Design of an indirect-fired falling-particle air preheater for MHD power... by Chris Dewey Jensen

advertisement

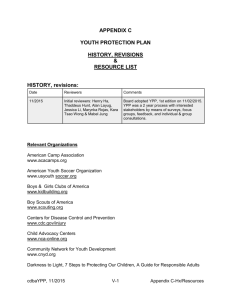

Design of an indirect-fired falling-particle air preheater for MHD power generation

by Chris Dewey Jensen

A thesis submitted in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE

in Chemical Engineering

Montana State University

© Copyright by Chris Dewey Jensen (1976)

Abstract:

A preliminary design for an indirect-fired falling-particle air preheater for a 400 MW (thermal) MHD

power generation plant was made.

The project was broken down into three major parts: material properties prediction, development of a

theoretical model, and capital and annual cost estimation of the overall design.

A theoretical model was developed for an indirect-fired cored-brick air preheater. Capital and annual

costs were estimated and compared to those of the falling-particle air preheater. It was found that

overall air preheat systems involving these two designs would have approximately the same capital

costs of ~ $44 x 10^6, and annual costs of ~$6 x 10^6.

An economic comparison was then made between overall indirect-fired air preheat designs, and overall

direct-fired designs. In both the falling-particle and cored-brick cases, the capital cost of the

indirect-fired design was approximately 50% greater than the capital cost of the direct-fired design. STATEMENT OF PERMISSION TO COPY

In p re s e n tin g t h is

th e s is in p a r t i a l

f u l f i l l m e n t o f th e req u irem en ts

f o r an advanced degree a t Montana S ta te U n iv e r s it y , I a g ree t h a t th e

L ib r a r y s h a ll make i t

f r e e l y a v a ila b le f o r in s p e c tio n .

I f u r t h e r agree

t h a t p e rm is s io n f o r e x te n s iv e copying o f t h i s th e s is f o r s c h o la r ly

purposes may be g ra n te d by my m ajor p r o fe s s o r , o r , in h is absence, by th e

D ir e c t o r o f L i b r a r i e s .

o f th is

It

is understood t h a t any copying o r p u b lic a tio n

th e s is f o r f i n a n c ia l

g a in s h a ll

not be a llo w e d w ith o u t my w r it t e n

p e rm is s io n .

S ig n a tu re

Date

DESIGN OF AN INDIRECT-FIRED FALLING-PARTICLE AIR

PREHEATER FOR MHD POWER GENERATION

by

CHRIS DEWEY JENSEN

. A th e s is s u b m itted in p a r t i a l f u l f i l l m e n t

o f th e re q u ire m e n ts f o r th e degree

of ,

MASTER OF SCIENCE

in

Chemical E n g in e e rin g

Approved:

C h a irp e rs o n , G raduate Committee

Head, M a jo r Depactmght

Graduate?Dean

MONTANA STATE UNIVERSITY

Bozeman, Montana

A ugust, 1976

iii

ACKNOWLEDGMENT

The a u th o r w ishes to g iv e s p e c ia l

thanks to D r. W illia m G e n e tti

f o r h is in v a lu a b le s u p p o rt in th e developm ent o f t h i s p r o je c t .

S p e c ia l

thanks a ls o goes to D r. R. L . Mussulman o f th e M echanical

E n g in e e rin g D epartm ent o f . h i s many h e lp fu l s u g g e s tio n s .

The a u th o r g r a t e f u l l y acknowledges f i n a n c ia l s u p p o rt from

ERDA/MHD D iv is io n .

F i n a l l y , thanks goes to S h e rry G reene, s e c r e ta ry f o r th e Chemical

E n g in e e rin g D ep artm en t, f o r her ty p in g o f t h i s

th e s is .

iv

TABLE OF CONTENTS

Page

V IT A ............................

........................ ..............................................................................

.

ACKNOLWEDGMENTS ................................

ii

iii

L IS T OF TABLES...........................

v iii

L IS T OF FIGURES ............................................... ....

.......................................... ....

ix

NOMENCLATURE.............. ..........................................................

.

ABSTRACT.....................................

x

x ii

INTRODUCTION............................................

I

CONVENTIONAL TURBINE AND MHD POWER GENERATION.

............................

I

COMPARISON OF E F F IC IE N C IE S ...............................

4

THE NEED FOR PREHEATED A IR ...................................................................

5

DIRECT AND INDIRECT-FIRED AIR PREHEATERS . . .

i . . . . .

.

6

.

8

MODEL DEVELOPMENT AND DESIGN OF. FALLING-PARTICLE AIR PREHEATER. .

14

-GENERAL AIR PREHEATER D E S IG N ...........................

INTRODUCTION................... ^

.

PREDICTION OF MATERIAL PROPERTIES.

. . . . . . . . . . . . . . . .

14

14

GENERAL DESIGN CONSIDERATIONS............................................................................ 15

PARTICLE SIZE DISTRIBUTION ..............................................

16

PARTICLE TERMINAL VELOCITIES AND CHAMBER DIAMETER...................

.

17

DETERMINATION OF INSULATIONTHICKNESS............................................................ 17

OVERALL HEAT LOSS TO SURROUNDINGS.....................................

DEVELOPMENT OF MODEL DESIGN COMPUTER PROGRAM ........................

•

■

_

- - : v .

-•

' ,

-

.

;

18

. .

20

TABLE OF CONTENTS (C o n t ) .

Page

MODEL DEVELOPMENT AND DESIGN OF CORED-BRICK AIR PREHEATER.

COST SUMMARYFOR INDIRECT-FIRED AIR PREHEATERS

. . . .

21

. . . .................................... 23

FALLING-PARTICLE AIR PREHEATERS.......................

23

CORED-BRICK AIR PREHEATERS. ...........................................................................

24

FUEL SOURCES FOR INDIRECT-FIRED AIR PREHEATERS . . .

................................... 25

INTRODUCTION . .................................................................

25

COAL CARBONIZATION......................................................................................... ....

.

25

COAL G A S IF IC A T IO N .................................................................

26

OVERALL INDIRECT-FIRED AIR PREHEAT SYSTEMS COST COMPARISON . . . .

30

CAPITAL COST COMPARISON........................................

30

ANNUAL COST ESTIMATION.

30

....................................................................................

COMMENTS. ...........................................................................................................................33

CAPITAL COST COMPARISON OF DIRECT AND INDIRECT-FIRED AIR

PREHEAT SYSTEMS.

................... ... ...................

. . . .

.......................................... ....

33

COMMENTS...........................

33

;APPENDICES ......................................................................

APPENDIX

'

A:

35

PREDICTION OF MATERIAL PROPERTIES. . . . . .

1.

CONSTITUENTS OF.COAL GAS, MOLE %.

2.

PRODUCTS OF COAL GAS COMBUSTION ........................................................

3.

HOT

4.

EXHAUST"GAS PROPERTIES...,

HOT AIR PROPERTIES.

.-.

36

. . . . . . . . .

. . . ..

. . .. . .

.

36

36

.

............................................................

-V

................., ' - ' i

. •.

____

................

37

38

•

.

‘. A r -

;-v

•'

V - . _•

v

; • * vV.- f/ ‘

•

‘

Vl

TABLE OF CONTENTS(Cont).

Page

5.

ALUMINA PARTICLE PROPERTIES.............................................. ....

6.

INSULATION DATA.

7.

MHD COAL EXHAUST GAS PROPERTIES.

.3 8

.........................................................................................

. . .................................

39

GENERAL DESIGN BALANCES................................. ................................

41

1.

COMPOSITION OF MONTANA SUB-BITUMINOUS COAL ............................

41

2.

AIR INPUT TO 400 MW(T) MHD COMBUSTOR..........................................

41

3.

HEAT TRANSFER RATE TO AIR IN PREHEATER ......................................

42

APPENDIX B:

APPENDIX C:

. .

38

MODEL DEVELOPMENT OF FALLING-PARTICLE AIR PREHEATER.

43

1.

PARTICLE SIZE DISTRIBUTIONS.

.............................................................

2.

TERMINAL VELOCITY AND CHAMBER DIAMETER CALCULATION. . .

43

3.

DETERMINATION OF INSULATION THICKNESS. ■. . .

45

4.

WALL HEAT LOSS DETERMINATION................... ...• . . .. .......................

5.

OVERALL HEAT LOSS DETERMINATION..................................................

6.

DEVELOPMENT OF DESIGN EQUATIONS.

7.

DEFINITIONS OF PROGRAM VARIABLES AND PROGRAMLISTING

. . . . .

. .

43

. ■. .

47

47

............................

.

.

49

53

APPENDIX D:

MODEL DEVELOPMENT.OF CORED-BRICK AIR PREHEATER . . .

65

APPENDIX E:

COST PREDICTION FOR FALLING-PARTICLE AIR.PREHEATER .

72

. I.

INSULATION COSTS,.

. .

.. .........................'.......................................

2.

STEEL COLUMN COST.

3.

ALUMINA PARTICLE COST...........................................................74

4.

MISCELLANEOUS CAPITAL COSTS

.

72

72

74

v ii

TABLE OF CONTENTS (C o n t ) .

Page

5.

ESTIMATION OF ANNUAL MAINTENANCE COSTS

APPENDIX F:

.

COST PREDICTION FOR CORED-BRICK AIR PREHEATER. . . .

INSULATION COSTS ............................................................. ..........................

76

2.

STEEL COLUMN C O S TS ................... \........................................ ..

76

3.

CORED-BRICK COST.

77

4.

MISCELLANEOUS CAPITAL C O S T S ..................................... ......................

77

5.

ESTIMATION OF ANNUAL MAINTENANCE COSTS.....................................

78

I.

DESIGN DATA

............................................... ....

FOR.COAL CARBONIZATION SYSTEM . . . . .

MASS AND ENERGY.

APPENDIX H:

79

BALANCES..............................

DESIGN DATA

79

FOR COAL GASIFICATION SYSTEM. . . . . .

1.

MASS AND ENERGY

2.

CAPITAL AND ANNUAL COST PREDICTION..............................................

81

BALANCES............................................... ......

BIBLIOGRAPHY . . . . . . . . .

•

76

1.

APPENDIX G:

•

75

81

82

..................... ..............................................................

.

■

83

.

■

)

..

.

y

- ■■

;

........... X

:

'

.

.

:

.

f

. y - '! -

:

.

.

