Results of continuous coal charring operations by Allen Ackers

advertisement

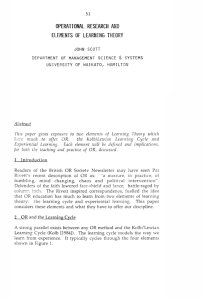

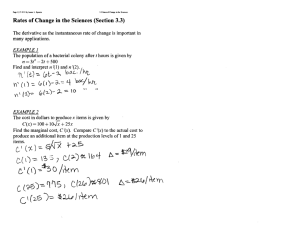

Results of continuous coal charring operations by Allen Ackers A THESIS Submitted to the Graduate Faculty in partial fulfillment of the requirements for the degree of Master of Science in Chemical Engineering Montana State University © Copyright by Allen Ackers (1957) Abstract: In order to produce soft coke or char from the non-coking coals of the northwestern United States, a medium temperature, continuous retorting process was developed at Montana State College. Originally sponsored by the P.D.P. Processing, Incorporated, the development has been supported by the State of Montana for the past two years and the work has been diverted towards the commercial utilization of western coals. The P.D.P. char process employs a stainless steel retort which comprises four concentric, vertical cylinders. The coal flows by gravity down the two-inch annular space between the two innermost cylinders. Hot flue gas is circulated on both sides of this annular space. The inner tube is rotated, thus assuring all char particles the same time-temperature history. The retort will produce char having less than 5 percent volatile matter, no moisture, and a 75 percent or more fixed carbon content. Char can be made from bituminous coal, sub-bituminous coal, and lignite. Specification grade creosote was made from bituminous coal. Coals from Red Lodge, Montana; Colstrip, Montana; Roundup, Montana; Sheridan, Wyoming; Spring Canyon, Utah; and Beulah, North Dakota were tested in the pilot plant. The retort operated with great success during the runs. The operating temperature of the retort was held around 11OO°F. The char produced meets specifications set by industries in the surrounding area. Estimated plant costs are $350,000 for a 100 ton/day plant, and $900,000 for a 500 ton/day plant. Under reasonably favorable circumstances, indicated payout time was under six years for four western locations. RESULTS OF CONTINUOUS COAL CHARRING OPERATIONS by ALLEN ACKERS A THESIS S u b m itted t o th e G rad u ate F a c u lty in p a r t i a l f u l f i l l m e n t o f th e re q u ire m e n ts f o r th e M a ste r o f S c ie n c e d e g re e o f i n C hem ical E n g in e e rin g at Montana S t a t e C o lle g e A pproved: Head, M ajor D epartm ent Bozeman, Montana May, 1957 -- O S r f Oj A rch iv es j k o t m '. I - u N m ome*. / Po S-Ir -\ - 2- TABLE OF CONTENTS Page A b s tra c t . . . . . . . I n tr o d u c tio n .................. Equipm ent and P ro c e d u re R e s u lts ........................... D is c u s s io n . . . . . . A cknow ledgnents . . . L i t e r a t u r e C ite d . . . , A ppendix ............................... • 3 . 4 . 5 .9 13 20 21 22 123661 -3 - ABSTRACT I n o r d e r t o p ro d u ce s o f t coke o r c h a r from th e n o n -c o k in g c o a ls o f t h e n o rth w e s te rn U n ite d S t a t e s , a medium te m p e ra tu re , c o n tin u o u s r e t o r t i n g p ro c e s s was d ev elo p ed a t Montana S ta te C o lle g e . O r ig in a lly sp o n so red by t h e P .D .P . P r o c e s s in g , I n c o r p o r a te d , th e developm ent h a s been su p p o rte d by th e S t a t e o f Montana f o r th e p a s t two y e a r s and th e work h a s been d iv e r te d to w a rd s th e com m ercial u t i l i z a t i o n o f w e ste rn c o a ls . The P .D .P . c h a r p ro c e s s employs a s t a i n l e s s s t e e l r e t o r t which c o m p rises f o u r c o n c e n tr ic , v e r t i c a l c y l i n d e r s . The c o a l flo w s by g r a v i t y down th e tw o -in c h a n n u la r sp ace betw een t h e two in n e rm o st c y l i n d e r s . Hot f l u e g as i s c i r c u l a t e d on b o th s id e s o f t h i s a n n u la r sp a c e . The i n n e r tu b e i s r o t a t e d , th u s a s s u r in g a l l c h a r p a r t i c l e s th e same tim e -te m p e ra tu re h i s t o r y . The r e t o r t w i l l produce c h a r h a v in g l e s s th a n 5 p e r c e n t v o l a t i l e m a tte r , no m o is tu r e , and a 75 p e rc e n t o r more f i x e d carbon c o n te n t. C har can be made from b itu m in o u s c o a l, su b -b itu m in o u s c o a l, and l i g n i t e . S p e c if ic a t io n g ra d e c re o s o te was made from b itu m in o u s c o a l. „ C o als from Red Lodge, M ontana; C o ls tr i p , M ontana; Roundup, M ontana; S h e rid a n , Wyoming; S p rin g Canyon, U tah ; and B e u lah , N o rth D akota were t e s t e d i n th e p i l o t p l a n t . The r e t o r t o p e ra te d w ith g r e a t su c c e ss d u rin g th e r u n s . The o p e r a tin g te m p e ra tu re o f th e r e t o r t was h e ld aro u n d UOO0F . The c h a r p ro d u ced m eets s p e c i f i ­ c a tio n s s e t by i n d u s t r i e s i n th e s u rro u n d in g a r e a . c irc u m s ta n c e s , in d i c a t e d p ay o u t tim e was u n d e r s i x y e a r s f o r f o u r w e ste rn l o c a t i o n s . -U INTRODUCTION D uring th e f i r s t y e a r s o f t h i s c e n tu r y , a m u ltitu d e o f lo w te m p e ra tu re c a r b o n iz a tio n p ro c e s s e s w ere d ev elo p ed ( 4 , 5 , 7 , 8 ) . Some o f th e s e n e v e r p a ss e d th e d e s ig n s t a t e , some w ere t r i e d o u t i n la b o r a to r y o r p i l o t s iz e u n i t s , and some com m ercial s iz e p l a n t s were b u i l t . was an u n q u a lif ie d s u c c e s s . None I n r e t r o s p e c t , th e d i f f i c u l t i e s seem t o have been due t o th e u n a v a i l a b i l i t y o f p ro p e r m a t e r i a l s o f c o n s tr u c ti o n , d i f f i c u l t y i n c o l l e c t i n g th e v o l a t i l e p o r ti o n s , and la c k o f m a rk e ts f o r t h e t a r s and o i l s p ro d u c e d . F u rth e rm o re , th e c h a r had t o compete p r i c e - w ise w ith coke b re e z e w h ich , more o f te n th a n n o t , was i n o v e rs u p p ly . < The s i t u a t i o n h a s a l t e r e d c o n s id e r a b ly . Today we f i n d t h a t co k in g c o a l i s n o t a s ab undant a s fo rm e rly and t h a t la r g e lo s s e s t o b re e z e i n coke­ making a r e n o t t o l e r a t e d . S t i l l f u r t h e r , b re e z e i t s e l f can now a b ly be rew orked and f e d t o th e b l a s t f