

same kinematic viscosity after the polymerization tests; the lighter the fraction of the total distillate the

smaller the initial kinematic viscosity and the greater the viscosity increase; storage time of fuel had

little effect on polymerization properties.

The second set of experiments showed that addition of Ca(OH)2 prior to pyrolysis decreased

thickening while limiting yield.

The third set of experiments found the best soap production method investigated was the fusion method

with no solvent. Other methods tried were the precipitation process and using both toluene and water at

different concentrations as solvents in the fusion method.

The fourth set of experiments showed that it would be desirable for the safflower oil to contain more

oleic acid esters than linoleic or linolenic acid esters.

Optimization of the process showed that addition of a stoichiometric amount of Ca(0H)2 for fusion

soap production, and no Ca(0H)2 added prior to pyrolysis, was most desirable.

The soap-pyrolysis fuels worked better as fuels in a diesel engine than safflower oil. PRODUCTION OF DIESEL FUEL FROM SAFFLOWER

OIL BY A SOAP-PYROLYSIS PROCESS

by

Scott Eric Kufeld

A thesis submitted in partial fulfillment

of the requirements for the degree

of

Master of Science

in

Chemical Engineering

MONTANA STATE UNIVERSITY

Bozeman, Montana

September 1988

/

/<

*r3 s'

ii

APPROVAL

of a thesis submitted by

Scott Eric Kufeld

This thesis has been read by each member of the thesis

committee and has been found to be satisfactory regarding

content, English usage, format, citations, bibliographic

style, and consistency, and is ready for submission to the

College of Graduate Studies.

,4/2/Z./#0

Date

Chairperson, Graduate Committee

Approved for the Major Department

Approved for the College of Graduate Studies

Date

iii

STATEMENT OF PERMISSION TO USE

In presenting this thesis in partial fulfillment of the

requirements

University,

to

for

master's

degree

at

Montana

State

I agree that the Library shall make it available

borrowers

quotations

a

under

from

the

this

rules

of

the

Library.

Brief

thesis are allowable without special

permission, provided that

accurate

acknowledgement

of the

source is ma d e .

Permission for

extensive quotation

or reproduction of

this thesis may be granted by my major professor, or

absence, by

the Dean

of Libraries

either, the proposed use

purposes.

of the

Signature

Date

when, in the opinion of

material is

for scholarly

Any copying or use of the material in this thesis

for financial gain shall not be

permission.

in his

allowed without

my written

iv

ACKNOWLEDGMENTS

The author would like to thank the faculty and staff of

the Chemical Engineering Department

University

for

their

guidance

thanks is extended to my

Scarrah,

author

for

his

would

also

and

research

advice,

like

help,

to

here

at

Montana State

assistance.

advisor,

and

Dr.

Special

Warren P.

encouragement.

acknowledge

Dr.

Robert

The

L.

Nickelson and Dr. Daniel L . Shaffer who served on my guiding

committee.

student,

in

Advice

by

the area

Finally, the financial

Department

of

John

Olson,

a

fellow graduate

of polymerization is also recognized.

support

Natural

gratefully appreciated.

W.

received

Resources

and

from

the Montana

Conservation

is

V

TABLE OF CONTENTS

Page

APPROVAL...................................................

STATEMENT OF PERMISSION TO U S E ......

ii

iii

ACKNOWLEDGMENTS...........................................

iv

TABLE OF CONTENTS.........................................

v

LIST OF TABLES.....................................

LIST OF FIGURES...........................................

vii

ix

ABSTRACT....................

x

INTRODUCTION...........................

I

RESEARCH OBJECTIVES.......................................

6

EXPERIMENTAL DESCRIPTION......

Soap Production................

Pyrolysis.....................................

Polymerization.........................................

Acid Number.............................................

Iodine V a l u e ...........................................

Nuclear Magnetic Resonance............................

Distillation......................................... . .

Yield.................

RESULTS AND DISCUSSION....................................

Pyrolysis Studies......................................

Aged Versus Fresh Soaps............................

Glycerol Content of the Soa p s.....................

Fatty Acid Content of Soa p s...................

Calcium Versus Magnesium Soa p s....................

Distillation Results................

Storage Effects...........................

Results for Pure Linoleic A c i d ....................

Pyrolysis With and Without Calcium Hydroxide Reactant

Soap Production...................................... . .

Unsaturation Studies. ..................................

Soap-Pyrolysis Process Optimization..................

10

10

11

16

21

21

22

23

24

26

26

26

29

32

34

35

38

39

40

43

50

56

vi

TABLE OF CONTENTS— Continued

CONCLUSIONS.......

RECOMMENDATIONS FOR FUTURE

69

RESEARCH.....................

71

APPENDICES.................................................

72

Appendix A-Optimization Results......................

Appendix B-Computer Program Used for Optimization....

REFERENCES CITED

73

77

82

vii

LIST OF TABLES

Table

Page

I.

Fatty Acid Distribution in Safflower Oil..

3

2.

Typical Ranges for Diesel Fuel Types......

23

3.

Fuels from Aged and Fresh Soaps...... .

27

4.

Fuels from Soaps With Different Amounts of

Glycerol...............................

30

5.

Fuels from Soaps With Different Free Fatty Acid

Contents........................

6.

The Total Distillate Versus the #2 Ran g e...... .

36

7.

Viscosity Results for Diesel Fuel Types........

38

8.

Aged Versus Fresh Fuels...... ...................

39

Experiments With/Without Calcium Hydroxide

Reactant....... ..................................

41

Viscosity Results of Fuels With/Without

Reactant........................ ..................

42

Results of Fuels from Different Soaps With

Solvent.... ...... ................................

47

Yields of Fuels from Different Soaps With

Solvent............... ............................

49

13.

Results of Fuels from Different Acid Soaps.....

53

14.

Results for the Complex Method of B o x ...........

61

15.

Results from the 32 Factorial...................

62

16.

Variable Levels Used for Optimization.......... .

64

17.

Final Run Results................................

66

18.

Coded and Uncoded Variables for the Mathematical

Model of the Soap-Pyrolysis Process.........

74

Values for Surface Yield Equation Calculation...

74

9.

10.

11.

12 .

19.

viii

Constants Estimate

ix

LIST OF FIGURES

Figure

Page

1.

Soap-Making Process Apparatus...................

12

2.

Pyrolysis Apparatus With Stainless Steel Vessel.

14

3.

Pyrolysis Apparatus With Glass Vessel...........

15

4.

Polymerization Apparatus.........................

18

5.

Viscometer and Temperature B a t h .................

20

6.

Variable Levels for Sequential Simplex

Optimization Technique...........................

59

Variable Levels for Complex Method of Box

Optimization Technique...........................

60

Variable Levels for the Factorial Experimental

Design............................................

