Alumina activated with anhydrous hydrogen fluoride as a dealkylation catalyst... hydrocarbons

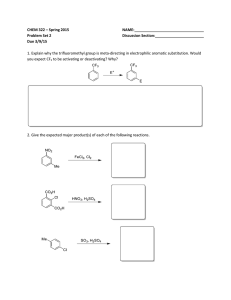

advertisement

Alumina activated with anhydrous hydrogen fluoride as a dealkylation catalyst for aromatic hydrocarbons by Emil O Kindschy A THESIS Submitted to the Graduate Committee in partial fulfillment of the requirements for the degree of Master of Science in Chemical Engineering Montana State University © Copyright by Emil O Kindschy (1948) Abstract: The purpose of this investigation was to evaluate anhydrous hydrogen fluoride activated alumina as a dealkylation catalyst for aromatic hydrocarbons. Toluene, ethyl benzene, xylenes, isopropyl benzene, diethyl, benzenes, monoamyl benzene, diamyl benzene, and triamyl benzene Were the aromatic hydrocarbons investigated. The average run charged about 600 cc. of aromatic hydrocarbon over 900 cc. of catalyst at a space velocity of approximately 0.5 volume per volume of catalyst per hour, and at atmospheric pressure. The temperature that yielded the most dealkylated and the least alkylated products was found for xylene and monoamyl benzene and this temperature used throughout the balance of the investigation. Runs were made using alumina unactivated with anhydrous hydrogen fluoride to obtain a standard of comparison for those runs with hydrogen fluoride treated alumina. All the aromatic hydrocarbons used except toluene were successfully dealkylated. Isopropyl benzene and the amyl benzenes were, dealkylated practically quantitatively. Alkylation took place with the xylenes and ethyl benzene. Benzene was found to be the ultimate dealkylation product of every aromatic hydrocarbon with two or more carbon atoms in every branch chain, while toluene was the ultimate dealkylation product of any aromatic hydrocarbon that contained only one carbon atom in any of its branch chains. The data obtained also showed that as the temperature increased, other conditions being held constant, dealkylation increased and alkylation decreased. 'All aromatic dealkylation products were the result of carbon-carbon fission at the benzene ring. ALUMIMA a c t i v a t e d ,w i t h a n h y d r o u s h y d r o g e n f l u o r i d e AS A DEALKYLATION CATALYST FOR AROMATIC HYDROCARBONS by EMIL 0, KIMDSCEY A THESIS Submitted to the Graduate Committee in , partial fulfillment of the requirements for tNe degree of Master of Science in Chemical Engineering at Montana State College Approved? Bozeman? Montana August, 1948 A/37/ 2 TABLE OF CONTENTS Page 4 Abstract I Introduction........ . ..................... II Equipment, Methods, and Materials. ............ A. Equipment . . . . . . . . o . . . . . . . . . B. Methods.. . . . . . . . . . .......... . . . C . Materials . . . . . . . . . . . . . . . . . . III Sample Calculations. . . . . . . 5 8 8 12 17 .............. 18 ........ ... 21 .'.... 27 VI Acknowledgment . . . . . . . . . . . . . . . . . 28 VII Literature Cited and Consulted ................ 29 VIII Appendix . . . . . . . . . . .................. Table I. . . . . . . . . . . .............. Dealkylation of Xylenes and Calculated Results 31 33 Table II . . . . . . . . . . . . . ............. Dealkylation of Mcnoamyl Benzene and Calculated Results 34 Table III. . . . . . . . . . . . . . . . . . . Dealkylation of Diamyl Benzene, Triamyl Benzene and Calculated Results 35 Table IV . . . . . . . . . . . . ............ Dealkylation of Toluene, Diethyl Benzene, Iso­ propyl Benzene and Calculated Results 36 Table V . . . . . . . . . . . . . . . . . . . Dealkylation of Ethyl Benzene and Calculated Results 37 IV Results. . . . . . . . . . . . . V Conclusions.......... Figure I . . . . . . . . . . . . . . . . . . . Diagram of Reaction Apparatus . Figure 2 . . . . . . . . . . . . . . .......... Distillation Curves for Runs 3 and 8 (Xylene) 38 39 10C835 3 Page FigT2I*e 3 o o e ,o o o o o o o o o e o o o e o o o e Distillation/ Curves for Runs 11 and 12 (Monoamyl Benzene) 4"0 F i g l i r e 4" I 4 o o e o e o o o o o o o e o o o o o o o e Distillation Curves for Runs 13 and 14 (Diamyl Benzene) F IgUre ^ ? o o o e e o o o e o e o » e o o e o o o e Distillation Curves for Runs 15 and 16 (Triamyl Benzene) Figure 6 0 * 0 0 0 0 0 0 © - © o © © © * © © © Distillation Curve for Run 17 (Toluene) 42 * © * 43 Figure 7 ® ® « « ° ° ® * ° ° ° ® ° ° ° ° ® ° ® ® ® Distillation Curves for Runs 18 and 19 (Diethyl Benzene) 1-44 Figure 8 0 0 0 0 © ® ® * * ® * © * ® ® ® ® ® ® ® ® Distillation Curves for Runs 20 and 21 (Isopropyl Benzene) 4*5 Figure 9 ® ® ® ® ® ® ® ® * ° ° ® ® ® ® ® ® ® ® ® ® Distillation Curves for Runs 22 and 25 (Ethyl Benzene) 4*6 Figure 10© e © ® ® ® © ® ® ® ® ® ® ® * ® ® ® ® ® ® Distillation Curves for Runs 22, 23, 24, and 25 (Ethyl Benzene) 4*7 X •'V I 4 ABSTRACT The purpose of this investigation was to evaluate anhy­ drous hydrogen fluoride activated alumina as a dealkylation catalyst for aromatic hydrocarbons. Toluene, ethyl benzene, xylenes, isopropyl benzene, diethyl, benzenes, monoamyl benzene, diamyl benzene, and triamyl benzene Were the aromatic hydrocarbons investigated. The average run charged about 600 ec. of aromatic hydro­ carbon ovdr 900 cc. of catalyst at a space velocity of ap­ proximately 0.5 volume per volume of catalyst per hour, .and at atmospheric pressure. The temperature that yielded the most dealkylated and the least alkylated products was found for xylene and monoamyl benzene and this temperature used throughout the balance of the investigation. Runs were made using alumina unactivated with anhydrous hydrogen fluoride to obtain a standard of comparison for those runs with hydrogen fluoride treated alumina. All the aromatic hydrocarbons used except toluene were successfully dealkylated. Isopropyl benzene and the amyl benzenes were, dealkylated practically quantitatively. Alky­ lation took place with the xylenes and ethyl benzene. Benzene was found to be the ultimate dealkylation pro­ duct of every aromatic hydrocarbon with two or more carbon atoms in every branch chain, while toluene was the ultimate dealkylation product of any aromatic hydrocarbon that con­ tained only one carbon atom in any of its branch chains. The data obtained also showed that as the temperature in­ creased, other conditions being held constant, dealkylation increased and alkylation decreased. 