V-

'

,

■

"

'

.

v iii

L IS T OF TABLES

TABLE

PAGE

I

FALLING-PARTICLE CHAMBER DIMENSIONS............................ ............................21

II

CORED-BRICK CHAMBER DIMENSIONS .

III

ESTIMATED CAPITAL COST OF AN INDIRECT-FIRED FALLING-

.

. . . .

.

. .

. ...................

22

PARTICLE AIR PREHEATER .................................................................................23

IV

ESTIMATED CAPITAL COST OF AN INDI RECT-FI RED COREDBRICK.AIR PREHEATER...........................

V

COST COMPARISON OF OVERALL INDIRECT-FIRED COREDBRICK AND FALLING-PARTICLE AIR

VI

24

PREHEAT SYSTEMS...................31

CAPITAL COST COMPARISON OF DIRECT AND INDIRECT-FIRED

AIR PREHEAT SYSTEMS.

..................................................................

. . .

c.

• - •• V

,*

.

,.

33

- 'J . v ; . •

'. L s

A , •» „ • ’ ‘

•

-T zk-

*-

\ f i ' I*

V. - . r

.

•

.‘ ' 1

^

/}

.•

^

»

-

■ ' • \ ■'

ix

LIS T OF FIGURES

FIGURE

1

PAGE

CONVENTIONAL TURBINE AND MHD POWER GENERATION

SYSTEMS COMPARISONS....................................................

2

2

COMPARISON OF DIRECT AND INDIRECT-FIRED AIR PREHEAT

SYSTEMS...........................

7

3

CROSS-SECTION OF A CORED-BRICK AIR PREHEATER .................................

IO

4

SIM PLIFIED SCHEMATIC OF FALLING-PARTICLE AIR PREHEATER

12

5

COLUMN INSULATION CROSS-SECTION.

6

AIR PREHEAT SYSTEM WITH COAL CARBONIZER AS FUEL SOURCE

. . .

27

7

AIR PREHEAT SYSTEM WITH COAL GASIFIER AS FUEL SOURCE . . . .

28

8

ENTHALPY OF MHD COAL EXHAUST GAS v s . TEMPERATURE.................... 40

. . . .

.

. . .

. .......................................19

X

■

NOMENCLATURE

(E xclu d es te rm in o lo g y used e x c lu s iv e ly in computer program .

See Appendix

C -7 f o r d e f i n i t i o n s o f program v a r i a b l e s ) .

EXPLANATION

SYMBOL

A

AC

cD

cP

0C

Fd

nT

UNITS

p a r t i c l e s u rfa c e a re a

ft2

p a r t i c l e c r o s s -s e c tio n a l a re a

ft2

drag c o e f f i c i e n t

dim en sionless

s p e c if ic h e a t (c o n s ta n t p re s s u re )

BTUZlbm0F

in s id e column d ia m e te r

ft

drag fo rc e

Ib f

to ta l

number o f ho les in c o r e d -b r ic k

col umn

dim en sionless

Nu

N u s s e lt number, hD/k

Pr

P ra n d tl number, C m/k

P

"

. dim en sionless

R

h e a t t r a n s f e r r e s is ta n c e

°F hr/BTU

Re

Reynolds number, Du^p/y

dim en sionless

St

S ta n to n number, Nu/RePr

dim ensionless

TW

o u ts id e w a ll

te m p e ratu re

. °R

p a r t i c l e te m p e ra tu re

°R

V

gas te m p e ra tu re

°R

T=

am bient te m p e ra tu re

°R

TS

uO

do

o v e r a ll h e a t t r a n s f e r c o e f f i c i e n t

h o le d ia m e te r in c o r e d -b r ic k

B T U Z h rft2oF

ft

Xl

NOMENCLATURE (C o n t)

EXPLANATION

SYMBOL

p a r tic le

d ia m e te r

f

fr ic tio n

fa c to r

g

a c c e le r a tio n o f g r a v it y

dP

g r a v ita tio n a l

9c

c o n s ta n t, 3 2 .1 7

UNITS

ft

d im en sio n less

ft /s e c 2

5'

f t l b m/ l b f sec

h

c o n v e c tiv e h e a t t r a n s f e r c o e f f i c i e n t

B T U Z h rft2oF

k

therm al c o n d u c tiv ity

B T U Z h rft0F

q

h e a t t r a n s f e r r a te

uA

uT

V

.

BTUZhr

gas v e lo c it y

ftZ s e c

p a r t i c l e te rm in a l v e lo c it y

ftZ s e c

p a r t i c l e v e lo c it y

ftZ s e c

gas mass flo w r a te

Ib mZhr

p a r t i c l e mass flo w r a te

I b mZbr ’

“g

wS

X

v e r t ic a l

5

in s u la t io n th ic k n e s s

U

v is c o s it y

pg

ps

0 .

TW

d is ta n c e from to p o f column

ft

ft

lb Z fts e c

gas d e n s ity

1V

p a r t i c l e d e n s ity

Ib mZ f t 3

tim e

shear s tre s s a t w a ll

AX

in c re m e n ta l change in X

ZIP

p re ss u re drop

ft3

sec

Ib f Z ft2

ft

Ib p Z in 2

ABSTRACT

(

A p r e lim in a r y design f o r an i n d i r e c t - f i r e d f a l l i n g - p a r t i c l e a i r

p re h e a te r f o r a 400 MW (t h e r m a l) MHD power g e n e ra tio n p la n t was made.

The p r o je c t was broken down in t o th re e m ajo r p a r ts :

m a te r ia l p ro p e rtie s

p r e d ic t io n , developm ent o f a t h e o r e t ic a l m odel, and c a p it a l and annual

c o s t e s tim a tio n o f th e o v e r a ll d e s ig n .

A t h e o r e t ic a l model was developed f o r an i n d i r e c t - f i r e d c o re d -b ric k

a i r p r e h e a te r .

C a p ita l and annual costs were e s tim a te d and compared to

those o f th e f a l l i n g - p a r t i c l e a i r p r e h e a te r .

It.w a s found t h a t o v e r a ll

a i r p re h e a t systems in v o lv in g these two designs would have a p p ro x im a te ly

th e same c a p it a l costs o f ~ $44 x 1 0 6 , and annual costs o f ^$6 x IO ^.

An economic comparison was then made between o v e r a ll i n d i r e c t - f i r e d

a i r p re h e a t d e s ig n s , and o v e r a ll d i r e c t - f i r e d d e s ig n s .

In both th e ...

f a l l i n g - p a r t i c l e and c o r e d -b r ic k c ases, th e c a p it a l c o s t o f th e i n d i r e c t f i r e d design was a p p ro x im a te ly 50% .g r e a t e r than the c a p it a l c o s t o f the

d i r e c t - f i r e d d e s ig n .

INTRODUCTION

CONVENTIONAL TURBINE AND MHD POWER GENERATION

Magnetohydrodynamic (MHD) power c o n versio n is a method o f g e n e ra tin g

e l e c t r i c i t y w ith fe a tu r e s s im i l a r to those o f a c o n v e n tio n a l steam

t u b r in e d riv e n g e n e ra to r.

These s i m i l a r i t i e s w i l l be d is c u s s e d , and then

fe a tu r e s p e c u lia r to MHD power con versio n w i l l

F ig u re I

illu s tr a te s

be d is c u s s e d .

a v e ry s im p l i f i e d steam tu r b in e d riv e n

g e n e ra to r and a MHD g e n e ra to r.

In th e case o f the steam tu rb in e g e n e ra to r,

th e th erm al energy o f h o t combustion products (form ed by th e b u rn in g o f

some f o s s il

to steam .

fu e l)

is tra n s fo rm e d in t o l a t e n t energy by v a p o riz in g w a te r

The tra n s fo rm a tio n to m echanical energy is accom plished by

expanding th e steam a g a in s t tu r b in e b la d e s .

r o ta te s a co n ductor (t h e a rm a tu re )

s ta to r).

F i n a l l y , th e tu r b in e s h a f t

in a s t a t io n a r y m agnetic f i e l d

(th e

As the lin e s o f m agnetic f l u x a re b ro k en , a n e t e le c tro m o tiv e

fo rc e and r e s u lt in g c u r r e n t flo w is c re a te d in accordance w ith F a rad a y 's

laws o f in d u c tio n .

I t should be p o in te d o u t t h a t th e w o rkin g gas in the

t u r b in e c o u ld be any h o t , high p re s s u re g a s, as w e ll as steam .

• The MHD power co n ve rs io n system has a number o f s i m i l a r i t i e s

-tu rb in e g e n e r a to r.

In th e MHD c a s e , th e conductor which breaks the lin e s

o f m agnetic fo rc e o f th e s t a t io n a r y m agnetic f i e l d

c o n d u c tin g f l u i d ,

co n d u c tin g f l u i d

to th e

u s u a lly a gas.

is a h o t , e l e c t r i c a l l y

Thus th e therm al energy o f th e

is tra n s fo rm e d d i r e c t l y to e l e c t r i c a l e n e rg y .

The

system c o n s is ts o f an expanding d u ct through which th e h o t gas flo w s ,

which is lin e d on two o p p o s ite s id e s w ith e le c tr o d e s .

The e le c tro d e s

■ 2 -

E le c tr ic a l

Thermal

K in e tic

Mechanical

Brushes

Arm ature

T u rb in e

S ta to r

Steam

Hot Combustion Products

E le c tr ic a l

Thermal

H ot Cond.

Exhaust

E le c tro d e s

E lec tro m a g n e t

FIGURE I .

CONVENTIONAL TURBINE AND MHD POWER GENERATION

SYSTEMS COMPARISONS

- 3 c a r r y th e c u r r e n t to th e e x te r n a l lo a d c i r c u i t in the same fashion*

as

th e brushes in th e c o n v e n tio n a l g e n e ra to r.

. I t should be noted here t h a t th e r o t a t io n a l m otion o f th e arm ature

in a c o n v e n tio n a l g e n e ra to r c re a te s a a lt e r n a t i n g c u r r e n t , whereas th e

co n tin u o u s m otion o f th e gas p a s t th e e le c tro d e s in an MHD g e n e ra to r

c r e a te s d i r e c t c u r r e n t .

The two types o f MHD systems p o s s ib le a re open c y c le and clo sed

c y c le .

In th e c lo sed c y c le case, th e conducting f l u i d

re g e n e ra te d through the use o f h e a t e xch an g ers.

o f system a re c y c le s in v o lv in g

is re c y c le d and

Examples o f t h i s ty p e

noble g a se s , and l i q u i d m e ta ls .

