Alumina activated with anhydrous hydrogen fluoride as a cracking catalyst... by Harry A Herzel

advertisement

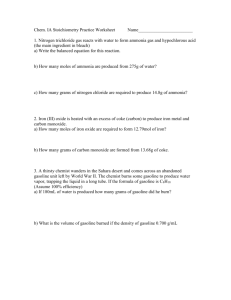

Alumina activated with anhydrous hydrogen fluoride as a cracking catalyst for gas oil by Harry A Herzel A THESIS Submitted to the Graduate Committee in partial fulfillment of the requirements for the degree of Master of Science in Chemical Engineering Montana State University © Copyright by Harry A Herzel (1949) Abstract: The purpose of this work was to evaluate alumina activated with anhydrous hydrogen fluoride as a cracking catalyst for a virgin gas oil. Preliminary investigation showed that at a liquid space velocity of 1 volume gas oil per volume catalyst per hour, on-stream cycle time should be approximately 30 minutes. These conditions were held throughout the investigation. Catalytic cracking runs were made over a range of the temperatures to determine the optimum cracking temperature. The temperature range was duplicated with runs using unactivated catalyst to obtain a standard of comparison. It was concluded that under the conditions of this investigation the gasoline yield, ultimate yield, and per cent conversion is greater for hydrogen fluoride activated catalyst than for untreated alumina at all temperatures studied; and that the optimum cracking temperature of the catalyst was 475 ± 5°C, The data obtained showed that the gas yield from the Reaction increased from 0,38 weight per cent to 4.0 weight per cent when the activated catalyst temperature was increased from 406°C. to 502°C,, anti from 0,20 weight per cent to 3=1 Weight.per cent when the unactivated catalyst temperature was increased from 404°C. to 497°C, The data also showed that the motor octane number of the gasoline samples obtained from the activated catalyst increased as the cracking temperature was increased. ALUMINA ACTIVATED WITH ANHYDROUS HYDROGEN FLUORIDE AS A CRACKING CATALYST FOR GAS OIL by HARRY A e HERZEL A THESIS Submitted to the Graduate Committee in partial fulfillment of the requirements for the degree of Master of Science in Chemical Engineering at Montana State College Approved: I Charge of" Major^Work 1!''rMlulJ vi,,nfr 'm in ; : ! ■ . Bozeman, Montana May, 1949 2 TABLE OF CONTENTS Page A b s t r a c t ............................... , 4 I I n t r o d u c t i o n .......................... . 5 II Equipment, Methods, and Compounds. . . . A. Equipment ........... . . . . . B . Methods ........................ C . Materials ......... . . . . . . 12 15 III Sample Calculations................. 16 IV R e s u l t s .................. 19 V C o n c l u s i o n s ........................... 23 VI Acknowledgment 24 VII Literature Cited ........................ 25 VIII Appendix ......... 26 . . . . . . . . . . . . . 8 8 Table I - Gas Oil A n a l y s i s ............. 27 Table II - Catalytic Cracking of Gas Oil with On-Stream Cycle Longer than 30 Minutes and Activated Catalyst. . „ 28 Table III - Catalytic Cracking of Gas Oil with an On-Stream Cycle of 30 M i n ­ utes and Activated Catalyst . . . . 29 Table IV - Catalytic Cracking of Gas Oil with an On-Stream Cycle of 30 M i n ­ utes and Unactivated Catalyst . . . 30 Table V - Sulfur Content and Octane R a t i n g ........................ .. 31 Figure I - Diagram of Reaction System. Figure 2 - Effect of Temperature on Gasoline Yield (Per Cent Gasoline on Gas Oil C h a r g e d ) ............... 92548 . 32 33 3 Figure 3 ~ Effect of Temperature on Gasoline Yield (Per Cent Gasoline on L i q u i d ' 34 Figure 4 - Effect of Temperature On G^sbline Yield (Per Cent- Gasoline on ProductP lU S Gas) O o e e io o o o e 35 Figure 5 - Effect of Temperature on Gdisoline Yield and Per Cent Conversion (Pdr cent Gasoline.on Gas Oil Charged), 36 Figure 6 - Effect of Temperature'On Gasoline Yield and Per Cent Conversion (Per cent Gasoline on Liquid Product) . ........... 37 Figure' 7 - Effect of Temperature On Gasoline Yield and Per Cent Conversion (Per Cent Gasdlirie on Product Plus Gas) 38 Figure 8 - Gas Production as aJFunetion of Temperature * , , , , # , , @ 0 , 0 0 0 , 3.9 Figure 9 - Octane Numbers and Sulfur Content as a Function of Temperature, 40 4 ABSTRACT The purpose Of this work was to evaluate alumina acti­ vated with anhydrous hydrogen fluoride as a cracking catalyst for a virgin gas oil. Preliminary investigation showed that at a liquid space velocity of I volume gas oil per volume catalyst per hour, on-stream cycle time should be approximately ■30 minutes. These conditions were held throughout the investigation, .Catalytic cracking runs were made over a range of the temperatures to determine the optimum cracking.temperature. The temperature range was duplicated with runs using unacti­ vated catalyst to o b t a i n s standard of comparison. It was