'All aromatic dealkyla­ tion products were the result of carbon-carbon fission at the benzene ring. 5 I INTRODUCTION The. purpose of this investigation is to evaluate hydrogen fluoride activated alumina as a dealkylation catalyst for aromatic hydrocarbons. Hytirogen fluoride activated alumina was selected as a catalyst because hydrogen fluoride has been used as a dealky­ lating as well as an alkylating catalyst for aromatic hydro­ carbons .. Brandt et al (2) used.liquid anhydrous hydrogen fluoride as a catalyst in the dealkylation of xylenes to toluene. Their investigation also showed that trimethyl benzene is formed concurrently by alkylation of the xylene. Frey (5) dealkylated polyethyl benzenes in the pres'ence of an excess of benzene and a catalyst of anhydrous liquid hydrogen fluoride to form ethyl benzene. Alumina impregnated with aqueous zinc chloride was used v to dealkylate xylenes and other polymethyl benzenes to toluene and also polyethyl benzenes to ethyl benzene (14). An alumina and silica catalyst was used to dealkylate dialkyl benzenes (9 ). / lattox (12) used a catalyst of alumina and other metal j , oxides in the "dealkanation" of diethyl benzene to xylene. That alkylation as well as dealkylation could take place might be expected from previous uses of hydrogen fluoride as an alkylating catalyst. Frey (4)(5) alkylated benzene using light olefins as the alkylating agents and substantially an­ hydrous liquid hydrogen fluoride as the catalyst. 1 Koch (8 ) / 6 alkylated the products of HKogasinn synthesis (hydrocarbons from the Fischer-Tropsch process) in the presence of anhy­ drous hydrogen fluoride and converted them into high-octane fuels similar to isooctane.. A number of other investigations have reported hydrogen fluoride, to be an alkylating catalyst (3), (10), (11), (13), (15)« Alumina has been used as a catalyst in the alkylation of aromatic hydrocarbons, Ipatieff and Monroe (6) used oxides of aluminum in the alkylation of benzene to toluene, and alumina with magnesium CbxIoride was used to alkylate aromatic hydrocarbons in another investigation (7)* Bepduse of the alkylating effect of hydrogen fluoride and alumina when used separately, part of this investigation was concerned with the alkylation effect of the alumina when activated with anhydrous hydrogen fluoride. This investiga«= I tion is primarily, however, a study of the dealkylation reaction. Data were not available In the literature on the dealky­ lation effect of alumina alone under the reaction conditions employed in this investigation. It was necessary, therefore, to make severalr uns with alumina unactivated by hydrogen fluoride in order to obtain a standard of comparison for those runs with hydrogen fluoride treated alumina. This study was not concerned with the determination of the optimum conditions of space velocity apd pressure in the 7 dealkylation system. All runs were conducted at essentially atmospheric pressure and the liquid space velocity,was held in the neighborhood of 0.5 vol. per vol. of catalyst per hour. The optimum temperature at this pressure and space velocity, however, was readily determined. As it was not feasible to attempt the dealkylation of all the known aromatic hydrocarbons, a representative group was selected. Toluene, xylenes, ethyl benzene, diethyl benzenes, isopropyl benzene, monoamyl benzene, diamyl benzenes, and tri­ amyl benzenes were chosen to be the dealkylated reagents. These compounds are all available commercially in a fairly pure state and were, therefore, not subjected to further purification. The boiling temperature; of compounds used or formed in this investigation were not corrected to standard pressure since no precise method, is available to make this conversion. The average barometric pressure during this study was approxi­ mately 635 mm. Hg. 8 II EQUIPMENT, METHODS, AND MATERIALS Ao Equipment The equipment used in this investigation consisted of the reaction system shown in Figure I, iron-constantan thermocouples9 a potentiometer, a precision rectification column, a graduated water-cooled receiver for the column, a vacuum system, three glass stem mercury thermometers, a Claisson type distillation flask with condenser, a ceramic heater, a one liter distillation flask, a Harvard type triple beam balance, a refractometer, and four autotransformers0 The reactor was made from a piece of three inch stand­ ard mild steel pipe 24 inches long„ Black pipe was used instead of galvanized to avoid vaporization of the zinc at the elevated temperatures of the reactions. The pipe was threaded at both ends with the bottom end capped and the top end fitted with a flanged head for easy removal. The thermo­ wells were made from pieces of 1/8 inch standard steel pipe 4-3/4 inches long and sealed at one end. The lower thermo­ well was placed two inches from the bottom of the reactor. The