u r n a c e s . p ro fit­ The d e c lin e i n th e a v a i l a b i l i t y o f b re e z e h a s l e d t o a s tr o n g e r demand f o r a n t h r a c i t e f i n e s , b u t th e s e a r e l im it e d by p ro d u c tio n r a t e s and l o c a t i o n . N on-coking c o a ls a r e i n g r e a t abundance th ro u g h o u t m ost o f th e U n ite d S t a t e s , and c h a r , which r e s u l t s from t h e i r c a r b o n iz a tio n , i s th u s re a d ily a v a ila b le . Modern h ig h te m p e ra tu re a l l o y s make p o s s ib le e q u ip ­ ment t o c a r r y o u t s u c c e s s f u lly t h e c h a r r in g o p e ra tio n a t a n econom ical c o s t. F i n a l l y , th e e v e r i n c r e a s in g demand f o r carbon a s a re d u c in g a g e n t c r e a t e s a m arket w hich can be f i l l e d b y c h a r . Exam ples w here c h a r a p p e a rs t o be an a c c e p ta b le form o f carb o n a r e t a c o n i t e r o a s t i n g , n o n f e r r o u s m e ta l s m e ltin g , and t h e p ro d u c tio n o f e le m e n ta l p h o sp h o ru s. -5 - I f t h e c h a r r in g te m p e ra tu re i s s u f f i c i e n t l y h ig h and th e p ro p e r g ra d e o f b itu m in o u s c o a l i s u s e d , th e v o l a t i l e p o r ti o n c o n ta in s a c re o ­ s o te f r a c t i o n w hich m eets American Wood P r e s e r v e r s ' A s s o c ia tio n s p e c i f i ­ c a tio n s . The l i g h t o i l and th e t a r s have a re a d y m ark et a s s o lv e n ts and c o a tin g , r e s p e c t i v e l y . T hus, i t a p p e a rs t h a t t h e r e i s a d e f i n i t e p la c e i n th e economy f o r an e f f i c i e n t c h a r p r o c e s s . W ith th e s e economic f a c t o r s i n m ind, a gro u p o f businessm en from L e w isto n , Id a h o founded th e P .D .P . P r o c e s s in g , I n c o r p o r a te d . T h is group e r e c te d a s m a ll p la n t a t M e lsto n e , M ontana, b a s in g t h e i r d e s ig n s more o r l e s s on t h e Hobson p a te n t ( 6 ) . T h is p l a n t n e v e r o p e ra te d s u c c e s s f u lly . F a i l u r e a p p e a rs t o have been due t o im p ro p er m a te r ia ls o f c o n s tr u c tio n and i n a b i l i t y to condense th e v o l a t i l e f r a c t i o n . I n 1954 th e p ro c e s s was moved t o th e l a b o r a t o r i e s o f th e B ig in e e r in g E xperim ent S ta tio n a t M ontana S ta te C o lle g e and th e developm ent h a s been c a r r i e d on t h e r e e v e r s in c e . EQUIPMENT AND PROCEDURE R e to r t T hree d i f f e r e n t r e t o r t s a r e m entioned i n t h i s t h e s i s . b a tc h r e t o r t , p i l o t p l a n t , and com m ercial r e t o r t . They a r e th e The b a tc h r e t o r t i s u se d o n ly t o g e t e s tim a te s on th e amount o f c h a r , o i l s , and d ry g a s t h a t can be produced from v a r io u s c o a ls . The b a tc h r e t o r t w i l l h o ld a p p ro x im a te ly one pound o f c o a l and i s h e a te d e l e c t r i c a l l y . The p i l o t p la n t i s b u i l t f o r c o n tin u o u s o p e r a tio n and w i l l produce 2 ^ - to n s o f c h a r i n a 2 4 -h o u r p e r io d . The p i l o t p la n t i s u sed t o p ro d u ce sam ples o f c h a r —6 — and o i l s f o r t e s t i n g p u rp o s e s . The com m ercial r e t o r t i s b e in g b u i l t i n Red Lodge, M ontana, and i s a m o d ifie d d e sig n o f th e p i l o t p l a n t . A s im p lif ie d d iagram o f th e p i l o t p l a n t a t Montana S t a t e C o lle g e i s shown i n F ig u re I . The r e t o r t c o n s i s t s o f a s e r i e s o f c o n c e n tric c y lin d e r s , th e in n e r one b e in g 14 in c h e s i n d ia m e te r and e ig h t f e e t lo n g . The c a r b o n iz a tio n ta k e s p la c e w ith in th e tw o -in c h w ide a n n u la r sp ace form ed by th e two in n e rm o s t c o n c e n tric v e r t i c a l c y l i n d e r s . Hot g a se s a r e p a ss e d on th e o u ts id e o f t h i s a n n u la r sp ace and th u s h e a t t o th e c o a l i s from b o th d i r e c t i o n s by c o n d u c tio n th ro u g h t h e s e w a l l s . C o a l, c ru sh e d t o l |- i n c h m in u s, i s f e d i n t o t h e a n n u lu s from above by g r a v i t y . The in n e r c y lin d e r i s r o t a t e d slo w ly on i t s v e r t i c a l a x i s , k e ep in g t h e c o a l i n s l i g h t a g i t a t i o n so t h a t each p a r t i c l e h a s a u n ifo rm tim e -te m p e r­ a t u r e h i s t o r y , w hich makes f o r a u n ifo rm p r o d u c t. The i n n e r tu b e h a s nubs w elded on i t s o u te r s u rfa c e t o a i d i n a g i t a t i n g th e c o a l and o p e ra ­ t i o n h a s been s u c c e s s f u l when r o t a t i o n r a t e was v a r ie d from 0 .5 t o 2 r .p .m . T em perature d u rin g th e p r o c e s s v a r i e s fro m 1100 t o 1200°Fj p r e s s u r e i s m a in ta in e d s l i g h t l y su b -a tm o sp h e ric ( n e g a tiv e ) by t h e e f f l u ­ e n t g a s blow er t o remove th e v o l a t i l e m a tte r from th e c o a l, and r e t e n t i o n tim e i s g e n e r a lly i n th e o r d e r o f 15 -2 0 m in u te s . Twin s ix - in c h s t a i n l e s s s t e e l screw co n v ey o rs o f a d ju s t a b le sp ee d remove t h e h o t c h a r from th e b ottom o f t h e r e t o r t . C o o lin g o f th e c h a r i s acc o m p lish e d by p a s s in g i t th ro u g h a s e r i e s o f w a te r - ja c k e te d screw conveyors b e f o r e i t e m its i n t o th e a i r . -7 - Th® second a n n u la r s p a c e , w hich c o n ta in s h o t c i r c u l a t i n g f l u e g a s , m ust be b rid g e d to p e rm it rem oval o f th e v o l a t i l e m a tte r and m o is tu re from t h e c o a l to th e t h i r d a n n u la r s p a c e . w ays. T h is i s acco m p lish ed i n two O r ig in a lly , t h i s was done b y p la c in g 80 tw o -in c h -d ia m e te r s t a i n ­ l e s s s t e e l tu b e s a t a 4 5 -d e g re e a n g le a c r o s s th e a n n u la r s p a c e . They worked s a t i s f a c t o r i l y e x c e p t w ith v e ry d u s ty c o a l s , i n w hich c a se th e r e was a te n d e n c y f o r them t o p lu g . To overcome t h i s o b je c t io n , a s l o t was c o n s tr u c te d betw een th e two tu b e s and a s e r i e s o f lo u v e r s , much l i k e a V e n etia n b l i n d , p la c e d i n i t . H ere th e v o l a t i l e m a tte r , m o is tu re and d u s t came o f f e a s i l y , y e t no c o a l s p i l l e d o v e r. So s a t i s f a c t o r i l y d id th e s e lo u v e rs o p e r a te t h a t th e f i r s t com m ercial r e t o r t w i l l have them e x c lu s iv e ly . The f o u r c o n c e n tr ic tu b e s o f th e r e t o r t a r e made o f No. 304 s ta in le s s s te e l. The com m ercial r e t o r t i s b e in g c o n s tr u c te d o f No. 310 b ecau se o f i t s even b e t t e r h e a t - r e s i s t i n g a b i l i t y ; how ever, a f t e r two and o n e - h a lf y e a r s o f i n t e r m i t t a n t u s e , th e s t a i n l e s s s t e e l i n th e p i l o t p la n t shows no a p p r e c ia b le d e t e r i o r a t i o n . H eat f o r th e p i l o t p l a n t i s f u r n is h e d by b u rn in g n a t u r a l g a s i n a fu rn ac e. O r ig in a lly , th e s e g a s e s w ere p a sse d th ro u g h t h e r e t o r t once and th e n s e n t to th e f l u e . I t was fo u n d t h a t such a p ro c e d u re gave i n ­ s u f f i c i e n t h e a t u t i l i z a t i o n and to o much h e a t p a s s e d up th e s ta c k . The h e a t sp ac e s a r e now jo in e d a t th e t o p w ith a m a n ifo ld and th e h o t g a s e s r e c i r c u l a t e d t o th e fu r n a c e by means o f a b lo w e r. v e n te d t o th e s t a c k . The e x c e ss g a se s a r e R o ta tio n o f th e c e n te r tu b e w ith o u t l o s s o f g a s e s i s acco m p lish ed by means o f a c o n v e n tio n a l w a te r s e a l a t th e to p and a -8 - c lo s e f i t on a c e n te r in g tu b e a t th e b o tto m . B y-P roduct R ecovery System The v o l a t i l e f r a c t i o n re c o v e ry system i s r a t h e r c o n v e n tio n a l and q u i t e f l e x i b l e b e ca u se o f th e v a r i e t y o f c o a ls and l i g n i t e s t o be in v e s ­ tig a te d . The h o t g a s e s from t h e r e t o r t a r e w ithdraw n th ro u g h th e e^ ^ - uen^’ Sa s b lo w e r. The f i r s t p ie c e o f equipm ent e n c o u n te re d i s a c y c lo n e f o r d u s t rem o v al. The amount o f d u s t v a r i e s g r e a t l y , d ep en d in g on th e n a tu r e o f th e c o a l b e in g c a rb o n iz e d . drum. N ext comes th e t a r k n o ck -o u t T h is i s eq uipped w ith a w a te r s p ra y a t t h e to p and m ost o f th e t a r and c re o s o te can be condensed h e r e . I f th e c o a l c o n ta in s a p p r e c ia b le m o is tu r e , t h i s i s a good p ro c e d u re . The a b s o r p tio n columns fo llo w in g c o n ta in s c re e n p l a t e s and c r e o s o te a n d /o r l i g h t o i l i s r e c i r c u l a t e d by means o f Pesco g e a r pumps. The g a s e m ittin g fro m th e l a s t a b s o rb e r can by r e c y c le d t o th e fu r n a c e a s a so u rc e o f h e a t . I n th e p i l o t p l a n t , f r e q u e n t s t a r t s and s to p s make t h i s u n d e s ir a b le and n a t u r a l g as i s u sed i n th e f u r n a c e . A ll th e b itu m in o u s and su b -b itu m in o u s c o a ls t e s t e d gave more th a n enough B .T .U .'s i n th e o f f - g a s t o m eet th e f u r n a c e re q u ire m e n ts . The l i g n i t e s t e s t e d , how ever, w ere d e f i c i e n t i n t h i s r e s p e c t and an economic b a la n c e on them would have t o in c lu d e some a d d i t i o n a l h e a t . F urnace The fu rn a c e was d e sig n e d t o p ro d u ce 500,000 B .T .U ./h o u r a t maximum c a p a c ity . The h e a t r e q u ir e d t o r a i s e th e te m p e ra tu re o f 500 pounds o f raw c o a l i n one h o u r from 70°F t o 900°F i s 2 3 4 ,0 0 0 B .T .U ./h o u r. T h is -9 - vaIu e was fo u n d by u s in g 0 .3 7 c a l/g ° C a s th e s p e c i f i c h e a t o f d iy c o a l and assum ing th e raw c o a l h a s 20 p e rc e n t m o is tu re ( 2 ) . The t h e o r e t i c a l h e a t re q u ire m e n ts a r e a p p ro x im a te ly o n e - h a lf o f th e amount o f h e a t th e fu r n a c e can f u r n i s h . The f u r n a c e i s equipped w ith a re c y c le system to g iv e e f f i c i e n t u t i l i z a t i o n o f th e h e a t . Commercial R e to rt F ig u re 2 shows th e d e s ig n o f a com m ercial r e t o r t m o d ifie d t o p ro c e s s c o a l a t a r a t e o f ab o u t tw o to n s an h o u r. The r e t o r t i s 16 f e e t h ig h and th e in n e r tu b e i s 40 in c h e s i n d ia m e te r . The tw o -in c h a n n u la r sp ace f o r c o a l i s m a in ta in e d and a l l th e v o l a t i l e m a tte r i s removed b y th e lo u v e r and s l o t a rran g em en t a s d e s c r ib e d ab o v e. To e lim in a te d i f f i c u l t y due t o e x p a n s io n , th e fu r n a c e i s o f f s e t t o one s id e in s t e a d o f b e in g p la c e d b e n e a th th e r e t o r t a s i n th e p i l o t p l a n t . RESULTS T e s t Runs L i g n ite c o a l from H ard in g C ounty, South D akota was r e t o r t e d i n t h e M ontana S ta te C o lle g e c h a r p l a n t . The ru n l a s t e d 16 h o u rs d u rin g w hich s i x to n s o f l i g n i t e was ru n th ro u g h th e r e t o r t . The p u rp o se o f th e ru n was t o see i f th e uranium i n th e l i g n i t e c o u ld be le a c h e d o u t b e t t e r a f t e r th e l i g n i t e was c h a r r e d . Sm all sam ples o f c h a r w ere le a c h e d w ith a h o t s o lu tio n o f sodium c a r b o n a te . The u ranium was le a c h e d o u t o f th e c h a r s a t i s f a c t o r i l y a f t e r th e l i g n i t e was c h a rre d a t r e t o r t te m p e ra tu re s above SOO0F a c c o rd in g t o th e r e p r e s e n t­ —10— a t i v e o f th e Atomic I h e r g y Com mission. The a n a l y s i s o f th e l i g n i t e and c h a r were o f no im p o rta n c e , s in c e th e o n ly i n t e r e s t was t o le a c h o u t th e uranium from th e c h a r . A f o u r - to n sam ple o f l i g n i t e c o a l from B eu lah , N o rth Dakota was ru n th ro u g h th e p i l o t p l a n t . im a te ly a t 1060°F. The te m p e ra tu re o f th e r e t o r t was h e ld ap p ro x ­ The o u t l e t te m p e ra tu re o f th e second a b s o r p tio n column was k e p t betw een ISO0F and 2 0 0 °F . o f th e b y -p r o d u c ts . T h is a s s u re d maximum re c o v e ry The c h a r pro d u ced was f a i r l y h ig h i n a sh c o n te n t, see