The catalytic hydrodesulfurization of Wyoming fuel oil by John R Hartwig

advertisement

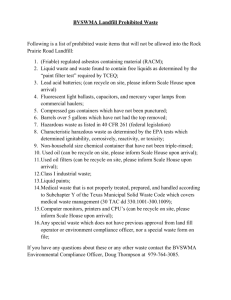

The catalytic hydrodesulfurization of Wyoming fuel oil by John R Hartwig A THESIS Submitted to the Graduate Faculty in partial fulfillment of the requirements for the degree of Master of Science in Chemical Engineering Montana State University © Copyright by John R Hartwig (1952) Abstract: This investigation was primarily concerned with the effect of gas recycle on the catalytic hydrodesulfurization of a number-three-fuel oil from a sulfur content of 2.2 percent to 0.5 percent or below. Initial gas compositions were either pure hydrogen or a gas mixture that was approximately 84 percent hydrogen. In the runs with an initial gas composition of pure hydrogen the make-up gas added was also pure hydrogen. Make-up gas for runs where gas mixtures were used was the same composition as the initial gas composition (i. e. approximately 84 percent hydrogen). Nickel oxide and nickel hydroxide catalysts were studied briefly, but the major emphasis was on molybdenum sulfide catalysts. Optimum desulfurization conditions were not evaluated. The emphasis was on the determination of gas consumption during continuous gas recycle operation. Conditions for the nickel study runs were: space velocity 0.1 to 3.0 gm. oil/gm. cat-hr., temperature 385 to 390°C, pressure 60 to 100 psig, and gas recycle rate from 0.4 to 2.0 liters gas/gm oil. Process variables for the molybdenum runs were: space velocity 0.7 to 1.3 gm oil/gm cat-hr, temperature 410 to 415°C pressure 500 psig, and gas recycle rate 0.9 to 1.8 liters gas/gm oil. The gas. consumption when pure hydrogen was used as the recycle gas was approximately 140 SCF/bbl and the gas consumption with a gas mixture on recycle was between 250 to 300 SCF/bbl. These consumption figures were obtained with molybdenum catalysts. The effectiveness of the desulfurization process when a gas recycle system was used was hot noticeably different than that when the process ; was carried out with the gas oh a one pass system. Specification oil was produced with molybdenum catalysts and a recycle gas with a hydrogen con-tent as low as 80 percent by volume. The molybdenum catalysts were far superior to the nickel catalysts as far as catalyst life and the degree of desulfurization were concerned. THE CATALYTIC HYDRODESULFURIZATION OF WYOMING FUEL O H • by ■ JOHN R«: HARTWIG A THESIS Submitted to the Graduate Faculty in partial fulfillment of the requirements , for the degree of Master of Science in Chemical Engineering at Montana State College Approved: Chairman ^/Examining (ksfnmlttee Bozeman, Montana August, 1952 ' 'y-i'j/j —2— TABLE OF CONTENTS page Abstract..................................................... Introduction. . . . . . . . . . . . . . 3 .......................... • 4 Equipment, Materials, and M e t h o d s ................. 7 Equipment .................................. 7 Materials. ..................................................... 9 Methods.......................................................... 10 Calculations..................................... Results and Discussion.................. 14 Conclusions.................................. Acknowledgement . . . . . . . ................................ ... 25 Literature Cited..................................... Appendix.......................................... 108556 ABSTRACT".. This investigation was primarily concerned with the -effect’-of-gas • recycle on the catalytic hydrodesulfurization- of a number three-fuel oil from a sulfur content of 2»2 percent to 0»5 percent or below; Initial-gascompositions were either pure hydrogen or a gas mixture that was -approx­ imately 84 percent hydrogen. In the runs with an initial gas-compositionof pure hydrogen the make-up gas added was also pure hydrogen. Make-up gas for runs where gas mixtures were used was the same composition as the initial gas composition (i. e. approximately 84 percent hydrogen)* Nickel oxide and nickel hydroxide catalysts were studied briefly, but the major emphasis was on molybdenum sulfide catalysts. Optimum desulfurization conditions were not evaluated. The emphasis was on the determination of gas consumption during continuous gas recycle operation. Conditions for the nickel study runs were; space velocity 0.1 to 3.0 gm. oil/gm. cat-hr., temperature 385 to 390°C, pressure 60 to 100 psig, and gas recycle rate from 0.4 to 2.0 liters gas/gm oil. Process variables for the molybdenum runs were: space velocity 0.7 to 1.3 gm. oil/gm cat-hr, temperature 410 to 415^0* pressure 500 psig, and gas recycle rate 0.9 to |r; 1 .8 liters gas/gm oil. The gas. consumption when pure hydrogen was used as the recycle gas • was approximately 140 SCF/bbl and the gas'consumption with a gas mixture ' on recycle was between 250 to 300 SCF/bbl. These consumption figures we^e obtained with molybdenum catalysts. The effectiveness of the desulfurization process when a gas recycle system was used was hot noticeably different than that when the process ; was carried out with the gas oh a one pass system. Specification oil was produced with molybdenum catalysts and a recycle gas with a hydrogen con- -i tent as low as 80 percent by volume. The molybdenum catalysts were far superior to the nickel catalysts as far as catalyst life and the degree of desulfurization were concerned. I M E Q D i r C T im The depletion of low sulfur content crudes in the United States is forcing refiners to employ increasing amounts of high sulfur crudes. Utilization of these crudes has forced refiners to develop economical pro­ cesses for removal dr conversion of sulfur compounds in the various products refined from them. Methods commonly used for desulfurization of gasoline are not satisfactory for the treatment of higher boiling petroleum fractions such as diesel and fuel oils. Such commercial processes as the Unisol process, the Solutizer.and Tannin Solutizer processes, hypochlorite treat­ ment j Gray desulfurization, treatment with bauxite catalysts, as well as caustic and acid washes, either do not reduce the sulfur content in the heavier distillates to the desired percentages or hydrocarbon losses are excessive. Although the identification of specific sulfur compounds in any particular petroleum fraction is a difficult task, and research in this direction has not been extensive until fairly recently (8 ) (9), it has been fairly well established (9 ) that the sulfur compounds in kerosine and fuel oil distillates are predominantly 'thlophenic in nature. These compounds are not receptive to any of the desulfurization treatments mentioned above. Successful desulfurization of fuel oil distillates to very low limits, has been accomplished by catalytic hydrodesulfurization. Work by Green (6 ) and Munro (3) with a molybdenum sulfide catalyst in a hydrogen atmosphere reduced the sulfur content -in a number^three fuel oil from approximately 2.2 percent to less than 0*5 percent. Several commercially adaptable -5catalytic desulfurization processes haVe been patented by the AngloIranian and Union Oil Companies (10) (Il) 6 These processes utilize cobalt and molybdena catalysts and hydrogen gas atmospheres at various pressures (200-700 psig) 6The inherent economic disadvantage of these