middle and upper thermowells were spaced at four inch intervals above the lower one. The catalyst bed extended from just below the bottom thermowell to within 1/2 inch of the top thermowell. Holes, 13/32 inch in diameter, were drilled in the reactor at these points and the thermowells, when welded to the reactor wall, extends# into tbe qxact 9 center of the catalyst spac$. The iron-eonstantan thermo­ couples were connected to a Brown potentiometer. This poten­ tiometer was calibrated.in millivolts and could be used to record temperatures up to 1200Gc, The millivolt readings were converted into (,degrees Gentifrade using a standard con­ version table for iron-constantan thermocouples with the reference junction at G0C e Two 3/8 inch low carbon steel rods were Welded onto the reactor on the opposite side from the thermowells to act as supports for the reactor chamber„ These rods were eleven in­ ches long o i The reactor was wrapped with asbestos: tape, Over this tape9 75 feet of niehrome wire with a resistance of I„079 ohms per foot was wound„ This winding drew 2,95 amperes from a 220 volt autotrangforfeero The winding was covered with as­ bestos tape and another resistance winding 33 feet long placed over it„ The second winding was connected to a H G volt auto^ransformer and drew about seven amperes. This second winding was covered with asbestos tape and then a one inch layer of magnesia was placed over ali the windings and tape, The malleable iron caps at the top and bottom of the reactor were drilled and tapped to take 1/2 inch short nipples, » The upper one was fitted with a 1/2 inch malleable iron cross and reduced to 1/8 inch,while the bottom one was reduced 10 directly to 1/8 Inch6 Feed was admitted to the top of the reactor from a 1000 m l o graduated separatory funnel through a lerkle-Korff type bellows pump operating on H O volt A 6 G« and connected to the reactor by 1/8 inch copper tubing0 To the bottom outlet, a 1/8 inch flexible copper tube was fitted. The tube led to a glass bulb type water cooled condenser 20 inches long.and a dry ice condenser connected in series as shown in Figure I e The gas meter following the dry ice trap was a three liter "Precision M Wet Test Metere The rectification column was constructed of three con­ centric glass tubes. The innermost tube was 33 mm, inside diameter and was packed with 1/8 inch Fenske stainless steel helices, A thermometer was fastened to the outside surface of the inner tube about halfway between top and bottom. The second or middle tube was wrapped with nichrome resistance wire which w a s .connected to a H O volt autotransformer to pro­ vide heat to the column. a protector and insulator. The third or outer tube served as The column was 48 inches high and -calibrated about 30 theoretical plates at total reflux. The top of the cjdlumn was fitted with an adjustable reflux head with a cold finger condenser and a thermometer to record vapor temperatures, A graduated water-cooled receiver was attached to the outlet from thg distilling head* Z 11 The vacuum system used consisted of a C6neo Hegavac pump connected through two surge tanks to the distillation system* The pump, operated on 220 volts A, C o , was capable of taking the first surge tank down to about one ram. Hg, absolute* The first surge tank connected to the second through a Sole­ noid valve. This valve was controlled by a mercury switch and an electronic relay to give the desired pressure upon the system* The second surge tank was connected to the distilla­ tion system with a tee to a mercury filled manometer. For the purpose of consistency in this investigation all vacuum distillations were made at 85 mm, Hg, absolute* The heater used for the distillation flask had a ceramic base supporting niehrome coils in a concave depression in which the distillation flask was placed. These coils were connected to a H O volt autotransformer* The one liter distillation flask used was equipped with a 35725 spherical joint* The Abbe type Valentine refractometer was capable of reading to six significant figures. All refractive indices were read at 20 ± Q 0I eC* The autotransformers were Superior Electric Company Powerstats, The H O volt powerstats had a voltage range of 0 to 135 volts and were fused at seven amperes. The 220 volt powerstats.had a voltage range of 0 to 260 volts and were fused at three amperes* 12 Bo Io Methods Preparation of the catalysts The reactor was filled with Berl saddles to a point about 1/4 inch below the bottom thermocouple. Nine hundred CCo of Harshaw 1/8 inch activated alumina pellets were placed in the reactor over the Berl saddles. The reactor was then completely filled with additional Berl saddles. These saddles acted as a preheat section. The manner of catalyst activation was similar to that outlined,by Berg et al (I). The catalyst was dried at 250GC. for two hours after being placed in the reactor. After cool­ ing to room temperature 9 anhydrous hydrogen fluoride was passed through for another hour with the catalyst at room temperature. With the hydrogen fluoride still passing through9 the temperature was increased to 400°C. in one hour. The catalyst was then purged with nitrogen gas for about fifteen minutes to sweep out the excess hydrogen fluoride. During the catalyst activation, the excess hydrogen fluoride was bubbled through kerosene and out a blow down line. 2. Making the reaction runs : The reactor was heated until the center thermocouple gave a reading slightly below the desired temperature. Dry ice was placed in the dry ice trap using a liquid such as acetone or