T able I I , i n com parison w ith o th e r c h a rs p ro duced i n th e r e t o r t . The f i x e d carbon c o n te n t o f th e c h a r d id n o t m eet th e re q u ire m e n ts o f th e i n d u s t r i e s t h a t can u s e c h a r i n t h e i r p r o c e s s e s . Such a sm all amount o f b y -p ro d u c t was c o l l e c t e d t h a t no t e s t s w ere made on th e o i l s . From p r e ­ v io u s e x p e rie n c e s w ith l i g n i t e and sub—b itu m in o u s c o a l s , i t was fo u n d t h a t s p e c i f i c a t i o n g ra d e c re o s o te c o u ld n o t be made from th e b y -p ro d u c ts p roduced when c h a r r in g th e c o a l s . A t e s t ru n was made i n th e s m a ll b a tc h r e t o r t t o e s tim a te th e u ltim a te y i e l d s o f o i l s and c h a r from th e lig n ite . Seven g a llo n s o f o i l s , 2010 pounds o f c h a r , and 5800 c u b ic f e e t o f d ry g a s w ere produced p e r one to n o f B eulah l i g n i t e . T here was n o t enough d ry g a s , w ith an e s tim a te d h e a tin g v a lu e o f 425 B . T . U . / c u . f t . o f d ry g a s , t o make th e r e t o r t s e l f - s u f f i c i e n t i n th e h e a t re q u ire m e n ts (3 ). A t e s t ru n was made on a 65—to n sam ple o f B ig Horn c o a l from S h e rid a n , Wyoming. The a v e ra g e r a t e t h a t t h e c o a l was ch arg ed t o th e r e ­ t o r t was 515 l b s / h r w ith th e te m p e ra tu re o f th e r e t o r t a t 1125°F. The -1 1 - c h a r produced was low i n a s h and v o l a t i l e m a tte r w h ile th e f i x e d carb o n c o n te n t was h ig h , see T ab le I . The o n ly d i f f i c u l t y w ith th e r e t o r t i n g o f t h i s c o a l was c au se d by th e h ig h m o is tu re c o n te n t. Some o f th e h e a t sup­ p l i e d t o th e r e t o r t had t o be u se d t o d r iv e o f f th e m o is tu re w hich i s o n ly a w aste b y -p r o d u c t. The l e s s th e m o is tu re c o n te n t, th e l e s s th e h e a t re q u ire m e n ts t o d r iv e o f f th e b y -p r o d u c ts . The la r g e amount o f m o is tu re c o l l e c t e d a l s o caused d i f f i c u l t y i n th e c o l l e c t i n g o f th e c o a l t a r s and l i g h t o i l s . W ith a la r g e volume o f w a te r and a s m a ll volume o f by­ p r o d u c ts , t h e l i g h t e r b y -p ro d u c ts c o u ld n o t r e a d i l y be d e c a n te d o f f . S p e c if ic a t io n g rad e c r e o s o te was n o t made from B ig Horn c o a l . The re a so n i s t h a t o i l s from t h e c o a l do n o t have a g r e a t enough d e n s it y t o m eet s ta n d a r d s . A s s o c ia tio n . The s p e c i f i c a t i o n s a r e made up by th e Am erican W o o d -P reserv ers' The m ain f r a c t i o n o f th e b y -p ro d u c ts m ust th e n be c l a s s i f i e d a s w o o d -p re se rv e r and s o ld a t a lo w er p r i c e . The l i g h t o i l s i n th e by­ p ro d u c ts have a norm al b o i l i n g p o in t i n t h e ran g e SO0C t o 210°C. T h is c o m p rises a p p ro x im a te ly 10 p e r c e n t o f t h e c o a l t a r s removed from th e c o a l. The heavy ends have a norm al b o ilin g p o in t ran g e o f 355°C and ab o v e. A p p roxim ately f i v e p e r c e n t o f t h e b y -p ro d u c ts was t a r p i t c h . The amount o f l i g h t and heavy ends may v a ry somewhat due t o th e th e rm o -c ra c k in g w hich ta k e s p la c e i n t h e r e t o r t . A s m a ll sam ple was r e t o r t e d i n a b a tc h p ro c e s s t o f i n d th e maximum y i e l d s o f c h a r and o i l s , s e e T ab le I I . One to n o f c o a l w i l l produce a p p ro x im a te ly 1040 pounds o f c h a r , 22 g a llo n s o f o i l s , and S000 c u b ic f e e t o f d ry g a s . At 425 B . T . U . / c u . f t . o f d ry g a s , th e r e i s enough h e a t -1 2 - i n th e d ry g a s t o r e t o r t a to n o f raw c o a l. The t e s t run on Brophy c o a l from Red Lodge, Montana l a s t e d ap p ro x ­ im a te ly f o u r m onths, w hich in c lu d e s t h e tim e s p e n t i n re d e s ig n in g and r e ­ p a i r i n g th e r e t o r t . The c h a r was p ro duced a t a r a t e o f 2^ to n s /d a y , and th e te m p e ra tu re o f th e r e t o r t was h e ld a t a p p ro x im a te ly 1120 °? w h ile th e d ry g a s was f l a r e d a t 130 ? . As shown i n T able I , t h e c h a r p ro d u ced h as a 75 p e r c e n t o r b e t t e r f i x e d carbon c o n te n t which m eets th e s p e c i f i c a t i o n s w hich were s e t by th e n o n - f e r r o u s and p h o sp h o ru s i n d u s t r i e s i n t h i s a r e a . The c h a r produced from Brophy c o a l a g g lo m e rated more so th a n th e r e s t o f th e c o a ls c h a r re d i n th e r e t o r t . The a g g lo m e rated c h a r i s v e ry d e s ir a b le i n th e p hosphorus in d u s t r y b e ca u se th e p h y s ic a l and c h em ica l p r o p e r t i e s o f th e c h a r a r e s i m i l a r t o n u t - s i z e co k e. S p e c if ic a t io n g ra d e c r e o s o te was made from t h e b y -p ro d u c ts a s shown i n T able I I I . The c re o s o te was made b y ta k in g one p a r t d e h y d ra te d cru d e o i l s and b le n d in g i t w ith two p a r t s o f a f r a c t i o n o f th e o i l s w hich h a s a b o ilin g p o in t ra n g e betw een 210° and 355°C. th e b y -p ro d u c ts w ith o n ly t h e w a te r d riv e n o f f . D ehydrated c ru d e o i l s a re The f r a c t i o n w hich b o i l s betw een 210 C and 355 C i s m inus th e l i g h t o i l s and th e h eav y e n d sj t h e r e ­ f o r e , th e b y -p ro d u c ts a r e d iv id e d i n t o t h r e e p ro d u c ts which a r e l i g h t o i l s , c r e o s o te , and heavy e n d s. The l i g h t o i l s a r e n o t i n any p u re fo n n such a s b e n zen e, to lu e n e , and o th e r p u re o rg a n ic compounds. The l i g h t o i l s may be u se d a s s o lv e n ts f o r weed s p ra y s and i n s e c t i c i d e s . The n o rm al b o i l i n g ra n g e f o r them was SO0C t o 210°C. The l i g h t o i l s com prise a p p ro x im a te ly 5 t o 15 p e rc e n t o f th e -1 3 - b y -p ro d u c ts condensed. The heavy ends a r e s o l i d s which resem b le th e a s p h a lt which i s p ro d ­ uced i n th e r e f i n i n g o f p e tro le u m . above 355°C . The heavy ends have a b o i l i n