catalytic hydrodesulfurizatioh processes is the need for a relatively rich (greater than 90%) hydrogen gas supply. This difficulty can be overcome^ however, by using the desulfurization process in conjunction with a '!catforming" unit for upgrading low octane gasolind, In a typical catalytic, reforming process (12 ) there is a net make of a gas mixture -which is: predominantly hydrogen' (approximately 90%)} with small quantities of methane, ethane, and propane present. The capacity of such a desulfurization unit would naturally be regulated by the quantity of make gas from the catformer and the amount of gas consumed in the desulfurization process. The primary objective of this research was the determination of gas consumption (as SGF/bbl,) for the catalytic hydrodesulfurization process developed here in the past few years by Koski (2), Munro (3), and Green (6 ), This process was developed for the desulfurization of Husky Oil Company’s number three fuel oil. The sulfur content in this fuel oil was to be reduced from 2 ,2 percent to 0 ,5 percent or below, As mentioned previously, the catalyst used was molyb­ denum sulfide (approximately 15$ Mo) impregnated oh an alumina carrier. The process variables for this catalyst were fairly well established in the preceding work. The optimum conditions found were: pressure,'500 psigj temperature 400-41O0C (752-770°F)$ gas to oil ratio, I «3 to 1„5 liters gas/gm oil; and a variable space.velocity, (this varied between approximately 0,4 and I eO gm oil/gm cate-hr„, depending upon the activity of the catalyst)o Aside.from the stated objective of the determination of gas con­ sumption data, three runs were made using nickel catalysts e The purpose of these runs was a final attempt (see work by Goykendall (?) and Haas ($)) to determine if there was any true catalytic effect with nickel catalysts, and to prove whether the process with nickel catalysts would work in the recycle apparatus used for the molybdenum catalyst studies. The gas recycle study (GRS) and the molybdenum comparison run (MCR) were made using pure hydrogen gas. The cat forming gas study run (GGR) used a gas mixture typical of the make gas from a "catforming" unit, In all the runs with molybdenum catalysts (i»e,, GRS, MCR & CGR), the effect of gas recycle on catalyst activity was also observed. The molybdenum comparison run (MGR), as the name indicates, was primarily a ■comparison test on a different batch of molybdenum catalyst delivered from the Harshaw Chemical Company, =7“ E QPIFMEMr, MATERIALS, AND'METHODS'' EQUIPMENT A schematic diagram of the recycle unit is shown in Figure I e The reactor itself is the same as that used by both Munro (3) and Green (6 ). Essentially it consists of a 16 inch length of Ig inch extra strong black iron pipe fitted with a Ig to 3 /4 inch reducer at the top and a Ig to | inch reducer at the bottom. Both the top and bottom of the reactor were fitted with unions to allow for easy takedown of the reactbr for loading I and unloading. Fitted on the top of the reactor were two crosses and an assembly of valves for gas, oil, and regeneration air inlet. line and thermowell tube were also fitted to this assembly. A -blow-out The thermowell tube was a zp inch black iron pipe which extended from the cross at the top of the reactor down through the vertical" axis of the reactor to within one inch of the bottom. It was possible to position three thermocouples at any point within the reactor with this system. The thermocouple^ were iron-constahtan and were used in conjunction with a Leeds and Northrup indicating potentiometer for temperature measurement. Fitted at the bottom of the reactor was a water cooled condenser. At7 the bottom of the condenser, connected from a cross, was the reactor . pressure gage, high pressure product receiver (a 12 inch Jerguson sight gage), a standpipe, and the reactor back pressure valve. At the bottom of the Jerguson product receiver was the receiving flask, caustic scrubbing train, and a wet test meter manufactured by the Precision Scientific Company. A constant oil level was maintained in the Jerguson receive** by hand adjustment of a needle valve at the bottom of the receiver» The reactor pressure was maintained by a Hason-Neilan small-volume air-to-close regulator valve» This pressure regulator was controlled by a Fisher Wizard proportional controllero A two cylinder, adjustable stroke, high pressure piston pump and an oil reservoir comprised the oil feed system. Three 33-foot lengths of beaded Nichrome wire, supplied with current from three 110-volt Powerstat autotransformers, provided variable heat input for the reactor. Two of these heating coils were located near the bottom of the reactor to heat the catalyst section and one was located higher up on the reactor to heat the preheat section. Alundum balls were used as preheat media. Gas flow to the reactor was metered by a Fisher fldwrater and regulat­ ed by a needle valve manufactured by the American Instrument Company. This needle valve was located ahead of the flowrater. The remaining equipment of the unit made up the gas recycle system* The compression pump was a two cylinder Hills-McCanna high pressure proportioning pump. The feed tank was made from a number one gas cylinder and the surge and compression tanks were made from number two gas cylinders, A- Brook's Rotameter metered the flow from the make-up tank. Extra strong black iron pipe and high pressure fittings were used throughout the unit where piping is indicated by double lines on Figure I. Single lines on the drawing indicate I / 8 inch stainless steel high pressure tubing Before the recycle unit as shown in Figure I was constructed, a different unit was used. This unit was essentially the same as the later unit with the exception of the gas recycle system. Instead of using an oil displacement method for gas compression, a small refrigerator compres­ sor was used to move the gas from the surge tank to the feed tank. This system worked quite well uqtil the middle of the "catforming" gas study run. At that time repeated compressor breakdowns caused so much trouble and unit shutdown time that the recycle unit as shown on Figure I was constructed. This unit did not cause any operational troubles and proved to be a great improvement over the old system. MATERIALS The oil used throughout this work was Husky Oil Company's number three fuel oil. percent. The sulfur content of this oil varied between 2.09 and 2.19 Additional data for this oil can be found on Table I in the appendix. Table II presents data for all the catalysts used in this research. Recycle gas used was either pure hydrogen or a gas mixture. The „ hydrogen was obtained from the Whitmore Oxygen Company of Salt Lake City, Utah. The gas mixture was obtained from the Matheson Chemical Company in East Rutherford, New Jersey. ordered) was: The composition of this gas mixture (as hydrogen, 89 percent$ methane, 3.5 percentj ethane, 1.5 percent5 propane, 2.5 percent; and propylene, 3»5 percent. To obtain this gas composition a Husky gasoline stock was sent to the Atlantic Refining ewIOw Company and run through their catalytic reforming unit® Analysis of the make gas from the run with the Husky stock gave the above composition® METHODS /rhe unit was started by applying