In the

open c y c le c a s e , th e co n d u ctin g f l u i d passes through th e MHD d u c t o n ly

once.

S in ce t h i s

paper is d ir e c te d tow ard th e design o f h e a t exchange

components f o r open c y c le d f o s s i l - f u e l e d MHD systems th e c lo s e d c y c le

system w i l l

n o t be discussed f u r t h e r .

In an open c y c le MHD system , th e h o t gas (com bustion products o f

some f o s s i l

fu e l)

is made an e l e c t r i c a l

s ee d , such as KgO o r KgCOg.

conductor by th e a d d itio n o f a

The low io n iz a t io n p o te n tia l o f th e seed

en ab les a f r e e flo w o f e le c tr o n s w it h in th e gas.

th is

typ e is c a lle d a plasm a.

The e l e c t r i c a l

^ c o n d u c tin g

gas o f

c o n d u c tiv ity o f th e gas is

a r e l a t i v e measure o f th e ease in which th e gas w i l l conduct e l e c t r i c i t y .

The optimum seed c o n c e n tra tio n is about 1-5% b y .w e ig h t ( 1 , 2 ) .

-J-:;

•

..

■■ :

■:

: V - '

' v.

.

■■

.v; i V-.-v

- v :■V.'. v,-. ~ ...

:..

{.

/

•

- 4 -

COMPARISON OF EFFICIENCIES

In th e ty p e o f power co n ve rs io n systems discussed so f a r ,

therm o­

dynamic e f f i c ie n c y is o p tim iz e d by m axim izing th e te m p e ra tu re o f th e

w o rkin g gas.

The presence o f h ig h ly s tre s s e d moving p a rts in a tu r b in e

g e n e ra to r becomes th e l i m i t i n g f a c t o r in th e w orking gas te m p e ra tu re ,

and thus in th e g e n e ra to r e f f i c i e n c y .

tr ic a l

As a r e s u l t o f t h i s , th e e le c ­

e f f i c i e n c i e s o b ta in e d in c o n v e n tio n a l steam tu r b in e power p la n ts

is between 30-45% .

In th e case o f MHD system s, no moving o r h ig h ly

s tre s s e d p a rts a re p re s e n t, and a l l

e x te r n a l

c o o lin g .

p a rts a re r e a d ily a c c e s s ib le to

Thus th e l i m i t i n g

f a c t o r in MHD e f f i c i e n c y is th e

te m p e ra tu re o f th e w orking gas i t s e l f , which can be much h ig h e r than th e

maximum te m p e ra tu re in a t u r b in e .

It

is fo re s e e n t h a t w orking gas

. te m p e ratu re s as h ig h as 5 0 0 0 -6 0 0 0 °F a re p o s s ib le f o r MHD a p p lic a t io n s .

E f f i c i e n c i e s o f systems em ploying p re s e n t te c h n o lo g y are p re d ic te d to be

about 50%.

as 60%.

Advanced systems a re fo re s e e n to have e f f i c i e n c i e s

as high

As a f u r t h e r comparison th e average e f f i c ie n c y o f a n u c le a r

f i s s i o n power g e n e ra tin g f a c i l i t y

is

32%.

Thus an advanced MHD p la n t

would have 1 .5 tim es the. e f f i c i e n c y o f a c o n v e n tio n a l steam tu r b in e p la n t,

and 1 ,9 tim e s th e e f f i c ie n c y o f a c o n v e n tio n a l n u c le a r p la n t .

I t should

be noted here t h a t th e advantage o f an MHD system is n o t is high e f f i ­

c ie n c y a lo n e , b u t i t s

a b ility

to c o n v e rt therm al to e l e c t r i c a l

in much h ig h e r te m p e ra tu re ranges th a n tu r b in e g e n e ra to rs .

energy

As a r e s u l t ,

th e exhaust gases from th e MHD d u c t would be tr a n s f e r r e d t o . a conven-

- 5 .t io n a l

gas o r steam tu r b in e g e n e ra tin g f a c i l i t y ,

The t o t a l

o r "bottom ing" p la n t .

power o u tp u t o f t h e . f a c i l i t y . w o u l d be about e v e n ly d iv id e d

between th e MHD -p la n t and the b ottom in g p la n t ( 1 , 3 ) .

THE NEED FOR PREHEATED AIR

The w o rking gas te m p e ratu re s necessary f o r e f f i c i e n t MHD power

g e n e ra tio n a re w e ll above gas te m p e ratu re s a c c e s s ib le .b y c o n v e n tio n a l

com bustion methods.

The combustion o f coal W ith am bient a i r g ives a

maximum te m p e ra tu re o f about 3 00 0 °F .

However, e f f i c i e n t MHD power

g e n e ra tio n re q u ire s a te m p e ra tu re o f about SOOO0F.

a v a ila b le in a c h ie v in g t h i s te m p e ra tu re .

oxygen.

Two methods a re

The f i r s t is th e use o f excess

In view o f th e high c o s t o f a f a c i l i t y

capable o f producing

th e amounts o f oxygen which would be necessary f o r a commercial s c a le

MHD i n s t a l l a t i o n , t h i s method is looked upon as uneconom ical w ith p re s e n t

te c h n o lo g y .

The second method in v o lv e s p re h e a tin g th e combustion a i r

b e fo re i t

used to burn th e c o a l.

is

e x t e n s iv e ly in th e s te e l

in d u s tr y .

T h is method has been used

C o n ven tio n al tube and s h e ll h e a t

exchangers can be used to p re h e a t a i r to about 1 70 0 °F .

To reach th e

te m p e ra tu re necessary f o r MHD power g e n e r a tio n , an a i r p re h e a t tem per­

a tu r e o f ab o u t SlOO0F is r e q u ir e d .

needed which w i l l

Thus a h e a t exchange system is

r a is e th e te m p e ra tu re o f a i r from 1 7 0 0 °F to 310 0 °F .

A number o f systems a re p r e s e n tly b e in g looked a t .

V-

.w

_-

, . '

.A .*

‘ -S'/..?

•

I'

V.... ■ •

-... V/

. . .-v -

.■

..

w . v -V . ! ...... .

■■■•

■■■

-

6

-

DIRECT AND INDIRECT-FIRED AIR PREHEATERS '

A i r p re h e a te rs a re o f two b a s ic ty p e s a cc o rd in g to how th e y f i t

i n t o th e o v e r a ll MHD process - d i r e c t - f i r e d and i n d i r e c t - f i r e d , as shown

in F ig u re 2 .

The d i r e c t - f i r e d

a i r p re h e a te r u t i l i z e s

th e therm al energy

o f th e MHD exh au st gas, which le a v e s th e MHD d u c t a t about 3 3 0 0 °F , to

d i r e c t l y p re h e a t a i r .

The i n d i r e c t - f i r e d a i r p re h e a te r u t i l i z e s

the

th e rm a l energy o f exhaust from a s e p a r a te ly f i r e d c le a n fu e l combustor

to p re h e a t th e combustion a i r .

d is a d v a n ta g e s .

The d i r e c t - f i r e d design has th re e b a s ic

F i r s t , th e MHD exh au st is

s la g , both o f which a re h ig h ly c o r r o s iv e .

laden w ith v a p o riz e d seed and

Second, as th e exh a u s t gas

t r a n s fe r s h e a t in t h e . a i r p r e h e a te r , both th e seed and s la g condense,

c o a tin g th e in t e r n a l works o f th e p r e h e a te r .

This s o lid re s id u e would

have to be c o n tin u o u s ly removed, not o n ly from an o p e ra tio n s s ta n d p o in t,

b u t a ls o because th e c o s t o f th e seed makes re c y c le im p e r a tiv e .

T h ir d ,

th e i n l e t p ressu re to th e MHD d u c t must be ~8 atm in o rd e r t h a t th e gas

can push i t s e l f through the d u c t.

As a r e s u l t o f t h i s , th e p reheated

com bustion a i r must be p re s s u riz e d to 8 atm .

p re s s u re from th e MHD d u c t is

d iffe r e n tia l

atm.

However, th e o u t l e t

Thus, th e re w i l l

be a pressure

o f ^6 % atm . between th e exh a u s t gas s id e and th e a i r s id e

o f th e p r e h e a te r .

d is a d v a n ta g e s .

a re e n c o u n te re d .

The i n d i r e c t - f i r e d a i r p re h e a te r has none o f these

S in c e .th e fu e l is c le a n , no problems w ith seed and s la g

A ls o , s in c e th e i n l e t p ressu re o f th e combustion

products o f th e fu e l can be a r b i t r a r i l y

:• .... V -:, .-V;

v .. ■:-> V:.

s e t , the h o t gas s id e and th e

-

. - v . v ; - v V v v v -

':V.;

Vv

- 7 Power Out

DIRECT-FIRED AIR PREHEATER

A ir

In v e r te r

Power Out

Steam

Supply

Heat

A ir

P reh e a t

MHD Duct

Feed A ir ^ lO O 0F

INDIRECT-FIRED AIR PREHEATER

FIGURE 2 .

Clean w

F u e l-Z -

P reheater

COMPARISON OF DIRECT AND INDIRECT-FIRED AIR

PREHEAT SYSTEMS

- 8 -

a i r s id e o f th e p re h e a te r can be run a t a 1 :1 pressure r a t i o .

The main

d is ad v a n ta g e o f th e i n d i r e c t - f . i r e d a i r p re h e a te r is t h a t , s in c e a

s e p a ra te c le a n fu e l must be employed, ~ 2 p o in ts in o v e r a ll c y c le

e ffic ie n c y w ill

be l o s t ( 5 , 8 ) .

A lso th e need f o r a c le a n fu e l

is a

d is a d v a n ta g e .

GENERAL AIR PREHEATER DESIGN

S ince c o n v e n tio n a l lo w -te m p e ra tu re h e a t exchange m a te r ia ls and

design a re in a d eq u a te f o r h ig h -te m p e ra tu re a i r p re h e a te r a p p lic a t io n s ,

new m a te r ia ls and designs must be c o n s id e re d .

M a te r ia ls most l i k e l y

to be a b le to w ith s ta n d h ig h -te m p e ra tu re c o rro s io n and therm al s tre s s

a re o f th e r e f r a c t o r y ty p e .