g ran g e The heavy ends c o n s t i t u t e a p p ro x im a te ly 5 t o 10 p e rc e n t o f t h e cru d e b y -p r o d u c ts . The amount o f l i g h t o i l s , c r e o s o te , and c o a l t a r depends upon th e amount o f c ra c k in g t h a t ta k e s p la c e i n th e r e t o r t . S in ce th e p ro d u c ts o f th e g r e a t e s t i n t e r e s t a r e c h a r and c r e o s o te , no e x te n s iv e t e s t s w ere made on th e l i g h t o i l s and c o a l t a r . The t e s t ru n s i n th e b a tc h r e t o r t gave th e fo llo w in g r e s u l t s a s shown i n T ab le I I . A p p ro x im ately 25 g a llo n s o f o i l s , 1070 pounds o f c h a r and 6450 c u b ic f e e t o f d ry g a s w i l l be p ro d u ced from one to n o f Eed Lodge c o a l. G oals from C o l s t r i p , M ontana; Roundup, M ontana; and S p rin g Canyon, U tah w ere t e s t e d i n th e b a tc h r e t o r t . The r e s u l t s o f th e s e t e s t s a r e shown i n T able I I and a re u se d t o c a l c u l a t e economic b a la n c e s f o r th e v a r io u s c o a ls . DISCUSSION The c o a l a n a ly s e s do n o t c o rre sp o n d w ith t h e c h a r a n a ly s e s i n T ab le I . C oal and c h a r a n a ly s e s shown i n T a b le I from th e s e v e r a l c o a l f i e l d s a r e from sam ples ta k e n a t random w ith r e s p e c t t o tim e and p la c e . T h e o re t­ i c a l l y , th e p e r c e n t f ix e d carb o n and p e rc e n t a sh f o r a g iv e n p e rc e n t v o l a t i l e m a tte r can be c a l c u l a t e d f o r th e c h a r from t h e a n a l y s i s o f th e c o a l. The t h e o r e t i c a l c a l c u l a t i o n s w i l l n o t alw ays be th e same o r even -1 4 - c lo s e t o th e a c t u a l a n a ly s e s o f th e c h a r s . The th e rm o -c ra c k in g o f th e c o a l t a r s i n th e r e t o r t w i l l p ro d u ce carb o n d e p o s it s on th e c h a r d u rin g th e r e t o r t i n g o f th e c o a l. i n th e c h a r . T h is w i l l in c r e a s e th e amount o f f i x e d carbon The a sh c o n te n t o f th e c h a r may be l e s s th a n t h e o r e t i c a l l y c a lc u la te d b ecau se of th e c h a r f i n e s l o s t i n r e t o r t i n g . S in c e m ost o f th e f i n e s a r e c o l l e c t e d i n th e c y c lo n e # i t seems re a s o n a b le t h a t p a r t o f th e a sh i s a ls o c o l l e c t e d i n th e c y c lo n e . D uring most o f th e tim e co v ered by t h i s r e p o r t , b u rn in g o f c o a l i n th e p i l o t p la n t r e t o r t o c c u rre d t o some e x t e n t . d id n o t w h o lly c o r r e c t th e t r o u b l e . R e p a irs d u rin g th e p e rio d T h is s i t u a t i o n w i l l cau se c o n s id e r­ a b le v a r i a t i o n i n c h a r a n a ly s is and y i e l d when compared t o r e s u l t s o b ta in e d w ith th e b a tc h r e t o r t . Ash w i l l b e removed b o th a s f l y —a sh o u t o f th e s ta c k and a s d u s t i n th e c y c lo n e . The more v o l a t i l e f r a c t i o n o f c o a l t a r o i l s a r e consumed, g iv in g a h ig h e r r a t i o o f t a r t o c r e o s o te th a n would be e x p e c te d . To sum m arize, th e r a t i o o f f ix e d carbon t o a sh i n th e c h a r may be d i f f e r e n t from t h a t r a t i o i n th e c o a l f o r th e fo llo w in g re a s o n s : v o l a t i l e m a tte r can be c a rb o n iz e d b e fo re i t le a v e s th e r e t o r t . The D irt, which shows up i n th e c o a l a n a ly s e s a s a s h , i s a s s o c ia te d w ith th e f i n e s and w i l l be removed i n th e cy clo n e a s d u s t and a s f l y a sh w ith th e f i n e s t h a t f a l l i n t o th e f u r n a c e . r a t i o in th e c h a r. These f a c t o r s in c r e a s e th e c a r b o n -to -a s h On th e o t h e r h an d , b u rn in g o f th e c h a r o r c o a l i n th e r e t o r t re d u c e th e c a r b o n -to -a s h r a t i o i n th e c h a r . S in c e m ost o f th e a n a ly s e s i n T ab le I i n d i c a t e a d e c r e a s e i n c a r b o n -to -a s h r a t i o , i t a p p e a rs t h a t i n t h i s p i l o t p l a n t , b u rn in g was t h e l a r g e s t f a c t o r . -1 5 - The y i e l d s o f c h a r , o i l s , and d ry c o a l gas shown i n T ab le I I were computed from th e y i e l d s produced from th e b a tc h r e t o r t . T h is i s o n ly an e s tim a te t o g iv e an economic s tu d y o f th e v a r io u s c o a l s . The c o a l was c h arg ed t o th e r e t o r t and h e a te d t o a p p ro x im a te ly 900°F. T h is te m p e ra tu re was m a in ta in e d f o r one h o u r t o in s u r e t h a t th e v o l a t i l e m a tte r i n th e c h a r was a p p ro x im a te ly f i v e p e r c e n t. The c h a r y i e l d s fo u n d from th e b a tc h r e t o r t w i l l n o t alw ays be th e same a s th e y i e l d s c a lc u la te d from c o a l a n a ly s e s . Again th e th e rm o -c ra c k in g o f th e c o a l t a r s d u rin g th e r e t o r t i n g w i l l g iv e an in c r e a s e i n th e c h a r . The amount o f o i l s and d ry c o a l g as produced a r e dependent upon th e le n g th o f tim e th e c o a l v a p o rs a re i n th e r e t o r t , and a l s o th e te m p e ra tu re o f th e c o a l v a p o rs . A number o f d i f f e r e n t w e ste rn c o a ls have been t e s t e d i n th e p i l o t p la n t. The p r i n c i p a l ones a r e l i s t e d i n T ab le I and a w ide v a r i a t i o n i n c o m p o sitio n w i l l be n o te d . The c h a r r in g o p e r a tio n removes a l l o f th e m o is tu re and m ost o f th e v o l a t i l e m a tte r and h a s some e f f e c t on th e f i x e d carbon and a s h . Some o f th e a n a ly s e s a r e ta k e n fro m c h a r s to r e d o u ts id e , and th e s e show a m o is tu re c o n te n t cau sed by th e w e a th e r. a sh c h a r , a low a sh c o a l m ust be c h a rg e d . To make a low W hether o r n o t th e p ro c e s s i s SGlf" " S u ffic ie n t w ith r e s p e c t t o h e a t depends upon th e amount o f non­ c o n d e n s ib le g as produced and th e m o is tu re c o n te n t o f a g iv en c o a l. Of th e c o a ls l i s t e d i n T ab le I , th e l i g n i t e s p ro d u ce i n s u f f i c i e n t g a s and c o n ta in to o much m o is tu re t o be h e a t s e l f - s u f f i c i e n t . To o p e