heat to the heating coils with the gas flowing through the reactor® The" reactor wa‘s set at the desired pressure during this period or when the catalyst temperature reached 3OO0 C 0 / Oil flow was started and the space velocity adjusted whten this catalyst temperature reached 3SO0 C 0 Readings were recorded after the desired cata­ lyst temperature was reached, with the gas flcjw, reactor pressure, and space velocity properly adjusted and maintained® • I 1 As the product oil collected in the"Jerguson pressure receiver it was allowed to drip slowly to the receiving flask® The receiving flask was ' . i N removed and replaced at"the desired sampling periods® Dissolved gases (predominately H 2S ), which flashed from the Qil when the oil left the pressure receiver, went to the caustic scrubbing train and then to the wet test meter where the gases were metered and passed to the exhaust line® In the operation of the unit, the recycle gas flowed from the feed tank through the flowrator and to the reactor® After the gas passed Y through the reactor and. the reactor back-pressure regulator, it flowed to the surge and compression tanks® I Mhen the pressure in these two tanks - reached 300 psig the surge tank was isolated from the compression tank and the compression pump was started® Compression oil (Husky’s number three fuel oil) was pumped from the compression- oil reservoir to the compression tank, compressing the gas in the compression tank® Mhen the pressure in ■=»11=* the compression tank became equal to 1that in'the feed tank (usually between 550 and 56G) psig) the valve between these two tanks was opened and the gas in the compression tank was pushed over to the feed tank. When all the gas in the compression tank had been pushed to the feed tank (as indicated by the appearance of oil in the sight glass on the compression tank) or when the pressure in the feed tank reached 600 psig, the compression pump was stopped and the valve between the feed and compression tank was closed. The valve between the surge and compression tank was then opened. The oil in the compression tank was forced back to the compression oil reservoir by the pressure from the surge- tank when the valve between the oil reser­ voir and the compression tank was opened. The compression cycle was 'f started again when the pressures in the compression and surge tanks again reached 300 psig. The compression cycle usually took about 1.5 hours for completion with 45 minutes to an hour between cycles.^) Arbitrary, standard pressures were set for the feed tank and the compression and surge tanks5 that for the feed tank was 600 psig, and for the compression and surge tanks it was 250 psig. When the pressure in the surge and compression tanks fell below 250 psig (with the pressure in the feed tank up to 600 psig) at the end of a compression cycle, make-up gas was added to bring the pressure in these two tanks back to 250 psig. fldw from the make-up tank was metered through the Brooks Gas rotameter and this flow was timed with a stopwatch. When desired, recycle gas samples Were taken from a bleed-off valve located on the downstream side of the reactdr back pressure regulator. =IS" The gas sample was passed through the caustic scrubbing train and the wet test meter before it was collected over water in eight liter glass sample bottles „ Analysis of the gas samples was made in a low -temperature^ fractionation column* Sulfur analysis of each oil sample was made by the lamp method (l)„ - SALGULATIONS ■ Tables IV, V, VI, VII, and VIII contain the tabulated data for all the runs made in this investigation* Th'e space velocity recorded was based on input oil* Each individual sample weight was corrected by the percent loss over a longtime period of the run as calculated from oil weight balances* For example; Percent loss, wt. basis = 2$. Then, for an individual sample" weigh- ' ing 800 gms*, input weight = = 8l 6 gms. Then, for an 8 hr. sample period with a l00 gm. catalyst charge, space velocity = 816 gms* oil - 1 .020 * (100 gms* c a t * K 8 hrs*) The gas flow (as recycle gas, SGF/bbl*) was calculated by dividing the gas flow per sample period by the oil weight per sample period* For example; _ With ah 80© gm. oil sample (816 corrected wt.) and a gas recycle rate (as indicated by the Fisher fIowrater) of 1070 liters (STP) per 8 hours; 2521 = 1.3 liters gas/gm oil. Then 1*31 liters gas/gm. oil 28*32 x .87$ gm. oil/cc* oil x lGOO ce/liters x liters/gal x 816 42 gal/bbl x Ft3/ liters = 6430 Ft3 A b l . (STP)* -13Hydrogen consumption was calculated from the make-up and bleed-off gas figures recorded for each sample period. Bleed-off figures were the wet test meter readings„ Make-up figures were from the Brook’s rotameter readings„ For example; For an 800 gm-oil sample (8l6 corrected) and gas make-up equal to 40 liters (STP) and bleed-off equal to 8 liters (STP)9 the gas consumed would be 32 liters (STP)o Then x 5 ^ 2 = 39,2 liters consumed/kilogram oil* 39*2 x 4=91 (conversion factor) = 193 Ft^ consumed/bbl oil* Gas. consumption, for any individual sample period varied widely so the figures presented in the data were cumulative averages * Por example; After ten samples, total gas eonsumtion equalled 3100 Ft^0 -Then for the tenth sample, 2^22 10 - 310 Ft^/bbl* -The catalyst temperatures presented in the data are averaged temper­ atures for each sample period indicated* The thermocouples for the cata­ lyst bed were located at the top and bottom of the catalyst bed* The top and bottom catalyst temperatures were averaged and these average tempera­ tures were averaged over the sample period* A thermodynamic study of probable reaction mechanisms for the cata­ lysts used and reported in this paper was not made since this was done previously by Munro (3 ) and Green (6 ) for the molybdenum sulfide catalysts, and by Haas (5 ) for the nickel catalysts* EESULTS M D DISCUSSION • With the exception of three relatively short runs using nickel catalysts a only one type of catalyst (MoS2 ) was used 0 The primary concern of this research was the study of the effect of gas recycle on the de­ sulfurization process, with determination of gas consumption especially emphasizede Tabulated data for all runs made in this study are presented in the appendix* ■All of the studies made on nickel catalysts were made primarily to observe the effectiveness of these nickel catalysts in the recycle unit and to determine whether the nickel catalysts1 desulfurization action was a chemical or catalytic reaction. In respect to the type of reaction of ■ the nickel catalysts, Haas (5) has already stated that the desulfurization by nickel catalysts was strictly a chemical reaction. ,If desulfurization was accomplished through a catalytic mechanism when nickel catalysts were used, a certain amount of hydrogen would neces­ sarily have to be consumed. The hydrogen is consumed by the combination with the sulfur in the oil (to form H 2S) and the combination with the hydrocarbon from which the sulfur was removed. However, for NSR-I and MSBkII (Tables III and B r) gas was produced and it was not necessary to add any make-up gas. For the third nickel study run (NSR-III, Table V) a total of 21.8 SCF/bbl was consumed. When compared to gas consumption with molybdenum catalysts (140 to 300 