63

Computer Program Used For Optimization..........

78

7.

8.

9.

X

ABSTRACT

The purpose of this research was to study the soappyrolysis process for making fuel

suitable

for use

in a

diesel

engine.

The process involved converting safflower

oil into a soap and then pyrolyzing the soap to obtain the

diesel range fuel.

Commercial high-speed and medium-speed

lubrication oils were investigated with five weight percent

soap-pyrolysis fuel contamination relative to polymerization

properties.

The first set of experiments studied pyrolysis process

variables.

It was observed that: fuel from soap aged three

months had a greater

initial kinematic viscosity than fuel

from soap aged two days and both these fuels had about the

same

kinematic

viscosity

after

48

hours

in

the

polymerization apparatus;

glycerol

in the soap decreased

yield; fuels from soap with a 50% excess amount of C a (OH)2

showed less thickening after the polymerization tests than

fuels from soap with a stoichiometric amount of Ca(OH)2 J

calcium soap is superior to magnesium soap since the yield

of fuel is greater; the #2 range distillate has less of an

initial kinematic viscosity than the total distillate and

both distillates have the same kinematic viscosity after the

polymerization tests; the lighter the fraction of the total

distillate the smaller the

initial kinematic viscosity and

the greater the viscosity increase; storage time of fuel had

little effect on polymerization properties.

The second set of experiments showed that addition of

Ca(OH)2 prior

to . pyrolysis

decreased thickening while

limiting yield.

The third set of experiments

found the best soap

production method investigated was the fusion method with no

solvent.

Other methods tried were the precipitation process

and using both toluene and water at different concentrations

as solvents in the fusion method.

The fourth set of experiments showed that it would be

desirable for the safflower oil to contain more oleic acid

esters than linoleic or linolenic acid esters.

Optimization of the process

showed that addition of a

stoichiometric amount of Ca(OH)2 for fusion soap production,

and no Ca(OH)2 added prior to pyrolysis, was most desirable.

The soap-pyrolysis

fuels worked better as fuels in a

diesel engine than safflower oil.

I

INTRODUCTION

In

the

insecurely

averted

predict.

was

mid-1980 *s

between

and

an

an

energy

energy

The energy

triggered

the

by

United

States

crisis

it

had momentarily

could

not confidently

future

it

crisis that

a

sudden

lasted from

but

brief

was

poised

1973 to 1978

Arab embargo upon

petroleum exported to the United States, quickly followed by

several years of sharply rising world petroleum prices.

United States was forced to recognize it had

dependent

upon

satisfy its

imported

own

existing

domestic

appeared

the

rapidly

rising

energy

United

petroleum within

petroleum

might

decades.

to take

the place

no

demands

longer

from its

More ominously,

face

a

shortage

it

of

Experts remained divided

and uncertain about the future [1].

of energy

become heavily

could

energy

production.

States

a few

and

The

An

alternative source

of fossil fuels might someday

help alleviate this problem.

Vegetable oils show

extenders for

much

diesel fuels.

promise

as

replacements or

Theoretically, a farmer could

plant a fraction of his land in oil producing crops

the

fuel

produced

Seed oils such as

attention

as

from

this to run his entire operation.

safflower oil

direct

and use

have received considerable

substitutes

suitable for use in a diesel engine.

or

additives

Safflower oil

for fuels

has the

2

attraction of

being able to be grown easily in Montana.

would be of great interest to

see

safflower

wouldn't have

prices

and

oil

to

replace

rely

finite

the agriculture

It

community to

diesel fuel since farmers then

on

fossil

fuels

availability,

and

with fluctuating

could

then be more

independent and in charge of their own destiny.

Researchers

estimate agricultural fuel needs for the United States could

be met by planting approximately 10%

with oilseed

crops

[2].

of the

total cropland

As an added benefit, vegetable oil

processing yields meal high in protein for animal

by-product

[3].

Despite

the

diesel fuel there

shows

feed as a

that

advantages

of

are

economic

diesel

still

prices

using

would

vegetable

problems.

oil for

Collins

have to double or triple

before even the best vegetable oils would become competitive

[4].

In

general,

if

a

raw material such a diesel fuel

becomes scarce,

its price will rise.

Since the relationship

between

and

absolute and a sign of

price

supply

is

not

scarcity is not a complete absence of material

but rather a

perception of dwindling supply by the consumer, the price of

diesel fuel is always under close scrutiny [5].

The

vegetable

chemical

oils

difference

is

also

between

responsible

diesel

for

vegetable oils form carbon deposits inside

engines

and

polymerize on

(2)

vegetable

contact with

fuel

and

problems:

(I)

direct injection

oil carried into the crankcase

the lubrication

oil leading to

3

eventual

engine

failure

related to differences in

[6].

These

the chemical

problems

are both

structure of diesel

fuel and vegetable oils.

Vegetable oils

are esters formed by the combination of

glycerol with three fatty

straight-chained,

saturated or

unsaturated.

double

bonds

carbon

double

bonds.

safflower is

and

given in

acids

fatty

be without any

unsaturation is a measure of the

fatty

Table I.

can

engines or

acid

distribution

be

solved

by

is to

change in physical

characteristics

vegetable

a

significant

of

deposits

appears

to

prevent

replace one large

The principal

reduction

the

in

This

formation

viscosity

lowering in

of

carbon

[7].

Table I. Fatty Acid Distribution of Safflower Oil

Fatty Acid

palmitic

stearic

arachidic

oleic

Iinoleic

Iinolenic

The

the transesterified

compared to the unmodified vegetable oil.

viscosity

either using

by transesterification.

triglyceride ester with three smaller esters.

is

of

It has been found that the

of transesterification

oil

acids are

that can be either

Saturated would

The

carbon deposition problem

indirect injection

These

monocarboxylic

carbon

net effect

acids.

Percentage

6.4

3.1

0.2

13.4

76.6-79.0

. 0.04-0.13

Composition

Cl 6Hs 2 O2

Cl 8H 3.6O2

C20H4002

Cl8H 3OO2

Cl 8Hs 2 O2

Cl8H30O2

[8]_______

No. of Double Bonds

0

0

0

I

2

3

4

Transesterification does

previously mentioned

of

polymerization

attacking

a

not

necessarily

polymerization problem.

is

thought

to

occur

carbon

double

bond

acting as a catalyst

in the

reaction [9].

polymerization

problem

should

modification of the chemical

The double

prevent the

The mechanism

by

oxygen first

with the carboxyl groups

be

Therefore, the

able

structure

to be solved by a

of

vegetable oils.

bonds could be removed by hydrogenation but this

results in a fuel

that

Decarboxylation or

is

a

solid

removal of

at

room temperature.

the carboxyl groups could be

accomplished by thermal means with

or

without

the

aid of

catalysts.