The m a te r ia l

used f o r th e h e a t - t r a n s f e r

medium should have a high therm al c o n d u c tiv ity and h e a t c a p a c ity fo r

e f f ic ie n t heat tra n s fe r.

The th re e most p o p u la r c a n d id a te s , in o rd e r

o f in c re a s in g c o s t, a re alum ina ( A ^ O g ) , magnesia (M gO ), and z ir c o n ia

(Z r O g ).

M a te r ia ls o f t h i s

ty p e a re employed in th e design o f both th e

h e a t t r a n s f e r medium and th e e x te r n a l

in s u la t io n o f th e a i r p re h e a te r.

O f th e many a i r p re h e a te r designs p r e s e n tly being re s e a rc h e d , two

w i l l be focused upon.

th e f a l l i n g - p a r t i c l e

These are the c o r e d -b r ic k a i r p r e h e a te r , and

a i r p r e h e a te r.

The c o r e d -b r ic k a i r p re h e a te r is b a s i c a ll y an in s u la te d column

packed w ith l o n g i t u d i n a ll y cored r e f r a c t o r y b ric k s o f high h e a t c a p a c ity .

A c r o s s -s e c tio n o f a t y p ic a l

c o r e d -b r ic k a i r p re h e a te r is shown in

- 9 F ig u re 3 .

The s e p a ra te b ric k s

a re o f hexagonal c ro s s -s e c tio n and th e

core d ia m e te r ranges from 0 .2 5 inches to 0 .7 5 inches ( 4 , 1 1 ) .

method o f o p e ra tio n is as fo llo w s :

The

th e a i r p re h e a te r column is s u it a b ly

v alv ed a t each end so t h a t h o t gas o r a i r can a l t e r n a t i v e l y be run

through th e column, in c o u n te rc u rre n t d ir e c t io n s .

In itia lly ,

b r ic k s a re heated f o r a s p e c ifie d p e rio d o f tim e by h o t.g a s .

is heated by ru n n in g i t

o f tim e .

th e cored

Then a i r

through .the colum n, a ls o f o r a s p e c ifie d amount

A problem is t h a t th e a i r o u tp u t is o f a c y c lic n a tu r e , w h ile

th e MHD process re q u ire s a c o n s ta n t flo w r a te o f combustion a i r .

T h is

problem is s o lv e d .b y th e use o f a number o f c o r e d -b r ic k a i r p re h e a te rs

o p e ra tin g in a c o ntinuous c y c le to o u tp u t a c o n s ta n t a i r flo w r a t e and

te m p e ra tu re .

The g r e a t e s t amount o f h e a t t r a n s f e r p e r u n it volume

(and th e r e f o r e th e h ig h e s t a i r p re h e a t te m p e ra tu re ) is o b ta in e d w ith

th e s m a lle s t flo w passage d ia m e te r, 0 .2 5 in c h e s .

problem in th e i n d i r e c t - f i r e d c as e .

T h is p re s e n ts no

However, in the d i r e c t - f i r e d

case,

c lo g g in g o f th e flo w passages by condensing seed and s la g re q u ire s t h a t

th e passage d ia m e te r be on th e o rd e r o f 0 .7 5 inches f o r e f f e c t i v e

o p e r a tio n .

Thus, f o r a g iv en a i r p re h e a t te m p e ra tu re , th e d i r e c t - f i r e d

a i r p re h e a te r w i l l

be o f c o n s id e ra b ly l a r g e r . s i z e th a n th e i n d i r e c t -

f i r e d a i r p r e h e a te r .

An im p o rta n t p o in t is t h a t therm al expansion o f

r e f r a c t o r y m a te r ia ls in th e s e te m p e ra tu re ranges is c o n s id e ra b le , and

must be accounted f o r in th e o v e r a ll column design ( 4 , 5 ) .

The f a l l i n g - p a r t i c l e

a i r p re h e a te r is shown by s im p l i f i e d schem atic

- 10 CORED ERICK MATRIX CONFIGURATION

1/4 INCH DIAMETER HOLE

O _ O

O _ O

O

FIGURE 3.

-o

CROSS-SECTION OF A CORED-BRICK AIR PREHEATER

- 11 in F ig u re 4 .

th e o th e r .

The design c o n s is ts o f two v e r t i c a l colum ns, one above

Small

0 .0 5 inch d ia m e te r) r e f r a c t o r y p a r t i c l e s

fa ll

through th e upper chamber, a re h e ld up a t th e in t e r f a c e between the

cham bers, and then f a l l

through th e lower, chamber.

The p a r t i c l e s are

th en r e tu rn e d to th e to p o f th e upper chamber by a pneum atic b lo w e r,

co m p letin g th e c y c le .

A t th e to p o f each chamber is a d i s t r i b u t o r

p la t e which spreads th e p a r t i c l e s e v e n ly across th e chamber d ia m e te r.

Hot gas (th e h e a tin g f l u i d )

e n te rs th e bottom o f th e upper chamber,

flo w s up th e chamber c o u n te rc u rre n t to th e flo w o f p a r t i c l e s , and e x it s

a t th e to p o f th e chamber through an exh au st m a n ifo ld ..

As th e gas

flo w s p a s t th e p a r t i c l e s , therm al energy is t r a n s fe r r e d to th e p a r t i c l e s .

In s im i l a r fa s h io n , a i r e n te rs the bottom o f th e lo w er chamber, flow s

upward c o u n te rc u rre n t to th e p a r t i c l e f lo w , and e x it s

m a n ifo ld .

through an exhaust

As th e a i r flo w s p a s t th e heated p a r t i c l e s , therm al energy

is t r a n s fe r r e d to th e a i r .

It

should be noted here t h a t th e design shown

in F ig u re 4 is s p e c if ic f o r th e i n d i r e c t - f i r e d c as e .

S ince both the

upper and lo w e r chambers a re a t n e a r ly th e same p re ss u re (~ 8 a tm ),

th e w e ig h t o f a number o f f e e t o f p a r t i c l e s

a t th e i n t e r f a c e between

th e chambers should o f f s e t any lea k ag e o f a i r o r hot gas.

However,

s in c e such a la r g e p re s s u re d i f f e r e n t i a l e x is ts between th e upper and

lo w er chambers in th e d i r e c t - f i r e d

c a s e , a complex v a lv in g mechanism o f

some s o r t must be d evised to p e rm it continuous flo w o f p a r t i c l e s

th e upper to lo w e r chamber, and m in im ize a i r ,le a k a g e .

from

U n lik e th e c o re d -

- 12 Exhaust Gas

P ~ 8 atm .

C lean Comb. Gas

T ~ 3500°F

A i r to MHD

M i-T e m p e ratu re

Pneumatic

Blow er

A ir

In le t

FIGURE 4 .

SIM PLIFIED SCHEMATIC OF FALLING-PARTICLE AIR

PREHEATER

- 13 b r ic k a i r p r e h e a te r , th e f a l l i n g

p a r t i c l e a i r p re h e a te r is a continuous

p ro c e s s , o u tp u ttin g a c o n s ta n t flo w r a t e and te m p e ratu re o f combustion

a ir .

Thus, c y c lic o p e ra tio n and i t s

complex v a lv in g a re unnecessary.

MODEL DEVELOPMENT AND DESIGN OF

FALLING-PARTICLE AIR .'PREHEATER

INTRODUCTION

A t h e o r e t ic a l model o f th e f a l l i n g

assembled on computer by W. E. G e n e t t i.

p a r t i c l e a i r p r e h e a te r was

A p r e lim in a r y design was then

made based on th e r e s u lt s o f th e model d a ta .

c a l l y w ith th e design o f an i n d i r e c t - f i r e d

h e a te r.

fa llin g

A ls o , a design f o r an i n d i r e c t - f i r e d

was made.

v ie w p o in t.

T h is th e s is d e a ls s p e c i f i ­

p a r t i c l e a i r p re ­

c o r e d -b r ic k a i r p re h e a te r

The two designs a re compared from both a s t r u c t u r a l and c o s t

In a d d it io n , a co st t r a d e o f f a n a ly s is is made f o r both th e

f a l l i n g - p a r t i c l e and c o r e d -b r ic k designs between th e i n d i r e c t - f i r e d and

th e d i r e c t - f i r e d

c ases.

Design and c o s t d a ta f o r d i r e c t - f i r e d

a ir

p re h e a te rs were p ro v id ed by W. E. G e n e tti and R. L . Mussulman.

PREDICTION OF MATERIAL PROPERTIES

As a p re lu d e to model developm ent o f th e a i r p r e h e a te r , e q u atio n s

were developed to p r e d ic t th e g e n era l p r o p e r tie s o f th e m a te r ia ls in v o lv e d

in th e d esig n f o r th e necessary te m p e ra tu re and p re ss u re ra n g e s .

m a te r ia ls in c lu d e th e h o t exh au st gases (h e a tin g f l u i d ) , a i r

f l u i d ) , fa llin g

(h e a te d

r e f r a c t o r y p a r t i c l e s , and i n s u la t io n .

As m entioned e a r l i e r , a s e p a ra te c le a n fu e l

a i r . p r e h e a te r .

The

This fu e l could be f u e l o i l ,

produced from th e d e v o l a t i l i z a t i o n . o f c o a l.

a v a i l a b i l i t y o f fu e l o i l and n a tu ra l

is n e e d e d .to f i r e

n a tu ra l

th e

g as, o r a fu e l

In view o f th e c o s t and

g a s, a fu e l produced from coal

- 15 d e v o l a t i l i z a t i o n was c a lle d f o r in th e o r ig in a l d e s ig n .

T h is fu e l

is

produced by th e h e a tin g o f coal to around 2 0 0 0 °F in th e absence o f

a i r , d r iv in g o f f th e v o l a t i l e , m a tte r as a gas w ith a h e a tin g v a lu e o f

O

ab o u t 575 B T U /ft .

T h is process is a ls o c a lle d c a r b o n iz a tio n .

C a rb o n iz a tio n o f 2000 lb o f coal y ie ld s about 1 1 ,0 0 0 f t ^

p lu s about 1400 lb o f coke.

o f coal g a s,

The c o n s t itu te n ts o f th e coal gas and i t s

products o f combustion a re presen ted in Appendix A.

E q u atio ns f o r th e fo llo w in g g e n e ra l p r o p e r tie s f o r a i r and th e

h o t exh au st gases were developed:

and h e a t c a p a c it y , a l l

v is c o s it y , therm al c o n d u c tiv ity ,

as a fu n c tio n o f te m p e ra tu re , and d e n s ity as

a fu n c tio n o f te m p e ra tu re , and p re s s u re .