SCF/bbl) the consumption of 21.8 SCF/bbl is not large. A possible conclusion to be drawn from the above discussion would be =■15" t h a t the s ulfur w a s r e m o v e d b y some o t h e r m e a n s (e»g« b y c h e m i c a l com­ b i n a t i o n w i t h t h e nickel.) a n d not b y c a r b o n to sulfur b o n d fissure w i t h subsequent f o r m a t i o n o f H 3S s a n d r e s u l t a n t h y d r o g e n consumption* For all the nickel study runs, gas analysis of the recycle gas re­ vealed a high hydrocarbon gas buildup (predominately methane). The hydro­ carbon buildup in the recycle gas that occurred when nickel catalysts were used indicates to'some extent the non-selectivity of these catalysts when they are used as desulfurization agents, Instead of breaking the carbon to sulfur bonds the nickel catalysts evidently induced a predominate carbon to carbon cracking with the production of large amounts of methane, Haas (5) also states that the desulfurization depends in a large part on space velocity. HSR-Il with HSR-III, This is amply demonstrated by comparison of HSR-I and The average space velocity for the first two runs was approximately 3 ,0 gm oil/gm cat,-hr, whereas that for the last run (HSR-III) was 0,1 gm oil/gm cat,-hr, In the first two*runs no specification oil was produced at all, whereas approximately 12 throughputs (i,e. 2400 gms oil ,) were achieved by blending samples I through 27 in the third 200 gms, cat, nickel study run. The different pressures used (i,e, 60 psig for HSR-I and- NSR-H, and 100 psig for HSR-III) in the nickel runs did not have any apparent affect on the degree of desulfurization. Results from the three nickel runs show that the nickel catalysts do not have a long catalyst life and that their desulfurization action is quickly lost after only a few oil throughputs» *=»3.6=" •Operating conditions for the HSR runs were established by the research laboratory of Husky Oil Company in Cody, Wyoming. The Gas Recycle Study (GRS, Table VI) was the first run made with gas recycle operation with an MoS 2 catalyst. The molybdenum catalyst used for this run had been used previously by Green (6 ) in his mixture .study run for a total of 60? hours. Successful desulfurization was accomplished for an additional 526 hours with this catalyst. During the GRS run the space velocity varied between 0.5 and O.S gm oil/gm cat.“hr. Gas recycle varied between 6000 and 11,000 SCP/bbl. -Pure hydrogen was used as make-up during this run. At the start of the run the recycle gas was approximately 100 percent hydrogen. At the end of the run the hydrocarbon buildup in the recycle gas did not exceed five percent. Gas consumption calculations were not made during the first 26 samples of ihis run. During this period, considerable difficulty was en­ countered in establishing operating procedures with the gas recycle system, and in establishing standard tank pressures to assure continuous gas flow and an accurate gas balance. Calculation of gas consumption was^started after sample 26. Frdm sample 26 through 36 there was a gas leak in one of the valve stems on the unit. Rather than shut down the unit and repair this leak, the gas escap­ ing from the ,valve stem was metered and the run was continued. The amount of gas leaking from the valve stem was approximately one-tenth of the gas recycle rate. Gas consumption during this period of gas bleed-off and including the gas bleed-off was between 220 to 275 SCF/bbl oil* -From sample 37 to the end of the run the gab leak was repaired and with no gas bleed-off the gas consumption leveled off at about 140 SCF/bbl, Gas samples were taken from the recycle unit at various times during the GRS run. Analysis of these gas samples revealed a buildup of hydro­ carbon gases. In order to ascertain the trend of this hydrocarbon gas buildup a method had to be developed to correlate the hydrocarbon buildup with some factor which would be independent of the size of the recycle unit and the total amount of gas being recycled. -1Mhen the space velocity and gas flow are kept constant, the rate of hydrocarbon gas buildup should also remain constant. However, the time it would take to obtain a specified hydrocarbon buildup would vary with the size of the reactor system and the total amount of gas in the system. -Correlation between hydrocarbon gas buildup and hours on stream would be meaningless if applied to other reactors. To overcome this, the number of gas recycles was calculated at each gas sample period and in this way it was possible to compare the hydrocarbon content of the recycle gas with the number of times the total volume of gas in. the reactor system had been passed through the reactor proper. ■The following calculation was applied to the GRS run to determine the number of recycles at each gas sample period. The calculation cited is for a ten day period of the run. 109 = average cubic feet recycled per day. IG = number1of days for which the calculation was made. 70 = cubic feet of gas in the reactor system at the arbitrary standard pressures, 12 = average cubic feet of make-up gas added per day during the period of calculation, = 13 recycles, Dttien the above method of calculation was applied to the G-RS run the hydrocarbon buildup after 8 recycles was 4 ,4 percent (volume percent)s after 9 recycles it was 5 ,0 percent, after 11 recycles it was 6 ,0 percent, and after 13 recycles the hydrocarbon content in the recycle gas was 4«6 percent. These calculations indicate that the amount of hydrocarbon gas buildup in the recycle gas was not excessive and that the percentage in­ crease in hydrocarbon content per recycle was relatively small (i,e, after 8 recycles it was .55 percent per recycle and after 13 recycles it was „35 percent per recycle). Oil losses for the gas recycle study on a weight basis were 3*1 per­ cent, In the work by Munro (3) and Green (6 ), oil losses averaged around 6,0 percent. In their studies the oil samples were collected at atmospher­ ic pressure and some oil was carried off as a mist. With the recycle unit- the oil samples were collected under pressure and no oil loss as a mist occurred. The M 0 S2 catalyst used in the GRS (Table Vi) run was used previously by Green (6 ) in his mixture study run. The same operating conditions were used for the first 34 samples of Green’s mixture e&idy run as were used in the gas recycle study. The only difference in that part of the mixture “19- study run being cited and the GRS run was the recycle of gas during the GRS run. With this in mind a comparison of the relative catalyst activity during the GRS run can be made with the activity of the same catalyst when no gas recycle was being used. Green’s mixture study run had an average space velocity (samples I through 34) of approximately 0,7 gm oil/gm cat.“hr. With this space velocity the average sulfur content of the effluent oil was approximately 0 .3 percent. In the gas recycle study the average space velocity was also •approximately 0.7« content in the product oil was about 0.4 percent. The average sulfur From these figures it would seem that the catalyst was not as active under gas recycle conditions. However, when the deactivation of catalyst with use is considered (the mixture study run by Green added 333 hours on stream time to the catalyst before it was used in the gas recycle study) the activity of the catalyst with gas recycle would seem to be the same as. that without gas recycle. The molybdenum comparison run (MGR, Table VII) was started with approximately the same operating conditions as were used for the gas recycle study. This run was made to compare the activity of MoS2 catalysts used in the past with a MoS2 catalyst prepared on a larger scale by the Harshaw Chemidal Company. With an initial space velocity of 0.7 gm oil/ »m cat.