A

project

primarily with

his results

found that

that

started

with

decarboxylation and

and continued

work

by Hiebert dealt

this investigation used

work in this area

by converting

the safflower

[10].

oil to

Hiebert

a soap and

■

then

pyrolyzing

the

fuel worked the best

modification

of

soap

of

the

to obtain a liquid diesel range

the

techniques

he

tried.

This

chemical structure was accompanied by

relatively low acid numbers (a

measure

of

the

free fatty

acid content) and significant unsaturation (a measure of the

carbon double bonds).

thickening effects

This procedure

significantly reduced

measured by kinematic viscosity.

increase in kinematic viscosity in 64 hours is

failure in lubrication oil tests

[11] .

A 375%

considered a

This current project

attempted to improve and learn more about the soap-pyrolysis

5

process

for

making

fuel

used in a diesel engine.

from safflower oil that could be

6

RESEARCH OBJECTIVES

The

experiments

performed

for

this

research have been divided into five tasks.

soap-pyrolysis

The purpose of

the first task was to investigate the effects of a number of

pyrolysis process variables that

might have

to

Soap

fuel

yield

and

quality.

addressed in this task; in fact,

safflower

oil,

linoleic

acid

production

rather than

was

not

starting with

(its principal component at

76.6-79.0%) was used to make the

simpler, representative

been important

soap

[12].

' By

using a

soap, the effects of the processing

variables were expected to be more apparent and not confused

by the

acids.

presence of

High

speed

polymerization tests.

soaps from

a number of different fatty

lubrication

The

oil

was

used

for

the

high speed lubrication oil is a

thirty weight oil.

Six specific process

this

first

task.

variables

First,

soaps

were

investigated for

that had been aged were

compared with fresh soaps to see how this affected the fuel.

Second, because

the soap

making could be simplified if the

glycerol did not have to be removed prior to pyrolysis,

without glycerol,

with an

amount added

soap

equivalent to that

produced in the soap making, and with an intermediate amount

consistent with

partial removal

were compared.

fatty acid content of the soaps was varied

to see

Third, the

how this

7

variable affected

the fuel.

soaps were compared since

literature indicates

have similar properties.

probably

have

lower

Fourth, calcium and magnesium

However, the magnesium soaps would

pyrolysis

change the nature of the fuel

fuel fraction of the

distillate

Also,

were

[13].

compared to

in

different

compared

with

which

fractions

one

its

polymerization

properties.

another.

fuels and

of

the

Sixth, any

an effect

Oxidation from contact

with air could have caused polymerization.

on fresh

the total

polymerization

changes in the fuel due to storage might have had

on

could

Fifth, a typical diesel

differences

characteristics.

distillate

temperatures

distillate was

for

these soaps

Tests

were made

after they had been stored for a period

of time.

The experiments completed for the second

pyrolysis

with

reactant.

and

without

Linoleic

safflower oil

acid

the

was

use of calcium hydroxide

again

used

fatty acids.

to compare fuels made

use of

than

soap from

a number

Another purpose of this task was

from pyrolysis

with and

without the

calcium hydroxide reactant with both medium and high

speed lubrication oils.

thirty

rather

to prepare the soaps so as to not confuse the

processing variables by the presence of

of different

task compared

weight

oil

forty weight oil.

and

The

High

speed

medium

addition

lubrication

oil

is a

speed lubrication oil is a

of

calcium

made to the soap just prior to. pyrolysis.

hydroxide■was

8

The experiments

for the third task concentrated on the

soap production process.

the soaps

the fuel

for this

yields

different

Safflower oil was used

task since

obtained

soap

it was important to compare

from

production

to prepare

the

vegetable

methods.

A

oils using

multi-step

precipitation process was compared to the single-step fusion

method for

aqueous

the production

solvents

investigated

of the soaps.

with

with

the

varying

fusion

In addition, non-

concentrations

were

method along with use of no

solvent for the process.

The fourth task attempted to investigate the importance

of the

degree of

research in

safflower

vegetable oil

this

oil

lab

to

a

has

unsaturation.

indicated

oils,

but

more

various

double bonds

products

for

degrees

to

of

soaps

any

the polymerization of

information was necessary [14]

approach used for this task involved

with

converting the

soap prior to pyrolysis significantly

decreases the role of unsaturation in

lube

that

Exploratory

The

converting fatty acids

unsaturation or number of carbon

and

then

differences

comparing

that

the pyrolysis

might be found.

High

speed lubricating oil was used for the polymerization tests.

The fatty acids used in this task would be different only in

the number of carbon double bonds.

Ihe

last

task

was

to

optimize

the

soap-pyrolysis

process for making fuel suitable for use in a diesel engine.

The

results

from

the

first

four

tasks

helped identify

9

important process

optimized.

information

It

variables and

was

now

together

techniques and levels of

process for

and

the

techniques that were to be

purpose

determine

variables

for

to

the

put

most

all

this

desirable

the soap-pyrolysis

making diesel fuel from safflower oil.

10

EXPERIMENTAL DESCRIPTION

Soap Production

Two methods

were used

to prepare

experiments.

The fusion method

these runs.

The

was

the soaps for these

employed

for

most of

process consisted of the following steps.

First, 200 grams of acid (oleic,

linoleic, or linolenic)

safflower

IOOOC.

oil

was

consisting of the

magnesium

heated

alkali

hydroxide)

to

hydroxide

with

Second, a solution

(calcium

or

hydroxide or

without

a

(demineralized water or toluene) was vigorously

Magnesium hydroxide

was only

some of

the

soaps

stirred in.

Toluene was only used

the soap production experiments.

the soaps were allowed to cool

After

solvent

used to prepare the magnesium

soaps in the pyrolysis studies.

solvent in

had

dried

or

which took

as a

Next,

several minutes.

they were ground into uniform

chunks using a hand grinder.

The precipitation method was

soaps.

First, 200

grams (in

acid was heated to IOOOC.

sodium

hydroxide

stirred in.

Third, the

and

This

some cases

Second, a

demineralized

process

sodium soap

also used

formed

mixed

with

a

180) of linoleic

solution consisting of

water

a

solid

was vigorously,

sodium soap.

was separated into two batches each

of which was dissolved in 500 ml of

then

to prepare the

solution

of

water.

calcium

Each batch was

chloride

and

11

demineralized

water

and

exchange precipitated

stirred.

out the

This

process

calcium soap.

of ion

Last, the two

batches of soap were combined and

washed with demineralized

water to

or calcium chloride since

remove any

sodium soap

they are both water soluble and the calcium soap is not.

Soap reactions

were performed

at atmospheric pressure

in a 1000 ml glass batch reactor with a glass top.

The 1000

ml reactor and glass top were both purchased from Ace Glass,

product Nos.

6506—35 and

6485— 16.