ttTromexw to give a better cooling medium. The density of the aromatic hydrocarbon being used wa^ measured I 13 "by weighing a 1000 cc„ sample on the Harvard triple beam bal­ ance, A charge, usually about 700 cc,, was placed in the separatory funnel and the pump started to fill completely all connecting tubing -to the reactor. If necessary, air was swept from the reactor by using a fifteen minute nitrogen purge. After the reactor was completely purged of air, the feed system was connected. Readings from all three thermo­ couples, the gas meter, and the volume of feed in the separ­ atory funnel were noted before the run was started and con­ tinued at ten minute intervals throughout the duration of the run. Upon completion of the run, the reactor was purged of all hydrocarbon vapors by passing nitrogen through for fifteen minutes. During this purge, the gas meter was taken out of the system and all condensable hydrocarbons were retained in the receiver. The receiver was -placed in a refrigerator maintained at -400C, to minimize evaporation of the reaction product prior to distillation. The same procedure was used in runs with both activated and unactivated catalyst, 3, Distillation of reaction products: Each charge was placed in the distillation -flask with about 100 grams of a suitable chaser. The chasers used for all runs ape tabulated in Tables 1-7, Heat flows to the column and distillation flask were adjusted by means of the aubotransformers in such a manner as to allow the column to flood and insure complete wetting of the packing. The heat 14 - flows were then reduced sufficiently to stop the flooding and the column permitted to operate at total reflux for one houro After the column had attained equilibrium^the reflux ratio was set at about 5/1 and overhead cuts taken. During this time a dry ice condenser was kept in series with the water condenser to retain any light hydrocarbon vapors pas­ sing through the latter. Vapor temperatures were t,aken at the beginning and end of each cut. The size of the cuts taken depended upon the rate of increase of the vapor temperature. When the breaks or mid-fractions were reached, smaller cuts were taken better to define the distillation curve. Distillation was continued until all the charge was dis­ tilled or until atmospheric distillation had to be abandoned in favor of vacuum distillation. If vacuum distillation had to be used, the charge was allowed to cool, the system placed under vacuum, and distillation recommenced. When vacuum distilling the products of the triamyl ben­ zene runs, a Glaisson type distilling flask was used instead of the rectification column because of excessive foaming. Refractive indices were taken whenever the rate of in­ crease of the vapor temperature.indicated that a plateau was reached on the distillation curve„ 4, Catalyst burn-off and reactivations As the catalyst was used, a deposit of carbonaceous 15 material was laid down upon the catalyst surface, reducing its activity and necessitating periodic burn-offs«, The cata­ lyst was burned -off at the end of every third run when dealkylating materials such as the xylenes, toluene, or ethyl benzene and at the end of every run when the reactant was diethyl benzene, isopropyl benzene, monoamyl benzene, diamyl benzene, and triamyl benzene» Burning off was accomplished by passing air through the reactor while maintaining the burn-off temperature below the sintering point of the catalyst, about 600°C, The burn off was done immediately after the completion of the run before the catalyst bed had time to cool* The catalyst was reactivated after the burn-off whenever hydrogen, fluoride was detected in appreciable amounts in either the products from the reactor or in the exhaust gases from the burn-off„ .Reactivation was accomplished by cooling the catalyst to room temperature and treating as described above„ 5» Plotting the data obtained from distillations The data were plotted as vapor temperature vs. weight per cent distilled. Whenever the water condenser was incap­ able of condensing all the vapors, an allowance was made on the distillation curves for the material retained in the dry ice trap'. This is indicated on the distillation curves when­ ever the first plotted point is not at the zero per cent 16 distilled abscissa. Whenever vacuum distillations were made, the vapor temp­ eratures were plotted on the same scale as the atmospheric distillation temperatures. All data for yields and conversions were taken from these distillation curves. \ / .:*•'* 17 C« Materials No attempt was made to purify any of the reagents used. Compound Meta and Para Xylene Grade Analytical Source Mallinckrodt Chemical Works Ortho Xylene Eastman Kodak Company Toluene Dow Chemical Company Ethyl Benzene Dow Chemical Company Diethyl Benzene Dow.Chemical Company Isopropyl,Benzene Dow Chemical, Company. Amyl Benzene Technical Sharpies Chemical C o , , Diamyl Benzene Technical Sharpies Chemical Co, Triamyl Benzene Technical Sharpies.ChemicaluCp, nrletreidecane. „■ • The Connecticut.;,Hard. Rubber Company Anhydrous Hydrogen Fluoride The Matheson Company Activated Alumina Pellets9 . 