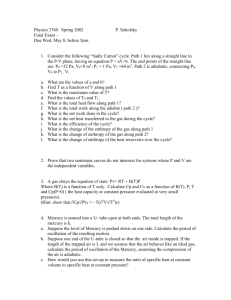

The application of furnace atomic absorption to the solution of... by Jerome Francis Lech

advertisement