A thermocouple measured

the temperature and a powerstat was used to control the heat

supplied

to

mantel.

the

reaction

vessel

by

The setup for the soap making

a

electric heating

process is

given in

Figure I.

Pyrolysis

Pyrolysis

is

the

process

condensing the resulting vapors

of

to obtain

Literature indicates

that pyrolysis

to the

aldehydes (ECHO)

formation of

heating

the soaps and

the diesel fuel.

of calcium soaps leads

and ketones (RCHORi)

shown in the following reactions.

(RCOO)2Ca + (HCOO)2Ca = 2RCH0 + 2CaC03

(RCOO)2Ca + (RiCOO)2Ca = 2RC0R1 + 2CaC03 [15]

Maximum liquid

was

chosen

to

temperatures were

prevent

Pyrolysis reactions

damage

were carried

about 8150F; this maximum

to

the

heating

mantel.

out in a 500 ml stainless

steel reactor vessel and then this was replaced by a 500 ml

12

S tirrin g M o to r

Condenser

Coid

Water

Out

—

Glass Top

Coid

Water

in

-------

Glass Reaction

Vessel

Soap Heater

Figure I. Soap-Making Process Apparatus

13

glass reactor after several

studies.

The glass

project.

Nos.

experiments into

reactor was

used for the rest of this

These were both purchased from Ace

6497—05

and

6927—22.

stainless steel and

glass

the pyrolysis

The

Glass, product

apparatus used with the

pyrolysis

vessels

is

given on

Figure 2 and Figure 3.

The reason the stainless steel vessel was chosen in the

first place was the ease of

vessel.

The change

to the

implemented because the

lower with

with the

(DNRC

Grant

vessel

Agreement

study.

The possible

yields

steel vessel

during

the

greater

reasons for

discussed in the Aged

Versus

were significantly

than those obtained

previous investigation

RAE-84-1041)

resulted in a significantly

to the glass

glass vessel in this study was

product

the stainless

glass

cleaning compared

[16].

This

yield

in

change

the current

this yield difference is

Fresh

Soaps

section

of the

Pyrolysis Studies.

The soap

was first put into either the stainless steel

or glass pyrolysis apparatus and a glass connector

the top

then

and was

emptied

insulation

was

attached to

into

a

packed

the condenser.

separatory

funnel.

around

top

apparatus, to minimize heat loss.

was a two-necked flask.

the

The 500

of

came out

The condenser

Fiberglass

the pyrolysis

ml glass reactor

The first neck led to the condenser

where the vapor temperature was measured and the second neck

was used to insert a thermocouple which measured the liquid

14

S tirrin g Motor

^ V a p o r Temp

Cold Water

OuK

Condenser

Stainless Steel

Reaction Vessel

„

Pyrolysis

Heater — -

Cold

Water

Collection

Vessel —

Figure 2. Pyrolysis Apparatus With Stainless Steel Vessel

15

Vapor Temp

Cold Water

Condenser

H eater

Glass

Reaction

Vessel

Cold

Water

In — "

Collection

Flask —

Figure 3. Pyrolysis Apparatus With Glass Vessel

16

temperature.

A

quarter-inch,

glass

covered

magnetic

stirring bar was used at the bottom of the flask to keep the

soap well mixed.

glass top

was also

three necks.

from

The 500 ml stainless steel reactor with a

the

pyrolysis.

The first neck was where

motor,

thermocouple to

third neck

used for

the

second

measure

the

attached to

condenser where the

the stirrer

neck was

used

went in

to insert a

liquid temperature, and

a glass

vapor

The glass top had

the

connector which joined the

temperature

was

also measured.

Heat was supplied by a different heating mantle than the one

used for soap production.

Polymerization

The

simulate

purpose

of

crankcase

polymerization

oil

conditions

determining thickening effects

percent concentration

measured

in

1500C

in

100

ml

(cupric

catalyst and

The.

Ten

Unocal

to

in a diesel engine for

to

adding

a

5 weight

The kinematic viscosity

used as

the

measure

of

batch, reactors

using

50

ml of

parts per millon of a soluble copper

or

CuAcAc)

was

used

as a

oxygen was. bubbled through at the rate of 3 cc

per 15 seconds.

was

was

reactions were carried out at

acetylacetonate

.

Super HDll

was

glass

lubrication oil.

form

of the fuel.

centistokes

thickening effects.

due

experiments

.

The. high

SAE 30W

SAE

.

40.

....

speed lubrication

while the

These

oil was Amoco

medium speed lubrication oil

commercial

lubrication oils

17

contain

lubrication

polymerization.

oil

Since

effects

commercial lubrication

no attempt

was

mechanisms

of

were put

made

additives

of

a

vegetable

affect

oil

fuel on

oil were the focus of this research;

to

study

how

polymerization.

into

that

additives

affect the

The 100 ml glass reactors

custom-built

constant

temperature bath.

Eight different samples could be tested simultaneously.

apparatus was arranged so

The polymerization

bath was

under a hood.

apparatus is shown in Figure 4.

pieces of equipment were

bath and

that the

used for

all were from Ace Glass.

The

Several

the constant temperature

These w e r e :

adapter #11

THD 24/40, product No. 5261-37; test tube, product No. 875202; 300

mm pore

c tubes,

product No. 7202-16;

bushing, product No. 7506-02;

24/40 bearing

11 mm nylon

c, product No.

8042-115; adapter inner, product No. 5028-30.

Evaporation

of

vegetable

oil

fuels

polymerization apparatus was considered.

in

the

Evaporation of the

soap-pyrolysis fuels would leave the lubrication oil left to

be measured for thickening.

Many

the

oil

high-speed

viscosity

lubrication

approximately

polymerization

tests.

the

The

contained the lubrication oil

fuel.

Evaporation

previous work [17].

was

not

of the

experiments with

ended up with a kinematic

same

as

the

control

control

polymerization tests

and

added soap—pyrolysis

no

considered likely because of

While current work had measurements for

kinematic viscosity initially and after 48 hours in the

C i r c u la t o r

Sample

Holder

Valves

Thermometer

Figure A. Polymerization Apparatus

19

polymerization

apparatus,

previous

work took measurements

every 10-12 hours up to 72 hours.

The earlier

work showed

the kinematic viscosity continued to increase above the neat

lubrication oil after the

evaporation

of

possibility.

A

soap-pyrolysis

viscosity at

fuels

was

400 C .

used

to

in

was

only

measure

a

the

remote

kinematic

The technique used was to add 8 ml of sample to

seconds

was

for 10

recorded

on

minutes.

multiplied

by

a

calibration

kinematic viscosity

Canon-Fenske

This viscometer

The initial

number

in centistokes.

viscometer,

No.

to

The

L799,

This was then

convert

it into

viscometer was a

size

was calibrated

viscosity was

Then the

a stopwatch as the oil

traveled between two marks on the viscometer.

