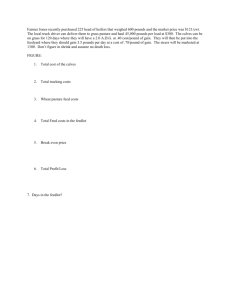

The feasibility of beef feeding cooperatives in Montana

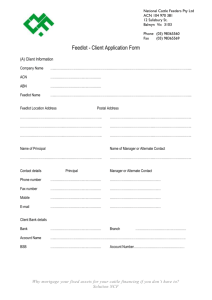

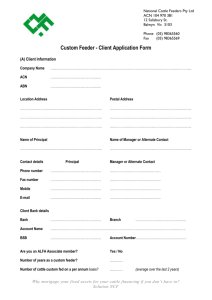

advertisement