“hr the sulfur content of the effluent oil was only 0« .1 percent, , ► *... - . »■* W • When the space velocity was nearly doubled, the percent sulfur in the product oil also increased, but it did not exceed 0.5 percent until the space velocity was raised above 1,35 gm oil/gm cat,“hr* The percent sulfur dropped from .519 to .304 when the space velocity was lowered from 1.331 to -20- .869 gm oil/gm cat.-hr. -Although this run (MOE) was comparatively short (l6 © hours), the above results demonstrate readily the higher activity of the MoS 2 catalyst used as compared to any of the molybdenum sulfide catalyst used previously, either in this research or in the work by Munro (3) and Green (6 ). In these studies specification oil was rarely produced if the space velocity exceeded 1.0. The average gas consumption was 140 SCF/bbl which was the same as the gas consumption for the gas recycle study. The buildup of hydrocarbons in the recycle gas was 4.2 percent after 10 recycles. This is also comparable to the gas recycle study. There is no apparent reason for the greater activity shown by the catalyst used in the MGR run (Table VII). The composition of this catalyst was nearly the same as the composition of MoS2 catalysts used previously (see Table II). The catalyst used for this run was a part of a somewhat larger batch than was usually ordered from the Harshaw Chemical Company for desulfurization studies. Usually, small (5 to 10 pounds) samples of catalyst were ordered, but in this ease about 40 pounds of the catalyst was made. A possible reason then, for the higher catalyst activity could be the method of manufacture of the catalyst. The same catalyst that was used for the MCE run was used for the "catforming" gas study run (CGR), Table VIII. The catalyst had been used for 160 hours during the MGR run. It was not regenerated or treated in any other way prior to its use in the GGR run* This catalyst exhibited a somewhat higher activity than those used in the past, but as the CGR run -21- progress ed the activity of the catalyst did declinee During the CGR run two air regenerations of the catalyst were made. The regenerations were made with, the catalyst in the reactor. air regeneration was made after sample 6l. The first In a total time of 2^ hours 938 liters (STP) of air was passed over the catalyst. Theaverage temp­ erature during this time was 450 dC and the maximum temperature attained in the catalyst bed was 600°Ge In the second catalyst regeneration (after sample 168) a total of 700 liters (STP) of air was passed over the catalyst for a period of 2 hours. The maximum temperature of the catalyst'during this regeneration was 620°G. The level of the catalyst activity was in­ creased after each air regeneration. Sample 61 had a sulfur content of „533 percent. Sample 62 (the first sample after the first catalyst re­ generation) had a sulfur content of .279 percent. The sulfur content of the product oil before the second regeneration was „569 percent. After this regeneration the sulfur content dropped to .264 percent. The gas used for the CGR run was a gas mixture considered typical of the make gas from a "catforming" unit. The analysis of this gas (as volume percent) was presented in the materials section. gas delivered was made as a check on its composition* An analysis of the Presented below is this analysis along with the composition specified when the gas mixtures were ordered. Specified composition (percent by volume) Delivered composition CH4 0^6 G3H 6 °3h8 89 3.5 1.5 3.5 2.5 84 6 .0 3.7 3.9 2.4 H2 =22= This check analysis indicated a somewhat leaner hydrogen composition than was anticipatedo The initial hydrogen content of the recycle gas was 84 percent. The hydrogen content of the recycle gas after 1341 hours of operation had dropped to 81,1 percent. This small decrease in hydrogen content did not noticeably affect the effective desulfurization during the run. Green (6) investigated the effect of gas composition on effective desulfurization and Silvey (4) has made a more thorough search in this direction. The average gas consumption for the CGE run was approximately twice that found for previous runs (GRS and MGR) where pure hydrogen was used for recycle and make=up, .Average consumption data for the CGR run varied between 280 to 290 SGF/bbl. The temperature readings shown on the data for samples 30, 35» and 36 (Table VIII) are not the actual temperatures for these samples. The dry cell in the temperature indicating potentiometer was nearly dead for the period between samples 30 to 3 6 , For the three samples cited, a close . cheek on the standardization of the potentiometer was not made and the temperatures for samples 30, 35» and 36 were lower than the actual readings taken. The fact that temperature is a critical factor in effective de­ sulfurization is readily shown by these three sample periods. They show that when the temperature is below a certain critical level (Munro (3 ) thought this was below 4d0°C) the sulfur content is correspondingly higher. For samples 30, 35, and 36 respectively the sulfur content of the effluent oil was ,646, ,552, and ,568 percent. The other samples taken during this *»23period were all below 0 o5 percent sulfur. From sample 99 to sample 106 gas consumption calculations were not made, At this time the'-method of gas compression was changed (see Equipment section)9 and establishment of new operating procedure, precluded any gas balance or gas consumption calculations. The period of the run from sample 130 to sample 145 also did not have any gas consumption data, At this time the pressure in the gas make-up cylinder fell below the pressure for which the Brooks rotameter .was calibrated and it was not possible to measure the quantity of make-up gas added to the reactor system. When, new cylinders of the make-up gas were delivered the gas consumption calculations.were resumed with sample 146 , The primary purpose of the CGR run (Table VIII) up to sample 6l was the determination of gas consumption and catalyst life using the "catforming" gas on recycle. After sample 6l it was decided to run at- a space velicity of 1 .0 until the sulfur content in the product oil exceeded 0.5 percent, When this occurred the catalyst was to be regenerated and the process repeated until the time between regeneration periods became excessively short, As the run progressed from sample 61«, the decision was then made to run until the composite blend of the product oil samples reached 0.5 percent sulfur. The catalyst would then be regenerated, and a composite blend equal to 6 ,5 percent sulfur would again be the point at which catalyst regeneration would take place. The run was ended, however, when it became obvious that the time in­ terval between catalyst regeneration was prohibitively long if the