ra te w ith one o f th e l i g n i t e s on a com m ercial b a s i s , one m ust be p re p a re d t o u se a su p p le m e n ta l so u rc e o f h e a t o r a c o a l d r i e r f i r s t . The c o a l from S h e rid a n , Wyoming -1 6 - c o n ta in s so much m o is tu re t h a t th e h e a t b a la n c e i s c lo s e . The o th e r s produce an e x c e s s o f g as above t h a t r e q u ir e d f o r r e t o r t i n g . The c h a r d a ta i n T ab le I a r e e x p e rim e n ta l and no s ig n if ic a n c e sh o u ld be a tta c h e d t o th e v a r i a t i o n i n v o l a t i l e m a tte r c o n te n t o f th e c h a r . The amount o f r e s i d u a l v o l a t i l e m a tte r i s a f u n c tio n o f th e tim e -te m p e ra tu re h i s t o r y o f th e c h a r and can b e v a r ie d o v e r a wide ra n g e . I n f a c t , w ith a v e ry h ig h r a t e o f th ro u g h p u t, th e r e t o r t a p p ro a c h e s a c o a l d r i e r ; i t rem oves m ost o f th e m o is tu re b u t v e ry l i t t l e o f th e v o l a t i l e m a tte r . t h i s c a s e , how ever, i t i s f a r from h e a t s e l f - s u f f i c i e n t . In Minimum v o l a t i l e m a tte r c o n te n t a t t a i n a b l e i n th e c h a r i s i n th e ra n g e o f one t o two p e r c e n t . The y i e l d s o f c h a r and o i l s v a ry c o n s id e ra b ly w ith th e d i f f e r e n t c o a ls . I n T able IV , t h i s v a r i a t i o n i s in d ic a te d u n d e r C h ar, C re o s o te , and T a r Y ie ld s . Of th e c o a ls t e s t e d , S p rin g Canyon, U tah and Roundup, M ontana have th e h ig h e s t c h a r y i e l d s — 1310 I b s / t o n and 1280 I b s / t o n , r e s p e c t i v e l y . On t h e o th e r h an d , C o l s t r i p , M ontana c o a l and B eu lah , N o rth D akota l i g n i t e gave o n ly 1005 I b s / t o n and 1050 I b s / t o n , r e s p e c t i v e l y . Even h a r d e r t o p r e d i c t from t h e c o a l a n a ly s is i s th e y i e l d . o f o i l s . S in ce t h i s i n v e s t i g a t i o n h a s so f a r been c o n fin e d t o w e ste rn c o a ls and an a r e a where th e m ark et demand f o r c r e o s o te i s good, l i t t l e c o n s id e r a tio n h a s been g iv en t o m aking l i q u i d p ro d u c ts o th e r th a n c r e o s o te . E x p erim en ts t o d a te i n d i c a t e t h a t c r e o s o te m e e tin g th e s p e c i f i c a t i o n s o f th e A m erican Wood P r e s e r v e r s ' A s s o c ia tio n can be made o n ly from b itu m in o u s c o a l. Of th e c o a ls l i s t e d i n T able I , o n ly t h a t from Red Lodge, M ontana and S p rin g Canyon, Utah y i e l d t h i s q u a l i t y c r e o s o te . T ab le I I I shows a com parison -1 7 - ° f c r e o s o te from Red Lodge c o a l w ith th e s p e c i f i c a t i o n s . g ra d e c r e o s o te i s w orth a b o u t 2 4 ^ /g a llo n . N o n - s p e c if ic a tio n g ra d e c re o s o te can be s o ld a s wood p r e s e r v e r f o r i V / g a l l o n . s o ld a t 1 5 / / g a l l o n . S p e c if ic a t io n L ig h t o i l s and t a r may be These v a lu e s w ere u sed i n c a l c u l a t i n g th e l i q u i d by­ p ro d u c t v a lu e s giv en i n T ab le IV . F o r c o a ls from w hich s p e c i f i c a t i o n c re o s o te co u ld n o t be made, th e e n t i r e b y -p ro d u c t was c o n s id e re d a s wood p r e s e r v e r and v a lu e d a t 1 4 / / g a l l o n . F o r c o a ls from which s p e c i f i c a t i o n g ra d e c re o s o te c o u ld be o b ta in e d , th e l i q u i d b y -p ro d u c t y i e l d was broken down i n t o a l i g h t o i l and t a r f r a c t i o n v a lu e d a t l $ / / g a l l o n and a sp ec­ i f i c a t i o n c re o s o te f r a c t i o n v a lu e d a t 24 / / g a llo n , and an a v e ra g e v a lu e p la c e d on th e com posite l i q u i d . F o r exam ple, th e Red Lodge c o a l y i e l d s 25 g a llo n s o f b y -p ro d u c t p e r to n o f c o a l from which 19 g a llo n s o f sp ec ­ i f i c a t i o n g ra d e c r e o s o te can be made, le a v in g s i x g a llo n s o f l i g h t o i l and t a r s . The v a lu e o f th e 25 g a llo n s o f b y -p ro d u c t b a se d on th e above f i g u r e s i s $ 5 .4 6 , g iv in g an a v e ra g e v a lu e o f 2 2 / / g a l l o n . The economic a t t r a c t i v e n e s s o f th e p ro c e s s v a r i e s g r e a t l y w ith th e c o a l c h a rg e d . consum ers. The l o c a t io n m ust be one t h a t i s re a s o n a b ly c lo s e t o th e The c h a r m ust be o f a q u a l i t y t h a t i s a t t r a c t i v e f o r th e p a rtic u la r u se r. F o r exam ple, th e n o n - f e r r o u s s m e lte r s w ant c h a r c o n ta in ­ in g l e s s th a n f i v e p e r c e n t v o l a t i l e m a tte r , s iz e d t o 3 / l 6- in c h m in u s, and c o n ta in in g a t l e a s t 75 p e rc e n t f ix e d c a rb o n . The e le m e n ta l pho sp h o ru s m a n u fa c tu re rs w ant c h a r c o n ta in in g l e s s th a n one p e r c e n t Ri i l f n r and l e s s th a n f i v e p e r c e n t v o l a t i l e m a tte r , a t l e a s t 75 p e r c e n t f ix e d carbon s iz e d i n th e ra n g e 3 /8 t o 3 / l 6 - i n c h , a n d , i n a d d i t i o n , t h e c h a r m ust have -1 8 - a g g l° m e ra te d . We have y e t t o f i n d a su b -b itu m in o u s c o a l o r a l i g n i t e which w i l l a g g lo m e ra te on h e a ti n g . F o r th e z in c fume s m e ltin g o p e r a tio n , th e c h a r sh ould c o n ta in 10-15 p e rc e n t v o l a t i l e m a tte r and be s iz e d t o 200 m esh. By th e p ro p e r s e l e c t i o n o f c h arg e m a t e r i a l , th e r e t o r t may be o p e ra te d t o produce a c h a r m e etin g any o f th e above s p e c i f i c a t i o n s . An a b b re v ia te d econom ic s tu d y i s p r e s e n t i n T ab le IV . An a v e ra g e c h a r p r i c e o f $ 12 . 