PORTABLE TOOLS AND EQUIPMENT

advertisement

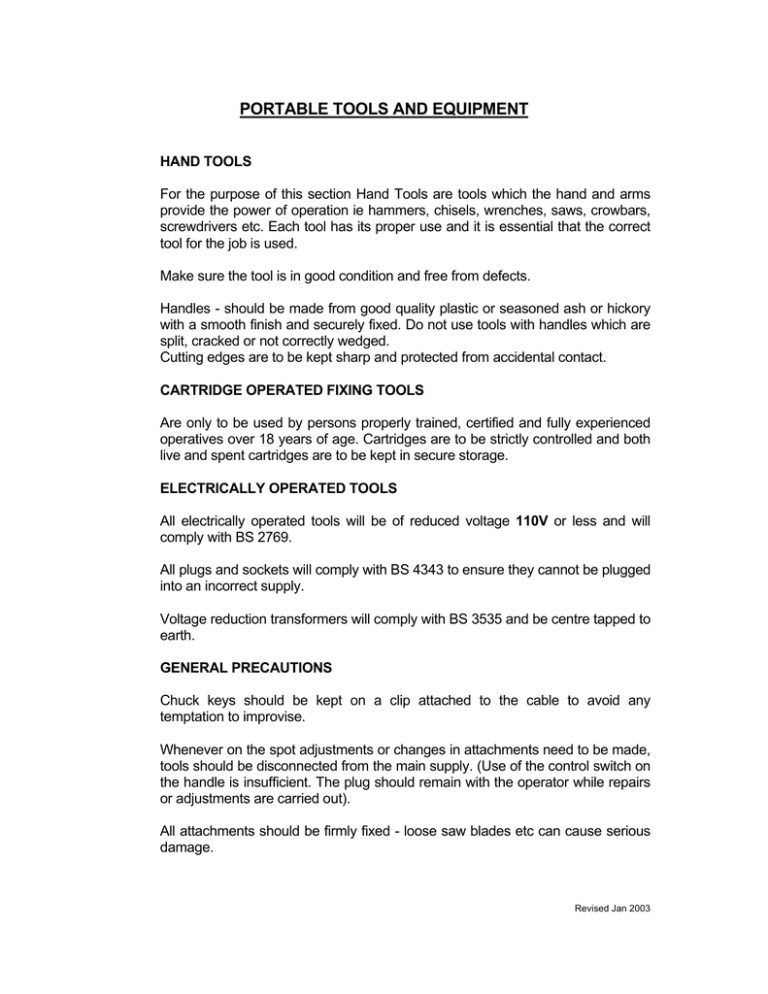

PORTABLE TOOLS AND EQUIPMENT HAND TOOLS For the purpose of this section Hand Tools are tools which the hand and arms provide the power of operation ie hammers, chisels, wrenches, saws, crowbars, screwdrivers etc. Each tool has its proper use and it is essential that the correct tool for the job is used. Make sure the tool is in good condition and free from defects. Handles - should be made from good quality plastic or seasoned ash or hickory with a smooth finish and securely fixed. Do not use tools with handles which are split, cracked or not correctly wedged. Cutting edges are to be kept sharp and protected from accidental contact. CARTRIDGE OPERATED FIXING TOOLS Are only to be used by persons properly trained, certified and fully experienced operatives over 18 years of age. Cartridges are to be strictly controlled and both live and spent cartridges are to be kept in secure storage. ELECTRICALLY OPERATED TOOLS All electrically operated tools will be of reduced voltage 110V or less and will comply with BS 2769. All plugs and sockets will comply with BS 4343 to ensure they cannot be plugged into an incorrect supply. Voltage reduction transformers will comply with BS 3535 and be centre tapped to earth. GENERAL PRECAUTIONS Chuck keys should be kept on a clip attached to the cable to avoid any temptation to improvise. Whenever on the spot adjustments or changes in attachments need to be made, tools should be disconnected from the main supply. (Use of the control switch on the handle is insufficient. The plug should remain with the operator while repairs or adjustments are carried out). All attachments should be firmly fixed - loose saw blades etc can cause serious damage. Revised Jan 2003 PORTABLE TOOLS AND EQUIPMENT (cont.) Guards are frequently incorporated, both in compliance with statutory requirements and because they have been specially designed to promote maximum safety in operation. Every precaution should be taken to see that these guards are not interfered with in any way. Goggles, helmets, dust masks, ear protectors, etc. should be worn as necessary when electric tools are in use. INSPECTION AND MAINTENANCE All electric tools should be carefully inspected before use for signs of faults in wiring, switching, guards etc. Maintenance should be carried out on a regular basis by a competent mechanic or electrician. It is recommended that a register be kept of all such maintenance. INDIVIDUAL TOOLS Power hand-held saws are fitted with spring loaded guards which only uncover the saw teeth when the tool is pressed against the work. A check should be made regularly to ensure that the guard is moving freely. To prevent damage to hands, the saw teeth above the sole plate are enclosed in a permanent guard. The work should be clamped and both hands used to control the saw. On the larger, portable stand models, a riving knife is fitted to prevent the cut from binding on the saw teeth and to prevent the material from binding at the back of the saw blade and kicking back. The riving knife should therefore be kept clean and comparatively sharp. The work area should be kept clear