concluded that under the conditions of this in­ vestigation the gasoline yield, ultimate yield, and per cent conversion is greater for hydrogen fluoride activated catalyst than for untreated alumina at all temperatures studied $ and that the optimum cracking.temperature.of the catalyst was 4?5 ± 50C, ■The data obtained showed that the gas yield from the Reaction increased from.0*38 weight per.cent.to 4,0 weight per cent when the activated catalyst temperature was increas­ ed from- 4 0 6 % , to 5020C 0, and from 0,20 weight per cent to 3 =1 Weight.per cent when the unactivated catalyst temperature was increased from 404c’C , to 497°Ce The data also showed that the motor octane number of the gasoline samples obtained from the activated catalyst increased as the cracking temperature w a s " increased, - 5 . I, INTRODUCTION The chief function of a cracking catalyst is its acceler­ ation of bond fracture„ It is generally understood that the- acceleration is hot random but selective to certain bonds. The work of Greensfelder«, V o g e 5 and Good. (6 ) brought out this selection of rupture„ 1® Their findings were as follows; Paraffins are cracked preferentially at those links which yield fragments of three or more carbon atoms» Shorter chains' tend to crack near the center carbon atom and longer chains tend to crack simultaneously in several places, 2„ Naphthenes tend to give three carbon atom chains. Cracking may take place in both the ring and side chain* 3« . In substituted aromatics, the link to the ring is sheared off to leave a bare aromatic, 4, Olefins are attacked in much the same manner as para­ ffins , except more readily„ Typical conclusions from catalytic cracking investigations were presented by McGrew (10) who use ”Tonsil" (a siliceous cracking catalyst) with varying amounts of potassium hydrogen phosphate to obtain a yield of 30*6 vol* per cent gasoline at 0*5 per cent phosphate from gas oil. Lee and Thomas (9) con­ cluded that §l zirconium oxide activated silicate would yield 28*7 v o l o per cent of 79*7 octane number gasoline from gas oil* 6 The catalyst quality is one'factor that will make a cat­ alytic process a success or a failure„ Conn and Connolly (4) showed that surface area, carbon forming tendency, and gas forming tendency had a profound effect- on gasoline production. Although the quality of surface area is fixed for any cata­ lyst, the gas forming and carbon forming tendencies are prim­ arily affected by, pressure and temperature, , Pressure, contact time, and temperature are probably the most important variables in any catalytic process. Since the conversion of a hydrocarbon feed stock varies with catalyst temperature, an exploration of the temperature variable should be included in the study of a catalytic process. Although it is nearly impossible to determine the temperature involved on the catalyst surface during cracking, an average temperature obtained by thermocouples inserted into the catalyst bed is usually significant for comparative purposes. The catalyst used in' this investigation-was alumina pel­ lets impregnated with anhydrous hydrogen fluoride, The cataly­ tic properties of hydrogen fluoride have been ,investigated for allied operations. Kuhn (8 ) reformed narrow-boiling branched chain gasoline hydrocarbons to a gasoline fraction of desired distillation characteristics by contact with hydrogen fluoride of at least 90 per cent concentration, Gibson (5) used hydro­ gen fluoride in a combination process of alkyIqtion and isomer­ ization of normal butane, and Clark (3) reported the use of 7 hydrogen fluoride as a catalyst in the alkylation of isobuty­ lene „ To obthin a comparison with results obtained with the hydrogen fluoride impregnated alumina, cracking runs were made with untreated alumina pellets„ These are referred to as "unactivated catalyst" runs in this work. The purpose of this thesis is to evaluate anhydrous hydro­ gen fluoride activated alumina as a cracking catalyst for a virgin gas oil. This investigation will report optimum crack­ ing temperature, gasoline yield, and gasoline quality in terms of octane number and sulfur content. No attempt was made to determine optimum conditions of pressure or space velocity in the cracking system. The space ‘ velocity was arbitrarily held at approximately I volume per volume of.catalyst per hour and at one atmosphere of pressure. The average barometric pressure during this study was approxi­ mately 635 mm. of Hg.. The investigation does not include, a report of carbon lay down, optimum on-stream time or catalyst life. The catalyst was apparently unaffected by burnoffs carried out below the sintering temperature of alumina. All per cents reported in the results are given as weight per cent. •8 II. EQUIPMENT, METHODS M D MATERIALS A. Equipment