00 / t o n i s a s s ig n e d t o th o s e c o a ls w hich a g g lo m e rate on h e a ti n g , $ 1 0 .0 0 /to n i f th e y do n o t a g g lo m e ra te . p r i c e i s e x p la in e d ab o v e. The b a s i s f o r th e c re o s o te O p e ra tin g ex p en ses a r e ite m iz e d on T ab le V I, P la n t a m o r tiz a tio n , p la n t l a b o r , and p r o p e r ty t a x and in s u ra n c e a r e b ased on a 1 0 0 -to n o f c h a r /d a y . These w i l l change s l i g h t l y f o r a 5 0 0 -to n o f c h a r /d a y p la n t when b ased on a p e r to n b a s i s . T h e re fo re , th e v a lu e o f $ 3 .5 0 /to n o f c o a l f o r o p e r a tin g e x p e n se , shown i n T ab le IV , i s a f a i r e s tim a te f o r b o th th e 5 0 0 -to n /d a y and 1 0 0 -to n /d a y p l a n t s . b a se d on p e r s o n a l i n v e s t i g a t i o n a t th e s e v e r a l s i t e s . C oal c o s t i s A ll th e c o a ls l i s t e d i n T ab le IV were fo u n d t o be f u e l s e l f - s u f f i c i e n t e x c e p t th e B eu lah , N o rth D akota l i g n i t e , w hich r e q u ir e d su p p le m e n ta l h e a t . T h is co u ld be o b ta in e d b y b u rn in g 0 .3 pounds o f l i g n i t e f o r each pound c h a r r e d , and th u s th e 6 0 //to n v a lu e shown f o r f u e l c o s t . The income p e r to n v a r i e s g r e a t l y w ith q u a l i t y and y i e l d o f c h a r and c r e o s o te . On th e b a s i s o f e a r l y 1957 c o s t s , c h a r p l a n t s em ploying t h i s p ro c e s s a p p e a r t o c o s t a s f o llo w s : 100 to n s /d a y - $350 , 000 ; 200 t o n s / d a y - $ 5 0 0 ,0 0 0 ; 500 to n s /d a y - $9 0 0 ,0 0 0 ; and 1 ,0 0 0 to n s /d a y - $ 1 ,6 0 0 ,0 0 0 ( l ) . These f i g u r e s e x clu d e w orking c a p i t a l . U sin g th e s e c o s t s e s ti m a te s . -1 9 - T ab le V p r e s e n ts a c o m p arativ e s tu d y o f in v e stm e n t r e tu r n f o r two d i f f e r e n t s iz e d p l a n t s a t th e l o c a t i o n s i n d i c a t e d i n T ab le IV . The 100 to n /d a y p l a n t a p p e a rs t o be e c o n o m ic a lly a t t r a c t i v e o n ly a t S p rin g Canyon, U tah and Red Lodge, M ontana, where p ay o u t tim e s a r e a p p ro x im a te ly 2 .9 and 5 .8 y e a r s , re s p e c tiv e ly . F o r t h e 500 to n /d a y p l a n t , how ever, a l l th e l o c a t io n s l i s t e d i n T a b le s IV and V a p p e a r t o be re a s o n a b ly sound e c o n o m ic a lly e x c e p t pos­ s i b l y Roundup, M ontana. A 100 to n /d a y p l a n t i s c u r r e n t l y b e in g c o n s tr u c te d a t Red Lodge, M ontana. I t i s e x p e c te d t o s e rv e th e n o n - f e r r o u s s m e lte r s i n Montana and th e e le m e n ta l phosp h o ru s in d u s t r y i n M ontana and Id a h o . \ -2 0 - ACKNOWLEDGMENTS The a u th o r w ish es t o th a n k P .D .P . P r o c e s s in g , I n c o r p o r a te d , f o r th e o p p o r tu n ity i t p r e s e n te d t o work on t h i s p r o j e c t . W ithout th e h e lp o f D. E . A tk in so n , who c o n s tr u c te d and h e lp e d ru n th e p l a n t , much o f th e work acco m p lish ed w ould have been im p o s s ib le . To th e C hem ical E h g in e e rin g S t a f f , th e a u th o r e x te n d s h i s g r a t i t u d e f o r much h e l p f u l a d v ic e . -2 1 - LITERATURE CITED 1. A tk in so n -B erg Company, P e rs o n a l C om m unications. 2. C o n ra d i, L o re n tz A ., "The C hem ical U t i l i z a t i o n o f th e B itum inous C o als o f W ashington", E n g in e e rin g E xperim ent S ta tio n R ep o rt No. 6 , U n iv e r s ity o f W ashington, S e a t t l e . J 3. G e n try , F rank M ., "The T echnology o f Low T em perature C a r b o n iz a tio n " : The W illia m s & W ilk in s C o ., B a ltim o re , 1928. 4. H obson, F rank E ., U. S . P a te n t 1 ,9 2 4 ,7 8 8 5. M in et, R. G ., S n it h , H. B ., J r . , & T r i l l i n g , C. A ., C hem ical E n g in e e rin g P r o g r e s s , jO , 342 (1 9 5 4 ). 6. P e r r y , John H ., C hem ical E n g in e e rs * Handbook. M cG raw -H ill Book Company, I n c . , New Y ork, New Y ork; 3 rd E d ., p . 235, 1950. 7* 8. Aug. 2 9 , 1933 . E:> & R ic e > N*> " I n d u s t r i a l E n g in e e rin g C h e m istry ", 4 %, "Low T em perature C a rb o n iz a tio n o f U tah C o a ls " , A R ep o rt o f th e Utah C o n se rv a tio n and R ese arch F o u n d a tio n t o th e G overnor and S ta te L e g i s l a t u r e , May, 1939. -2 2 - APPENDIX Page T ab le I C oal and C har A n a l y s e s ............................................................ 23 T ab le I I D ata on V a rio u s C oal from B atch R e t o r t .........................28 T ab le I I I Com parison o f C re o so te from Red Lodge, M ontana C oal w ith A m erican Wood P r e s e r v e r s ’ S p e c i f i c a t i o n s ............................................. 29 T ab le IV C om parative Economics o f S e v e ra l C hars .................... .30 T ab le V Economic Com parison T ab le VI O p e ra tin g E x p e n s e s ..................................................................... F ig u re I S im p lif ie d Flow Diagram o f th e C har P l a n t . . . . F ig u re 2 Diagram o f Com m ercial R e t o r t .............................................. 34 .................. . . . . . . . . . 31 33 -2 3 TABLE I COAL AND CHAR ANALYSES A n aly ses I n P e rc e n t' Red Lodge, Montana S to k e r C oal C oal M o istu re V o la tile M a tte r F ix ed Carbon 8 .6 7 .7 8 .2 1 2 .7 1 2 .1 1 1 .8 1 2 .8 1 0 .1 9 .8 9 .9 3 5 .1 3 3 .7 3 3 .5 3 2 .0 3 2 .7 3 2 .2 3 2 .0 3 1 .2 3 1 .1 3 3 .5 4 8 .3 5 0 .6 5 0 .1 '4 7 .8 4 8 .6 4 8 .5 4 8 .7 5 0 .0 4 7 .9 4 4 .5 Ash 8 .0 8 .1 8 .2 7 .6 6 .6 7 .5 6 .5 9 .7 1 1 .2 1 2 .1 C har M o istu re n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le 5 .2 5 .2 5 .1 5 .2 5 .0 5 .0 V o la tile M a tte r 1 .3 3 1 .4 1 .4 6 .3 7 .3 6 .3 6 .5 6 .2 5 .2 6 .4 6 .3 7 .4 5 .0 5 .7 5 .8 F ix e d Carbon Ash 8 2 .9 8 3 .5 8 3 .2 8 2 .5 7 8 .7 8 1 .0 8 1 .6 8 2 .1 8 1 .2 7 5 .1 7 4 .9 7 4 .8 7 8 .9 7 7 .1 7 5 .3 1 5 .6 1 5 .3 1 5 .5 1 1 .1 1 4 .0 1 2 .7 1 1 .9 1 1 .8 1 3 .9 1 3 .3 1 3 .8 1 2 .7 1 1 .1 1 2 .2 1 4 .0 -2 4 - TABLE I (c o n tin u e d ) COAL AND CHAE ANALYSES A n aly ses i n P e rc e n t Roundup, M ontana - S la c k C oal C oal M o istu re 13.0 1 0 .6 1 2 .7 V o la tile M a tte r F ix e d Carbon 3 1 .0 3 2 .4 3 0 .5 4 6 .5 4 7 .1 4 7 .3 Ash 9 .5 9 .9 9 .5 Char M o istu re n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le V o la tile M a tte r F ix e d Carbon Ash 1 2 .1 1 1 .4 1 1 .0 7 .8 8 .3 7 .4 7 2 .5 7 3 .4 7 3 .8 7 8 .0 7 7 .0 7 7 .7 1 5 .4 1 5 .2 1 5 .2 1 4 .3 1 4 .7 1 4 .9 C o ls tr i p , Montana - S la c k C oal C oal Mois tu r e 14.2 1 6 .5 V o la tile M a tte r F ix ed Carbon 3 6 .1 3 5 .2 4 0 .5 4 0 .8 