1/8 inch-..diameter Harshaw Chemical Company , • 18 III SAMPLE CALCULATIONS The sample calculations of conversions and space velocity were based on Run #15 using activated catalyst and triamyl benzene as the reagent. This run was chosen because it yielded the most complex reaction products. In this run, however, the conversions and the yields were the same. There­ fore, the sample calculations of yields were based upon Run #3 using activated catalyst and a meta and para xylene mixture. A0 Determination of per cent liquid products These data were taken from Figure 5» the distilla­ tion curve for the activated triamyl benzene run. The division lines between compounds on this curve were located at the arithemetic mean of the temp­ eratures of the adjacent plateaus. The quantity of the distillation charge between the zero per cent distilled point and the first point on the dis­ tillation curve represents that fraction of the dis­ tillation charge which passed through the water con­ denser and was retained in the dry ice trap placed in series with the column condenser. This fraction of the distillation charge contained G^, and . hydrocarbons. 530.2 gramss Thus, for a distillation charge of 19 Crams Weight Per Cent 118.0 22.3 Pentenes 88.5 16.7 Benzene 72.6 13.7 150.3 28.3 71.6 13.5 0.0 0.0 29.2 530.2 ___ SjI 100.0 Compound O g, and C^ Amyl Benzene Diamyl Benzene Triamyl Benzene Distillation Losses Be Calculation of per cent of theoretical yield - converted per pass: For benzenes c 6h Me w„ 3^c 5h 11^3--- c 6h 6"^ 3 C5H10 288,50 78.11 3(70.13) Based upon the amount of triamyl benzene charged to the reactor, 689 gramss Theor, Yield; = 186 grams no Actual Conversion; A jj§t~ x s 39»O^ In" like manner, it can be determined that: Conversion, per cent and Amyl Benzene 42.3 Diamyl Benzene 13.7 Benzene _32a0 95.0 20 Ce Calculation of liquid space velocity? In Run # 1 5 760 Ce, of trlamyl benzene were charged to the reactor in le75 hours. Since the reactor contained 900 ce. of catalyst, it was determined that % Space Velocity De Calculation of yields: In Figure 2, charging xylene over activated catalyst, 60«5 per cent of the distillation charge was un­ reacted xylene. Since the distillation charge was 400el grams, (400 el)(0 ©605 ) s 242 grams of unconverted xylene e From the original charge to the reactor, 431 grams, 431 - 242 - 189 grams of xylene were consumed or held up by the reactor. cent of the total charge. This represents 43.9 per The yield of toluene cal­ culated by the method given in these sample calcu­ lations was 16.0 per cent of the theoretical. If 43.9 per cent of the xylene made 16.0 per cent of the theoretical yield of toluene, then 100 per cent of the xylene would make - 36®4 per cent of theoretical yield of toluene. 21 IV RESULTS Xyleness Table I in the appendix tabulates the conditions and results of the xylene runs« Runs 1-4Jsrere made using a meta­ para xylene mixture as the reactor charge and the activated catalysto Run I 9 at 40I0O „9 produced neither alkylation nor dealkylation products of xylene c At 44©°C«,9 Run 2 9 the liquid product from the reactor contained l8 o5 per cent trimethyl benzene and 12 per cent toluene, while at 5l0°C«,, Run 3? the yield of trimethyl benzene decreased to 16 per cent of the liquid product and the yield of toluene increased to 15 per cent of the liquid product» In Run 4, the temperature was in­ creased to 5420C o and an analysis of the products showed only 13 per cent trimethyl benzene while the yield of toluene was increased to 19„1 per cent of the product0 At 542°C„9 however, an inspection of the.catalyst after the run showed that part of the catalyst had sintered* These results showed.that as the temperature increased, the amounts of dealkylated products also increased, while the amounts of alkylated products decreased* Since this investi­ gation was primarily interested in the dealkylation reaction, 500°C o was chosen the optimum temperature for dealkylating xylenes without sintering the catalyst. The meta-parq xylene mixture was partially separated into its components by freezing. The para-rich xylene mixture gave slightly lower yields than the mixture used in Runs 1-4, but the yields of both.the alkylated and the dealkylated products were considerably lower for the meta-rich xylene mixture 6 Run 7 9 made with ortho xylene on the activated catalyst, gave essentially the same yield of toluene, 14*7 per cent of the liquid product, as the meta-para xylene mixture but gave a slightly higher alkylation to trimethyl benzene than did the meta-para xylene mixture * At 504°Co and essentially the same conditions of space velocity and pressure, the unactivated catalyst was inactive towards either the alkylation or the dealkylation reaction* No benzene was detected in the dealkylation products of any of the xylenes nor was- benzene detected when an attempt was made to dealkylate toluene itself (Run 17)» From the fact that alkylation did take place in these runs, it was presumed that part of the toluene formed was al­ kylated back to xylene, while at the same time, some of the trimethyl benzene formed by alkylation of xylene was dealkylated back to, xylene* Traces of ortho xylene were detected in the.products of the me tap-para xylene runs, Whether this was due to the isomerization effect of the catalyst, the alkylation of toluene to ortho xylene, or the dealkylation of trimethyl benzene was not determined* 23 lonoamyl Benzenes At 427°C e? 75«5 per cent of the theoretical yield of benzene was detected in the reaction products. At 504°C.9 Run IG9 this conversion was increased to 84 per cent. Run Il5 duplicated the results of Run 10 after the catalyst was burn­ ed off and reactivated. The conditions and results of these runs are tabulated in Table II. Only 16«8 per cent of the theoretical benzene was formed5 however 9 when monoamyl ben­ zene was passed over the unactiVated alumina catalyst at 503°0. No appreciable amounts of alkylated products were de­ tected in any of the monoamyl benzene runs 9 nor were any aromatic dealkylated