ultimate deterioration of the catalyst was to be determined« CONCLUSIONS The brief studies made with nickel catalysts indicate that these catalysts are inferior to molybdenum catalysts as far as catalyst life and the degree of desulfurization are concerned. Data from these studies also substantiate in some measure the contention that the nickel catalysts desulfurize for the most part through a chemical reaction mechanism and that they do not act as true catalytic desulfurization agents. Gas consumption data found with HoS 2 catalysts indicate a higher consumption figure with a Mcatformingtt gas mixture than with pure hydrogen when these gases are.recycled. When either hydrogen or a gas mixture was. used as the recycle gas, the hydrocarbon gas buildup per recycle was not excessive and the buildup of hydrocarbon gases that did occur did not noticeably affect the de­ sulfurization process. Use of a gas mixture in the desulfurization process, as well as the continuous recycle of the effluent gases, did not noticeably affect the degree of desulfurization obtained with HoSg catalysts. Deactivation of the molybdenum catalysts with prolonged use was in­ dicated by the studies made, but air regeneration restored the activity of these catalysts to a higher level than that of the fresh catalyst,. Although the molybdenum catalysts did exhibit some deterioration with use, specification oil was produced for 526 hours without catalyst regeneration when pure hydrogen was used as make-up and for 493 hours before regeneration was necessary when "cat'forming".gas was used as make*= up. . At^IJOWIEmEMENT The author wishes to thank the Husky Oil Company who sponsored the fellowship under which this work was carried out. - 26- LITERATURE CITED (I) A 0 S 0 T. M 5 STANDARDS■GN PETROLEUM AND LUBRICANTS, American Society for Testing Materials, Philadelphia9 (1941),« (.2) Koski5 O 0 H 05 M 0S 0 Thesis5 Montana State College (1951)* (.3 ) Mnnro 5 B> L 05 M 0S 0 Thesis5 Montana State College (1952)* (4) Silvey5 F 0 C 05 M 0S 0 Thesis5 Montana State College (1953)« (.5 ) Haas 5 P 0 A 05 M 0S 0 Thesis5 Montana State College (1951)* (6 ) Green 5 K 0 J 05 M 0S 0 Thesis5 Montana State College (1952)* (7 ) Cdykendall5 J.0 W 05 M 0S 0.Thesis5 Montana State College (1952).* (5) Brovm 5 H 0 R 05 and Meyersori5 S 05 Ind0 Epg 0 Chem05 44, Hp 0 Il 5 2620-2631, (1 9 5 2 ). (.9 ) Hatch 5 L 0 F -05 Petroleum Refiner5 32 5 No. 6 5 105-107 (1953)* (IO) Anon5 Petroleum Refiner5 3l, Np. 6 5 108 (1952)* (II) Anon5 Petroleum Refiner5 31, No. 9, 226 (1952)* (12) Anon 5 Petroleum Refiner, 31, No*.9, 114 (1952)* ”27" APPEIfflIX page 28 Table I Fuel Oil Inspection Data, Table II Catalysts Table III Tabulated Data for Nickel Study Run One 0 0 0 0 0 * 0 0 Table IV Tabulated Data for Nickel Study Run Two o o o o o o o o Table V Tabulated Data for Nickel- Study Run Three o o o o o o o o 32 Table VI Tabulated Data for Gas Recycle Study 0 0 0 0 0 * 0 0 34 Table VII Tabulated Data for Molybdenum Comparison Run, » Table VIII Tabulated Data for Catforming Gas Study Run Figure I Reactor Diagram o o o o o , o b o o o o 0 * o 0 o o O o O o . 31 37 O o 30 0 O e O o O O o o ’ TABLE I FUEL OIL INSPECTION DATA Sample Designation Charge Stock No. 3 Oil CGR Comp. 103-10? CGR Comp. 60-168 A e-P6I Ao-5,-ToM„ Distillation I6BoPo 5% 1# 2# 3# 4# 50# 60# 70# 80# 90# 95# E. -P. 3P.6 op 425 504 520 536 548 ■ 558 567 575 584 594 6ii 625 652 3 4 .6 PF 160 3 4 .2 418 411 461 572 6Q3 630 649 599 627 645 Recovery 9 9.9# 9 7 .0 # 97.5# 462 497 513 526 538 550 562 op 145 • 494 512 524 536 548 560 575 Residue 0.8# I .2 5 # 1 .5 # Loss 0 .2# 1 .7 5 # 1.0# Wt 6 # Sulfur • 2.19# ■ «460 # .539# -29- TABLE II CATALYSTS Run Number Catalyst and Composition N S M and NSR=III Nickel Oxide NiO 10, AlgO^ Balance NSR=II Nickel-Hydroxide Ni(OH)2 GRS Molybdenum Sulfide MpS2 1556 Ai2O3 Balance MCR and CGR Molybdenum Sulfide . Mo 9.66$ S 7.97$ Al2 O3 Balance Identification Code Harshaw Number 3 Calcined . Ni-0301 T 1/8" Harshaw Number 3 Harshaw Mo-X-L32l -42 T 1/8" Harshaw Mo-0801=T 1/8" RI 34-1 Lot. 191- A-l-1 TABLE T H T A B U L A T E D D A T A F O R N I C K E L S T U D Y R U N O N E (NSR-I) Rtin N u m b e r s ’ ' NSR-I G r a m s “Catalyst s 100 Catalyst.,Reference: N i O H a r s h a w #3 Calcined, N i » 0 3 0 1 O i l Charge 0 API; -^*30 Percent Sulfur: 2,19 Samp 6 Total Avg, Cat. Reactor Space Vel, Recycle Ft3/bbl Nb, Hours Temp, °F psig ,-Gms/gm/hr I 2 I 3 4 5 I 3 5 7 .9 6 11 7 13 15 17 8 9 Yields Wt4 734 673 711 732 714 723 730 729 729 97.7 59 63 1.94 3.12 3.07 3.24 60 2 ,6 6 64 64 6l 2.67 3.21 3.03 • 3.41 60 6l 62 T 1/8" Hp Consumpe Ft3Zbbl 3530 . 2100 2070 2010 2260 2260 1920 2040 2010 -7.13 !field Product gms oil # S 190 612 .68 1 .2 2 600 634 1.24 1.43 520 522 629 1.71 1.69 Recycle Gas He H2 96.9 3 .1 1 .6 8 594 1 .6 1 658 1.76 83.4. 1 6 .6 T A B L E 'TV T A B U L A T E D D A T A F O R N I C K E L S T U D Y R U N T W O (NSR-II) R u n Number:"" Grams C a t a l y s t : Catalyst-Referenced Oil" Charge 0 API; — Percent Sulfur; Samp6 Total No6 Hours I 2 3 4 5 6 7 B 9 10 il 12 I 2 4 6 8' 10 12 14 16 18 20 21 Yield; NSR-II IOO N i ( O H ) ^ s H a r s h a w #3 30 2=19 Avg^6Cat6 Reactor Temp60F psig . 59 757 729 725 721 725 725 725 725 725 725 725 725 Wte % 61 58 60 57 58 61 61 61 62 60 61 98.6 Space Vel6 ,Recycle Ft^/bbl gms/gm/hr 2.09 3.07 2.99 3.37 -3.12 3.05 3.22 2.89 3.12 3.08 3.14 3.47 Ho Consump6 Ft3/Tbbl 3120 1970 2130 1890 2040 206 304 590 665 615 . 601 635 572 616 608 2030 187© 22l0 1980 2060 2030 1880 Yield Product gms oil % 8 620 -9.65 342 .83 1.18 1.44 1.58 1.70 1.70 1.71 1.76 1.82 1.82 1.87 1.89 Recycle Gas H2 He ~ 10 Q — ’ V- 86.7 13.3 TABLE V TABUL A T E D D A T A F OR N I C K E L S T U D Y R U N T HREE (NSR-IIl) R u n Numbers NSR-III G r a m s Catalysts 200 Catalyst R e f e r e n c e s . N i O H a r s h a w #3 C alcined O i l Charge 0 APls »,30 P e rcent Sulfur: 2,19 Samp, No, I 2 3 4 5 6 7 8 9 10 Il .12 13 14 15 16 17 18 19 20 21 22 23 24 25 Total Hours 3 11 15 19 23 27 31 35 39 43 47 51 55 59 63 67 71 75 79 83 87 91 95 99 103 AvgeCat, Reactor Tempe0F psig 579 741 102 ,0588 18,400 loo .0264 40,300 ,0869 ,1081 .1243 ,1238 .1211 ,1205 ,1175 ,1191 ,1300 ,1175 ,1125 .1250 .1053 .1204 .1225 .1125 .1175 .1132 ,1090 .1211 .1225 .1131 .1190 11*300 9,080 720 98 723 723 725 99 99 97 725 lol 723 725 725 97 723 IOO loo . 725 723 725 725 725 723 725 725 725 725 725 725 725 725 Space Vel, Recycle Ft3/bbl gms/gm/hr 96 98 102 103 105. 102 i03 105 104 101 102 99 99 IQl 101 8,500 9 ,230 ' 9,430 8,800 9i710 8;250 8,150 9,720* 9,420 8,500 10,100 8,800 8,660 9i440 9,7©0 8,660 9 ,oio 8,750 8,660 8,690 8,910 H 2 Consump. Ft^/bbl Yield gms oil Product # S 1.18 31 37 , .27 6-1 .09 76 .17 88 ■ .14 .87 .13 85 .19 .22 84 82 ,25 .24 84 92 .26 82 .31 80 .38 88 .36 74 .41 84 .43 86 .4 7 .56 79 82 .65 81 .68 76 .77 .84 85 86 .9 0 80 .92 84 .9 7 Recycle Gas H2 -He ~100 . ■ •• 34.4 • . 65.6 T A B E E V (continued) • T A B U L A T E D DA T A F O R N I C K E L S T U D Y R U N T H R E E (-NSR-Hl) Samp0 No o 26 27 28 29 30 Yield; Total Hours 107 Hl 115 H9' 123 Avg, Cat, Temp00F 97 99 90 98 96 725 725 725 723 725 Wt0 £ Vol. % Reactor psig Space Vel0 gms/gm/hr .1190 »1131 »1219 .1225 .1769 Recycle Ft3/bbl 8,910 9s370 8,710 8,660 6,040 87.8 90.4 Composite Samples #1=27: «514^ S e Composite Samples #1=27 consumed 21e8'Ft3 H^/bbl oil* H2 Consump. Ft3/bbl Yield Broduct Recycle gms oil ~% S -Oas % He 84 80 86 86 124 1.04 1.08 1.10 1.10 1.20 37.7 62.3 TABlA V T TABULATED DATA FGE GAS RECYCLE STUDY Run WiamberT GRS Grams Catalysts 100 Catalyst"Reference: Harshaw MoX=L321-42 OiT''Charge-0API: " ~ 3 0 ' Percent Sulfur: 2,19 Slamp, No. Total Hours 6 I 2 14 22 3 30 4 ■ 5 . 