The cracking unit comprised the following equipments a 1000 ml graduated separatory fupnel, a bellows pump, an electrically heated reactor, a water cooled condenser, a dry ice condenser, Erlenmeyer receivers, a gas m e t e r , a Harvard type triple-beam balance, Powerstats, a Brown potentiometer, arid iron-constantan thermocouples. Equipment for the rectification of the cracked product was as follows: a precision rectification column, a round bottom distilling flask, a distilling flask heating mantle., a reflux condenser, dry ice traps, thermometers, Powerstats, and a side arm vacuum flask. Equipment exactly as described by the A.S.T.M. Standards (I) was used for sulfur determin­ ations by the lamp method. The 1000 ml graduated separatory funnel, which acted as the gas oil charge reservoir, was connected to a Merkle-Korff bellows pump with 1/4 inch neoprene tubing. The bellows pump charged the feed stock to the reactor through three feet of 1/4 inch annealed copper tubing. The reactor body was made of a three inch black standard mild steel pipe 24 inches long with standard pipe threads at both ends. The top of the reactor was fitted with a three inch flange, a three inch short, nipple and a three inch stand­ ard cap. Changing the catalyst was simplified by opening the 9 reactor at the flange rather than at the cap, A 1/2 inch hole was drilled into the cap and threaded to take a 1/2 inch standard nipple and a 1/2 inch standard cross. Two openings of the cross were closed with plugs and the third outlet was fitted with a 1/4 inch by 1/2 inch reducer. this reducer a copper tubing fitting was screwed. Into This fitting held the gas oil feed line from the bellows pump. The bottom of the reactor tube was fitted with a three inch standard pipe cap. A 1/2 inch hole was drilled into the cap and threaded to take a 1/2 inch standard nipple and a 1/2 inch standard sleeve assembly. The sleeve opening was fitted with a 1/4 inch by 1/2 inch reducer. Into the reducer was screwed a copper tubing fitting which held a 1/4 inch copper tube approximately eight inches long. The copper tube led to a glass bulb type water condenser 10 indies long and a dry ice condenser connected in series. A diagram of this equipment is shown in Figure I. Three 1/8 inch standard black pipes, 4-3/4 inches long and sealed at one end, were inserted through holes drilled through one side of the reactor. These pipes, which were welded to the reactor so that the sealed ends were approxi­ mately at the reactor center line, acted as thermowells, and were so located that they would give the temperature at the t o p , middle and bottom of the catalyst bed. The reactor body was wound with two layers of asbestos 10 tape to Insulate the heating coil. This heating coil which • . ’ - was connected to a 220 volt Powerstat, was. made of 75 .f$et of Nichrome wire rated at '1,079 ohms per foot. of asbestos tape were wound over the coil. Two more layers Next, two lengths of Nichrome wire 33 feef IPn S and rated at 1,079 ohms pqr foot were wound around the Reactor so. that one wire controlled the preheat section and the second controlled the catalyst section. The !-ends of these windings were connected to 110 volt Pgwerstats. Magnesia bgts were then wired to the reactor bo^y and covered .with asbestos mud j;o provide the necessary insulation against heat loss. The reactor was filled with Berl saddles to the undersur­ face of the lower thermocouple. Nine hundred milliliters of 1/8 inch alumina pellets were placed on top of the Berl saddle lay­ er and the remaining space above filled with more Berl saddles. The distillation cpltunn was constructed of three lengths o^. .glass tubing arranged concentrically and held in position by means of asbestos t^pe and glue. with 1/4 inch glass helices. The inner tube-was;p a c k e d ■ A thermometer was attached to the outside of. the inner tpbo near the center,. The middle . tube was wound with Nichrome w i r e 'to provide heat ^ The amount offbeat supplied was controlled by a Powerstat * • The outer.tube provided added insulation and also protected the Nichrdme wind­ ing . The overall height of the column was 24 inches. height of the packing was 22 inches. The 11 The refiux condense,]? was ^attached to the top of the column by a 29/42 standard tapered groupd glass joint. A second ther­ mometer Was attached t 6 the refluijc cpndensbr to measure vapor temperature. I : - The potentiometer used was manufactured by the Brown Company-and could be used to record temperature up ?to 12009c. This-'..instrument gave readihgs in miliiVolts^ which were- convert­ ed to degrees Centigrade by means of a table provided by the manufacturer* % The Powerstats were small-autotransformers manufactured by ,Superior Electric Company . jThe. ,maximum input .w a s ..7-1/2 amperes at H O volts and five amperes at 220 vol t s < The out­ put,ranged from 0 to 135 volts for the H O volt Powers tat. and 0 to 235 volts ,for the 220..VolttPowerstat« . .