products other than benzene found. Diamyl Benzene and Triamyl Benzenes Table III tabulates the conditions and results of the dealkylation of diamyl benzene and triamyl benzene. At 4980C » with the activated catalyst, diamyl benzene formed 63.3 per cent of the theroetical yield of benzene, 26.4 per cent of the theoretical yield of monoamyl benzene, and no unreacted diamyl benzene. Over the unactivated catalyst, however, at the same conditions of temperature, pressure, and liquid space.velocity, the reaction products contained no benzene and 38.8 per cent of the theoretical monoamyl benzene. Triamyl benzene with the activated catalyst at 499°C. 24 formed 39«0 per cent of the theoretical benzene9 42„3 per cent monoamyl benzene9 13®7 per cent diamyl benzene9 and no un­ reacted triamyl benzene remained. At 500oC e and with the un­ activated catalyst, only a trace of benzene or monoamyl benzene was formed, but 41.1 per cent of the theoretical yield of dipamyl benzene was detected. The presence of the intermediate products of the de­ alkylation of these polyamyl benzenes to benzene9 indicated that the contact time was too short for the dealkylation re­ action to be complete. A s -in the dealkylation of monoamyl benzene9 the polyamyl benzenes did not form alkylation products9 nor did any dealky­ lation occur except at the benzene ring. Toluene: Table IV gives the conditions and results of the dealky­ lation of toluene, diethyl benzene, and isopropyl benzene. The dealkylation of toluene, as mentioned previously, formed no appreciable amount of benzene. Even though no alky­ lation products of toluene were apparent, it cannot be stated that alkylation of toluene would not take place with the catalyst under the conditions used. Since any alkylation would depend upon a product of dealkylation for the alkylating reagent, and since no dealkylation took place, no alkylation of toluene could occur even though the catalyst was active 25 with respect to aIkylatione Diethyl Benzene i At 500°Co with the activated catalyst, 38.6 per cent of the theoretical yield of 'ethyl benzene was formed by dealky­ lation of diethyl benzene. No appreciable amounts of benzene nor alkylated products of diethyl benzene were found. The unactivated catalyst was inactive towards diethyl benzene at 499gC . Isopropyl Benzene; Eighty-six per dent of the theoretical yield of benzene was produced when isopropyl benzene wars passed over the act!-: vated catalyst at 505°Co At 500GC o, the unactivated catalyst formed only 2,9 per cent of the theoretical amount of benzene. In neither of these runs was any liquid reaction product found other than benzene. Ethyl Benzene s Ethyl benzene was reacted under four different stages of the catalyst cycle. of these runs. Table V shows the conditions and results Run 22, made with activated catalyst, showed that ethyl benzene formed 17,4 per cent of the theoretical benzene and 4.9 per cent of the theoretical yield of diethyl benzene, Under the same conditions of temperature, pressure, and 26 space velocity, the activated catalyst, when fouled with car­ bon, was inactive for either alkylation or dealkylation. This is shown in the results of Run 23« When the earboned catalyst was burned off, the conversion to benzene was 7,2 per cent of theoretical and the conversion to diethyl benzene was 4,6 per.cent. This shows that the catalyst had part of its former activity restored by the car­ bon burn-off but that it needed reactivation with anhydrous hydrogen fluoride to recover all of its previous activity. The unactivated alumina gave approximately the same results as the earboned catalyst. Figure 10 shows the distillation curves for the ethyl benzene runs under all these conditions of the catalyst cycle. It is important to note that for none of the hydrocarbons used, was any liquid dealkylation product detected other than those that resulted from cleavage at the benzene ring. 27 V C OHGLUSIOJSfS The following conclusions may be drawn concerning both alkylation and dealkylation with the hydrogen fluoride acti­ vated alumina catalysts I, Benzene is the ultimate dealkylation product for all aromatic hydrocarbons that contain two or more carbon atoms in every branch chain, 2o Toluene is unaffected by the catalyst under the conditions used in this investigation and will probably be the ultimate dealkylation product of any aromatic hydrocarbon that contains only one carbon atom in any of its branch chains, 3o Pressure and space velocity being constant, dealky­ lation will increase as the temperature increases and alkylation will decrease as the temperature increases, 4. The rate of dealkylation increases with the length of the side chains on any aromatic hydrocarbon, 5o Alkylation probably takes place whenever dealkylation occurs but when the molecules are large, (diethyl benzene or larger) the alkylated products are so 'readily dealkylated that none appear in the final product, 6o Dealkylation with this catalyst and at the conditions used always takes place at thq benzene ring. •Ss 28 VI ACKNOWLEDGMENT The amthor acknowledges with thanks the courtesy of the Dow Chemical Company who furnished the toluene ? isopropyl benzene ^ ethyl benzene9 and diethyl benzene used in this investigation® He also acknowledges with thanks the courtesy of the Sharpies Chemical Company who furnished the mono-, di-, and triamyl benzene used in this research® 29 TII LITERATURE CITED AND CONSULTED (1) Berg 9 .Lo 3 Simmer 9 G 0 L 09 .and Montgomery9 Co W 09 (To Gulf Research and Development Go*); U* S . Patent 2,397,639 (April 2, 1946) (2) Brandt 9 P 6 Lo 9 Lee 9 R 0 J» 9 Radford, H 0 D 0 9 Klemm 9 Lo EU 9 and Drennan 9 P* S*i Paper presented before the Division of Petroleum Chemistry of the Anu Chem 0 Soe 09 April9 1947 (35 Burk 9 R 0 E 09 and Hughes, E* C 09 (To Standard Oil Co, of Ohio); U. S* Patent 2,399,662 (May 7, 1946) > Frey, F, E 09 (To Phillips Petroleum Co,); U, S, Patent 2,372,320 (March 27, 1945) (4) (5) . Frey 9 F, E 09 (To Phillips Petroleum Co*); U 0' S , Patent 2,394,905 (Feb. 12, 1946) (6 ) .. Ipatieff9 V, N*, and.Monroe 9 G, S 09 (To Universal Oil . .