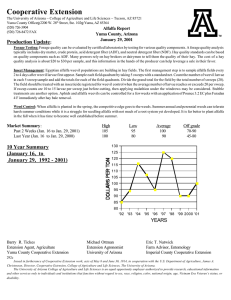

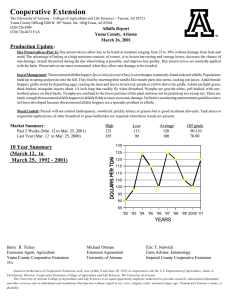

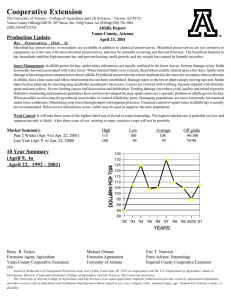

Evaluation of alfalfa hay and factors affecting hay value

advertisement