Main line efficiency of sprinkler irrigation systems by Robert Goldthwaite Arrington

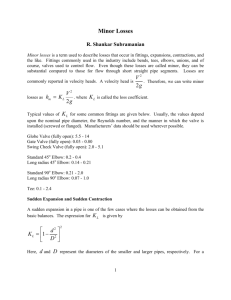

advertisement