21859.

Therefore,

A drawing of the viscometer is given in

the viscometer and let in stand

time

measurement.

Future work in this area should be considered.

viscometer

Figure 5.

48 hour

350, report No.

at 40«c

and IOOOC.

measured and then the sample was

put into the 100 ml glass reactors which were placed in the

constant temperature bath for 48 hours.

time the

final viscosity reading was taken.

work done on this

Natural

Resources

Processing

[18],

it

At the end

of

was

project

and

the

Montana

Under previous

Department of

Conservation (RAE-84-1041, Chemical

Vegetable

shown

for

of this

Oils

to

Prevent Polymerization)

the thickening properties of the fuel

were apparent after 48 hours; the

kinematic viscosity using

straight safflower oil had increased 110% from about 95-200

20

C irc u la tin g

Motor

•Thermometer

Viscometer

figure 5. Viscometer and Temperature Bath

21

centistokes

while, using

the

safflower soap decomposition

product had led to approximately a

22% increase

from about

90-110 centistokes.

Acid Number

The

oil

product is the

relative measure of free fatty acid content.

The procedure

used

acid

is

number

described

dissolving the

heating until

of

in

diesel

ASTM

range

boiling.

The

base

oil

D

or

466-78.

product

this

in

95%

involved

ethanol and

Then a titration procedure was used

with phenothalin as the

found.

an

indicator

used

for

until

the

the

endpoint was

titration was potassium

hydroxide with a normality of close to 0.1.

Iodine Value

The

iodine

unsaturation or

value

ASTM

D

the

carbon double

The method used was

to

is

of

bonds present in the sample.

procedure performed according

This

method has been shown to give

for oils

conjugated double bonds.

and their

derivatives with non—

These are the only type present in

■safflower oil and its derivatives.

20 ml

measure

the Wijs

1959— 69.

accurate results

relative

The procedure was to add

of carbon tetrachloride and 25 ml of Wijs solution to

the diesel sample.

one hour.

After

This was

this hour,

to be

stored in

the dark for

20 ml of 15% potassium iodide

and 100 ml of demineralized water were added.

This was then

22

titrated

with

sodium,

the indicator.

that were

thiosulfate solution using starch as

Simultaneously,

made up

of 25

blanks had

to be titrated

ml of Wijs solution, 20 ml of the

15% potassium iodide solution,

and 100

ml of demineralized

water.

Nuclear Magnetic Resonance

The

Carbon-13

Nuclear Magnetic Resonance Spectrometer

used was a Bruker WM-250 with a Aspect

NMR

spectra

provided

qualitative

2000 computer.

information

about

functional groups attached to the carbon molecules.

parameters

had

to

be

tested

in

appropriate set to use for these

order

The

the

Several

to determine the

oil products.

These were

receiver gain, receiver delay, and the number of scans.

The

receiver gain varies with the concentration differences.

An

appropriate receiver gain would be set so the free induction

decay is two centimeters above and below the screen midline.

A typical

receiver gain

for these

samples was

receiver delay is the time between scans.

set by

choice of

the other

delay was around two

scans should

be taken

seconds

parameter.

for

these

The

This was already

A typical receiver

samples.

Enough

to give a good signal to noise ratio

which varies by the square root of the number of

the concentration

1600.

scans.

As

of the sample is increased, the lower the

number of scans that are needed.

The

1.5 ml

sample of oil

was mixed with 0.5 ml of solvent (deutero chloroform).

This

23

fairly high concentration required only 500 scans which gave

good results.

There

were

several

areas

of

interest

spectrum.

The unsaturation region occurred

parts per

m i I Ion.

Ketones

Esters

were

from

were found

NMR

between 110-140

mil Ion.

All peaks

at 170

parts per

205 to 208 parts per m i I Ion.

Finally, solvent had three peaks with

parts per

the

The carboxylic acid region was found at

180 parts per mil Ion.

mil Ion.

in

the middle

one at 77

were done in comparison with

the solvent.

DistiIlation

Distillations

characteristics

were

of

one

done

set

to

of

determine

products in the pyrolysis

tests.

The method used is described in

Davis,

a

Chemical

Engineer

at

volatility

ASTM D

86-78.

Tom

the Farmers Union Central

Exchange in Billings, MT, provided these

typical ranges for

diesel fuel:

I. Typical Ranges for Diesel Fuel Types

Diesel Fuel Type

heavier-#3

regular-#2

lighter-#!

Initial(OF)

Endpoint(OF)

500

. 430

315

720

625

520

It should be noted these ranges vary with the season.

The

apparatus

used

included

reactor used in pyrolysis, a vapor

the

same

500 ml glass

temperature thermometer,

24

a water

cooled condenser,

and a glass recovery flask.

procedure used was to heat the organic product

vapor would

condense and

product was distilled in

the

temperature

was

temperature was

brown.

slowly.

The

collect in a recovery flask.

The

order of

lightest tp

increased.

material to come off

was

a

The

very

increased the

a green

tint.

heaviest as

first and lightest

light

yellow.

As the

color of the product went to

The heaviest diesel that came off

color with

The

was a

dark brown

The differently colored products

did not stay separate as they mixed in the recovery flask.

Yield

Yield was calculated two wa y s .

were used

which

When the

various acids

to make the soap and in the soap production study

used

computed per

safflower

oil

to

make

of organic

the weight of soap

second way

charged

it

yields

starting

the

This

minus

was done

the

yield was

was charged since

was

important

water

by taking

and dividing

this number

it by

by taking

product.

A

used when safflower oil

to

compare

vegetable oils.

the fuel

This yield was

calculated per 100 grams of total safflower oil

was done

yield was

product collected and dividing it by

to calculate

from

the

100 grams of dry soap since the effects of the

process variables were important.

the weight

soap,

used.

This

the weight of organic product collected

the soap

was multiplied

charged for

pyrolysis.

Then

by the total weight of soap and

25

divided by the weight of safflower charged.

26

RESULTS AND DISCUSSION

Pyrolysis Studies

Aged Versus Fresh Soaps

The

first

set

of experiments compared polymerization

properties of fuels prepared from soaps

for two

months prior

that had

to pyrolysis with fuels prepared from

fresh soaps aged three days before pyrolysis.

prepared by

the fusion

hydroxide mixed

High

two

different

numbers for

with 71

speed lubrication

for the polymerization tests.

these experiments.

The soap was

method with linoIeic acid and a 50%

excess amount of calcium,

demineralized water.

been aged

Table 3 gives

grams of

oil was used

the results of

The fuels obtained from these soaps aged

times

had

similar

properties.

The acid

the fuels dried two months were both 0.7.