- -The. gas meter used was .a three liter "Precision" Wet Test metero 12 Bo 1«, Methods Activation of the Alumina Pellets s The manner of catalyst activation was similar to that outlined by Berg (2). for two hourso The-alumina pellets were dried at 250°C„ After the drying period, the reactor was allow­ ed to cool to room temper&tur^„ Anhydrous.hydrogen fluoride was then passed- through the catalyst for two hours 9 and for another hour while the catalyst temperature was being raised to 4000C „ The catalyst was- then purged with nitrogen for about fifteen minutes to sweep out the excess hydrogen fluor­ ide o The hydrogen fluoride leaving the reactor was bubbled through kerosene and out a blowdown line* 2* Making the Cracking R u n s : The reactor was heated until the middle thermocouple was approximately five degrees above the desired temperature» The air in the reactor was then displaced by a nitrogen purge last­ ing approximately fifteen minutes« The feed lined was connect­ ed immediately after the nitrogen purge and the bellows pump started. Dry ice was placed in the condenser and initial reactor temperature was recorded„ Readings of the gas meter? charge reservoir, and the three thermocouples were taken at five minute intervals. The flask containing the product was removed, weighed, and placed in a refrigerator maintained at =400C to minimize loss of the lighter hydrocarbons. The re­ actor was allowed to stand until the gas meter stopped 13 recording gas flow. This final reading gave the total gas produced during the on-stream cycle. Upon completion of the run, the reactor was again purged6with nitrogen until all hydro­ carbon vapors were removed. The carbon laydown was then burned off the catalyst by passing a stream of air through the reactop. The temperature of the burning zone was maintained at approximately 500 0C . during the regeneration. The same pro­ cedure was utilized for the control runs. 3c Measuring Gas Density; A nineteen liter bottle filled with water was connected to the downstream side of the gas meter during the cracking cycle„ As the gas left the m 6ter it was allowed to displace the water until the bottle completely drained. Weight of the bottle plus a i r , the bottle plus gas, and room temperature were recorded. 4 0. Distillation of Reaction Products; The charge was placed in a distillation flask which was surrounded by a heating mantel. The Powerstats were adjusted so that the column would flood and completely wet the packing. Hydrocarbons that did not condense on the cold finger were led to a dry ice trap. The heat input was then reduced until flooding stopped and the column was permitted to operate at total reflux for one hour. The reflux ratio was then set at about 5 sl and all products boiling up to the recorded end points were taken off as the gasoline sample. The weights of 14 residue and gasoline sample were then recorded. 5o Sulfur Determination of Gasoline Product % The sulfur determination was made exactly as prescribed by the A.S.ToM. Standards. To check technique of operation, a determination of the sulfur content of a known solution was madeo This sample was made from a mixture of thiophene and thiophene free benzene„ 60 Preparation of Gasoline Product for Octane Bating % The gasoline samples had to be neutralized because ok the acidic nature of the catalyst used in this investigation. . This was accomplished by washing the gasoline with a 10 per cent sodium hydroxide solution. was approximately three minutes. Contact of sample with base 15 C. Materials No attempt was made to purify any of the reagents used* Compound Grade Source Benzene Thiophene Free General Chemical C o 0 Sodium Hydroxide Electrolytic C «P, Fisher Scientific Co, Hydrogen Peroxide C,P, Fisher Scientific Co, Methyl Bed Analytical Fisher Scientific Co, Thiophene Synthetic Eastman Kodak Co, Nitrogen 95% water pumped The Matheson Co, Anhydrous Hydrogen ■ Fluoride Alumina Pellets, 1/8 inch diameter The Matheson Co, Harshaw Chemical Co, The material charged to the reactor was a virgin atmos­ pheric gas oil from Elk Basin and Frannie, Wyoming, crude . oils in approximately 70 - 30 ratio, A laboratory analysis of this material is given in Table I, ^ 1IZJlaI/-! I 11,'I'/'r 16 III. SAMPLE CALCULATIONS The sample calculations are based on Eun #13 because optimum gasoline yield was attained here. Calculations on a:ll runs were made by exactly the same methods. A. Average Gas R a t e : During Run 1 3 ? as for each run made, the gas meter was read in liters every five minutes. From these readings the quantity of gas passing through the meter for each five min­ ute interval was calculated. By averaging these values and dividing by five minutes, the gas rate in liters per minute was obtained. Ne^t the total gas oil charged was divided, by the on-stroam time to obtain grams of gas oil charged per minute. Dividing the former by the latter and multiplying by 1000 gave the average gas rate in c c ’s of gas produced per gram of gas, oil charged. B. Calculation of Liquid Snace Velocity: In each run the space velocity was held at, I cc liquid gas oil charged per cc catalyst per hour. C. ' Density of Gases Produced by Cracking: Weight of 19.1 liter flask plus air 6248 gms. Weight of 19.1 liter flask plus gas 6236 gms. Difference ' 12 gms. Density of air at 25°C. and 640 mm of Hg. pressure is 0.99748 grams per liter (7). Therefore 19.1 liters times 0.99748 grams pdr liter less 12 grams yields 7»0^ grams of gas T- 17 contained in the f Iask 0 Finally the density of the gas is calculated as 7*05 divided by 19 »I which equals 0»370 grams per liter* D0 Calculation of Yields: The yield of cracked product is given in weight per cent and based on the grams of gas oil charged. The yields of resi­ due and gas and losses from rectification are given in weight per- cent and based on the grams of gas oil charged. Thus for R u n 13: Cracking Grams Gas Oil charged to Reactor 395 Liquid Product 328.9 8.0 Gas Losses Weight Per Cent 83.3 2*0 ' 5 8 .1 14*7 200.4 50.8 Rectification Residue Gas and losses • 14.5 3.6 The gasoline product was calculated with three different basis, namely 5 by grams gas oil charged, by grams liquid pro­ duct from the reactor, and by grams liquid product plus grams gas produced by cracking. T h u s , for Run 13: Grams Gas Oil Charged 395 Liquid Product from Reactor 328.9 Gas Produced on Cracking- 8.0 18 Gasoline Produced 114 c0 Basis of Calculation Per Cent Gasoline Gas Oil Charged 28.8 Liquid Product 34.7 Liquid Product Plus Gas 33.8 E0 Calculation of Per Cent Ultimate Y i e l d : For Run 13, 328*9 grams of liquid product less 114,0 grams of gasoline yields 214.9 grams of unconverted gas oil. Therefore, the 395.0 grams of gas oil charged less 214.9 grams of unconverted gas oil yields 180.1 grams of gas oil converted to gas, carbon, gasoline, and losses. Finally 114.0 grams of gasoline divided by 180.1 grams of converted gas oil times 100 gives an ultimate yield of 63*3 per cent. F. Calculation of Per Cent Conversion on Charge: For Run 13? per cent conversion of gas oil to gas, coke, and gasoline may be obtained by subtracting 50.8 per cent resi due from 100 per cent. This method of calculating per cent conversion includes losses from cracking and distillation.as conversion 19 IV. RESULTS Although optimum on-stream time was not investigated, an initial run was mac}e to determine how activation dropped off with cycle time. This run was made for a period of 146 minutes at approximately 400°C. Results of data taken during the first 73 Ainutes of operation appear in Table II as Run 5® Results of data taken during the last 73 minutes appear in Table II as Run 6. From these results it is possible to com­ pare gasoline yield for the first 73 minutes with that obtained from the last 73 minutes. During R un 5» 12.3 per cent of th6 charge was converted to.gasoline while Run 6 yielded 4.53 per cent. In Run 7? the temperature was increased to 501°C .9 and the reactor was charged for 67 minu t e s . .This run converted 23.6 per cent of the gas oil charged to gasoline. These results showed that as the on-stream time increased the gasoline yield decreased. Therefore, a 30 minute on­ stream cycle was arbitrarily chosen for the investigation. These results also showed that increasing the catalyst temper­ ature w o u l d .increase the gasoline yield. The remainder of the investigation was concerned therefore with finding that temper­ ature which would give a maximum yield of gasoline. Table III tabulates the results of cracking gas oil with an anhydrous hydrogen fluoride activated alumina catalyst. The runs are arranged in the order of increasing temperatures, The results show that as temperature increases, the per cent gasoline yield increases= until the catalyst temperature reaches 475°Co) then begins to decrease. A graphical repre­ sentation of this is given in Figure 2 where per cent gasoline yield based on gas oil charged and per cent ultimate yield are both plotted as a function of temperature0 • Figure 3 shows that a maximum ultimate yield of 63 .3 per cent is reached at 4750Co) for the activated catalyst. This plot does not show whether or not a maximum gasoline production based on per cent of liquid product had been reached at 4750G OSI since the highest reaction temperature investigation gave a gasoline yield which fell.on the plateau which began at approx­ imately 475°Co 1 The gasoline yields were also calculated on the .basis of liquid product plus gas because the method of calculating gas­ oline yield based on liquid product alone does not consider gas ■ oil converted to gas by the catalyst, and the result of this I calculation plotted in Figure 4 shows that a maximum gasoline yield was obtained at 475°Cc The calculated results given in Table III include per cent conversion of gas oil to carbon, gas, losses, and gaso­ line. Figure 5 shows how both gasoline yield based on gas oil charged and per cent conversion varied with catalyst temper­ ature. This graph shows that at approximately 475°C= a maxi­ mum gasoline yield of 28.8 weight per cent was obtained with the activated catalyst. 