38 6 46 54 7 62 8 70 9 10 78 ii 86 12 94 102 13 HO 14 118 15 16 126 17 134 18 142 150 19 20 158 166 21 22 174 182 23 ISLQ24- Avg. Cat. Temp °F Space Velo Recycle gms/gm/hr .Ft3/bbl H2 Consump. Ft3/bbl 770 770 770 772 770 770 770 770 770 770 770 774 ' 772 774 770 770 768 770 770 .900 .664 .637 .670 .540 .575 .572 .550 .535 .554 .565 .561 11,2 5 0 —~ 11,200 11,100 11,100 11,600 ***” —— .566 10,900 .527 .530 11 ,3 0 0 .604 10,200 .655 9 ,6 2 0 .636 0626 768 .631 770 770 770 768 .632 9,660 10,000 9,430 9,720 9,230 9,360 9,610 .655 =655 .619. 5,350 8,740 10,000 9 ,3 4 0 12,020 11,100 11,150 11,450 — — — ™ =■” Yield gms oil Product ^ 8 500 .681 493 474 497 401 426 425 408 397 410 418 416 418 391 394 .566 464 504 488 481 484 =■— ™— =«=” 476 502 502 474 .511 .471 .453 -415 .400 .396 .397 »375 .403 .403 .375 .388 . .356 .397 .452 .437 .402 .397 .423 .458 .417 .403 Recycle Gas He H2 —100 & f ; 96:5 3.5 95.7 4.3 - TABLET 371 (continued) TA B U L A T E D D A T A F O R G A S R E C Y C L E S T U D Y Samp. No. 25 26 27 28 29 30 31 32 33 34 35 36 37 33 39 40 41 42 . 43 44 45 46 47 48 49 50 51 52 5354 55 Total Hours 198 ' 206 214 222 230 238 246 254 262 270 278 286 294 302 310 318 326 334 342 350 358 366 374 382 . 390 398 406 "414 422 430 438 Space Vel. gms/gm/hr Recycle Ft3/bbl 768 .648 770 770 770 772 768 768 770 772 770 770 770 ’ 774 772 772 770 770 772 772 770 772 770 768 770 770 770 772 770 770 770 772 .681 9,520 9,230 9,660 9,030 9,520 9,030 9,370 9,660 9,910 9,180 8,840 Avg. Cat. Temp. °F .650 .664 .641 .652 .633 .622 .633 .672 .718 .682 .96? *854 .606 .567 .531 .672 .688 .678 „688 .685 *713 .690 .690 .697 *705 .715 .707 .722 . .712 9 ,0 8 0 6,480 7,410 10,450 11,100 1 1 ,4 4 0 9,420 . 9,130 8,980 9,270 9,130 8,740 8,940 9,040 9,220 8,880 8,740 8,740 8,780 8,840 Ho Consump. Ft3/bbl Yield gms oil Product ^ S .. . 498 174 217 277 286 275 242 269 521 .438 .408 .413 .431 .393 .417 .428 .395 .382 .397 .412 .414 .528 .504 *425 .358 .381 246 258 257 249 55 68 89 94 96 82 82 82 73 69 89 103 123 131 133 134 141 134 132 499 504 490 499 484 476 485 514 552 523 750 660 464 434 425 518 532 523 532 530 552 532 532 535 550 558 551 560 553 Recycle Gas H2 He 95*2 4.8 96.3 3.7 95.6 4.4 .422 .456 .454 »455 .447 .467 .447 *452 .454 .460 .467 .481 .474 .464 T A B L E .T I (continued) T A B U LATED D A T A F O R GA S RECYCLE' S T U D Y Samp * No. Total Hours 56 57 446 454 462 470 478 486 494 58 59 60 61 62 63 64 65 66 Yields Avg. Cat a Temp. 0F 502 510 518 526 Wti % 768 770 770 770 770 772 770 770 772 768 770 96.9 Space Tel. gms/gtn/hr Recycle Ft3/bbl i7l3 »699 .718 ' »725 .720 .675 .703 .691 »692 . .680 .769 8,780 9,080 8,740 8,740 8,840 9,340 9,080 9,230 9,520 9,230 . 8,590 Ho Consump. Ft3/bbl 142 137 135 134 132 131 130 134 137 141 140 ■ Yield gms oil . 560 . 543 558 564 560 525 546 536 537 528 596 Rpoduct Recycle Gas H2 He .464 «472: .471 «481 .476 .443 *480 .471 .478 .455 .478 95.0 5.0 94.0 6.0 95.4 4.6 . TABLE VII TABULATED DATA FOR. MOLYBDENUM COMPARISON RUN Run Number? MCR Grams Catalyst; • 100 Catalyst Reference; HarshawMo-0801 T l/8" RI 34=1 Lot 191A-1-1 Oil Charge 0APi; ^30 Percent Sulfur; 2.19 Reactor Pressure; 500 psig 2 3 4 5 ' 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Space Vel 0 gms/gm/hr Recycle Ft3/bbl I 16 24 32 40 48 56 64 72 80 761 .743 8,550 128 574 768 .6?? 9,000 126 770 0694 8,820 74 538 536 .109 770 .961. 6,260 100 743 .211 770 770 1 .0 1 2 ■ 1=021 6,180 Ho 6 ,0 6 0 107 768 1.289 i255 .224 ■ .421 770 772 1.301 4*800 4,540 783 790 997 138 88 779 772 770 768 770 772 768 770 772 770 96 104 Il2 120 128 136 144 152 160 1.298 1.296 1.300 768 . Composite Yield; •1 .3 0 0 • 1.310 1.300 1.365 1.350 1.369 1.331 .869 .868 Wt0 % 97=5 Ho Consump;, I I Total Avg. Cat0 Hours Temp-. 0F £ Samp= No. 127 Yield; gms oil Product % 8 =Ioi .086 4.4 - .491 95.5 .496 .515 ' .532 4.5 4,780 4,650 . Iooi .420 ?423 4,750 123 ioii 4,860 4,710 4,600 4,600 140 141 132 138 141 134 139 .143 1015 1011 4,550 4,810 5,140 . 5,150 1016 1065 1052 1067 1039 '-«100 95.6 1017 1002 .413 123 130 133 4,920 ,Recycle Gas He % =419 =442 =457 678 .519 .304 677 .317 95.8 . 4.2 TABLE' V I H TABULATED DATA FOR CATFORMING GAS STUDY RUN Run Number; Grains Catalyst Catalyst References Oil Charge 0APIs Percent Sulfurs Reactor Pressures Samp. No. Total Hours I 3 2 11 19 3 4 . 27 35 5 6 43 5l 7 8 59 67 9 10 75 Il . 83 12 91 99 13 107 14 115 15 16 123 131 17 18 139 19 147 20 155 21 163 22 171 179 23 CGR IOO Harshaw Mo-0801 T 1/8" RI 34=1? Let 191A-1-1s Previously on MCR 160 Hrs» — 30 2,19 500 psig Avg. Cat. Temp. °F . 766 770 768 768 770 772 768 766 766 765 768 768 772 770 770 768 768 770 770 765 772 770 775 H2 Consump. Ft3/bbl Space Vel0 gms/gm/hr Recycle Ft3/bbl 1.140 .936 .662 . 1.031 .849 1.000 .901 .740 1.005 1.008 1.045 1.0l2 1.004 .990 1.078 1.012 .895 .874 .917 .944 .946 .926 .940 5,610 —83 5,600 9,550 —82 6 ,0 4 0 234 279 245 247 296 284 288 7,280 6 ,250 ' 7,120 8,640 6 ,4 0 0 6,350 .6 ,1 3 0 ■ 6,230 6,0706,380 5,940 6,190 7,240 7,500 7,350 7,050 6,730 7,000 6,866 216 Yield gms oil 333 730 515 825 660 779 70l 576 783 785 288 814 286 284 293 786 • 781 779 838 787 301 298 306 311 318 314 308 306 292 696 670 716 734 736 720 732 Product $ S .515 O441 .304 .427 .377 .457 .421 .379 .459 .498 .491 .481 .450 .495 .518 .474 .472 .473 .478 .496 .479 «448 ,453 Recycle Gas H2 He 84.0 16.0 TABLE'VIII (continued) TABULATED DATA FQB C A T FO R M IN G GAS STUDY RUN. Samp. Total No. ■Hours 24 25 •26 27 28 29 3031 32 33 34 35 36 37 3# 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 . 187 195 203 211 219 227 235 243 251 259 267 275 283 291 299 307 315 323 341 349 357 365 373 381 389 397 405 413 ' 42l 429 Avg, Cat. Temp. 0F 768 772 759 770 770 770 763* 772' 770 774 770 770* 770% 772 . 772 770 768 772 768 770 768 770 770 774 770 770 772 770 772 772 Space Vel. gms/gm/hr Recycle Ft^/bbl .906 .964 .860 .934 .943 .934 .918 7,250 6,760 7,460 6,840 6,960 ■ .869 • .765 .732 .784 . .793 .789 .773. .808 .782 .797 .865 .842 .921 1.048 .888 .864 .957 .854 .743 .692 .695 .698 .706 6 ,9 0 0 7,000 7,400 8,410 8,910 8,260 8,060 8,220 % Consump. Ft3/bbl 291 275 261 276 263 255 264 268 264 262 8,020 7,660 7,770 6,980 6 >070 7,150 7,550 6,810 7,610 264 265 267 258 265 266 ■ 263 262 261 260 258 258 258 257 254 8 ,650 256 9,210 9,300 9,260 9,110 257 259 260 261 8,320 8,290 8,320 Yield gms oil 705 751 669 727 734 726 714 . 675 594 569 610 624 613 600 628 608 628 673 655 718 816 692 673 747 666 578 541 542 543 55© Product # 8 .483 .483 .494 .438 .481 .576 Recycle Gas Hg He 82.6 17.4 82.3 17.7 .646 .482 .439 .448 .467 .552 .568 .456 .425 .468 .450 .436 »46$ .447 .496 .514 .483 .482 .496 ,455 .393 »417 .368 .415 T A B E E V H I (continued) TA B U LATED D A T A F O R CATFO R M I N G G A S S T U D Y R U N 54 55 56 57 $8 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 Total Hours 437 445 453 461 469 477 485 493 501 509 517 525 533 541 549 557 565 573 581 5d9 597 605 613 621 629 637 . 