9 .2 8 .5 F ix ed Carbon Ash Ash C har M o istu re n e g lig ib le n e g lig ib le n e g lig ib le V o la tile M a tte r 1 3 .5 1 2 .9 6 .2 7 0 .9 7 1 .6 7 6 .4 1 5 .6 1 5 .5 1 7 .4 -2 5 - TABLE I (c o n tin u e d ) COAL AND CHAR ANALYSES A n aly ses i n P e rc e n t S h e rid a n , Wyoming - S la c k C oal C oal M o istu re 20.2 2 1 .1 22.2 2 0 .9 2 1 .4 22.2 2 3 .4 22.8 V o la tile M a tte r F ix e d Carbon 3 2 .8 3 3 .2 3 4 .8 3 5 .4 3 4 .8 3 3 .0 3 2 .6 3 1 .1 4 3 .6 4 3 .2 3 9 .0 3 9 .6 3 9 .8 3 9 .0 4 0 .9 3 8 .0 Ash 3 .4 2 .5 4 .0 4 .1 4 .0 5 .8 4 .1 8 .1 ' Char M o istu re n e g lig ib le n e g lig ib le n e g lig ib le 1 .7 n e g lig ib le n e g lig ib le V o la tile M a tte r 1 8 .5 1 9 .6 2 1 .6 3 .8 3 .8 3 .9 F ix ed Carbon ' 7 4 .3 7 3 .3 7 1 .6 87.2 8 8.6 8 7 .0 Ash 7 .1 7 .0 6 .7 6 .8 7 .6 9 .1 —2 6 TABLE I (c o n tin u e d ) COAL AND CHAR ANALYSES A n aly ses i n P e rc e n t S p rin g Canyon, Utah - S to k e r C oal C oal M o istu re V o la tile M a tte r F ix e d Carbon 3 .7 3 .4 3 .9 4 3 .0 4 2 .4 4 1 .9 5 0.6 4 9 .7 4 9 .0 Ash 2 .7 4 .5 5 .2 C har M o istu re n e g lig ib le n e g lig ib le n e g lig ib le V o la tile M a tte r 1 0 .3 1 1 .0 1 1 .2 F ix e d Carbon 7 9 .1 7 8 .0 7 8 .6 Ash 10.6 11.0 10.2 B eu lah , N o rth D akota - L i g n ite C oal M o istu re 1 1 .7 1 2 .4 1 2 .4 11.2 1 1 .4 1 5 .1 1 4 .4 V o la tile M a tte r 3 1 .8 3 0 .5 3 0 .4 3 2 .2 3 1 .8 3 2 .2 3 2 .2 F ix ed Carbon 4 4 .8 4 5 .5 4 6 .0 4 5 .4 4 5 .0 4 1.2 4 2 .4 Ash 1 1 .7 1 1 .5 1 1 .3 1 1.1 1 1.8 1 1.6 1 1.1 -2 7 - TABLE I (c o n tin u e d ) COAL AND CHAR ANALYSES A n aly ses in P e rc e n t B eu lah , N o rth D akota - L ig n ite C har M o istu re n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le n e g lig ib le V o la tile M a tte r 9 .5 9 .3 1 0 .1 9 .4 9 .3 8 .0 9 .2 F ix ed Carbon Ash 7 4 .8 7 4 .2 7 3 .2 7 3 .1 7 2 .5 7 3 .0 7 3 .5 1 6 .7 1 6 .4 16.8 1 7 .4 1 8 .2 1 9 .1 1 7 .4 TABLE I I DATA ON VARIOUS COAL FROM BATCH RETORT C oal Char % O ils % W ater % G a ls , o i l / to n o f c o a l C u.f t . o f d ry g a s /to n o f c o a l S h e rid a n , Wyo. 5 2 .9 9 .7 1 7 .8 1 8 .7 8000 Roundup, Mont. (Sample No. I ) 64.0 4 .9 5 1 7 .5 1 1 .9 8000 Brophy 5 3 .4 1 0 .5 1 3 .3 25.2 6450 S p rin g Canyon, Utah 65 .5 14.6 4 .5 C o l s t r i p , Mont. 50.2 6.1 21.2 1 4 .4 7900 B eu lah , N.D. L ig n ite 51 3 .1 29.2 7 .5 5800 (w ashed) . 35 — -2 9 TABLE I I I COMPARISON OF CREOSOTE FROM RED LODGE, MONTANA COAL WITH AMERICAN WOOD PRESERVERS' SPECIFICATIONS S p e c if ic a t io n C re o so te from Red Lodge C oal I. I t s h a l l c o n ta in n o t more th a n % w a te r . I. No w a te r . 2. I t s h a l l c o n ta in n o t more th a n 2# o f m a t e r i a l in s o lu b le i n b e n z o l. 2. 0 .8 5 # . 3. The s p e c i f i c g r a v i t y o f th e c r e o s o te a t 38°C s h a l l be n o t l e s s th a n 1 . 03 . 3. 4. The d i s t i l l a t e s h a l l b e : 4. Up Up Up Up 5. to to to to 210°C 235°C 315°C 355°C S p e c if ic g r a v i t y i s 1 . 032 . < % 5-25# >36# >60# The c r e o s o te s h a l l y i e l d n o t more th a n 5# o f coke r e s id u e . 5# 22 . 2# 7 1 .4 # 8 2 .6 # 5. 4 .2 3 # TABLE IV COMPARATIVE ECONOMICS OF SEVERAL CHARS C oal Source C o ls tr i p , M ont. Roundup, Mont. S h e rid a n , Wyo. ( 12.00 ( 10.00 ( 10.00 ( 10,00 ( 12.00 1070 1005 1280 1040 1310 ( 6.40 ( 5.00 ( 6.40 ( 5.20 ( 7 .8 5 Revenue C har P r ic e - $ /to n C har Y ie ld - I b s / t o n Income from C har - $ /to n c o a l L iq u id b y -p ro d u c t Y ie ld - g a l / t o n 25 14 12 19 S p rin g Canyon U tah 35 B eu lah , N.D. ( 10.00 1050 ( 5 .2 5 8 -oc- Red Lodge, M ont. vi> L iq u id b y -p ro d u c t V alue - / / g a l 22 14 14 14 22 14 Income from b y -p ro d u c ts S /to n o f c o a l ( 5 .5 0 ( 1 .9 6 ( 1.68 ( 2 .6 6 ( 7 .7 0 ( 1.12 T o ta l Income - S /to n ( 11.90 ( 6.96 ( 8 .0 8 ( 7 .86 (1 5 .5 5 ( 6 .3 7 O p e ra tin g E xpenses $ /to n o f c o a l ( 3 .5 0 ( 3 .5 0 ( 3 .5 0 ( 3 .5 0 ( 3 .5 0 ( 3 .5 0 C o al C ost - S /to n ( 4 .7 5 ( 2 .2 5 ( 4 .5 0 ( 2.65 ( 5.00 ( 2.00 ——— ( 0.60 E xpenses F u e l C ost - ( / t o n ——— T o t a l C ost - ( / t o n ( 8 .2 5 N et Income b e f o r e Income Tax - ( / t o n ( 3 .6 5 ——— ( 5 .7 5 ( 1 .2 1 ——— ——— ( 8 .0 0 ( 6 .1 5 ( 8.50 ( 6.10 ( 0 .0 8 ( 1 .7 1 ( 7 .0 5 ( 0 .2 7 P TABLE V ECONOMIC COMPARISON Red Lodge, Mont. IOO to n /d a y P la n t P la n t In v e stm en t C o ls tr i p , Mont. Roundup, M ont. S h e rid a n , Wyo. S p rin g Canyon, B eulah Utah N.D. $ 350,000 $350,000 $350,000 $ 350,000 $ 350,000 $350,000 N et Income a f t e r F e d . I n c . Tax $ 61,400 $ 20,4 0 0 $ $ 2 8 ,8 0 0 $ 119,000 $ A nnual R etu rn on In v e stm e n t - % 1 7 .5 5 .8 0 .4 8 .2 3 4 .0 5 .8 17.2 —— 12.2 2 .9 $ 900,000 $ 900,000 $ 900,000 $ 900,000 $ 900,000 $ 900,000 $370,000 $ 165,000 $ 70,000 $207,000 $ 655,000 $ 86,000 1 8 .3 7 .8 5 .5 12.8 P la n t P ayout Time - y r s . 500 to n /d a y P la n t P la n t In v e stm e n t N et Income a f t e r F e d . I n c . Tax A nnual R etu rn on In v e stm e n t - % P la n t P ayout Time - y r s . 41 . 2 .4 1 ,3 5 0 23 4 .4 73 1 .4 4 ,5 5 0 1 .3 • — 9 .6 1 0 .4 -3 2 TABLE TL ESTIMATED OPERATING EXPENSES ' Charge — 170 to n s o f c o a l/d a y y i e l d s 100 to n s /d a y o f c h a r , 350 d a y s /y e a r . Per Ton o f C oal E le c tric ity $ 0 .0 8 P la n t la b o r - 5 m e n /s h if t; 3 s h i f t s / d a y ; $ 2 . 00 / h r . $ 1 .4 4 P la n t S u p e rin te n d e n t - $550/m onth $ 0 .11 Steam Gas W ater $ 0 .0 9 R e p a ir M a te r ia ls $ 0.25 P ro c e s s R o y a lty $ 0 .5 0 P a y r o ll Taxes and O ffic e O verhead $ 0 .0 6 P r o p e r ty Tax & In s u ra n c e - 3% o f P la n t In v e stm e n t $ 0 .1 0 S e llin g and A d m in is tra tiv e E xpenses $ 0 .2 8 P la n t A m o rtiz a tio n - 10% o f $350,000 In v e stm e n t $ 0 .6 0 ---------- TOTAL EXPENSE $ 3 .5 1 1 23m FIGURE SIMPLIFIED FLOW DIAGRAM COAL OF THE CHAR PLANT BIN COMBUSTION GAS CYCLONE DEMISTER MANIFOLD EFFLUENTj ^ GASES COMBUSTION GAS RETURN DUCT DRY 6 AS TO FURNACE CYCLONE SEPARATOR - CYLINDER I TAR KNOCKOUT DRUM CYLINDER 2 EFFLUENT GAS TUBE CYLINDER 3 CYLINDER 4 CHAR DUST COMBUSTION GAS RETURN BLOWER COAL STOCK PILE <■ BURNER COMBUSTION GASES CHAR AUGERS FURNACE DRY CREOSOTE BAS LIGHT OILS arch N378!icS7^ te R<$llltS o f COdtinuniM #w»i -»___ _______ 5 - • '»