Chemical Vapor Deposition (CVD) SiO

advertisement

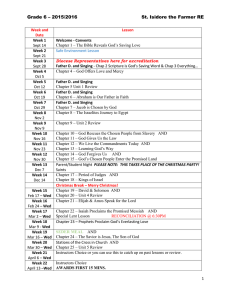

Chemical Vapor Deposition (CVD) Processes: gift of SiO2 - Expose Si to steam => uniform insulating layer… clean and simple or metal film growth : … Contrast with high vacuum, single element… clean and simple CVD: toxic, corrosive gas flowing through valves, T up to 1000°C, multiple, simultaneous chemical reactions, gas dynamics, dead layers… whose idea was it? Insulator x, , InsulatorSi0 Si0 x wet growth wet growth Figure removed for copyright reasons. Figure 4-1 in Ohring, M. The Materials Science of Thin Films. 2nd ed. Burlington, MA: Academic Press, 2001. ISBN: 0125249756. Poly PolySiSielectrode: electrode: 0.3 0.3- -0.4 0.4µm µmCVD CVD Gate Gateoxide: oxide: 500Å x, , 500ÅSi0 Si0 x dry drygrowth growth CVD is the single most widely used deposition method in IC manufacture 3.155J/.152J Wed., Oct. 12, 2005 1 CVD reactors Four reaction chambers (similar to those for Si oxidation) Control module Control T, gas mixture, pressure, flow rate 3.155J/.152J Wed., Oct. 12, 2005 2 CVD is film growth from vapor/gas phase via chemical reactions in gas and on substrate: e.g. SiH4 (g) → Si (s) + 2H2 (g) Do not want Si to nucleate above substrate (homogeneous nucleation), but on substrate surface (heterogeneous nucleation). Twall Reactor Transport of precursors across dead layer to substrate Removal of by-products Susceptor film T sub> Twall Pyrolysis: thermal decomposition at substrate 3.155J/.152J Wed., Oct. 12, 2005 Chemical reaction: Decomposed species bond to substrate More details… 3 CVD Processes 8 1 Bulk transport of by-product Bulk transport Reactant molecule Carrier gas (Maintain hi p, slow reaction) J1 ∝ Dg ∆C 7 2 Transport across bndry layer 3 Diffusion of (g) by-product 4 Decomposition 5 Adsorption 6 Desorption Reaction with film J 2 ~ k iCi Surface diffusion 3.155J/.152J Wed., Oct. 12, 2005 4 Hi vel, low P Gas transport Low vel, hi P Laminar flow across plate: 2 Hi vel, low py Transport across “boundary layer” Figure removed for copyright reasons. Low vel, hi py… …shorter λ Figure 4-7a in Ohring, 2001. J1 ∝ Dg ∆C kB T λ= 2π d 2 P Knudsen NK ≡ λ L Viscous flow Dimension Dimensionout outofof screen screenmust mustalso also be considered be considered 3.155J/.152J <1 Figure removed for copyright reasons. L Figure 4-7b in Ohring, 2001. Dgas ≈ λv x 2 Laminar flow pipe. Wed., Oct. 12, 2005 Conductance ∝ A/L 5 J1 = −hg (Cg − Cs ) dC D Revisit gas J1 = −D =− Cg − Cs ) ( dynamics: dx δ (x) Boundary layer Layer thickness, δ(x) D= And we saw gas diffusivity λ vx (unlike solid) z u 2 boundary layer gas vel: u0 δ (x) Cg Cs us = 0 wafer 1 δ = L x=L x wafer Fluid dynamics: δ (x) δ (x ) = ηx ρ u0 ρ = mass density, η = viscosity η 2 L 2 ∫ δ (x )dx = 3 L ρ u L ≡ 3 Re 0 0 L uL Reynolds #: Re = ρ 0 η ease of gas flow 3D So: hg = δ → 2 L Re D 3.155J/.152J Wed., Oct. 12, 2005 6 Where δ (x ) = ηx ρ u0 does come from? z u Diffusion Eq.: C C ∂C ∂ 2C =D 2 ⇒ ≈D 2 t δ ∂t ∂z Cg δ (x) Cs wafer x=L x δ = Dt η D(cm /s) = ρ 2 σ η ⎛ m2 ⎞ −2 η = (Nsm ), ε& ρ ⎜⎝ s ⎟⎠ Analogous to diffusion length t = x / u0 δ = η= viscosity, Re = ρ ρ = mass density 3.155J/.152J η x ρ u0 Wed., Oct. 12, 2005 Reynolds #: ease of gas flow u0 L η 7 Several processes in series Simplify CVD to 2 steps: Boundary layer AB J1 = Dg δ ∆C J2 B A J 2 = ksCs Sticking coefficient γAB, 0 ≤ γAB ≤ 1 AB bounces