This

compares to acid numbers of 1.0 and 1.4 for fuels from soaps

dried

®

three

days.

The

iodine

ficantIy from one another.

values

did

The fuels from

not

differ

soaps dried

two months

had iodine values of 136 and 141 while the fuels

from soaps

dried three

150..

days had

iodine values

of 149 and

Therefore, no significant differences existed relative

to acid numbers and

results of

iodine values.

spectra confirmed

small acid numbers and significant unsaturation.

The yields of the fuel from

was not

NMR

comparable since

the soaps

the pyrolysis

aged different times

apparatus had been

27

changed from stainless steel to glass and will

later in

this section.

soap and pyrolysis

apparatus

for

The

was

the

be discussed

yield is per 100 grams of dry

performed

in

the

stainless steel

soaps : dried three days (fresh) and the

glass apparatus was used

for

fuels

from

soaps

dried two

months (aged).

Table 3. Fuels from Aged and Fresh Soaps_____________ _______

Viscosity

Initial

Final

Soap % Y ieId Iodine V a l . Acid No.

(cSt)

(cSt)

fresh

16.7

149

1.0

65.8

68.1

109.1

110.1

fresh

17.4

150

1.4

70.1

69.9

105.8

107.4

aged

49.5

136

0.7

82.8

80.1

115.3

108.8

aged

45.0

141

0.7

78.5

77.5

105.1

107.4

The

vapor

temperatures

observed were much lower with

the stainless steel compared to the glass apparatus used for

pyrolysis.

When the

stainless steel

used the maximum vapor temperatures

200-2IOOF.

pyrolysis vessel was

were

in

the

range of

With the glass vessel the vapor temperatures got

as high as 4000F.

The liquid product recovery

was

considered

complete

when

formed several

it fell to about 10 seconds

between drops of product . into the

lightest and

first of

layers and

the product

separatory funnel.

The

to come out was a clear

28

water

layer.

The

organic

layer

was

next.

When the

stainless steel pyrolysis vessel was used this organic layer

took the

The

form of

layers

were

two distinctly

a

light

different colored layers.

yellow and a dark brown.

These

organic layers did not stay separated when they mixed in the

separatory

funnel.

When

the

stainless

apparatus was used, but the rate at which

was

reduced,

the

organic

steel pyrolysis

heat was supplied

product took another form.

The

product was then formed in one distinct yellow—brown mixture

with the

color yellow

was different again

used.

The

more apparent.

when

product

the

then

glass

This organic product

pyrolysis

vessel was

usually took the form of a more

uniformly colored brown liquid product with a green

tint on

the last of the product.

There

is

difference in

a

possible

yield between

pyrolysis vessels.

explanation

the glass

of

As the soaps were heated they vaporized

take place

a longer

top increased

the

longer

to

have

a

the volume causing

holding

time.

polymerization was possibly catalyzed • by components

stainless steel-

First,

retention time with the stainless steel

apparatus since the glass,

vapor

in the

This could be more drastic when the stainless

steel pyrolysis apparatus was used for two reasons.

there was

extreme

and stainless steel

in both vessels and polymerization could

vapor phase.

this

vessel.

The polymers

Second,

in the

could then condense

and, since they, would be much less volatile

than the soaps,

29

they would char rather than vaporize.

The thickening

soaps

dried

kinematic

two

different

viscosity

months increased

increase was

dried three

when

effects of

the

an

were

fuels

average

of

the

after

are

48

and 106.3

from

centistokes)

the average

examined

hours

in

were

Table 3.

very

close

The

and

soaps aged

two months

The average initial viscosities of

soaps

were

while

centistokes compared to 109.6 and

three days.

fuels

soaps dried two

observation takes place

106.6 centistokes for the fuels from

compared to

from

The

48 hours for the fuels from soaps

numbers

taken

different.

36.9%

An interesting

actual

averaged 112.0

times

the

57.8% after

days.

viscosities

for

the fuels obtained from the

dried

much

two

greater

months

than

(81.5

and 78.0

those of fuels from

soaps dried three days

(67.0 and

shows that

soaps aged the longer period of time

gave

fuels from

fuels

These

with

fuels

greater

from

initial

soaps

aged

approximately the same kinematic

Some of

70.0 centistokes).

kinematic

different

This

viscosities.

times

viscosity after

were

at

48 hou r s .

this variation in initial viscosity might have been

due to the switch that occurred in the pyrolysis apparatus.

Glycerol Content of the Soaps

The second set of experiments for the pyrolysis studies

investigated the

the fuel.

with

effect of glycerol content of the soaps on

The soap was again prepared by the

linoleic

acid

and

a

50%

excess

fusion method

amount of calcium

30

hydroxide mixed with 71 grams of demineralized water.

High

speed lubrication oil was used for the polymerization tests.

The results are given

in Table

4.

Fuels made

from soaps

without added glycerol were compared against fuels made from

soaps with 23 and 46 grams of glycerol added.

was added

prior to

pyrolysis.

glycerol that would

every three

glycerol

be

moles of

is

the

produced

from

calcium soap.

total

Correspondingly, 23

There is

amount

The glycerol

only one mole of

vegetable

oils for

Therefore, 46 grams of

that

would

be

produced.

grams represents half the amount in the

soap.

Table 4. Fuels from Soaps With Different Amounts of Glycerol

Viscosity.

Glycerol

Initial

Final

Added

%Yield

Iodine V a l . Acid No.

(cSt)

(cst)

none

none

23g

23g

46g

46 g

12.6

13.7

11.6

10.7

5.8

4.5

134

124

129

131

—

—

—

—

—

—

1.3

1.0

1.9

1.9

1.6

1*7

The glycerol content of

properties of

the soaps

the fuel significantly.

the fuels from soaps without

1.0.

Acid, numbers

glycerol

1.9.

100.3

107.0

110.9

109.8

108.5

107.1

did not

change the

The acid numbers for

added

were

1.3 and

for fuels made from soaps with 46 grams

of glycerol added were 1.7 and

fuels from

81.8

72.7

74.9

75.7

77.8

76.9

soaps with

1.6.

Acid numbers

for the

23 grams of glycerol added were both

Iodine values showed

fuels that could be tested.

this

same

consistency

for the

Since the yields were only 5.8%

31

and 4.5% for the

added not

fuels obtained

enough product

determination.

Iodine

with 46

grams of glycerol

was available for an iodine value

values

for

the

fuels

without added glycerol were 134 and 124.

from soaps

Iodine values from

soaps with 23 grams of added glycerol were 129 and 131.

NMR spectra

The

once again confirmed the findings of small acid

numbers and showed a significant unsaturation region.

Thickening effects

the addition

of the

of glycerol

fuels were

to the

not affected by

soaps prior to pyrolysis.