21 Figure 6 shows how both gasoline yield based on liquid product and per cent conversion varied with catalyst temper­ ature „ The per cent gasoline yield obtained from, the acti­ vated catalyst increased rapidly until a catalyst temperature of approximately 4 7 5 ° C . was reached and then remained nearly constant up to the highest catalyst temperature investigated« Figure 7 shows how both gasoline yield based on liquid product plus gas obtained from the reaction and per cent con­ version varied with catalyst temperature. This plot shows that a maximum per cent gasoline yield of 3 3 c8 weight per cent was obtained at a catalyst temperature of 475°C. with the activated catalyst. Figures 5? 6 and 7 also show that the per cent conversion of gas oil increased as the catalyst temperature was increased. The results of catalytic cracking of gas oil with un­ treated alumina pellets are tabulated in Table I V . These re­ sults are plotted on Figures 2, 3» 4, 5? 6 and 7 so that the effect of the hydrogen fluoride activation on the gasoline yield may be compared. It should be noted that the activated catalyst curves are similar to the unactivated catalyst curves in shape and that both show the same approximate temperature where maximum ultimate yield was attained. Figures 2 ? 4 9 5 and 7 show a maximum gasoline yield for both activated and unactivated catalyst at approximately 475°C. Tables III and IV show that the per cent gas produced by 22 the activated, as well as the unactivated catalyst increased as the temperature increased, A plot of these results, Figure 8, shows that from 410°Ce to 480 ° C ,, the per cent of the charge converted to gas by the activated catalyst is less than the per cent converted by the unactivated catalyst., which indicates a low gas forming ability for the activated catalyst in this temperature range„ In Table V are tabulated the results of the sulfur and octane number ratings of the gasoline samples taken from Runs 9, 11, 13 and 15 of Table III, The octane numbers showed a tendency to increase as the catalyst temperature, was increased The sulfur contents, of the gasoline samples went through a min imum value of 0,384 per cent at 4 5 0 ° C , A plot of octane number as a function of reaction temperature and sulfur con­ tent as a function of the same variable is given as Figure 9» 23 Vo CONCLUSIONS The following conclusions may be drawn concerning the cracking of a virgin gas oil with the hydrogen fluoride acti­ vated catalyst: 1«, Gasoline yield and per cent convers-ion- is greater for hydrogen fluoride activated alumina, compared with untreated alumina, at all temperatures studiedo 2o At one atmospherecf pressure and a space velocity of one volume of charge per volume of catalyst per hour, gasoline yield and ultimate gasoline yield reach a maximum at a cracking temperature 475 t 5°Co The per cent conversion of gas oil increases with catalyst temperaturee .3„ The per cent £as yield from the reaction increased when the catalyst temperature was increased, 4o The motor octane number of the gasoline samples obtained with the activated catalyst increased as the cracking temperature was increased. 24 VIc ACKNOWLEDGMENT The author acknowledges with thanks the courtesy of the Carter Oil Company who furnished the gas oil u.sed in this investigation, and of the Phillips Petroleum Company for determining the octane numbers of the gasolines® 25 VIIo LITERATURE CITED (1) AoSeTol. Committee D-2, nP e t r o l e m Products and Ltibricantsn 9 D90-41T. 272-276 (1941). (2) B e r g 9 'I., Sumner9 G. L o 9 and Montgomery9 C e W o 9 (To Gulf Research and Development Co.): U.So Patent 2,397,639 (April 2 ? 1946). (3) Clarke9 L. A 0 ? (To The Texas Go.); U eS. Patent 2 94 0 3 9501 (July 9, 1946). ............... (4) C o n n 9 -M. Eo9 and Connolly, G. Co, "Testing of Cracking Catalysts", I n d 0 E n g 0 C h e m .? 