Optimization of particle detachment by collapse-pulsing during air scour

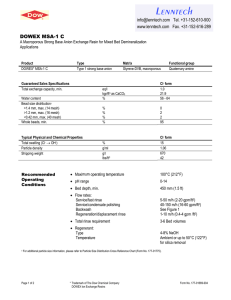

advertisement