The kinematic viscosity for the fuel from soap with no added

glycerol increased

Likewise»

the

an

average

kinematic

of

3.4.2%

46.6% and

that glycerol content

performance of

48 hours.

viscosity increased for the fuels

made with 23 and 46 grams of glycerol

average of

after

added to

the soap an

39.4%.

This leads to the conclusion

of

soaps

the

does

not

affect the

the fuel in a diesel engine with regard to a

tendency to polymerize.

Although the

glycerol

significantly affect

content

the polymerization

decrease the yield calculated per

Yield was

steel

low because

apparatus.

glycerol added,

of

100

pyrolysis was

Yields

with adding

obtained

the

did not

properties, it did

grams

of

dry soap.

done in the stainless

from

23 grams,

soaps

with

no

and adding 46 grams

were averaged to be 13.2%, 11.2%, and 5.1%.

decreasing yield

soap

The

pattern of

with increasing glycerol added to the soap

leads to the conclusion

that glycerol

is not

desirable in

32

the soap

prior to pyrolysis.

Fatty Acid Content of Soaps

Next in the pyrolysis

studies was

the fatty acid content of the soaps.

linoleic

acid

polymerization

This

was

used

tests

presented

a

an investigation of

The fusion method with

to , produce

used

the

soaps

and

the

the high speed lubrication oil.

problem

when

an

attempt

increase the fatty acid concentration.

was

made to

The first try was to

heat the soap to turn it to a liquid form and add

the fatty

acid

Then

which

would

have

corresponding acid

was

the

soap

been

linoleic

number could

would

starting to pyrolyze.

not

be measured.

return

Nex t ,

it

acid.

to

was

linoleic acid to prepare the soaps.

the

The problem

a liquid form before

tried

to

add excess

Several runs were tried

using excess linoleic acid to complete

the reaction.

This

.

technique proved

to be a failure.

it just remained in

the

liquid

Solid soap never formed,

state.

Finally,

it was

determined how much excess calcium hydroxide was required to

produce a solid soap.

that solid

it was discovered

soap required at least stoichiometric amounts of

calcium hydroxide.

50% excess

After several runs

The two soaps compared in this study had

and stoichiometric amounts of calcium hydroxide.

This was not the initial comparison that was to be

made but

it was the best that could be accomplished.

The results

fuel does seem to

are given

be

in Table

changed

5.

slightly

The nature of the

by

the

amount of

33

excess calcium

hydroxide used.

The acid numbers for fuels

from soaps with a stoichiometric amount of calcium hydroxide

were 6.1

and 8.1.

Acid numbers for fuels from soaps with a

50% excess amount of calcium hydroxide were both

0.6.

This

showed

were

also

a

changed:

slight

181

and

stoichiometric

difference.

184

amount

for

of

Iodine

fuels

values

from

calcium

soaps

hydroxide

with

compared

a

to

iodine values of 132 and 139 for fuels from soaps with a 50%

excess amount

of calcium

hydroxide.

This means fuels made

from soaps with less calcium hydroxide had more unsaturation

and more

free fatty acid content.

Yields were not affected

by the calcium hydroxide in the soaps.

of

dry

soap

were

stoichiometric

hydroxide.

and

averaged

the

The glass

50%

Yield per

100 grams

to be 42.6% and 49.1% for the

excess

amount

of

calcium

pyrolysis apparatus was used for all

these experiments.

Table 5. Fuels from Soaps with Different Free Fatty Acid

Contents

Viscosity

Initial

Final

Ca(OH)? %Y ieId Iodine V a l . Acid No.

(cSt)

(cSt)

50%xs

43. 8

132

0.6

76.7

77.7

106,3

101.9

50%xs

54.5

139

0.6

75.9

77.6

105.1

107.4

0%xs

41.2

181

6.1

76.5

76.7

117.8

118. I

0%xs

43.9

184

8.1

76.9

76.9

120.0

121.4

34

The thickening

the free

of the

fatty acid

fuel did seem to be affected by

content of

viscosities increased

the soaps.

The kinematic

an average of 54.5% and 36.9% for the

fuels from soaps with the higher free fatty acid content and

the lower

free fatty

difference in

this

acid content respectively.

increase

viscosities of the fuels.

was

higher

free

fatty

polymerize faster.

significant if

the

final kinematic

The initial kinematic viscosities

were all within 1.8 centistokes.

the

in

The major

acid

This

Fuels made from soaps with

content showed a tendency to

probably

higher free

would

fatty acid

have

been more

contents could have

been achieved.

Calcium Versus Magnesium Soaps

The fourth

set

compared calcium

of

tests

for

hydroxide

and

The results from the

were used

for the

pyrolysis studies

soaps with magnesium soaps.

soap was prepared by the fusion

magnesium

the

59

process with

The magnesium

33.1 grams of

grams of demineralized water.

other tests

in the

calcium soap.

pyrolysis studies

Magnesium soaps gave such

low yields not enough product was

available for

The stainless steel pyrolysis apparatus was used.

apparatus a typical yield.from other

studies for

were

preferred

to

the

0%.

, Thus,

magnesium

calcium soaps gave a greater yield.

With this

the pyrolysis

the calcium soaps was around 10-15%.

soaps gave yields that approached

soaps

runs in

any tests.

Magnesium

the calcium

soaps since

the

35

For a possible explanation of this

the

reader

is

difference in

pyrolysis

first

referred

yield between

vessels

given

the

magnesium

in

the

discussion of the

the stainless

in

the

section of the Pyrolysis Studies.

that

to

difference in yield

the

Aged

It is

soaps

steel and glass

Versus

Fresh Soap

possible, however,

promotes

vapor

phase

polymerization more than the calcium found in the soaps.

this is

true it

would cause

decreased yield

If

for the same

reason as discussed earlier.

Literature indicates

pyrolysis temperatures

the 1920’s Sato in

of calcium

magnesium soaps

might have lower

than their calcium counterparts.

Japan investigated

and magnesium

that the magnesium soaps

the dry distillation

soaps of soybean Oil.

decomposed

In

at

Sato found

lower temperatures

and gave heavier products than the calcium soaps

[19].

Distillation Results

The pyrolysis

studies next

fractions of the diesel fuel.

fuel corresponding

to the

for polymerization

tests.

Soap

prepared by the fusion method using linoleic acid

and a 50% excess amount of

calcium hydroxide

grams of demineralized water.

up of extremely

liquid

Fuel, and the fractions of the

#2 diesel range were tested with

high speed lubrication oil

was again

investigated the different

diesel

light,

#1,

products.

distillate was 51 weight

mixed withx 71

The total distillate was made

#2,

The

#3,

#2

percent of

and

extremely heavy

fraction

the total

of the total

product and

36

the

fractions

range fuel

product was

that

lighter

fraction were

properties

and heavier than the #2

approximately equal.

compared to

given in Table 6.

the

were

the #2

range and

acid

of

numbers

the

of

Iodine values for the

while iodine

the results are

This comparison proved the differences in

fuel

were

not significant.

numbers for the total distillate were

to

This total

0.8

0.8 compared

and 0.9 for the #2 diesel range.

total

values for

0.6 and

Acid

distillate

the #2

were

136

diesel range

and 130

were 141 and

138.