off surface 3.155J/.152J Good adhesion Reaction rate constant, ks …no sold-state diffusion here, reaction occurs at surface. Let’s analyze, solve for J2… Wed., Oct. 12, 2005 8 Two main CVD process: J1 = Dg δ ∆C A B J1 = hg(Cg − Cs) Boundary layer B J2 A J 2 = k sCs In steady state: J1 = J2, hg ( Cg - Cs ) = ksCs Electrical analogy: hg Cg , Cs = hg + k s J 2 = k sCs = hg k s hg + k s J1 = J2, R = R1+R2 G = 1/R= G1G2 /(G1+G2) Two processes in series; slowest one limits film growth 3.155J/.152J Wed., Oct. 12, 2005 9 Cg Two main CVD process: J1 = Dg δ ∆C A B J1 = hg(Cg − Cs) Boundary layer B J2 A J 2 = k sCs J 2 = k sCs = ⎛ # ⎞ ⎟ Film growth rate ≡ v = J⎜ ⎝ area − t ⎠ hg k s hg + k s Cg Cg N f = v= 1 1 hg + k s N f + hg k s hg k s C g 1 , ⎛ # ⎞ Nf⎜ ⎟ ⎝ vol ⎠ v (thickness/time) Slower process controls growth 3.155J/.152J Wed., Oct. 12, 2005 10 Two main CVD process: A B J1 = hg (Cg − Cs) Boundary layer J2 B A J 2 = k sCs Cg N f v= 1 1 + hg ks Examine these 2 limits of growth: hg limited or ks limited… Reaction limited growth, Transport limited growth, ks<< hg: hg << ks: 3λ v xCg Re 3DCg hg Cg Re = → v= 4LN f 2LN f Nf ∆G − k sCg Cg k 0e kT = v= Nf Nf ease of gas flow 3.155J/.152J Wed., Oct. 12, 2005 11 Transport limited growth : Reaction limited growth : 3λvxCg Re hgCg 3DCg Re = → v= 4LN f 2LN f Nf Most CVD is done in this limit ∆G − k sC g Cg v= = k 0e kT Nf Nf ∆G = free energy change in reaction where gas dynamics, reactor design are important. (∆G ≅ ∆H for gas becasue gas reaction no ∆S) Remedy for boundary layer J2 B A Susceptor, 3o -10o More uniform ug, Cg ⇒ uniform film growth rate , v 3.155J/.152J Choice of reactants and temperature are critical Wed., Oct. 12, 2005 12 CVD FILM GROWTH GAS TRANSPORT-LIMITED 3λ vx Cg v= Re 4N f L λ= kBT , 2 2π d Pg REACTION-RATE LIMITED v= 2k B T , vx = πm Nf − k 0e ∆G kT ∆G = ∆H - T∆S Re ~ u0 (∆G ≅ ∆H for gas → no ∆S for gas reaction) 1 = Pg k B T 3.155J/.152J Nf = Cg ∆G = free energy change in reaction Cg v ∝T k sCg 1 − ∆H 2 v~e u0 Wed., Oct. 12, 2005 kT 13 Transport limited v ∝T ln (v) 1 2 high T u0 low T gas − vel, Most CVD is transport-limited. ln (v) Slow, layer-by-layer growth, epitaxy. Requires high T, low pressure, low gas viscosity. Chamber design, gas dynamics control process. To reduce nucleation of products in gas phase, use low partial pressure (LPCVD). u0 − ∆H v~e Rate: T 1/2 ⇒ ∆H Arrhenius-like 1/T 1000K 3.155J/.152J Reaction limited Wed., Oct. 12, 2005 400K T 14 kT Review CVD We saw… CVD is film growth from vapor/gas phase via chemical reactions gas and at substrate: e.g. SiH4 (g) → Si (s) + 2H2 (g) in Twall Reactor Transport of precursors across dead layer to substrate 3.155J/.152J Removal of by-products Susceptor film T sub> Twall Pyrolysis: Chemical reaction: thermal decomposition at substrate Decomposed species bond to substrate Wed., Oct. 12, 2005 15 Reaction limited Gas transport limited ln (v) v ∝T 1/ 2 u0 low T Transport-limited CVD. Chamber design, gas dynamics control film growth. Non uniform film growth. ln (v) Slow, layer-by-layer growth, epitaxy, require high T, low pressure, λ/L = NK >> 1. That puts you in the Reaction-limited regime u0 T 1/2 − ∆H v~e Rate: Arrhenius-like ⇒ ∆H 1/T 1000K 3.155J/.152J high T Wed., Oct. 12, 2005 400K T 16 kT Some CVD reactions Silane pyrolysis Silane oxidation (450°C) SiH4 (g) + O2(g) → SiO2 (s) + 2H2 (g) (heat induced reaction) SiH4 (g) → Si (s) + 2H2 (g) ( 650°C) (by LPCVD for gate oxide) This ⇒ poor Si at 1 atm, so use low pressure rate Si - tetrachloride reduction Probability 4 and ProbabilityofofSiCl SiCl 4 and 2H2 meeting goes as 2H meeting goes as cc1*c*c222 2 1 2 v c1c2 2 Poly Si SiCl4 (g) + 2H2 (g) → Si (s) + 4HCl (g) (1200°C) SiCl4 H2 (Si-tetrachloride actually much more complex than this; PSiCl 4 PH 2 Crystalline etch 8 different compounds are formed, detected by RGA) 3.155J/.152J Wed., Oct. 12, 2005 17 Some CVD reactions (cont.) Doping Phosphine Diborane 2PH3 (g) →2P (s) + 3H2 (g) B2H6 (g) →2B (s) + 3H2 (g) Si-nitride compound formation 3 SiCl2H2 (g) + 4NH3 (g) → Si3N4 (s) + 6H2(g) + 6HCl (g) (750° C) (dichloro-silane) rate c1c2 2 GaAs growth Trimethyl Ga (TMG) reduction SiCl4 (CH3)3 Ga + H2 → Ga (s) + 3CH4 Arsene Or 2AsH3 → 2As (s) + 3H2 H2 Least abundant element on surface limits growth velocity ⎯⎯ ⎯ ⎯⎯ → 6 GaAs (s) + 6 HCl g As4 (g) + As2 (g) + 6 GaCl (g) + 3 H2 (g)← ⎯ 3.155J/.152J 750°C 850°C Wed., Oct. 12, 2005 18 How can you select process parameters to get desired product and growth characteristics? Consider: 1) SiH4 (g) → SiH2 (g) + H2 (g) Three unknown pressures Ptot = PSiH4 + PH2 + PSiH2 Total pressure = ∑ partial Ps …still have 2 unknown Ps PSiH2 + PSiH4 Si=> H 2) Conservation of atoms 4PSiH4 + 2PSiH 2 + 2PH 2 …still have 1 unknown P = const PPmolecule ∝∝NNmolecule molecule molecule 3) “Equilibrium constant”, K (cf. Law of mass action) K≡ PH 2 ⋅ PSiH2 PSiH4 ∆G − kT rate c1c2 2 = K0e SiCl4 And similarly for each reaction. H2 These 3 equations provide a starting place for growth parameters. (Many equations for real systems; done on computer) Do a run, analyze results, …tweak process. 3.155J/.152J Wed., Oct. 12, 2005 19 Where does ∆G − PH 2 ⋅ PSiH2 K≡ = K0e kT come from? PSiH4 Consider “mass action” for dice… Consider “mass action” for electrons and holes: N-type semiconductor Intrinsic semiconductor Conduction band n ni EF p pi Valence band Recombination 2 probability set i i by energy gap and number of each species n = n pi n n = np 2 i p K indicates a bias at equilibrium in the reaction toward the products(different molecular species) 3.155J/.152J Donor levels EF Wed., Oct. 12, 2005 More free electrons => more recombination, fewer holes (Eg same) K PSiH4 = PH2 ⋅ PSiH2 20 Exercise Assume reaction: AB → A + B Ptot = 1 atm, T = 1000 K, ← K = 1.8 × 109 Torr × exp ( - 2 eV / kB T ) = 0.153 Assume PA ≈ PB find PAB Solution: K= PAPB = 0.153 PAB and Ptot = PA + PB + PAB , PA ≈ PB. ∴ 760 Torr = 2PA + PAB PA2 = 0.153 PAB = 0.153 (760 - 2 PA), quadratic → PA = 10.8 Torr = PB , so PAB = 738 Torr 2 PA + 0.306PA − 0.153 × 760 = 0 Small value of K, 0.153 Torr, implies that at equilibrium, the product of the right-hand side partial pressures Is but 15% of the reactant (left-hand-side) partial pressure; the reaction may not produce much in equilibrium. What if you change T? 3.155J/.152J Wed., Oct. 12, 2005 21 Atmospheric Pressure CVD: APCVD (little used today, but illustrative) High P, small λ => slow mass transport, large reaction rates; film growth limited by mass transfer, boundary layer; (quality of APCVD Si from silane is poor, better for dielectrics). Example: SiH4 + 2O2 → SiO2 + 2H2OT = 240 - 450°C Done in N2 ambient (low partial pressure of active gas, reduces film growth rate) add 4 - 12% PH3 to make silica flow, planarize. ln v Transport ltd APCVD low T, Figure