„ Products Co*); U, S, Patent 2,352, 199 (June 27, 1944) (75 Ipatieff9 V, No, and Sehmerlihg9 L 09 (To Universal Oil Products Co, ); Uo S, Patent 2,329,858 (Sept0 21, 1943) (8 ) Koeh 9 H ; Reichsamt Wirtschaftsaus bau, Pruf-Nr, 102 (PB52004), 49-57 (1940) (9) Kutz 9 W 0 M o , and Corson 9 B e Po; Ind 0 Eng, Chem 0 38, 761-4 (1946) (10) .Lisp9 C 0 B 09 (To Universal Oil Products Co*); U, Se Patent 2,372,505 (March 27, 1945) (11) Linn 9 G 0 B 0, (To Universal Oil Products Co0); U 0 S e Patent 2,373,580. (April 10, 1945) (12) . Mattox 9 W 0 J,, (To Universal Oil Products Co,); U 0 S e Patent 2 ,386,969 (Get, 16, 1945) (13) . O 0Kelly 9 A, A c, Meadow, J 0 R 09 and Woodward, R 0 E 09 (To Soeony-Vaeuum Oil Co., Ine,); U, S, Patent 2,414,271 (Jan, 14, 1947) (14) Sehmerling9 L 09 and Ipatieff9 V, N 09 (To Universal Oil . . Products Co,)s U e S* Patent 2,349,834 (May 3 0 , 1944) 30 (15) Woodward9 R 0 E o 9 Hawthorne9 W 0 P., and Meadow9 J 0 R 6 9 (To Soeony"VacuTim Oil Co, 9 Inc0) ; H 0 S 0 Patent 2,409,090 (Oet0 S 9 1946) 31 VIII APPENDIX Page A6 B. C* !IclDle X ^ o a e o o o e o e o o o e e o e e o o Dealkylation of Xylenes and Calculated Results e o 33 e XaDle XX * 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 .Dealkylation of Monoamyl Benzene and Calculated Results 3^* XaDle XXXo e e e 0 0 0 0 0 e 0 0 0 0 0 e 0 0 0 0 0 e 3^ Dealkylation of Biamyl Benzene9 Triamyl Benzene9 . and Calculated Results 36 D0 TaDle IV Dealkylation of■Toluene9 Diethyl Benzene9 Isopropyl Benzene 9 and Calculated Results Eo XaDle V o o 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 c o o 37 Dealkylation of Ethyl Benzene and Calculated Results Fe - J- 0 F l g U r e l O o O o O o O O o O o O 0 0 O O 0 O o O e O o O o O o e O o O e O O o O ® O O o O o o o 3^ Diagram of Reaction System G. FlgUre R o o o o o o o o o o o o o o o o o o o Distillation Curves for Runs 3 and 8 (Xylene) Ee Figure 3 O o o o o c o o o o o C O o o o o o o o o Distillation Curves for Runs 11 and 12 (Monoamyl Benzene) 1» Figure 4 © O O O O O O O O O O O O O O O O O O O Distillation Curves for Runs 13 and 14 (Diamyl Benzene) K, L, o o O o 39 o 40 © 41 Figure ^ ? o O © ‘ O O O O O O O O O O O O O O O O O O O Distillation Curves for Runs 15 and 16 (Xriamyl • Benzene) 42 O O - O S O Figure 6 _ Distillation Curve for Run I? (Toluene) 43 0 6 0 6 0 0 0 0 0 6 0 0 0 0 6 0 0 0 0 0 0 0 6 0 0 0 e 0 e o 0 Distillation Curves for Runs 18 and 19 (Diethyl Benzene) o o 44 32 Page H6 Oe Figure 8 » Distillation Curves for Runs 20 and 21 (Isopropyl Benzene) 45 FigUre ^ o o o e o e o o o e o o o o b e o o e Distillation Curves for Runs 22 and 25 (Ethyl Benzene) 46 e © FigUre 10 o e e o o e e o o e 6 @ o o e o e o -e»e Distillation Curves for Runs 22, 23, 24 and 25 (Ethyl Benzene) 4/^ TABLE I Dealkylation of Xylenes and Calculated Results Run Nd. I m & p Isomer Catalyst Act'd Temp. 0C . 401 Barometer pres. mm. 643.3 Charge cc. 435 Charge5 mols 3.53 Length of run5 hrs6l I liq. Sp. Vel., Hr.--L 0.484 cc. gas/ mol charge O Dist1n charge, grams 363.8 Dist8n pressure, mm. 647.6 Chaser Tetradecane Toluene Refractive Index Boiling Point, °C. io Liquid Product O Conversion, % Theor. Ultimate yield, $ Trimethyl Benzene Refractive Index Boiling Point, °C. % Liquid Product O Conversion, % Theor — Ultimate yield, % , — --------------- . — — — 2 m & p Act'd 440 3 m & n Act'd 510 6 4 3 .7 643.7 500 735, 5.96 4.05 I I 0.818 0.556 414 1611 593.4 400.1 644.2 635.2 Tetra- Tetradecane decane 4 m & p Act'd 542 637.4 385 3.13 I 0.428 3860 6 8 7 m 0 m & p Act'd Act'd Unact'd 508 522 504 645.1 628.5 635.2 320 385 635 2.66 3.12 5.14 I 1.42 0.75 0.429 0.474 0.498 490 1740 745 264.3 3 1 1 .6 527.8 313.3 642.4 6 2 8 . 0 637.4 6 2 6 . 5 634.8 Tetra- Amyl Amyl Amyl Tetradecane BenzeneBenzene Benzene decane 5 p Act'd 504 647.3 340 2.75 O.8 3 0.455 360 263.3 1.4964 1.4961 1.4968 1.4951 104 103 103 103 12 12 15 17.5 16 12.9 19.1 12.7 36.4 51.6 36.8 35.3 1.5042 1 . 5 0 3 6 1.5040 160 159 159 16 18.5 13 13.1 10.9 15.3 29.4 42.0 2 9 .5 103 8 8.7 36.4 1.4960 103 13.5 14.7 37.8 1.4995 160 10 1 2 .5 10.0 9.4 1.5039 160 19 _ 1 2 .5 M 40.1 — — — — — — 160 2 8 .9 3 2 .8 ——— *C-J C= 0 • W W- • — Wm CW ——_ _ 0 aw 34 TABLE II D e a l k y l a t i o n of M o n o a m y l B e n z e n e a n d C a l c u l a t e d R e s u l t s Run No. Catalyst Temp °C. Barometer Pres. mm. Charge, cc. Charge, mols Length of run, hrs. Liq. S p . Vel, Hr.-I c c . gas/mol charge Dist1n charge, grams Dist'n Pressure, mm. Chaser 9 act'd 427 641.5 710 4.12 1.50 0 .5 2 6 586.5 6 3 8 .6 tetradecane Benzene Refractive Index 1.5005 Boiling Point, 0C „ 74 % Liquid Product . 41.5 Conversion, % Theor. 75.5 Ultimate yield, % 93 10 act'd 504 635.5 770 4.46 1.75 0.489" 6040 574.7 631.9 tetradecane 11 act'd 504 641.5 1.5009 74 51 84 84 1.5003 74 52 ^ 87.5 87.5 790 4 .5 7 1.67 0.527 5750 601.1 635.2 tetradecane 12 unact'd 503 638.2 525 3.04 1.17 0.500 4460 416.8 641.7 tetradecane 1.4992 74 16.8 75 35 T A B L E III D e a l k y l a t i o n of D i a m y l B e n z e n e and T r i a m y l B e n z e n e and Calculated Results Run No. Compound Catalyst Temp. °C. Barometer pres.9 mm. Charge 9 cc. Charge, mols Length of Run, hrs. Liq., S p o Vel., hr. cc. gas/ mol charge Dist’n charge, grams Dist’n pressure, mm. Vacuum pressure, mm. Chaser 13 Diamyl Benzene Act'd 498 635.5 765^ 2.98 1.67 0.508 10,860 510 6 3 7 .1 85 Triamyl Benzene Benzene Refractive Index 1.5002 74 Boiling Point, OC. % Liquid product 29 Conversion, % Theor. 