Table 6. The Total Distillate Versus the #2 Diesel Ranee

Viscosity

Initial

Final

Fuel

Iodine Val . Acid No.

(cSt)

(cSt)

total

136

0.6

82.0

110.1

total

130

0.8

81.0

106.7

#2

141

0.8

62.3

62.2

108.4

108.3

#2

138

0.9

63.6

63.7

106.5

106.5

Thickening

distillate and

effects

the #2

were

different

diesel range

The total distillate had

initial

when

the

total

product were compared.

viscosities

of

82.6 and

81.0 centistokes and final viscosities after 48 hours in the

polymerization apparatus

of

110.1

and

106.7 centistokes.

The #2 diesel range had initial viscosities of 62.2 and 63.7

centistokes and final

viscosities

after

48

hours

in the

37

polymerization

apparatus

of

108.3

and 106.5 centistokes.

The total distillate experienced a 32.5% average increase in

kinematic viscosity after 48 hours while the #2 diesel range

had a 70.6% average increase.

This

shows

the

#2 diesel

range experiences

a greater increase in kinematic viscosity

after 48 hours in

the polymerization

the

total

viscosities

compared

to

distillate

were

the

much

#2

because

greater

diesel

apparatus compared to

the

for

range.

initial

the

kinematic

total distillate

After 48 hours the #2

diesel product gave about the same viscosities as

the total

distillate.

Next,

the

total

distillate

was separated into three

fractions: lighter than #2, #2, and heavier than

These three fractions were then compared.

in Table 7.

fraction had

#2 diesel.

Results are given

Thickening effects were different.

The lighter

an 93.0% increase in kinematic viscosity.

The

regular VA2 diesel increased an average of 70.6% in kinematic

viscosity.

The

heavy

kinematic viscosity.

fraction

Al I

these

had an 27.2% increase in

increases

hours in the polymerization apparatus.

were

after 48

38

Table 7.

Fuel

Viscosity Results for Diesel Fuel Types

Viscosity

Initial

Final

(cSt)

(cSt)

light

56.4

107.8

regular

(#2)

62.3

62.2

63.6

63.7

108.4

108.3

106.5

106.5

heavy

77.9

99.1

These results indicate that for hot

should be

made up

diesel range.

of diesel

This is what

weather regular #2

on the heavier side of the #2

Tom Davis,

a chemical engineer

at the Farmers Central Union Exchange just outside Billings,

Montana, said is the case.

Storage Effects

Next, storage effects on the fuel were studied.

Fuel fresh from pyrolysis

was tested

pyrolyzed and let stand for ten weeks.

and compared

Polymerization tests

used high speed lubrication oil and the soaps

by the

fusion method

amount

of

calcium

demineralized water.

Table 8.

hydroxide

mixed

were 5.1 and 1.3.

were prepared

acid and

with

a 50% excess

71

grams

of

Data for these experiments is given in

Properties of the fuel were

storage process.

numbers of

with linoleic

to fuel

not affected

by this

For fuel fresh from pyrolysis acid numbers

This

4.2 and 0.6.

compared

to

the

aged

fuels acid

Iodine values for fresh fuels were

39

160 and 147.

The iodine values for the aged

fuels were 143

and 150.

Table 8. Aged Versus Fresh Fue Is

Fuel

Iodine V a l .

fresh

fresh

aged

aged

Viscosity

Initial

Final

CcSt)

(cSt)

Acid No.

160

147

143

150

5.1

1.3

0.6

4.2

77.5

71.7

71.0

85.6

111.0

112.0

108.3

108.0

Thickening effects were also similar.

from pyrolysis

the kinematic viscosity increased an average

of 49.5% after 48

For

fuel

that

For fuel fresh

hours

had

in

been

the

aged

polymerization apparatus.

ten

weeks

the

kinematic

viscosity increased an average

of 39.1%

the polymerization

In conclusion, the fuel aged

apparatus.

for ten week behaved

similarly

in

the

after 48

hours in

simulation

of the

diesel engine.

Results for Pure Linoleic Acid

Next, the

pure linoleic acid was compared to the other

results in the Pyrolysis Studies.

linoleic

acid

was

153

The iodine

which was comparable to the iodine

values found for the soap-pyrblysis fuels.

of 15.5

for the

value for the

The

acid number

linoleic acid was significantly higher than

that of the acid numbers of

the soap-pyrolysis

fuels.

The

polymerization results showed an initial kinematic viscosity

of

96.4

centistokes

and

after

48

hours

one

centistokes with the high speed lubrication oil.

of

178.0

This is an

40

85% increase in thickening of

significantly

more

than

the

linoleic

greater.

which is

that of the soap—pyrolysis fuels.

In addition, the initial viscosity of

much

acid

the linoleic

acid is

Therefore, soap-pyrolysis fuels would work

better than pure

linoleic

acid

in

a

diesel

engine with

regard to tendency to polymerize.

Pyrolysis With and Without Calcium Hydroxide Reactant

The

next

step

after

the

pyrolysis

completed was to investigate pyrolysis with

use

of

calcium

hydroxide

as

a

just prior

the

the

A

review

pyrolysis with the use

of

product in

the

[20].

following

The calcium

to the

heating of

literature indicated that

of calcium

may produce hydrocarbons

were

and without the

reactant.

hydroxide reactant was added

soaps.

studies

hydroxide as

a reactant

Hydrocarbons (RH) would be a

reaction

of

calcium

soap with

calcium hydroxide:

(RCOO)2Ca + Ca(OH)2 = 2RH + 2CaC03

A

charge

of

12.37

stoichiometric amount

water.

grams

of

required

The precipitation

calcium hydroxide was the

if

the

soap making

contained no

process was used to

prepare the soaps in this

group

insure no

hydroxide would be present in the

soaps.

amount

excess calcium

The

of

precipitation

sodium

demineralized water

method

hydroxide

and

a

of

soap

50%

experiments

used

mixed

excess

so

as to

a stoichiometric

with

86

amount

grams

of

of calcium

41

chloride mixed

with 176

grams of demineralized water.

amount of calcium hydroxide

required on

a wet

The

basis could

not be calculated until after the pyrolysis with the calcium

hydroxide

reactant

content of

was

the soaps

performed

because

was unknown.

the

moisture

It was determined after

pyrolysis with the calcium hydroxide reactant

was performed

that the amount of calcium hydroxide required on a dry basis