3 9 , 1138-1143 (1947)* (5) Gibson9 J 0 D 0, (To Phillips Petroleum C o . ) ; U.S. Patent 2,347,317 (April 24, 1944). (6) Greensfelder, B 0 S 0, V o g e 9 Ho H., and Good, G. M., "Catalytic Cracking of Pure Hydrocarbons", In d 0 E n g . C h e m oa 3 Z 9 1168-1176 (1945)o (7) Hodgman, C 0 D . , "Handbook of Chemistry and Physics", Chemical Rubber Publishing Co. Twenty-Fifth Edition, (1941). (8) Kuhn,. Co S 0 J r 0, (To Socony-Vacuum C o . , Inc.); U 0S 0 Patent 2,403,929 (July 16, 1946). (9) L e e 9 E0 C 09 and Thomas9 C 0 L 0, (To Universal Oil Products Co.); U 0S 0 Patent 2,406,613 (August.27, 1946). (10) McGrew, E* H . , (To Universal Oil Products C o 0); U 0S. Patent 2,377,093 (May 20, 1945). 26 VIII APPENDIX Page A0 Table I - Gas Oil Analysis » » o , e . = <> » „ „ . 27 B0 Table II - Catalytic Cracking pf Gas Oil With OnStream Cycle Longer than 3<? Minutes and Acti­ vated Catalyst 0 * * * * * * * * 0 * * * * « * 2’ 6 Table III - Catalytic Cracking of Gas Oil with an On-Stream Cycle of 30 Miputes arid Activated Catalyst* * * * * 0 * * * * * 0 * * * 0 0 @ % 29 Table IV - Catalytic Cracking of Gas Oil with an On-Stream Cycle of 30 Minute^ and Unaetivated' Cataly s t 0 * 0 0 0 0 © © 0 0 :« * * * 0 0 0 *0 0 30 Eo Table V - Sulfur Content and Octane Ratings* * * * * 31 Fo Figure I - Diagram of Reaction Systep0. * * * * „ „ * ■■ i ■ : .: Figure 2 - Effect of Temperature on Gasoline Yield (Per Cent Gasoline cn Gas Oil Charged)-» „ „ „ » 32 33 F i g u r e -3 - Effect of Temperature on Gasoline Yield (Per Cent Gasoline on Liquid Product) 0 0 „ e » 34 Figure 4 - Effect of Temperature on Gasoline Yieldz(Per Cent Gasoline on Prodtict Plus Gas) » » * « 35 Go Ho Io J0 Figure 5 ~ Effect of Temperature on Gasoline Yield and Per Cent Conversion (Per Cent Gasoline on Gas O i l .Charged)© « $ » * © © © © © © © © © © © © © 36 Figure 6 - Effect of Temperature on Gasoline Yield and Per Cent Conversion (Per Cent Gasoline on Liquid Product) 0 0 0 0 0 * 0 0 0 0 0 0 0 0 0 0 0 0 0 0 37 Lo Figure 7-= Effect of Temperature on Gasoline Yield and Per Cent Conversion (Per Cent Gasoline on Product Plus Gas) © © © © » © © © © © © © ©o' © 38 Mo Figure 8 - Gas Production as a Function of Temperature o © © © © © © © © © © © © © © © © © 39 Figure 9 - Octane Numbers and Sulfur Content as a Function of Temperature © © * © © © * © © © « © 40 No 27 TABLE I Gas oil analysis as given by the Carter Oil Company, Billings, Montana. T ime: Date: 10 A .M„ 8/12/47 Gravity Distillation Product: Source: 0AoP.!. I.B.P. 5$ 10$ 20# 30$ 40$ 50$ 60$ 70$ 80$ 90$ 27.9 524°F 558 570 580 588 601 614 628 648 Sulfur, Weight Per Cent 1.56 676 714 Per Cent Recovery 95$ at 730°F Viscosity 52„6 S e c . at Remarks: 2$ at 550°F 71$ at 650°F Tested by CS and CRS Gas Oil No. 5 Unit #4 Stream IOO0F. S.U. 28 TABLE II Catalytic Cracking of Gas Oil with On-Stream Cycle Longer than 30 Minutes and Activated Catalyst Run No. Catalyst, cc. 5 800 6 800 7 900 I I I CRACKING: Liq. Sp. Vel., hr.-1 Gas Oil Cracked by Catalyst Before Run began, grains Temp., 0C On-Stream Cycle, mins. Ave. Gas Rate, cc. gas/gram charge Total Gas, Liters Charge, grams Product, grams % Liquid Product Gas, grams dJo Gas Carbon and Losses, grams tJ0 Carbon and Losses 0 415 73 24.8 17.0 869 810.9 93.3 6.3 0.73 51.8 5.97 869 418 73 8.7 7.3 869 839.4 96.5 2.7 0.31 26.9 3.1 0 501 67 140 120 869 631.6 72.7 44.5 5.1 192.9 22.2 RECTIFICATION: Barometric Press., mm. End Point, °C. Gas and Losses, grams % Gas and Losses Residue, grams % Residue Gasoline Product, grams % Gasoline on Gas Oil % Gasoline on Product % Gasoline on Product / Gas % Ultimate Yield % Conversion on Charge 633.8 210.0 36.8 4.2 666.9 76.8 107.2 12.3 13.2 13.1 65.0 19.1 637.9 210.9 8.1 0.9 792 91.2 39.3 4.53 4.68 4. 67 57.0 7.94 629.1 210.0 25.5 2.9 400.7 46.2 205.4 23.6 32.5 30.4 46.5 50.8 29 TABIE III Catalytic Cracking of Gas Oil with an On-Stream Cycle of 30 Minutes and Activated Catalyst Run No. Catalyst, cc. 15 900 CRACKING: Liq.. Sp. Vel., hr-1 Temp., 0C. Gas Rate cc. gas/gram charge Total Gas, liters Charge, grams Product, grams % Liquid Product Gas, grams % Gas Carbon and Losses, grams % Carbon and Losses 406 7.04 3.9 376 268.9 71.5 1.44 0.38 105.7 27.1 RECTIFICATION: Barometric Press., mm End Point, 0C. Gas and Losses, grams % Gas and Losses Residue, grams % Residue Gasoline Product, grams % Gasoline on Gas Oil # Gasoline on Product % Gasoline on Product / Gas $ Ultimate Yield % Conversion on Charge 637.1 210.1 6.5 1.73 233.3 62.0 29.2 7.77 10.85 10.84 21.4 36.3 I 9 900 13 900 11 900 . 