Chapter 4: ICE – In Practice, An Organizational Quagmire

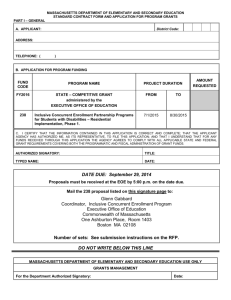

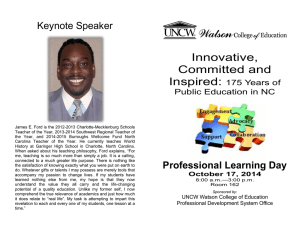

advertisement