63.3 Ultimate Yield, % 63.3 Amyl Benzene -1.4892 Refractive Index. Boiling Point, °C. IlS85 % Liquid product 23 Conversion, % Theor. 26.4 26.4 Ultimate yield, % Diamyl Benzene Refractive Index Boiling Point, 0C . % liquid product Conversion, % Theor. Ultimate yield, % e= *=« * > . 14 Diamyl Benzene Unact1d 496 638.2 2.08 1.17 0.510 6,430 428.5 641.7 85 Triamyl Benzene 0 «=—•=* ass S b 1.4889 182 28 38.8 76.6 15 Trlamyl Benzene Act'd 499 635.5 760 2.39 1.75 0.482 2 5 ,1 0 0 530.2 634.8 85 None 1.4998 74 13.7 39.0 39.0 1.4892 11865 16 Triamyl Benzene Unact'd 500 638.2 525 1.60 1.17 0.500 17,600 4 0 5 .5 85 None S 3S SS B Trace S 3S SS S « = » S 3 S S ___ S SS B C = . 2 8 .3 Trace 42.3 42.3 aaosr. 1.4826 1.4824 1 3 .7 1 3 .7 41.1 60.0 a eso t> ■ SS B S B IT .P csosa S 3S B» ■ow e= «3— S B S 3S 3 36 TABLE IV Dealkylation of Toluene, Diethyl Bdnzene, Isopropyl Benzene and Calculated Results Compound Toluene Diethyl Benzene Run No 0 Catalyst Temp. 0Ct Barometer Pres., mm. Charge, cc. Charge, mols Length of run, hrs. Liq. S p . Vel., hr.”1 cc. gas/mol charge Dist'n charge, grams Dist'n pressure, mm. Chaser 17 Act'd 499 636.3 580 5.41 1.37 0.472 170 462.8 18 19 Act'd Unact'd *99 503 638.7 639.3 570 635 3.66 4 .0 7 1.42 1.25 0.507 0.499 10,900 1,550 451.0 469.8 641.8 6 3 6 .6 635.9 Diethyl Tetra- TetraBenzene decane decane Benzene Refractive Indfex —— Boiling Point, °C --% Liquid Product 0 Conversion, % Theoz1e- Ultimate Yield, % — — Ethyl Benzene Refractive Index Boiling Point, °C. — % Liquid Product Conversion, % Theor.-— Ultimate Yield, % ■»■»€=> ■=•=» 0 O *» *D W m om om m — — 1.4959 127 *==•» OB O 38.6 68.1 Co*==- Isopropyl Benzene 21 20 Act'd Unact'd 500 505 634.2 634.6 545 725 5.21 3.92 1.58 1.17 0.510 0.519 6 ,4 6 0 2,280 451.0 487.0 634.2 634.4 Diethyl Diethyl Benzene Benzene 1.5003 74 72 86 86 74 2 2.9 40.8 mm m om s* m s mm mm mmmmmm — — ——— • = « « = 37 TABLE V D e a l k y l a t i o n of E t h y l B e n z e n e Run No. Catalyst Temp. 0C. Barometer Pres.9 mm. Charge, ce. Charge, mols Length of run, hrs. Liq. Sp. Vel.,hr."1 ce. gas/mol charge Dist1n charge, grams Dist'n pressure, mm. Chaser 22 Act'd 507 639«3 620 5.06 1.33 0.518 2,540 507.7 635.9 Tetradecane 24 23 Carboned Burned Off 522 508 632.9 629.3 490 505 4.00 4 .1 3 1.00 1.17 0.560 0.467 1,380 815 403.4 420.9 639.3 629.3 TetraTetradecane decane ■=»***D 0 1.4997 74 5.5 7.2 31.4 25 Unact’d 502 635.2 535, 4.36 1.17 0.510 775 453.6 637.1 Amyl Benzene <k >t e o o Komomo 0 0 OD 6.0 4.6 25.8 II 8O II I Benzene Refractive Index 1.5009 Boiling Point, °C. 74 % Liquid Produce 13.5 Conversion, % Theor.17.4 Ultimate Yield, % 59.6 Diethyl Benzene Refractive Index 1.4965 Boiling Point, 0C 0 170 % Liquid Product 6.5 Conversion, % Theor.4.9 Ultimate Yield, % 16.8 and C a l c u l a t e d R e s u l t s «*■=»* 38 3k BE R L SADDLES THERMOWELLS CATALYST BERL SADDLES DRY I CE COND EN SER FEED A WATER _ CONDENSER TO BLOW DOWN BELLOWS CAS PUMP RE CEI VER Figure I. Diagram of Reaction System METER ______ I 160 3 140 XYLENE Lu NO h- 120 XYLENE o ACT'D CATALYST •UNACT'D 0 20 4-0 WEIGHT Figure 2. PER 60 CENT CATALYST 80 DISTILLED Distillation Curves for Runs 3 and 8 100 A M Y L B E N Z E N E B E N Z E N E AMYL BENZENE RENTE NES ACT'D •UNACT'D WEIGHT Fi g u r e 3 PER C E N T CATALYST CATALYST DISTILLED Distillation Curves for Runs 11 and 12 D I A M Y L BENZENE B E N ZENE A M Y L BENZENE^) BENZENE DIAMYL BENZENE o ACT'D C A T A L YS T • U N ACT'D P E N T E N E S WEIGHT Figure 4 CATALYST --- Dl S T 1N A T 8 5 M M 40 PER CENT 60 DISTILLED 80 D i s t i l l a t i o n - C u r v e s for Run s 13 and 14 A BS. TRI A M Y L BENZENE DIAMYL BENZENE z> 140 AMYL BENZENE I J BENZE TRIAMYL 0 PENTENE 20 WEIGHT Figure 5. 40 PER CENT BENZENE ACT'D CATALYST • UNACT'D CATALYST -DIST'N 85 60 DISTILLED AT 80 Distillation Curves for Runs I5 and 16 MM. ABS. TOLUENE I- 9 0 TOLUENE ACT'D CATALYST 60 WEIGHT F i g u r e 6. PER CENT DISTILLED D i s t i l l a t i o n Curve for R u n 17 B E N Z E N E ETHYL B E N Z E N E VAPOR T E M P E R A T U R E DIETHYL DIETHYL o ACT'D • UNACT'D WEIGHT Figure 7» PER CENT BENZENE CATALYST C A TA L Y S T DISTILLED D i s t i l l a t i o n Curves for Runs 18 and 19 I70 ISOPR O P Y L BENZE N E I U O w K 130 D I< K U CL 5 vn UJ l<r O 90 CL 03 < > I N Z E N E / ISOPROPYL o ACT'D 50 • UNACT'D I 0 20 W E I G H T Figure 8. 40 PER C E N T 60 DISTILLED BENZENE C A T A L Y S T CATALYST 80 D i s t i l l a t i o n Curves for R uns 20 and 21 100 DIETHYL 150 T E M P E R A T U R E U BENZENE B E N Z E N E VAPOR E T H Y L E T H Y L BENZENE ACT'D • U N ACT'D WEIGHT Figure 9. 40 PER CENT B E N Z E N E CATALYST CATALYST 60 DISTILLED D i s t i l l a t i o n C u r v e s for Runs 22 and 25 DI ETHYL ETHYL b e n z e n e BENZENE H- O O C5 CD o Ul y BEN ZEN E WEIGHT Figure 10. 40 PER CENT BENZENE CATALYST e U N ACT'D a CARBONED 9 20 ETHYL ACT'D BURNED 60 DISTILLED CATALYST CATALYST OFF C A T A L Y S T 80 Distillation Curves for Runs 22, 23, 24 and 25 _____ CT.TE IINTVFRSITY libraries 3 1762 10014641) 4 # A;-; i: A# A !'W.; A Illll . ' ill N578 K578a "I'" cop. 2 100895 Kindschv. E. 0. Alumina activated with anhydr­ ous hydrogen fluoride as a ... DATE I S S U E D TO IfiiTtTa-MB' MUS 21 -5t h I o#-# Q H o l o — v<5"7 8 a C O D. , .I'i 100895