These e q u a tio n s , along

w ith o th e r p e r t in e n t m a te r ia l p r o p e r tie s a re presented in Appendix A.

GENERAL DESIGN CONSIDERATIONS

A l l p re h e a te r desig n w o rk , both f o r t h i s r e p o r t and f o r th e G e n e t t iMussulman d e s ig n , was done on th e b a sis o f a 400 megawatt (th e rm a l) MHD

power g e n e ra tio n f a c i l i t y .

power in p u t to th e MHD .d u c t.

r e a c tio n and i t s

The th erm al power r a t in g is d e fin e d as th e

The s to ic h io m e try o f the. MHD combustion

r e la t e d mass b a lan c e s a re presen ted in Appendix B - I .

As

is evidenced by th e a i r re q u ire m e n t f o r th e combustion r e a c t i o n , th e a i r

p re h e a te r must supply 1 .2 7 9 .x IO 6 I b r a i r / h r to th e com bustor.

As p r e v i ­

o u s ly m e n tio n e d , th e te m p e ra tu re o f th e preh eated a i r m ust-be about SlOO0 F

-

16

-

S in ce c o n v e n tio n a l s h e ll-a n d -t u b e h e a t exchangers a re cap a b le o f producing

a i r te m p e ratu re s o f 1700 F , t h is is assumed to be th e a i r i n l e t te m p e ra tu re

o f th e a i r p r e h e a te r .

W ith these p aram eters s e t , th e h e a t t r a n s f e r r a t e

to th e a i r in th e p re h e a te r can be c a lc u la te d (Appendix B - 3 ) .

found to be 5 .1 5 5 x IO^ B T U /h r.

This was

I t should be noted a t t h i s p o in t t h a t

t h i s design f o r a 400 MW h eat.e x ch an g e f a c i l i t y

c a lls f o r th re e a i r

p re h e a te r colum ns, two running s im u lta n e o u s ly in p a r a l l e l , and one s p a re .

5

Thus, f o r one column, th e a i r flo w r a te would be 6 .3 9 5 x 10

I b / h r and

th e h e a t t r a n s f e r r a t e to th e a i r would be 2 .5 7 8 x 10^ B T U /h r.

PARTICLE SIZE DISTRIBUTION

The n e x t s te p in model development was to o b ta in a r e a l i s t i c

d i s t r i b u t i o n o f th e alum ina p a r t i c l e s .

s iz e

I t was found t h a t th e ta b u la r

alu m in a s to c k s u p p lie d by the Aluminum Company o f America would have to

be c l a s s i f i e d , narrow ing th e p a r t i c l e s iz e d i s t r i b u t i o n down to usable

ra n g e s .

Two p a r t i c l e s iz e ranges were in v e s tig a te d . . I n

th e la r g e s t p a r t i c l e d ia m e te r is 0 .0 5 i n .

The wide d i s t r i b u t i o n

0 .0 3 8 - 0 .0 5 i n . d ia m e te r, and the narrow d i s t r i b u t i o n

d ia m e te r.

e i t h e r case,

is

is 0 .0 4 2 - 0 .0 5 i n .

These d is t r ib u t io n s w i l l be r e f e r r e d to as "b lo w o u ts ", s in c e

any p a r t i c l e s m a lle r th an th e in c lu d e d range would blow o u t th e to p o f

th e chamber.

Appendix C -I .

These two p a r t i c l e s iz e d is t r ib u t io n s a re l i s t e d

in

- 17 PARTICLE TERMINAL VELOCITIES AND CHAMBER DIAMETER

The in s id e d ia m e te r o f th e chamber is a fu n c tio n o f th e te rm in a l

v e l o c i t y o f th e p a r t i c l e s .

The te rm in a l v e l o c i t y o f a p a r t i c l e

d e fin e d as t h a t v e lo c it y a t which th e f a l l i n g

is

p a r t i c l e stops a c c e le r a t in g .

In o th e r w o r d s ,s in c e drag in c re a s e s as v e lo c it y in c re a s e s , i t

is th e

maximum a t t a i n a b l e v e lo c it y o f th e p a r t i c l e

The

in a given f l u i d .

te rm in a l v e l o c i t i e s o f th e s m a lle s t p a r t i c l e s were c a lc u la t e d , sin ce

th e y would be th e f i r s t to “blow o u t" .

The maximum g a s .v e lo c it y ( a t

maximum te m p e ra tu re ) was then taken to be 100% o f t h i s te rm in a l v e l o c i t y .

Thus, s in c e th e a i r mass flo w r a t e is known, th e a i r chamber d ia m e te r

can be c a lc u la t e d .

These c a lc u la t io n s a re p resen ted in Appendix C -2 .

A t t h is p o in t , i t was i n i t i a l l y

were z e r o ; thus

= qga s -

assumed t h a t chamber h e a t losses

In t h is m anner, a gas mass flo w r a te was

found and gas chamber d ia m e te r c a lc u la t e d in analogous .fa s h io n to th e

a i r chamber d ia m e te r, as p re se n te d in Appendix C -2 .

r a te is 6 .5 2 x IO^ I b / h r .

The gas mass flo w

The in s id e dia m e te rs o f th e gas and a i r

chambers a r e , r e s p e c t iv e ly , 1 4 .2 f e e t and 1 1 .1 f e e t ( f o r th e 0 .0 4 2 inch

blow out c a s e ).

DETERMINATION OF INSULATION THICKNESS

The th ic k n e s s o f in s u la t io n needed to e f f e c t i v e l y in s u la t e th e

column was now d e te rm in e d .

P ro p e rtie s o f th e in s u la tio n

used are

p re se n te d in Appendix A -6 .

A t r i a l - a n d - e r r o r s o lu tio n to th e in s u la tio n

18 th ic k n e s s was made fo llo w in g

th e procedure presen ted in Appendix C -3 ,

w ith th e l i m i t i n g c o n d itio n t h a t th e maximum o u te r w a ll te m p e ra tu re

should n o t be above % 2 5 0 °F .

an o v e r a ll

The r e s u lt in g w a ll c r o s s -s e c t io n , having

th ic k n e s s o f 3 .5 f e e t ,

is shown in F ig u re 5 .

OVERALL HEAT LOSS TO SURROUNDINGS

W ith th e w a ll c ro s s -s e c tio n known, th e r a t e o f h e a t lo s s through

th e w a ll

can now be d e te rm in e d .

The h e a t t r a n s f e r e q u a tio n developed

in Appendix C -3 is used to f in d th e o u te r w a ll

v alu e s o f gas te m p e ra tu re .

Then (q /A ) loss is found a t each o f these

te m p e ra tu re s , and a curve is f i t

is

(q /A )i

te m p e ra tu re a t v a rio u s

as a fu n c tio n o f Tg.

to th e d a ta .

The r e s u lt in g eq u atio n

These c a lc u la t io n s a re r e la t e d in

Appendix C -4 .

O v e ra ll a i r p re h e a te r h e a t lo s se s can now be c a lc u la t e d .

o v e r a ll

The

lo sses are assumed to be the sum o f th e h e at losses in the a i r

and gas cham bers, p lu s th e h e a t lo s s from th e p a r t i c l e r e c y c le system .

The fo llo w in g two assum ptions must be made:

1.

The h e ig h ts o f th e gas and a i r chambers are 20 f e e t and

30 f e e t ,

2.

r e s p e c t iv e ly .

The h e a t lo s s from th e p a r t i c l e

re c y c le system is approxim ated

by th e a r it h m e t ic average o f th e h e a t losses from th e gas and

a i r chambers.

T h is p ro ced u re is o u tlin e d in Appendix C -5 .

W ith th e o v e r a ll h e a t

-

ro

(4 )

(3 )

r2

(2 )

^

(I)

r.

I

O u ter Wall

In n e r Wall

I

r3

19 -

3

................ -V T ^—

1 .1 2 5 f t

A r4

1 .1 2 5

ir 3

(I)

Norton AH-199B

(2 )

Norton AN-599

(3 )

J o h n s -M a n v ille JM -3000

(4 )

J o h n s -M a n v ille JM-23

FIGURE 5 .

-------------- t+ d ----------------- H

0 .7 5 f t

0 .5 0 f t

A r2

A r1

COLUMN INSULATION CROSS-SECTION

— 20 -

lo s s known, th e amount o f h e a t tr a n s fe r r e d from th e h o t gas to the

p a r tic le s

can be d e te rm in e d , and a r e f in e d v a lu e f o r th e gas e x i t

te m p e ra tu re is found to be 2 3 3 0 °F .

The average p a r t i c l e te m p e ra tu re

between th e chambers is assumed to be th e average o f th e bottom gas

te m p e ra tu re and th e to p a i r te m p e ra tu re , o r 3 30 0 °F .

te m p e ra tu re in th e p a r t i c l e

re c y c le system is

The average p a r t i c l e

s p e c ifie d to be th e average

o f th e to p gas te m p e ra tu re and th e bottom a i r te m p e ra tu re , o r 2 0 1 5 °F.

T h is method o f e s tim a tin g th e chamber h e ig h ts to a r r iv e a t th e o v e r a ll

h e a t lo sses is assumed to be r ig o r o u s , s in c e h e a t losses amount to o n ly

~ 0.2% o f th e t o t a l h e a t t r a n s f e r r a t e .

Now t h a t a l l

h e a t t r a n s f e r r a te s a re known, the p a r t i c l e mass flo w

r a t e is c a lc u la t e d to be 6 .5 4 x IO^ I b / h r .

DEVELOPMENT OF MODEL. DESIGN COMPUTER PROGRAM

A computer program was developed to a s s is t in th e p r e lim in a r y

design o f th e a i r p r e h e a te r .

The o p e ra tio n o f th e program in v o lv e s

th e s o lu tio n o f th re e sim ultaneous d i f f e r e n t i a l

b alan ce between p a r t i c l e s

e q u a tio n s :

and a i r across a d i f f e r e n t i a l

a momentum b a lan c e on a f a l l i n g

an energy

elem ent o f tim e ,

p a r t i c l e , and an o v e r a ll energy b a la n c e ,

in c lu d in g h e a t lo s s e s , across a d i f f e r e n t i a l

balan ces a r e developed in Appendix C -6 .

column e le m e n t.

