Design and application of a microwave moisture meter

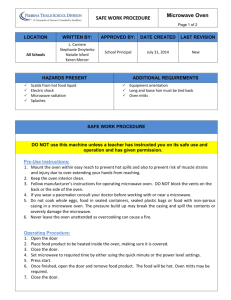

advertisement