645 653 661 669 677 Avgc Cat. Temp. °F 770 768 770 768 770 781 777 779 775 768 775 775 775 779 774 770 775 781 779 777 775 775 779 781 781 775 779 779 779 772 775 Space Vel. gms/gm/hr .686 0737 .709 ' .694 .804 1*139 1.148 .926 *915 .932 1.075 1.103 1.095 1.059. 1.080 1.080 .990 .976 .998 1.006 1.032 .979 1.006 .989 .940 .968 *975 ,961 .963 1.081 1.062 Recycle Ft3/bbl 9,450 8,820 9,460 9,310 , 7,760 5,800 5,640 6*910 7,150 7,190 5,980 5,590 5,540 5,910 ^ 5,940 5,860 6,580 6,600 6,450 6*380 6^370 6,380 6,550 6,530 6,830 6 ,6 4 0 6 ,650 6*750 6,320 ' 5,930 6 ,1 4 0 Ho Conpumpe Ft3/bbl 262 263 264 265 265 264 261 263 256 255 253 255 254 251 251 252 254 253 254 252 252 252 248 249 247 246 246 245 243 245 241 Yield gms oil 535 574 552 542 627 88? 895 743 TH 725 835 893 875 846 863 863 759 758 776 783 803 761 783 768 730 746 752 741 743 835 822 Product # S R e c y c l e Gas H2 He .424 .477 .466 .482 .472 .579 .592 .533 .279 .353 .359 .387 .384 »399 *455 .450 «416 .400 .393 .413 .458 .419 .423 *436 .414 .441 .438 .437 .443.460 .491 81.0 19.0 "Otr Samp. No. ■TABLE! V I I I (Goptinued) T A B ULATED D A T A •F O R 'C A T F O R M I N G G AS S T U D Y R U N Samp. No. 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 iob" ioi 102 103 104 . 105 106 107 108 109 110 111 112 113 114 115 Total .Avg. Cat. Hours Temp. °F 685 693 701 709 717 725 733 741 749 757 765 773 781 789 797 805 813 821 829 837 845 853 861 869 877 885 893 901 909 917 925 77,7 777 . 779 775 779 781 775 777 779 779 779 779 779 779 781 779 779 779 777 779 779 779 779 779 779 779 777 777 .781 779 777 . Space Velo gms/gm/hr 1.068 1.091 1.098 1.098 1.062 1.058 . .981 .981 .972 1.175 1.114 1.061 1.031 .956 .947 .974 .968 ,990 .976 6973 .923 .943 .963 1.021 1.036 1.041 1.034 . 1.048 1.062 1.043 ‘ 1.034 Recycle. Ft3/bbl 6,140 6,170 5,960 5,800 6,000 6,010 6,600 6,830 6,730 5^540 5,670 5,950 6.240 6,220 6,700 H2 Consump. FtVbbl 239 239 237 235 233 231 230 231 23l 234 233 237 232 232 e-™=a 6,780 6,810 6,520 6 ,460 6,710 6,980 6,650 6,780 6,340 6,250 6,230 6 ,2 5 0 6,070 6,080 6,190 6,100 — = 560 364 299 309 308 269 290 357 310 Yield. gms oil •824 842 847 842 821 81? 757 757 749 923 892 850 809 750 736 758 753 771 759 757 718 749 749 795 807 810 806 814 829 813 ' 806 Product # S R e c y c l e Gas H2 He .503 .514 .516 i545 .500 .506 .468 • .470 .468 .557 .558 .507 .487 .536 .425 .448 .461 .475 .477 .453 .i424 .436 «460 .431 .473 .489 .510 .543 .514 *534 .517 81.5 18.5 $ TABEET-'VIII (continued) T A B U L A T E D D A T A F OR C A T F O M B T G G A S S T U D Y RUIf Samp, No, Total Hours ii6 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 933 941 949 957 965 973 981 989 997 1005 1013 1021 1029 1037 1045 1053 1061 1069 1077 1085 1093 iioi 1109 1117 1125 1133 1141 1149 1157 1165 1173 Space Vel» Avg, Gat, Temp, 0F • gms/gm/hr 781 779 770 781 777 775 779 784 772 777 777 775 779 781 779 781 779 777 779 781 775 782 782 777 779 779 777 782 779 777 781 1.019 .991 .991 .969 .945 .980 »968 .972 »940 .930 .956 1,028 1.039 1.025 1.025 1.039 1.011 1.034 1.008 .986 1.005 1.025 .975 1.022 1 .0 0 6 1.006 1.000' .995 1.006 1.013 1.03l Recycle Ft3/bbl Ho Consump0 Ft3/bbl Yield gms oil Product jg g 6,420 6,540 315 282 270 298 293 304 336 363 361 340 354 364 794 772 773 754 744 763 753 756 731 723 744 800 808 799 798 808 787 806 785 769 782 798 759 796 783 783 778 774 783 789 804 .491 »502 .531 .500 .430 .535 .503 .517 .513 .465 .469 .527 .535 .531 .538 6,500 6^680 6,810 6 ,4 0 0 5,980 6,670 6,920 6,930 6,750 6,260 6,200 6,280 6,280 6,600 5,950 3,830 5,450 6,530 6,420. 6,280 6,610 6,310 6,840 6,410 6*450 6,370 6,410 6,360 6,660 364 346 cooes* = = * = O = O O = O = O = O = = = O O C=^=O S3 = O = O . = 0 = 0 356 .526 .514 .570 .546 .514 .534 .520 .500. .571 .558 .547 .548 .548 .529 .571 .548 Recy c l e Gas H2 He TABIE V H I Cc o n t i n u e d ) T A B U L A T E D D A T A F O R .CATFO R M I N G G AS S T U D Y R U N Samp6 No6 Total Hours Avg., Cat, Temp6 °F 147 148 149 159 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 16 ? 168 169 170 171 172 173 174 175 176 177 1181 1189 1197 1205 1213 1221 1229 1237 1245 1253 1261 1269 1277 1285 1293 1301 1309 1317 1325 1333 1341 1349 1357 1365 1373 1381 1389 1397 1405 1413 1421 779 781 . 779 777 779 779 777 779 781 777 779 781 779 777 78l 777 779 781 777 779 781 779 779 777 781 779 775 779 777 775 781 Space Vel6 gms/gm/hr 6,486 6,310 6,300 6,380 6,390 6^330 6,830 5,850 5,960 6,160 6,310 .992 1,021 1,022 1,010 1,007 1,019 1 ,006 1,100 1,079 1.047 1,021 1,020 i995 1,000 .995 .997 1.031 1,019 .989 .994 1,045 1,028 1,031 .989 .945 1 ,015 1,009 1,027 1,002 1,024 1.034 Recycle Ft3/bbl 346 344 348 341 338 337 326 6 ,2 7 0 315 316 307 310 313 6,510 322 6 ,3 0 0 313 319 322 320 326 317 ’ 309 321 314 313 305 6,530 6,480 6,250 6,330 6,510 - ■ Hg Consump, Ft3Zbbl 6,520. 6,230 6,560 6,280 6,520 6,850 6 ,36 © 6,370 6,270 6,440 6 ,3 2 0 6 ,2 5 0 310 303 300 299 293 292 297 - Yield gms oil 772 796 797 786 784 7.93 783 856 840 815 798 795 774 778 775 777 803 794 791 795 836 823 803 768 . 734 790 786 798 780 797 806 Product % S Recycle Gas H2 He .562 .574 .565 .599 »567 .578 .645 .581 .582 ,605 .517 .575 <*465 ,581 ,548 .548 ,618 ¥ .665 .617 .588 .578 .589 .264 .331 .345 .352 .359 .370 .382 .393 .423 81,1 18,9 TABLET VIII (continued) ■ TABULATED DATA FOR GATFORMIEG GAS STUDY RUE Samp, Eoe Total Hours 178 1429 1437 179 180 1445 181 1453 182 1461 183 1469 184 1477 1485 185 186 1493 1501 18? 188 . 1509 189 1517 190 1525 191 •1533 1541 192 1549 193 Space Vel, gms/gm/hr Avg, Cat Teppe °F 781 779 781 779 779 . 779 779 779 78l 779 779 783 779 775 781 777 Composite Yields • Wte Wte Wte Wte '^ .994 .949 .994 .977 .964 .982 .960 ,968 .972 .940 .981 .934 1.909 .937 .952 .945 % 97.3 97.2 96.8 97.3 101 99.1 % % % 1q\ $ Wte % Recycle Ft-Vbbl Ho Consump, Ft-5Zbbl 6,500 6,790 6,510 6,600 6,700 6 ,5 6 0 6,TlG 6,660 294 ■ 294 296 297 292 293 298 295 6 ,7 0 0 296 7,180 7,140 291 292 . 28? 291 6 ,9 0 0 290 6,780 6,810 285 287 6 ,6 2 0 6 ,9 0 0 (Samples I through 8) (Samples 9 through 61) (Samples 99 through 123.) (Samples 99 through 123 ) . (Samples 169 through 193) Yield gms oil Product $ S 772 i414 738 .429 772 »405 .448 753. 748 . .475 .425 763 746 .451 .445 753 .448 755 743 .425 776 .483 .458 739 720 .478 .467 741 .468 752 .447 747 Recycle Gas . Composite %'S: .464 (Samples 62 through 123 ) ,502 (Sampled 62 through 168) »414 (Samples 169 through 193) Total Oil throughputs 145,232 Gme First catalyst regeneration at Sample .61, Second catalyst regeneration at Sample 168, ^Temperatures for these samples are incorrect due to non-standardization of potentiometer. r THERMOWELL ROTAMETER BLOW OUT LINE REGENERATION AIR LINE OIL RESERVOIR HEATING COILS PRESSURE GAGE----- FLOWRATOR / - M A K E UP GAS TANK Figure I. Reactor Diagram r-FEED GAS TANK ALUNDUM BALLS FEED. PUMP PRESSURE GAGE 7 CATALYST CONDENSER RESSURE GAGE BACK PRESSURE VALVE SIGHT "GLASS l— [ X COMPRESS/ ~ l ON TANK SURGE TANK CONTROLLER STANDPIPE-^ PRESSURE GAGE EXHAUST RECEIVING FLASK COMPRESSION PUMP 'I CO rn rn ro COMPRESSION OIL RESERVOIR WET T EST METER CAUSTIC WASH MONTANA STATE UNIVERSITY LIBRARIES 762 1001 4207 2 N578 H259c Cop. 2 108556 bydTodesulfuri»|tlon of Wyoming fuel oxl. a ' , - r ’v C1 Ci ' ]" t/'.r-f r./,. - a _____ j > • y i'A N S rT S f i f i d r i e c i b e c r fik c -s - r H ^59c fiAdr<-t< - r 6 # is ' # IPPFFA 1.2