D e f in it io n s o f a l l

These

program

v a r ia b le s , a program l i s t i n g , and a program o u tp u t are p re se n te d in

Appendix C -7 .

As can be s ee n , th e program o u tp u t g iv es a l i s t i n g o f

im p o r ta n t chamber parameters in .in c r e m e n t s o f h e i g h t , s t a r t i n g a t th e to p

o f th e gas o r a i r column and.moving down.

Based on t h i s data and data

a lr e a d y p re s e n te d , o v e r a l l chamber dimensions can be c a l c u l a t e d .

are l i s t e d

These

in T a b le I .

TABLE I .

FALLING PARTICLE CHAMBER DIMENSIONS

Gas Chamber

A i r Chamber

Blowout ( i n . )

.0 3 8

.042

.03 8

.042

In s id e D ia m eter ( f t )

1 5 .1

1 4 .2

1 1 .8 4

1 1.1

O utside D ia m eter ( f t )

2 2 .1

2 1 .2

1 8 .8 4

1 8.1

Chamber H e ig h t ( f t )

2 0 .5

1 4 .2

3 9 .8

3 0 .0

Gas Mass Flow Rate ( I b / h r )

6 .5 2 x l0 5

Max. Gas V e l o c i t y ( f t / s e c )

1 8 .9

6 .5 2 x l0 5

6 .3 9 5 x l0 5

2 1 .5

Gas I n l e t Temperature ( 0F)

3500

3500

Gas E x i t Temperature ( 0F)

2330

2330

1 8 .3 4

.

6 .3 9 5 x l0 5

2 0 .8 8

1700

1700

3100

3100

MODEL DEVELOPMENT AND DESIGN .OF CORED-BRICK. AIR PREHEATER

A model was developed to s i z e an i n d i r e c t - f i r e d cored b r i c k a i r

p r e h e a tin g system.

It

i s assumed t h a t a 400 megawatt (th e rm a l) power

g e n e r a tio n f a c i l i t y would r e q u i r e an a i r p r e h e a te r system c o n s is t in g o f

seven s e p a r a te cored b r i c k chambers, s i x on l i n e w i t h one s p a r e .

At

any given ti m e , two columns would be h e a t in g a i r o r be being heated by

-

h o t gas.

22 -

The model c o n s is ts o f an energy b a lance across a d i f f e r e n t i a l

elem ent o f chamber a r e a , assuming th e b r ic k s to be i s o t h e r m a l .

For the

i n d i r e c t - f i r e d c a s e , b r ic k s w i t h . 0 .2 5 inch d ia m e te r holes a re used.

T h is h o le s i z e giv es th e b r i c k s a c r o s s - s e c t io n a l

25%.

g e om etric p o r o s i t y o f

C o n v e ctiv e h e at t r a n s f e r data ( 1 7 ) f o r h e a t t r a n s f e r c o e f f i c i e n t s

i n c i r c u l a r tubes is used.

Pressure d ro p , as w e ll as volume, must be

o p tim iz e d t o g iv e th e b e s t d e s ig n .

Appendix D.

Model development i s p resented in

An i n s u l a t i o n th ic k n e s s o f 3 .5 ' f t

is assumed.

The chamber

dimensions r e s u l t i n g from t h i s model a re presented in T a b le I I .

TABLE I I .

CORED BRICK CHAMBER DIMENSIONS

Hole D iam eter ( i n . )

0 .2 5

O v e r a ll H e ig h t ( f t )

2 3 .3

In s id e D iam eter ( f t )

8 .9

O utside D iam eter ( f t )

15.9

AT

- A i r Flow ( 0F)

aV

155

AT

- Gas Flow ( 0F)

dv

100

Pressure Drop, psi

4 .4 3

. COST SUMMARY FOR IN D IR E C T-F IRED

• AIR PREHEATERS

FALLING-PARTICLE AIR PREHEATERS

C a p it a l

c o s t p r e d i c t i o n f o r th e i n d i r e c t - f i r e d f a l l i n g - p a r t i c l e a i r

p r e h e a te r is developed i n Appendix E..

o n ly .

T a b le I I I

These costs are f o r one u n i t

gives c o s t data f o r both, one u n i t and f o r an o v e r a l l

t h r e e - u n i t system.

TABLE I I I .

ESTIMATED CAPITAL COST OF INDIRECT-FIRED

FALLING-PARTICLE AIR PREHEATER

0 .0 3 8 i n . Blowout

U n i t Cost

T o ta l C o s t*

0 .0 4 2 in . Blowout

U n it Cost

T o ta l C ost*

$ 2 .2 7 x l0 6

$ 6 . S lx l O 6

$ 1 .7 2 x l0 6

$ 5 .2 x l0 6

1 .7 3 x l0 6

5 . ID x lO 6

1 .3 3 x l0 6

5 . OxlO6

Alumina P a r t i c l e s

.1 2 x l0 6

.3 6 x l0 6

.IB x lO 6

.4 5 x l0 6

P ip in g

.3 x l0 6

.D xlO 6

.S x lO 6

.DxlO 6

Valves

1 .3 6 x l0 5

.4 1 x l0 6

.IS B x lO 6

.4 1 x l0 6

S te e l

In s u la tio n

I n s tr u m e n t a t io n

S tru c tu re

TOTAL

* T o ta l Cost o f 3 u n it s

.S x lO 6

.S x lO 6

■ 6 .2 x l0 6

4 .7 x l0 6

2 0 .2 x l0 6

1 7 . OxlO6

.

/

- 24 CORED-BRICK AIR PREHEATERS

C a p ita l

costs f o r the c o r e d - b r ic k a i r p r e h e a te r system are

developed in Appendix F.

A g a in , th e s e f i g u r e s a re f o r one u n i t o n ly .

The o v e r a l l c o r e d - b r ic k a i r p r e h e a t e r system c o n s is ts o f seven u n i t s .

These costs a re summarized i n T able IV .

TABLE I V .

ESTIMATED CAPITAL COST OF INDIRECT-FIRED

CORED-BRICK AIR PREHEATER

U n i t Cost

T o ta l

Cost (7 u n i t s )

$ .21 6 X IO 6

$ 1 .5 1 x IO6

In s u la tio n

.662 X IO 6

4 . 6 3 x IO 6

Cored B r ic k

.552 X IO6

3 .8 6 x IO6

S te e l

P ip in g

Valves

I n s tr u m e n t a t io n

S tru c tu re

TOTAL

1 .1 x IO 6

.136 X IO 6

.9 5 x IO 6

. 3 x IO6

3 . 0 x IO6

$ 1 5 .4 x IO6

FUEL SOURCES F O R IN DIRECT-FIRED AIR PREHEATERS

INTRODUCTION

A complete i n d i r e c t - f i r e d a i r p r e h e a t e r system w i l l

in c lu d e a f u e l

source o f some s o r t .

n e c e s s a rily

Since the purpose o f i n d i r e c t - f i r e d

a i r p r e h e a t e r design i s t o g e t away from th e disadvantages o f using

th e seed and s la g - l a d e n MHD e xhaust gas as an energy s o u rc e , th e fu e l

should be c le a n and burn e f f i c i e n t l y .

under c o n s i d e r a t i o n a r e f u e l

The th r e e m ajor f u e l s p r e s e n t l y

o i l , n a tu r a l gas, and s y n t h e t i c gas made

from p a r t i a l I y o r c o m p le te ly g a s i f i e d c o a l .

c o s t and s c a r c i t y o f f u e l o i l

and n a t u r a l

However, in l i g h t o f the

gas, the c o s t o f running a

commercial s c a le i n d i r e c t - f i r e d a i r p r e h e a te r w i t h these m a t e r i a l s

would be p r o h i b i t i v e .

been c o n c e n tra te d upon.

Thus, th e p o s s i b i l i t y o f coal

g a s i f i c a t i o n has

Two b a s ic g a s i f i c a t i o n designs a r e c o n s id e re d ,

co al c a r b o n i z a t i o n and coal g a s i f i c a t i o n .

COAL CARBONIZATION

Coal c a r b o n i z a t i o n in v o lv e s th e h e a t in g o f coal in th e absence o f

a ir.

A t a te m p e ra tu re o f 1800 - 2 0 0 0 °F , the v o l a t i l e m a t t e r in the

coal i s d r iv e n o f f as an i n t e r m e d i ate-BTU f u e l

v a lu e o f a p p r o x im a te ly 550 B T U /ft^ ( 1 0 ) .

fu e l

gas, having a h e a tin g

I f t h i s gas co u ld be used to

th e a i r p r e h e a t e r , then coal would be th e s o le f u e l source o f the

o v e ra ll

power g e n e r a tio n complex.

The c a r b o n iz a t io n o f a ton o f coal

y i e l d s a p p r o x im a te ly 1 1,0 00 f t 3 o f t h i s f u e l gas plus about 1400 Ib ^

o f coke.

The coke b y -p ro d u c t would be mixed w i t h th e coal fe e d to

-

th e MHD combustor.

Mass and energy balances f o r t h i s system a re

pre se n te d i n Appendix G.

MHD exh a u s t gases.

F ig u re 6 .

26 -

The c a r b o n iz e r would b e .h e a te d by d i f f u s e d

A s i m p l i f i e d design o f th e system is shown in

The balances pre se n te d in Appendix G re v e a l t h a t , even i f

pure coke were used as th e s o le f u e l

source in th e MHD combustor, the

coke flo w r a t e from th e coal c a r b o n iz e r would be n e a r l y tw ic e the

necessary coke flo w r a t e t o th e MHD combustor.

a lo n e , th e use o f coal c a r b o n i z a t i o n t o f u e l

p r e h e a te r appears h i g h l y i n f e a s i b l e .

Thus, on t h i s ba sis

the i n d i r e c t - f i r e d a i r

Because o f t h i s ,

an economic

study o f coal c a r b o n i z a t i o n was n o t pursued.

COAL GASIFICATION

The p o s s i b i l i t y o f using g a s i f i e d coal as th e f u e l

i n d i r e c t - f i r e d a i r p r e h e a t system was i n v e s t i g a t e d .

g a s i f i c a t i o n o f coal t o s y n t h e t i c f u e l

source f o r th e

The complete

gas o f high BTU c o n te n t

( ~ 950 B T U /f t^ STD) in v o lv e s h e a t in g th e coal to g a s i f y th e v o l a t i l e

m a t t e r , s h i f t r e a c t i n g the carbon monoxide w i t h w a t e r to form hydrogen

and carbon d i o x i d e , removal o f HgS and COg, and f i n a l l y m ethanation

o f th e r e s u l t i n g gaseous m i x t u r e .

