Document 13475562

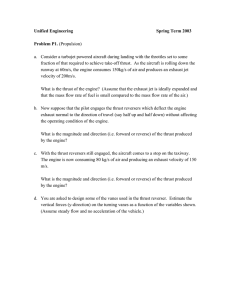

advertisement

PRODUCTION OF THRUST Newton’s 2nd Law (e.g. S F = d/dt (mv)) for a control volume of fixed mass with steady flow in and out and no acceleration of the frame of reference relative to inertial coordinates: ÂF = Sum of external forces on control volume, e.g. Pressure forces Shear forces Body forces Reaction forces Û Ù u (r u ) ⋅ nds ıs Net flux of momentum through surface of control volume For x-component of vectors: Û F = Â x Ùı ux ru ⋅ nds s Waitz, 2002 1 PRODUCTION OF THRUST Û T - D + Â Pr essure Forces = Ù ru x (u ⋅ n )dA ıs È ˘ Û Û Ù (PR - Po )dA R ˙ = Ù ru x (u ⋅ n )dA T - D + Í -PeAe + Po Ae ıA R Î ˚ ıs Û Ù ru x u ⋅ ndA = r eue Aeue - ro uo Aouo + Û Ù rux u ⋅ ndA ıs ıC s - A o -A e Û ˙ ou o + Ù ˙ eue - m ru u ⋅ ndA =m ıCs -A o -A e x Û Û ˙ eu e - m ˙ o uo + Ù T - D - (Pe - Po )Ae - Ù (PR - Po )dAR = m ru u ⋅ ndA ıC s - Ae - Ao x ıAR Waitz, 2002 2 PRODUCTION OF THRUST Everything that relates to flow through the engine is conventionally called thrust. Everything that relates to the flow on the outside of the engine is conventionally call drag. Therefore, gathering only those terms that relate to the fluid that passes through the engine, we have: ˙ eue - m ˙ ouo + (Pe - Po )Ae T=m The thrust is largely composed of the net change in momentum of the air entering and leaving the engine, with a typically small adjustment for the differences in pressure between the inlet and the exit. Waitz, 2002 3 EFFICIENCY We have related the thrust of a propulsion system to the net changes in momentum, pressure forces, etc. Now we will look at how efficiently the propulsion system converts one form of energy to another on its way to producing thrust: propulsive power what you get = overall efficiency = fuel power what you pay for propulsive power = thrust⋅ flight velocity = Tu o ˙ fh fuel power = fuel mass flow rate ⋅ fuel energy per unit mass = m Thus, Tuo hoverall = ˙ fh m Waitz, 2002 4 EFFICIENCY It is often convenient to break the overall efficiency into: thermal efficiency and propulsive efficiency where 2 ˆ Êm ˙ ˙ e u2 u m e- o o Á ˜ 2 2 rate of production of propellant k.e. Ë ¯ hthermal = = ˙ fh fuel power m hprop = Tuo propulsive power = 2 ˆ rate of production of propellant k.e. Ê ṁe u2 ˙ u m e- o o Á ˜ 2 2 Ë ¯ Such that, h overall = h thermal h propulsive Waitz, 2002 5 OVERALL PROPULSION SYSTEM EFFICIENCY Trends in thermal efficiency are driven by increasing compression ratios and corresponding increases in turbine inlet temperature. Whereas trends in propulsive efficiency are due to generally higher bypass ratio engines (After Koff, 1991) Waitz, 2002 6 EFFICIENCY The thermal efficiency is the same as that used in thermodynamics. For an ideal Brayton cycle it is a function of the temperature ratio across the compressor Tatm Wnet = 1= 1hth-idealBraytoncycle = Tcomp. exit Qin 1 g -1 (PR) g Higher temperature ratio = higher pressure ratio = higher thermal efficiency Waitz, 2002 7 PRESSURE RATIO TRENDS Waitz, 2002 8 TURBINE INLET TEMPERATURE • Desire for