A tentative method of estimating k and u for Janssens... by Harry F Steeves

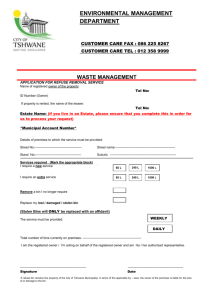

advertisement