However, m ethanation o f th e CO-Hg

gas m ix tu r e has y e t to be c o m m erc ially dem onstrated.

g a s f i c i a t i o n system w i l l

Thus the

be p resented h e r e , b u t i t should be noted t h a t

progress is necessary b e fo r e the system i s t e c h n o l o g i c a l l y f e a s i b l e .

Data on th e system is pre se n te d i n Appendix H.

F ig u re 7 d e p ic t s a

- 27 -

Fuel

Gas

P reheate # _

T=1700

MHD Duct

Combustio

Chamber

FIGURE 6 .

AIR PREHEAT SYSTEM WITH COAL CARBONIZATION

AS FUEL SOURCE

To

Bottoming

P la n t

- 28

a

'

1700°F

G a s ifie r

Preheater

L. I .

MHD Duct

FIGURE 7.

AIR PREHEAT SYSTEM WITH COAL GASIFIER

AS FUEL SYSTEM

A ir

-

29 -

s i m p l i f i e d coal g a s i f i e r as th e f u e l

p re h ea te r.

source f o r an i n d i r e c t - f i r e d a i r

Data on th e p o s s i b i l i t y o f p a r t i a l char r e c y c le or o th e r

uses f o r c h ar was not a v a i l a b l e .

The p a r t i c u l a r g a s i f i c a t i o n process

i n v e s t i g a t e d i s th e CC^-acceptor p r o c e s s , as i t

c a p ita l

cost o f a l l

processes looked a t .

has th e lo w e s t o v e r a l l

However, i t

i s o n ly capable

o f g a s i f y i n g l i g n i t e and no n -c a kin g sub-bitum inous c o a l s .

Data was

n o t a v a i l a b l e on t h e f e a s i b i l i t y o f u t i H i z i n g Montana sub-bitum inous

coal in t h e CC^-acceptor process.

coal

As i s shown in Appendix H - l , the

flo w r a t e to th e g a s i f i e r would be about 47% o f th e t o t a l

f l o w r a t e t o th e power g e n e r a tin g complex.

The c a p i t a l

coal

c o s t f o r the

g a s i f i c a t i o n system i s e s tim a te d a t $ 2 7 .5 x 10^, w i t h an e s tim a te d

annual o p e r a t in g c o s t o f $ 4 . 3 x 106 ( 7 ) .

OVERALL INDIRECT-FIRED AIR PREHEAT

SYSTEMS COST COMPARISON

CAPITAL COST COMPARISON

As can be seen in comparing Tables I I I

and I V , the f a l l i n g - p a r t i c l e

p r e h e a te r ( 0 . 0 4 2 i n blow out) and th e c o r e d - b r ic k p r e h e a te r have n e a r l y

th e same c a p i t a l

co st,

v a r y in g b y . o n ly $ 1 .6 x 10®.

T h is i s w i t h i n th e

l i m i t s o f e s tim a te d accuracy f o r a .l o n g - r a n g e economic a n a l y s is o f

t h i s ty p e .

w ill

Assuming t h a t th e c a p i t a l

c o s t o f th e f u e l

be th e same f o r both a i r p r e h e a t systems, o v e r a l l

source system

system c a p i t a l

costs can now be e s t im a te d .

-ANNUAL COST ESTIMATION

An e s t im a te o f annual maintenance costs f o r th e a i r p r e h e a te r was

made.

The development o f th e s e costs is presented in Appendix E-5

f o r th e f a l l i n g - p a r t i c l e a i r p r e h e a t e r , and in Appendix F-5 f o r the

c o r e d - b r ic k a i r p r e h e a t e r .

I t should be noted t h a t th e s e f i g u r e s are

q u i t e rough e s t im a t e s , and should be weighed w ith a p p r o p r ia t e

s k e p t ic is m .

T a b le V pre se n ts an o v e r a l l c a p i t a l and annual cost

comparison f o r th e two i n d i r e c t - f i r e d a i r p re h e a t systems.

- 31 TABLE V.

■

COST COMPARISON OF OVERALL INDIRECT-FIRED

CORED-BRICK AND FALLING-PARTICLE AIR PRE­

HEAT SYSTEMS

C o r e d -B r ic k

A i r P r e h e a te r

P r e h e a te r C a p i t a l

Cost

$ 1 5 .4 x IO6

F a llin g -P a rtic le

A i r P re h e a te r

( 0 . 0 4 2 i n . Blowout)

$

1 7 .0 x IO6

Fuel Source C a p i t a l Cost

2 7 . 5 x IO6

2 7 . 5 x IO 6

TOTAL C a p i t a l

4 2 . 9 x IO 6

4 4 . 5 x IO 6

Cost

TOTAL Annual Cost

(in c lu d e s f u e l source)

$

5 . 8 x IO6

$

6 . 4 x IO 6

COMMENTS

A number o f im p o rta n t p o in ts should be made in c o n s id e r in g these

two o v e r a l l

1)

designs:

The l e v e l o f te c h n o lo g y o f th e c o r e d - b r ic k a i r p r e h e a te r design

i s much h ig h e r than t h a t o f th e f a l l i n g - p a r t i c l e

d e s ig n .

a i r p re h e a te r

The u t i l i t y o f th e c o r e d - b r ic k design has been

demonstrated i n a number o f a p p l i c a t i o n s , and an abundance

o f design d a ta i s a v a i l a b l e .

The f a l l i n g p a r t i c l e d e s ig n ,

however, has not y e t been dem onstrated.

2)

Since th e f a l l i n g - p a r t i c l e d e s ig n .o u tp u ts a s te a d y a i r flo w

r a t e a t a u n iform te m p e r a tu r e , o p e r a t io n o f th e MHD combustor

and duct would p ro b a b ly be smoother than w ith th e c y c l i c

-

32 -

o p e r a tio n s o f th e c o r e d - b r ic k d e s ig n .

3)

The need f o r c o n s t a n t - o p e r a t in g

w ill

v a lv e s in th e c o r e d - b r ic k

in c re a s e annual m aintenance costs as a r e s u l t o f v a lv e

breakdown and a t t r i t i o n .

v a lv e s w i l l

W ith th e f a l l i n g - p a r t i c l e

d e s ig n ,

be used o n ly f o r s t a r t u p , shutdown, and flo w r a t e

c o n tro l.

4)

P a r t i c l e replacem ent through a p p r o p r ia t e access p o r ts

(p ro b a b ly

i n th e p a r t i c l e r e c y c le system) i n th e f a l l i n g - p a r t i c l e

design w i l l

be a r e l a t i v e l y e f f o r t l e s s p ro c e d u re , r e q u i r i n g no

equipment shutdown and d i s m a n t l i n g .

C o r e d -b r ic k replacem ent

i n th e c o r e d - b r ic k d e s ig n , however, w i l l

shutdown and complete d is m a n t l i n g .

r e q u i r e column

CAPITAL COST COMPARISON OF DIRECT AND

INDIRECT-FIRED AIR PREHEAT SYSTEMS

C a p ita l

c o s t data f o r d i r e c t - f i r e d

c o r e d - b r ic k and f a l l i n g -

p a r t i c l e a i r . p re h e a t systems was s u p p lie d by W. E. G e n e tti and R. L.

Mussulman ( 1 2 ) .

These d a ta a re compared w i t h i n d i r e c t - f i r e d design

d a ta i n T a b le V I .

Only th e 0 .0 4 2 i n . blowout design o f t h e f a l l i n g -

p a r t i c l e a i r p r e h e a te r i s c o n s id e re d .

Annual c o s t d a ta f o r d i r e c t -

f i r e d a i r p r e h e a t systems was not a v a i l a b l e .

TABLE V I .

CAPITAL COST COMPARISON OF DIRECT AND

• ■ INDIRECT-FIRED AIR PREHEAT SYSTEMS

DIRECT-FIRED

O v e r a ll

C a p i t a l Cost

INDIRECT-FIRED

F a llin g -P a rt.

C o r e d -B ric k

F a llin g -P a rt.-

C o re d -B ric k

$ 3 0 .4 x IO6

$ 3 1 .3 x IO 6

$ 4 4 .5 x IO6

$ 4 2 .9 x IO 6

As can be seen, i n each design case th e c a p i t a l

f i r e d a i r p r e h e a t system i s about 75% o f t h e c a p i t a l

c o s t o f the d i r e c t c o s t o f th e

i n d i r e c t - f i r e d system.

COMMENTS

In comparing th e o v e r a l l designs o f d i r e c t and i n d i r e c t - f i r e d a i r

p r e h e a t systems, the f o l l o w i n g comments can be made:

I)

T o t a l coal f u e l costs f o r th e o v e r a l l

.

power g e n e r a tin g

complex w i t h th e i n d i r e c t - f i r e d a i r p re h e a t system w i l l

be

- 34 n e a r l y double those o f th e o v e r a l l

a i r p r e h e a t.

complex w i t h d i r e c t - f i r e d

However, s in c e the therm al energy o f th e MHD

exhaust gas w i t h i n d i r e c t - f i r e d a i r p r e h e a tin g i s not used t o

preheat a i r ,

a g r e a t e r percentage o f the t o t a l

t h e complex w i l l

power o u tp u t o f

be produced by th e bottom ing p l a n t .

In

a d d i t i o n , a l a r g e r bottom ing p l a n t would be a b le t o u t i l i z e

th e therm al energy o f th e exhaust gas l e a v in g th e i n d i r e c t f i r e d a i r p r e h e a t system.

2)

S ince th e environm ent w i t h i n th e d i r e c t - f i r e d system design

i s much more c o r r o s i v e than t h a t o f th e i n d i r e c t - f i r e d

system d e s ig n , annual maintenance costs can be expected to

be s u b s t a n t i a l l y h ig h e r w ith the d i r e c t - f i r e d system.

3)

A few p o in ts i n o v e r a l l

thermodynamic e f f i c i e n c y a r e l o s t in

th e power g e n e r a tin g complex using an i n d i r e c t - f i r e d

p r e h e a t s y s te m .( 5 , 8 ) .

a ir

APPENDICES

-

APPENDIX A:

I.

2.