removed for copyright reasons. reaction rate Figure 9-4a in Plummer, J., M. Deal, and P. Griffin. Silicon VLSI Technology: limited Fundamentals, Practice, and Modeling. Upper Saddle River, NJ: Prentice Hall, 2000. ISBN: 0130850373. Note Noteinduction inductionheating heatingofof substrate; substrate;cold coldwalls walls 1 /T 3.155J/.152J Wed., Oct. 12, 2005 22 Low Pressure CVD (LPCVD) for dielectrics and semiconductors λ Equilibrium not achieved at low P where L (molecular flow, few collisions). = Kn > 1 kB T λ= 2π d 2 P lower P => higher Dg, hg; this improves transport reduces boundary layer, extends reaction-controlled regime (which is where you operate) ks term Hot Hotwalls walls hg at 1 Torr ln v LPCVD hg at 760 Torr Figure removed for copyright reasons. Figure 9-4b in Plummer et al., 2000. Transport limited Reaction limited 1 /T 3.155J/.152J Conversely: Conversely:ififyou youwanted wantedtotowork workinin transport limit at low T, you must transport limit at low T, you must reduce gas flow reduce gas flow Wed., Oct. 12, 2005 23 Low Pressure CVD (LPCVD) for dielectrics and semiconductors If hot-wall reactor ⇒ uniform T distribution but surface of reactor gets coated. So system must be dedicated to 1 species to avoid contamination. If cold-wall reactor Reduce reaction rate, reduce deposition on surfaces. For epi Si. All poly-Si is done by hot-walled LPCVD; good for low pin-hole SiO2, conformality Figure removed for copyright reasons. Figure 9-4b in Plummer et al., 2000. 3.155J/.152J Wed., Oct. 12, 2005 24 Low Pressure CVD (LPCVD) for dielectrics and semiconductors In such non-equilibrium, large λ, reactant-starved cases, growth rate can be controlled by reaction kinetics LPCVD is kinetically throttled; transport-rate controls film growth Silane pyrolysis SiH4 (g) → Si(s) + 2H2 (g) T = 575 - 650°C 10 - 100 nm/min (APCVD is at equilibrium; transport limited) LPCVD Requires no carrier gas Fewer gas-phase reactions, fewer particulates Eliminates boundary-layer problem Lower p => larger Dg, extends reaction limited regime Good conformal growth (unlike sputtering or other PVD methods which are more directional) Strong T dependence to reaction growth rate. Easier to control T with hot-walled furnace. 3.155J/.152J Wed., Oct. 12, 2005 25 R.F. Plasma-enhanced CVD (PECVD) for dielectric MOS metallization: avoid contact interaction betw. Al & Si, SiO2, ∴T < 450°C At low T, surface diffusion is slow, must supply kinetic energy for surface diffusion. Plasma provides that energy…and enhances step coverage. What is a plasma? Ionized noble gas, accelerated by AC (RF) or DC voltage, collides with active species in gas and at surface, importing Ekin Metal CVD Step coverage is important for electric contacts. oxide WF6 + 3H2 → W + 6 HF ∆G ≈ 70 kJ / mole (0.73 eV/atom) oxide semi below 400°C 3.155J/.152J Wed., Oct. 12, 2005 26 Figure removed for copyright reasons. Table 4-1 in Ohring, 2001. 3.155J/.152J Wed., Oct. 12, 2005 27 When a system undergoes a process in which only heat energy, dQ, and pV work occur at constant T, B B ∫ dG = RT ∫ d ln( p) ⇒ G A dp dp dG = NkB T or RT p p Vdp dQ = TdS B then dG = Vdp ⎛ dG ⎞ pB exp⎜− ⎟∝ ⎝ RT ⎠ pA − GA = RT ln(pB / pA ) A Define this ratio pB/pA, as K For multiple reagents: K≡ PH 2 ⋅ PSiH2 PSiH4 − = K0e ∆G kT Entropy of mixing, dSmix = −RN i ln(N i ) , leads to similar result 3.155J/.152J Wed., Oct. 12, 2005 28