higher turbine inlet temperature is driven by desire for high specific work • Specific work is work per unit of airflow • High work per unit of airflow = smaller engine, lower weight, etc. Waitz, 2002 9 Work WORK BRAYTONBrayton CYCLECycle SPECIFIC 3 2.5 TR=TT4/T0 2 TR = 4 TR = 5 1.5 TR = 6 TR = 7 1 0.5 For a given turbine inlet temperature, there is a compressor pressure ratio that maximizes the work per unit of airflow 0 0 10 20 Compressor Waitz, 2002 30 Pressure 40 50 Ratio 10 TURBINE INLET TEMPERATURE TRENDS Waitz, 2002 (After Koff, 1991) 11 PROPULSIVE EFFICIENCY We can use our expression for thrust to rewrite the equation for propulsive efficiency in a more convenient form ˙ (ue - uo ) T ªm (sin ce m˙ e ª m˙ o ) Then, ṁ uo (u e - uo ) 2uo 2 hp = = = ṁ 2 uo + ue 1+ ue 2 ue - uo 2 uo ( Waitz, 2002 ) 12 TRENDS IN BYPASS RATIO Waitz, 2002 (After Koff, 1991) 13 OTHER EXPRESSIONS FOR OVERALL EFFICIENCY Specific Impulse (I or Isp): thrust I= fuel weight flow rate (units: seconds) Thrust Specific Fuel Consumption (SFC or TSFC): mass flow rate of fuel SFC = thrust (units: lbm/hr/lbf or kg/s/N) Waitz, 2002 14 IMPLICATIONS FOR ENGINE DESIGN Considering jointly the expressions for thrust and propulsive efficiency, hprop ˙ (ue - uo ) F @m 2 = ue 1+ uo As ue ↑ uo F ↑ ˙ m hprop Ø As ue Æ1 uo F Ø ˙ m hprop ↑ Also, as Waitz, 2002 F ↑ ṁuo Ainlet Ø Drag Ø 15 PROPULSIVE EFFICIENCY AND SPECIFIC THRUST 1.0 1.5 �p 2 3 0.5 6 ue / u0 11 0 0 1 5 10 F / m u0 Image adapted from: Kerrebrock, J. L. Aircraft Engines and Gas Turbines. 1991. Waitz, 2002 16 PROPULSIVE EFFICIENCY VS. FLIGHT SPEED Reproduced with the kind permission of Rolls-Royce plc.Copyright Rolls-Royce plc 1986. Used with permission. Waitz, 2002 17 PROPULSIVE EFFICIENCY AND SPECIFIC THRUST For fighter aircraft that need high thrust/weight and fly at high speed, it is typical to employ engines with smaller inlet areas and higher thrust per unit mass flow However, transport aircraft that require higher efficiency and fly at lower speeds usually employ engines with relatively larger inlet areas and lower thrust per unit mass flow Waitz, 2002 18 PROPULSIVE EFFICIENCY Image removed due to copyright considerations. At low flight velocities, the highest propulsive efficiency is typically obtained with a propeller or an unducted fan Image removed due to copyright considerations. Waitz, 2002 . with permission. Reproduced with the kind permission of Rolls-Royce plc.Copyright Rolls-Royce plc 1986. Used 20 AIRCRAFT AND ENGINE DESIGN ISSUES • Thrust ≈ (mass flow) x (change in velocity across engine) • Range ~ fuel efficiency (commercial and military) – Thermal efficiency High pressures and temperatures – Propulsive efficiency Large mass flow with small velocity change • Maneuverability (military) – High thrust-per-weight, small compact engine • Supersonic flight (military) – Low drag, small compact engine Waitz, 2002 High energy conversion per unit volume (high temperatures and pressures) Small mass flow with large velocity change 21 AN EXAMPLE OF CYCLE PERFORMANCE IMPROVEMENT Waitz, 2002 22