36 -

PREDICTION OF MATERIAL PROPERTIES

C o n s titu e n ts o f Coal Gas, Mole %

CO

CO2

H2

N2

O2

CH^

8 .6

1 .5

5 2 .5

3 .5

0 .3

3 1 .4

H e a tin g V a lu e , B T U /ft^

575

Products o f Coal Gas Combustion

CO2

H2O

N2

Mole %

8 .7 7

2 1 .2 3

7 0 .0 0

W eight %

1 4 .1 5

14.01

7 1 .8 5

(A v e . M ol. W t. = 2 7 . 2 8 )

Flame Temp. = 3665°F

Notes on p r e d i c t i o n o f exhaust gas and a i r p r o p e r t i e s :

a)

V i s c o s i t y and therm al c o n d u c t i v i t y o f gaseous m ix tu re s were found

a t given te m p e ratu re s assuming t h a t :

pmix ~ I ^ i y i

- '

*Snix ~ |^i*S'

where y .. = mole f r a c t i o n o f component i .

V i s c o s i t i e s and thermal

c o n d u c t i v i t i e s were c a l c u l a t e d a t a number o f te m p e r a tu r e s .

d a ta were then f i t

t o th e f o l l o w i n g general e q u a tio n s :

B

- m i x * AT

b)

mix

The h e a t c a p a c i t y o f th e exhaust gas was assumed to"obey the

f o l l o w i n g e x p re s s io n :

m

+ X

twH2O cPH2O

+ Wr

'PC0,

The

-

37 -

w a t e r v a p o r, and carbon d i o x i d e , r e s p e c t i v e l y .

The X is a f a c t o r

in tro d u c e d t o account f o r d i s s o c i a t i o n o f HgO and COg in the gas a t

high te m p e r a tu r e s .

X i s e s tim a te d from h e a t c a p a c i t y data

c a l c u l a t e d f o r coal combustion gases and the com position o f such

gases.

S ince th e w e ig h t f r a c t i o n s and h e a t c a p a c i t i e s o f a l l

gas c o n s t i t u e n t s a re known, th e f a c t o r X can be c a l c u l a t e d a t

a number o f te m p eratu res

(1 5 ).

Cp^ was c a l c u l a t e d f o r a number o f te m p e ra tu re s , and a curve was

fit

t o th e r e s u l t i n g data ( 1 4 , 1 5 ) .

fo llo w e d by W. E. G e n e tti

A s i m i l a r procedure was

in d e ve lo p in g the h e a t c a p a c ity e q u atio n

fo r hot a i r .

c)

The Id e a l Gas Law is assumed a c c u r a te in th e d e n s it y e q u a tio n .

3.

Hot Exhaust Gas P r o p e r t ie s

• Temperature Range:

P = 3 7 . 4 P /T

T = °R ,

k = 1 .2 3 4 x 10

ii = 1 .5 2 x 10

2000 - 4000°F

- 4 r 778

- 7 -J-.684

P = ATM, p = l b m / f t 3

T=°R,

k=

B T U /h rft°F

T = °R ,

y = Ib m /fts e c

Cp = - . 0 2 6 0 + 5 .1 0 0 x IO "6 T + 2 .9 6 7 x IO- 8 T "2

T = °R

-

4.

38 -

Hot A i r P r o p e r t ie s

Temperature Range:

P = 3 9 .1 2 P /T

1500 - 3500°F

T = °R ,

Q -4 t .5 8 3

k = 4 .7 3 6 x TO

y = 6 .0 7 x 10

- 7 -J-.513

P = ATM,

p = l b m/ f t

T = °R ,

k = B T U Z h rft0F

T = °R ,

y = I b mZ f t s e c

3

C = .2261 + 2 .8 2 9 5 x IO - 5 T - 2 .2 8 6 x IO - 9 T2

P

T = °R ,

5.

Alumina ( P a r t i c l e )

Note:

Cp = BTUZlbm0F

P r o p e r t ie s

The alumina p a r t i c l e

used i n t h i s design i s a t a b u l a r

alumina pro d u c t o f th e Aluminum Company o f Am erica.

pure fused a lu m in a .

It

is 99.5%

The p a r t i c l e d ia m e te r range i s 0 .0 3 6 in -

0 .0 5 in .

P = 232 I b mZ f t

3

k = 2 .9 1 + 2 .9 1 8 x 10- 6 ( T - 2 7 6 0 ) 2 - 1 . 5 6 1 1 x 10- 1 2 ( T - 2 7 6 0 ) 4

T = °R ,

k = B T U Z h rft0F

Cp = .25667 + 1 .6 3 3 9 x IO - 5 T

6.

T = °R ,

Cp = BTUZlbm0F

I n s u l a t i o n Data

The i n s u l a t i o n i s o f f o u r b a s ic ty p e s .

A v c o -E v e r e tt Research L a b o r a t o r i e s ,

This d a ta was s u p p lie d by

I n c . , E v e r e t t , Mass ( 5 ) .

- 39 M fg .

(I)

Norton

Type

Thickness

in .

AH-199B

3

k,

B T U /h rft°F

■ C o s t, $ Z f t 3

1 .7 9

140

( 2 ) Norton

AN-599

4 .5

.894

120

( 3 ) J o h n s -M a n v ille

JM -3000

4 .5

.292

100

( 4 ) J o h n s -M a n v ille

JM-23

4 .5

.119

80

7.

MHD Coal Exhaust Gas P r o p e r t ie s

These p r o p e r t i e s o f th e exhaust gas from an MHD duct were

developed by W., E. G e n e t t i .

p = 4 0 .9 4 6 P/T

T = °R ,

P = ATM,

k = .000872

T=

k = B T U Z h rft0F

p = 6 .0 8 4 x 10

Cp = .848446 -

-7

jk

°R ,

T

' = °R,

I b mZ f t 3

p = I b mZ f t s e c

.0004834T + 1 .0 1 1 0 6 x IO - 7 T2

T = ° R,

8.

p =

F o llo w in g is a graph ■;

Cp == BTUZlbm0F

F ig u re 8,, o f e n th a lp y o f MHD coal exhaust

gas v s . te m p e r a tu re , e s tim a te d by Avco E v e r e t t Research L a b o r a to r ie s

In c .

40 -

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

0

500

1000

1500

Gas Temp -° K

8.

ENTHALPY OF MHD COAL EXHAUST GAS vs. TEMPERATURE

- 41 APPENDIX B:

I.

GENERAL DESIGN BALANCES

Composition o f Montana S ub-bitum inous Coal

P roxim ate A n a ly s is

(6 )

Weight P e rc e n t

(as r e c e i v e d )

M o is tu re

2 4 .3

V o l a t il e M a tte r

2 8 .6

F ixed Carbon

3 9 .6

Ash

7 .5

100.0

U lt im a t e A n a ly s is

(as r e c e iv e d )

Ash

7 .5

S u lfu r

0.8

Hydrogen

•

Carbon

.

6.1

5 2 .2

0.8

N itr o g e n

3 2 .6

Oxygen

100.0

H ig h e r H e a tin g Value

2.

8944 B TU /lb^

A i r I n p u t t o 400 MW (T h e rm a l) MHD Combustor

Heat In p u t = 400 x IO 6 W att

I

x

3 .4 1 4 BTU

h r w att

= 1 .3 6 5 6 x IO9 BTU/hr

■

lb

Coal Rate = 1 .3 6 5 6 x IO 9 BTU/hr x - g g ^ 'BTU = 1 ^527 x 1()5

_ 42 -

Formula f o r M o is tu re and Ash-Free C o a l :

CH. 8 ° . 0 8 N. 0 2 S .00 8

Combustion R e a ctio n :

CH. 8 ° . 0 8 N.0 2 S .00 8

+

1 .1 7 8 0 2

->

CO2 + .4 H2O + .02N0 + .OOSSO2

Assume m o le c u la r w e ig h t o f coal = 1 4 .6 2 (m o is tu re and a s h - f r e e )

A i r re q u ire m e n t f o r coal combustion:

1 .1 7 8 mole O2

mole coal

x

mole coal

1 4 .6 2 lb Coal

x

32 l b O9

_______ _ £

mole O2

100 lb A i r

21 lb O2

= 1 2 .2 8 lb A i r

l b coal (m o is tu r e -a s h f r e e )

The m oistu re and a s h - f r e e coal r a t e i s :

( 1 . 5 2 7 x IO5 ) ( . 6 8 2 ) = 1 .0 4 1 x IO 5 I b / h r

Thus, th e combustion a i r r a t e i s :

A i r Rate = 1.0 4 1 x IO5 l b coal

hr

= 1 .2 7 9 x IO5 lb

x

1 2 .2 8 lb a i r

l b coal

a ir/h r

H eat T r a n s f e r Rate to A i r i n P r e h e a te r

3100°F

qa i r

Wa i r

z ITOO0F

Cpa i r

1 .2 7 9 x IO u l b a i r

dT

x

4 0 3 .0 4 BTU

5 .1 5 5 x IO8 BTU/hr

- 43 -

APPENDIX C:

I.

MODEL DEVELOPMENT OF FALLING-PARTICLE AIR

P a r t i c l e S iz e D i s t r i b u t i o n

Blowout

No. F r a c t io n

0 .0 4 2 i n .

. D ia m e te r, i n .

0 .0 5

0 .0 1 1

0 .0 5

0 .0 1 8 2

0 .0 4 6

0 .1 2 8

0 .0 4 6

0 .1 0 3 3

0 .0 4 4

0 .2 5 6

0 .0 4 5

0 .2 0 6 7

0 .0 4 2

0 :2 5 6

0 .0 4 4

0 .1 5 5 0

0 .0 4 0

0 .1 9 3

0 .0 4 3 5

0 .1 0 3 4

0 .0 3 9

.0 .1 0 5

0 .0 4 3

0 .1 5 5 0

0 .0 3 7 5

0 .0 5 1

0 .0 4 2

0 .2 5 8 4

0 .0 3 8 i n .

D ia m e te r, i n .

2.

PREHEATER

Blowout

No. F r a c t io n

Term inal V e l o c i t y and Chamber D iam eter C a l c u l a t i o n

Term inal v e l o c i t y is c a l c u l a t e d using th e general e q u a tio n f o r

s p h e r ic a l

p a rtic le s

developed i n McCabe and S m ith , U n i t O perations

o f Chemical E n g in e e r in g , Second E d i t i o n , pp. 1 64 -1 6 9:

U uT

I