455 31.8 29.5 745 634.2 85.0 10.9 1.5 99.9 13.4 I 473 40.8 21.5 395 328.9 83.3 8.0 2.0 58.1 14.7 502 65 41.3 378 279.2 73.9 15.3 4.0 83.5 22.1 512 156.2 390.7 2184 1467.4 67.2 144.8 6.6 571.8 26.2 641.4 210.5 33.1 4.45 413.5 55.4 187.6 25.2 29.6 29.2 62.8 40.1 634 210 14.5 3.6 200.4 50.8 114.0 28.8 34.7 33.8 63.3 49.1 628.8 210.0 19.2 5.1 163 43.2 97 25.6 34.8 32.9 49.5 56.8 641.5 210.5 52.1 2.2 904.4 41.4 511.9 23.4 34.9 31.7 41.7 58.6 I I 8 1000 I 30 TABLE IV Catalytic Cracking of Gas Oil with an On-Stream Cycle of 30 Minutes and Unactivated Catalyst Run No. Catalyst, cc. 20 900 19 900 18 900 17 900 CRACKING: Liq.. Sp. VeI., hr I Temp. 0C. Gas Rate, cc. gas/gram charge Total Gas, liters Charge, grams Product, grams % Liquid Product Gas, grams % Gas Carbon and Losses, grams aJo Carbon and Losses I 404 3.44 2.15 375 343.8 91.5 0.8 0.2 30.4 8.1 I 452 29.4 18.65 419 372.1 88.8 6.9 1.6 40.0 9.6 I 478 66.9 28.2 366 298.6 81.6 10.4 2.8 57.0 15.6 I 497 57.6 33.9 407 308 75.8 12.6 3.1 85.9 21.1 RECTIFICATION: Barometric Press., mm End Point, 0C. Gas and Losses, grams dJo Gas and Losses Residue, grams % Residue Gasoline Product, grams % Gasoline on Gas Oil d Jo Gasoline on Product dJo Gasoline on Product / gas dJo Ultimate Yield d Jo Conversion on Charge 639.2 210.2 2.3 0.61 333.5 89.4 8.0 2.13 2.33 2.32 20.4 10.6 641.4 210.5 3.3 0.7 326.1 77.8 42.7 10.2 11.5 11.3 47.7 22.2 641.8 210.6 3.3 0.9 224.7 61.5 70.2 19.2 23.5 22.7 51.4 38.5 641.8 210.6 3.6 0.9 248.5 61.2 56.2 13.8 18.2 14.3 36.4 38.7 31 TABLE V Sulfur Content and Octane Ratings Run Temp. 0C. 400 Sulfur Content, % Motor Octane, 0 ml I ml Research Octane, 0 ml I ml Gravity, A.P.I. 0.663 450 475 0.384 0.457 500 0.5 77.8 80.7 79.6 — — — — 91. 6 — — 55.5 93.8 — 58.3 58.0 82.5 83.3 96.5 97.7 52.0 89 106 123 157 189 220 251 278 304 331 366 390 427 96.5 1.0 83 83 102 128 154 182 215 249 281 311 342 363 403 94.0 1.0 85 85 HO 141 168 192 216 242 268 301 345 374 417 94.0 1.0 84 93 112 140 168 200 233 266 296 323 357 384 423 95.9 1.0 — 92.0 ASTM DISTILLATION, F at 760 am First Drop 5% evaporated 10% 20% 30% 40% 50% 60% 70% 80% 90% 95% End Point Recovery, % Residue, % 32 2k BE R L SADDLES Si \ E / S' CATALYST ^2 FEED CJ V A ‘T H E R M O W E L L S -BERL SADDLES DRY I CE CONDENSER WATER _ CONDENSER TO B L O W DOWN BELLOWS PUMP CAS RECEI VER Figure I Biagram of Reaction System METER O-ALUM lNA ACTIVATED NA/ I T H A NH Y D R OU S H YD ROCE N FLUORIDE Z O A - A L U M I NA UNACT IVATED L- LU >~ 502°C Q LU LU Z O u> LO J ^ i a 0C I19 7 3C Z CO 4 5 2 °C y LU < CC _ ^ " 4 55° ( O - 512 °C O Zj CC o X CO < U U _l t- O U A l Ic 4 0 6 °C LU CL 4 0 4 °C A------------ L 20 PER C E N T JO ULTIM ATE 40 50 YIELD Figure 2 Effect of Temperature on Gasoline Yield (Per Cent Gasoline on Gas Oil Charged) 70 0 —A L U M I N A A C T I V A T E D F L U O R IDE A -A LU MINA WITH A Nl-i Y DROUS HYDROCEhj UNACTIVATED I- 4 0 U 3 512 °C Q 5 0 2 °C 4 7 3°C O CK ' ) 4 5 5 ° C _/ CL Q 30 D Cf _] z O w 20 A 4 78 °C Z _J O (Tl < O I- 10 4 5 2 0CzfZ 406 ‘ Z W U oc U CL 4 0 4 °C l " PER C E N T ULTIMATE YIELD Figure 3 Effect of Temperature on Gasoline Yield (Per Cent Gasoline on Liquid Product) u> — PER CENT CASO l I NE YI ELD ON TOTAL PRODUCT O-ALUM INA ACTIVATED F L U O R IDE W I T H A N HY D R OU S H Y D ROC E N A - A L U M I NA U N A C T I V A T E D PERCENT U LTIM A TE YIELD Figure 4 Effect of Temperature on Gasoline Yield (Per Cent Gasoline on Product Plus Gas) ... O- A L U M I N A FLUORIDE ACTIVATED W ITH A- A L U M I N A UNACTIVATED ANHYDROUS HYDROGEN Z O O _l UJ > r A/I 740 o L 2>0 W UJ S g _1 < O X (Z) O < O d 4 5 5 =C j 512 °C CjU X 20 z I-0 G - a Z (Z) W < U O o / 1-78 °C 497 °C Cf 452 O O) O O 10 O a ^ 0 , 0 2 °C 4 0 4 °C X 60 PER C E N T C O N V E R S I O N ON C H A R G E Figure 5 Effect of Temperature on Gasoline Yield and Per Cent Conversion (Per Cent Gasoline on Gas Oil Charged) O-ALUMINA ACTIVATED FLUOR IDE U D Q O Gd A-ALU MINA W IT H ANH Y DRO US HY DROCE h U N A C T I VATED C L Q 4 7 3 "C o D 5 0 2 °C d C >12 °C 4 5 5°C ' z O Q _l O U UJ UJ -o > r UJ Z ' A, 497°C _1 O 452 < 106 " C o O IZ UJ I -T O O o: LU Q- IO 20 30 40 50 60 PER C E N T C O N V E R S I O N O N CHARGE F ig u r e 6 Effect of Temperature on Gasoline Yield and Per Cent Conversion (Per Cent Gasoline on Liquid Product) PRODUCT 0 —A L U M I N A A C T I V A T E D FLUORIDE A NH Y DROU S HYDRO GEN UNAC TIVATED TOTAL A -A LU M IN A WITH 4 7 3 °C ------ - 5 0 2 eC 512 °C YIELD ON 4 5 5°C F78°C CU PER C E N T GASOLI NE CD • I 452 4 0 6 °C 497 °C 0 4 0 4 °C I 0 IO 20 30 40 PER C E N T C O N V E R S I O N 50 60 ON C HAR GE Figure 7 Effect of Temperature on Gasoline Yield and Per Cent Conversion (Per Cent Gasoline on Product Plus Gas) 70 IO 0 - A - Q A L U M I N A A C T I VATED W ITH ANH YDROUS H Y D R O GE N FLUORIDE A L U M IN A UNACTIVATED W O 8 a. < x U -J O 6 (/) < ' O Z O u> vO if) 4 < O HZ A U U 2 CK Ul CL 380 400 420 R E A C T I ON 4 40 4 60 480 TEMPERATURE °C F ig u r e 8 Gas P r o d u c tio n as a F u n c tio n o f T e m p e ra tu re 5 oo 520 OF G A S O LIN E MOTOR CONTENT PER C E N T SULFUR RATING SULFUR CONTENT R E SE A RCH O C T A N E OCTANE RATING 4 80 4 40 REACTION TEMPERATURE 500 °C Figure 9 Octane Numbers and Sulfur Content as a Function of Temperature MONTANA STATE UNIVERSITY LIBRARIES Illlllllllllllli 3 1762 10014311 2 I