of all potential tripping hazards. Drills. The common operating fault lies in trying to drill too large a hole at once; as the bit breaks through the last piece of metal it binds and stops the motor. The torque set up twists the tool against the user's wrist and can easily cause a bad sprain. All material to be drilled should be firmly secured so that it cannot spin as the drill begins to bite. Rotary hammer drills should be fitted with a safety clutch to protect both operator and tool should the drill bit snag. All drills should be kept sharp and a punch mark should always be made as a starter. Where necessary, pilot holes should be drilled. Drills, once switched off, should be held until they have ceased turning before being set down. Revised Jan 2003 PORTABLE TOOLS AND EQUIPMENT (cont.) Grinders. Grinders must be fitted with protective guards. Grinders must be clearly marked with their maximum rotating speed. Abrasive wheels larger than 55mm diameter must be marked with their maximum running speed. The proper size and type of wheel or disc must be fitted to suit the tool to be used. Eye protection must be worn. Mounters of wheels or discs must be competent, properly trained and appointed in the Register (Form F2346). Chain Saws. Chain Saw accidents are rarely trivial. The tool can kill and is more than capable of severing an arm or leg. It is essential, therefore, that operators are properly trained and supervised. Before use, a check should be made that: - guards are in position and in good repair. the chain, guide bar and sprocket are undamaged. all external fittings are secure. the chain is sharp and the tension is in accordance with the manufacturer's instructions. the lubrication system is working. In use, it is essential to have a secure foothold and to hold the saw firmly, with both hands. Protective clothing - safety helmet, ear defenders, eye protection, close-fitting clothing, gloves and chain saw operator boots - should be worn. Revised Jan 2003 PORTABLE TOOLS AND EQUIPMENT (cont.) SAFETY CHECKLIST Electrical tools Before Use 1. 2. Check for BS 2769 and double insulated marks. Check details on tool plate, which should include: Type \ Serial No \ Voltage \ Volts AC/DC \Frequency (Normally 50Hz) Current \ Amps \ Speed RPM 3. 4. Check that the tool is fitted with the correct plug. Check that the lead is not cut or frayed and that it is effectively clamped at entry to the tool and plug. 5 Check that there are no cracks or pieces missing from the tool casing 6 Check that all screws are in place and secure 7 permissible number of power tools on each circuit or transformer is not exceeded. 8. Check that the extension lead is suitably rated for the electrical current. During Use DO DO DO DO DO DO DO NOT DO NOT DO NOT DO NOT disconnect the tool before adjusting or working on it. disconnect the tool when not in use. report any defects immediately. keep the tool clean and free from damp. wear appropriate protective equipment - goggles, ear muffs, helmet etc. always hold the side handle, where applicable. carry the tool by its cable. use any "makeshift" cable. try to repair a defective tool - report it. start or stop tools when under load. Revised Jan 2003